271:

constantly being fed with compressed air from the compressed-air tank. This means that the fuel-feed-pump has to overcome the resistance caused by the injection-air-pressure. A separate cam on the camshaft (as seen in Fig. 5 and on the two-cylinder Johann-Weitzer-engine on the right) would activate the injection valve so the compressed air would then press the fuel into the combustion chamber. Before the injection valve opens, neither fuel nor compressed air can enter the combustion chamber. The closed nozzle design allowed for a good air-fuel-mixture at the time which made it very useful for high capacity engines. This also resulted in lower fuel consumption compared to the open nozzle design. Biggest disadvantages were the higher manufacturing cost and the injection nozzle restrictions that made designing engines with horizontal cylinders considerably difficult, since in horizontal cylinder engines, compressed air can easily enter the cylinder without pressing a sufficient quantity of fuel into the combustion chamber which leads to engine misfire or post-ignition.

275:

air from entering the cylinder; the fuel constantly enters a prechamber above the combustion chamber in the cylinder. Between prechamber and combustion chamber, the disc-type atomisers are placed to separate the chambers from each other. At injection, the compressed air would then press the fuel through the disc-type atomisers into the combustion chamber. Manufacturing engines featuring the open nozzle design was considerably cheaper and easier than making them with a closed nozzle design. It also allows for using tar as fuel. However, fuel supply is insufficient and at the beginning of the injection, too much fuel enters the combustion chamber which causes too much pressure buildup inside the cylinder. This, as well as the problem that it is impossible to supply high capacity engines sufficiently with fuel, means, that the open nozzle design can only be used for smaller engines.

140:

Diesel wanted to replace the air-blast injection system with a superior system ever since; an improved accumulating system which allowed for direct injection without a huge compressor was patented by Diesel and Rudolf

Brandstetter in 1905. Nevertheless, this improved system was still insufficient and Diesel considered direct injection without a huge compressor „unfeasible“. It took another ten years for the first working direct injected Diesel engines which were not air-blast injected to show up in 1915; the precombustion chamber, which made motor vehicle Diesel engines possible, had been invented in 1909.

42:

113:. The compressed air comes from compressed-air tanks which feed the injection nozzle. A large crankshaft-driven compressor is used to re-fill these tanks; the size of the compressor and the low rotational frequency of the engine's crankshaft means that air-blast injected Diesel engines are huge in size and mass, this, combined with the problem that air-blast injection does not allow for quick load alteration makes it only suitable for stationary applications and watercraft. Before the invention of

77:

65:

30:

17:

157:

right). The discs are slightly misaligned to increase constriction. Depending on the capacity of the engine and, therefore, quantity of injected fuel, either two, three or four dics are used per injection nozzle. The disc material depends on the fuel type. In general, bronze casting and phosphor bronze casting are used; for engines running on

164:

For engines with disc-type atomisers, the injection pressure should be in sync with the rotational frequency of the crankshaft. This means that with an increase in rotational frequency, the air pressure must be increased as well. Usually, at injection, 97% air and 3% fuel are getting injected through

139:

says that Diesel knew about

Brayton's invention and that it is therefore very likely that Diesel decided to replace his own inferior injection system with an air-blast injection system similar to Brayton's. Diesel did so in February 1894, because he could not come up with a better solution, however,

274:

The open nozzle design was mostly used for engines with horizontal cylinders and unusual for engines with vertical cylinders. It can only be used for four-stroke engines. Like in the closed nozzle design, the fuel is fed to the injection nozzle. However, the injection valve only prevents compressed

168:

Neither disc hole diameter calculation nor the proper size of the discs were known engineering knowledge at the beginning of the 20th

Century. The disc designs were usually based on the engineers' experience. While big holes require a lot of compressed air and therefore consume more engine power,

156:

The ring-type atomiser is based on the principle of different air velocities occurring inside the nozzle, which force the fuel to mix up with air. Disc-type atomisers have small perforated discs placed above each other with small gaps in between (as seen in Fig. 6 in the sectional drawing on the

117:

injection, air-blast injection was the only way a properly working internal air fuel mixture system could be built, required for a Diesel engine. During the 1920s, air-blast injection was rendered obsolete by superior injection system designs that allowed much smaller but more powerful engines.

134:

wanted to build an engine with direct injection for which he tried using accumulating in 1893. Due to the highly viscous fuels Diesel used and thermal afterburning occurring, the principle of accumulating did not work sufficiently. Therefore, Diesel had to improve the injection system. German

270:

The closed nozzle design was the initial and most common design, it is usually found in vertical engines (such as the Langen & Wolf engine as seen on the right). It can be used for both two- and four-stroke engines. The injection nozzle is supplied with fuel from the fuel-feed-pump while

109:. Unlike modern designs, air-blast injected Diesel engines do not have an injection pump. A simple low-pressure fuel-feed-pump is used instead to supply the injection nozzle with fuel. At injection, a blast of compressed air presses the fuel into the combustion chamber, hence the name

165:

the injection nozzle. The injection pressure is between 5 and 7 MPa which limits the rotational frequency. Also, with increasing engine load, the injection pressure must be reduced to prevent misfire.

153:

Initially, sieve-type atomisers were used for the injections nozzles, until the sieves were widely replaced by discs. Also, ring-type atomisers were used for some engines.

213:

253:

233:

267:

In the early 20th

Century, two different injection nozzle designs for air-blast injected engines were common: The open nozzle and the closed nozzle design.

697:

676:

655:

629:

608:

587:

566:

542:

521:

500:

455:

431:

410:

389:

368:

344:

323:

302:

89:

715:

476:

720:

469:

Bau und

Betrieb von Dieselmaschinen: Ein Lehrbuch für Studierende. Erster Band: Grundlagen und Maschinenelemente

114:

41:

176:

693:

672:

651:

625:

604:

583:

562:

538:

517:

496:

472:

451:

427:

406:

385:

364:

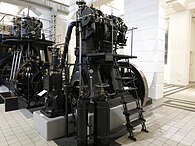

340:

319:

298:

76:

118:

Rudolf Diesel was granted a patent on air-blast injection in

November 1893 (DRP 82 168).

238:

218:

136:

127:

102:

709:

131:

106:

29:

173:

recommends a disc hole diameter depending on the indicated cylinder power output:

64:

488:

170:

16:

316:

295:

256:

90:

Grazer Waggon-&Maschinen-Fabriks-Aktiengesellschaft vorm. Joh.Weitzer GRAZ

158:

20:

US patent #432260 Brayton's 1890 4 stroke kerosene fuel air blast engine

403:

15:

53:

Langen & Wolf Diesel engine using air-blast injection, 1898

70:

Lateral view, compressor and compressed-air tanks well visible

448:

Leistung und Weg: Zur

Geschichte des MAN Nutzfahrzeugbaus

424:

Leistung und Weg: Zur Geschichte des MAN Nutzfahrzeugbaus

382:

Leistung und Weg: Zur Geschichte des MAN Nutzfahrzeugbaus

169:

holes being too small reduce the engine power output.

241:

221:

179:

471:, 2nd issue, Springer, Berlin / Heidelberg, 1948,

247:

227:

207:

130:in 1890 for a four-stroke kerosene fueled engine.

314:Rüdiger Teichmann, Günter P. Merker (publisher):

293:Rüdiger Teichmann, Günter P. Merker (publisher):

126:The air-blast injection system was first used by

690:Die Steuerungen der Verbrennungskraftmaschinen

669:Die Steuerungen der Verbrennungskraftmaschinen

648:Die Steuerungen der Verbrennungskraftmaschinen

622:Die Steuerungen der Verbrennungskraftmaschinen

601:Die Steuerungen der Verbrennungskraftmaschinen

580:Die Steuerungen der Verbrennungskraftmaschinen

559:Die Steuerungen der Verbrennungskraftmaschinen

535:Die Steuerungen der Verbrennungskraftmaschinen

514:Die Steuerungen der Verbrennungskraftmaschinen

493:Die Steuerungen der Verbrennungskraftmaschinen

337:Gemischbildung und Verbrennung im Dieselmotor

8:

289:

287:

240:

220:

184:

178:

161:, the discs are usually made from steel.

355:

353:

318:, 7th issue, Springer, Wiesbaden, 2014,

297:, 7th issue, Springer, Wiesbaden, 2014,

82:Camshaft and rocker arms seen from above

642:

640:

638:

553:

551:

283:

450:.Springer, Berlin / Heidelberg, 1991,

442:

440:

426:.Springer, Berlin / Heidelberg, 1991,

384:.Springer, Berlin / Heidelberg, 1991,

235:is the hole diameter in millimetres,

7:

405:, Springer, Berlin/Heidelberg 1962,

14:

335:Anton Pischinger, Otto Cordier:

75:

63:

40:

28:

361:Die Entstehung des Dieselmotors

1:

737:

692:, Springer, Berlin, 1914,

671:, Springer, Berlin, 1914,

650:, Springer, Berlin, 1914,

624:, Springer, Berlin, 1914,

603:, Springer, Berlin, 1914,

582:, Springer, Berlin, 1914,

561:, Springer, Berlin, 1914,

537:, Springer, Berlin, 1914,

516:, Springer, Berlin, 1914,

495:, Springer, Berlin, 1914,

208:{\displaystyle D^{2}=0,2N}

363:, Springer, Berlin 1913,

716:Diesel engine components

339:, Springer, Wien, 1939,

255:is the power output in

721:Fuel injection systems

446:MAN Nutzfahrzeuge AG:

422:MAN Nutzfahrzeuge AG:

380:MAN Nutzfahrzeuge AG:

249:

229:

209:

88:Diesel engine made by

21:

250:

230:

210:

128:George Bailey Brayton

115:precombustion chamber

19:

239:

219:

177:

35:Compressed-air tanks

111:air-blast injection

99:Air-blast injection

245:

225:

205:

22:

698:978-3-642-47608-2

677:978-3-642-47608-2

656:978-3-642-47608-2

630:978-3-642-47608-2

609:978-3-642-47608-2

588:978-3-642-47608-2

567:978-3-642-47608-2

543:978-3-642-47608-2

522:978-3-642-47608-2

501:978-3-642-47608-2

456:978-3-642-93490-2

432:978-3-642-93490-2

411:978-3-662-11843-6

390:978-3-642-93490-2

369:978-3-642-64940-0

345:978-3-7091-9724-0

324:978-3-658-03195-4

303:978-3-658-03195-4

248:{\displaystyle N}

228:{\displaystyle D}

728:

701:

686:

680:

665:

659:

644:

633:

618:

612:

597:

591:

576:

570:

555:

546:

531:

525:

510:

504:

486:

480:

479:, p. 94 & 95

467:Friedrich Sass:

465:

459:

444:

435:

420:

414:

401:Friedrich Sass:

399:

393:

378:

372:

357:

348:

333:

327:

312:

306:

291:

254:

252:

251:

246:

234:

232:

231:

226:

214:

212:

211:

206:

189:

188:

103:direct injection

101:is a historical

79:

67:

44:

32:

736:

735:

731:

730:

729:

727:

726:

725:

706:

705:

704:

687:

683:

666:

662:

645:

636:

619:

615:

598:

594:

577:

573:

556:

549:

532:

528:

511:

507:

487:

483:

466:

462:

445:

438:

421:

417:

400:

396:

379:

375:

359:Rudolf Diesel:

358:

351:

334:

330:

313:

309:

292:

285:

281:

265:

237:

236:

217:

216:

180:

175:

174:

151:

149:Atomiser design

146:

124:

96:

95:

94:

93:

85:

84:

83:

80:

72:

71:

68:

57:

56:

55:

54:

50:

49:

48:

45:

37:

36:

33:

12:

11:

5:

734:

732:

724:

723:

718:

708:

707:

703:

702:

681:

660:

634:

613:

592:

571:

547:

526:

505:

481:

460:

436:

415:

394:

373:

349:

328:

307:

282:

280:

277:

264:

261:

244:

224:

204:

201:

198:

195:

192:

187:

183:

150:

147:

145:

142:

137:Friedrich Sass

123:

120:

107:Diesel engines

87:

86:

81:

74:

73:

69:

62:

61:

60:

59:

58:

52:

51:

46:

39:

38:

34:

27:

26:

25:

24:

23:

13:

10:

9:

6:

4:

3:

2:

733:

722:

719:

717:

714:

713:

711:

699:

695:

691:

688:Julius Magg:

685:

682:

678:

674:

670:

667:Julius Magg:

664:

661:

657:

653:

649:

646:Julius Magg:

643:

641:

639:

635:

631:

627:

623:

620:Julius Magg:

617:

614:

610:

606:

602:

599:Julius Magg:

596:

593:

589:

585:

581:

578:Julius Magg:

575:

572:

568:

564:

560:

557:Julius Magg:

554:

552:

548:

544:

540:

536:

533:Julius Magg:

530:

527:

523:

519:

515:

512:Julius Magg:

509:

506:

502:

498:

494:

490:

485:

482:

478:

477:9783662004197

474:

470:

464:

461:

457:

453:

449:

443:

441:

437:

433:

429:

425:

419:

416:

412:

408:

404:

398:

395:

391:

387:

383:

377:

374:

370:

366:

362:

356:

354:

350:

346:

342:

338:

332:

329:

325:

321:

317:

311:

308:

304:

300:

296:

290:

288:

284:

278:

276:

272:

268:

263:Nozzle layout

262:

260:

258:

242:

222:

202:

199:

196:

193:

190:

185:

181:

172:

166:

162:

160:

154:

148:

143:

141:

138:

133:

132:Rudolf Diesel

129:

121:

119:

116:

112:

108:

104:

100:

91:

78:

66:

43:

31:

18:

689:

684:

668:

663:

647:

621:

616:

600:

595:

579:

574:

558:

534:

529:

513:

508:

492:

484:

468:

463:

447:

423:

418:

402:

397:

381:

376:

360:

336:

331:

315:

310:

294:

273:

269:

266:

167:

163:

155:

152:

125:

110:

98:

97:

47:Lateral view

489:Julius Magg

171:Julius Magg

105:system for

710:Categories

279:References

326:, p. 382.

305:, p. 381.

135:engineer

700:, p. 275

679:, p. 268

658:, p. 280

632:, p. 263

611:, p. 261

590:, p. 274

569:, p. 269

545:, p. 265

524:, p. 271

503:, p. 270

458:. p. 419

434:. p. 417

413:, p. 414

392:. p. 440

159:coal tar

371:, p. 21

122:History

696:

675:

654:

628:

607:

586:

565:

541:

520:

499:

475:

454:

430:

409:

388:

367:

347:, p. 1

343:

322:

301:

144:Design

92:, 1915

694:ISBN

673:ISBN

652:ISBN

626:ISBN

605:ISBN

584:ISBN

563:ISBN

539:ISBN

518:ISBN

497:ISBN

473:ISBN

452:ISBN

428:ISBN

407:ISBN

386:ISBN

365:ISBN

341:ISBN

320:ISBN

299:ISBN

712::

637:^

550:^

491::

439:^

352:^

286:^

259:.

257:PS

215:.

243:N

223:D

203:N

200:2

197:,

194:0

191:=

186:2

182:D

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.