355:

of air causes a wave of expansion to travel down the fabric. The flexing of the bag shatters and discharges the dust cake. The air burst is about 0.1 second and it takes about 0.5 seconds for the shock wave to travel down the length of the bag. Due to its rapid release, the blast of air does not interfere with contaminated gas flow. Therefore, pulse-jet baghouses can operate continuously and are not usually compartmentalized. The blast of compressed air must be powerful enough to ensure that the shock wave will travel the entire length of the bag and fracture the dust cake. The efficiency of the cleaning system allows the unit to have a much higher gas to cloth ratio (or volumetric throughput of gas per unit area of filter) than shaking and reverse air bag filters. This kind of filter thus requires a smaller area to admit the same volume of air.

107:

on the surface of the filter media. This traps fine particulates but also provides protection for the bag itself from moisture, and oily or sticky particulates which can bind the filter media. Without a pre-coat the filter bag allows fine particulates to bleed through the bag filter system, especially during start-up, as the bag can only do part of the filtration leaving the finer parts to the filter enhancer dustcake.

155:

187:

171:

404:

486:

Gas volumetric flow rate – Baghouses are created to accommodate a range of gas flows. An increase in gas flow rates causes an increase in operating pressure drop and air-to-cloth ratio. These increases put more mechanical strain on the baghouses, resulting in more frequent cleanings and high particle

278:

nozzle mounted at the reverse-jet baghouse top of the bag. Since the duration of the compressed-air burst is short (about 0.1 seconds), it acts as a rapidly moving air bubble, traveling through the entire length of the bag and causing the bag surfaces to flex. This flexing of the bags breaks the dust

63:

Most baghouses use long, cylindrical bags (or tubes) made of woven or felted fabric as a filter medium. For applications where there is relatively low dust loading and gas temperatures are 250 °F (121 °C) or less, pleated, nonwoven cartridges are sometimes used as filtering media instead of

540:

Reverse air bags have anti-collapse rings sewn into them to prevent pancaking when cleaning energy is applied. Pulse jet filter bags are supported by a metal cage, which keeps the fabric taut. To lengthen the life of filter bags, a thin layer of PTFE (teflon) membrane may be adhered to the filtering

526:

materials are either felted or membrane. Nonwoven materials are attached to a woven backing (scrim). Felted filters contain randomly placed fibers supported by a woven backing material (scrim). In a membrane filter, a thin, porous membrane is bound to the scrim. High energy cleaning techniques such

354:

This type of baghouse cleaning (also known as pressure-jet cleaning) is the most common. It was invented and patented by MikroPul in 1956. A high pressure blast of air is used to remove dust from the bag. The blast enters the top of the bag tube, temporarily ceasing the flow of dirty air. The shock

282:

Reverse pulse-jet dust collectors can be operated continuously and cleaned without interruption of flow because the burst of compressed air is very small compared with the total volume of dusty air through the collector. On account of this continuous-cleaning feature, reverse-jet dust collectors are

106:

To ensure the filter bags have a long lifespan they are commonly coated with a filter enhancer (pre-coat). The use of chemically inert limestone (calcium carbonate) is most common as it increases efficiency of dust collection (including fly ash) via formation of what is called a dustcake or coating

437:

Cartridge collectors use perforated metal cartridges that contain a pleated, nonwoven filtering media, as opposed to woven or felt bags used in baghouses. The pleated design allows for a greater total filtering surface area than in a conventional bag of the same diameter, The greater filtering area

387:

336:

A rod connecting to the bag is powered by a motor. This provides motion to remove caked-on particles. The speed and motion of the shaking depends on the design of the bag and composition of the particulate matter. Generally shaking is horizontal. The top of the bag is closed and the bottom is open.

322:

Continuously cleaned baghouse compartments always filtering. A blast of compressed air momentarily interrupts the collection process to clean the bag. This is known as pulse jet cleaning. Pulse jet cleaning does not require taking compartments offline. Continuously cleaned baghouses are designed to

286:

The short cleaning cycle of reverse-jet collectors reduces recirculation and redeposit of dust. These collectors provide more complete cleaning and reconditioning of bags than shaker or reverse-air cleaning methods. Also, the continuous-cleaning feature allows them to operate at higher air-to-cloth

441:

Cartridge collectors are available in single use or continuous duty designs. In single-use collectors, the dirty cartridges are changed and collected dirt is removed while the collector is off. In the continuous duty design, the cartridges are cleaned by the conventional pulse-jet cleaning system.

345:

Air flow gives the bag structure. Dirty air flows through the bag from the inside, allowing dust to collect on the interior surface. During cleaning, gas flow is restricted from a specific compartment. Without the flowing air, the bags relax. The cylindrical bag contains rings that prevent it from

318:

Intermittently cleaned baghouses are composed of many compartments or sections. Each compartment is periodically closed off from the incoming dirty gas stream, cleaned, and then brought back online. While the individual compartment is out of place, the gas stream is diverted from the compartment’s

251:

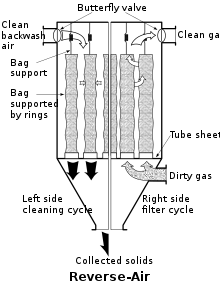

Reverse-air baghouses are compartmentalized to allow continuous operation. Before a cleaning cycle begins, filtration is stopped in the compartment to be cleaned. Bags are cleaned by injecting clean air into the dust collector in a reverse direction, which pressurizes the compartment. The pressure

224:

Shaker baghouses range in size from small, handshaker devices to large, compartmentalized units. They can operate intermittently or continuously. Intermittent units can be used when processes operate on a batch basis; when a batch is completed, the baghouse can be cleaned. Continuous processes use

47:

or gas released from commercial processes out of the air. Power plants, steel mills, pharmaceutical producers, food manufacturers, chemical producers and other industrial companies often use baghouses to control emission of air pollutants. Baghouses came into widespread use in the late 1970s after

428:

The rotating mechanical cage option consists of a fixed cage attached to the cell plate. Nested inside the cage holding the bag is a secondary cage that is allowed to rotate 90 degrees to impact the inside of the filter bag. This beating action accomplishes the same desired effect of creating a

346:

completely collapsing under the pressure of the air. A fan blows clean air in the reverse direction. The relaxation and reverse air flow cause the dust cake to crumble and release into the hopper. Upon the completion of the cleaning process, dirty air flow continues and the bag regains its shape.

266:

In reverse pulse-jet baghouses, individual bags are supported by a metal cage (filter cage), which is fastened onto a cell plate at the top of the baghouse. Dirty gas enters from the bottom of the baghouse and flows from outside to inside the bags. The metal cage prevents collapse of the bag. The

71:

and is directed into the baghouse compartment. The gas is drawn through the bags, either on the inside or the outside depending on cleaning method, and a layer of dust accumulates on the filter media surface until air can no longer move through it. When a sufficient pressure drop (ΔP) occurs, the

209:

In mechanical-shaker baghouses, tubular filter bags are fastened onto a cell plate at the bottom of the baghouse and suspended from horizontal beams at the top. Dirty gas enters the bottom of the baghouse and passes through the filter, and the dust collects on the inside surface of the bags.

247:

In reverse-air baghouses, the bags are fastened onto a cell plate at the bottom of the baghouse and suspended from an adjustable hanger frame at the top. Dirty gas flow normally enters the baghouse and passes through the bag from the inside, and the dust collects on the inside of the bags.

537:, twill weave, or sateen weave, increase or decrease the amount of space between individual fibers. The size of the space affects the strength and permeability of the fabric. A tighter weave corresponds with low permeability and, therefore, more efficient capture of fine particles.

500:

Pressure drop (ΔP) is the resistance to air flow across the baghouse. A high pressure drop corresponds with a higher resistance to airflow. Pressure drop is calculated by determining the difference in total pressure at two points, typically the inlet and

407:

420:

Although the principles of this method are basic, the rotating mechanical cage cleaning method is relatively new to the international market. This method can be visualized by reminding users of putting a floor covering rug on a

411:

410:

406:

405:

412:

544:

Some baghouses use pleated cartridge filters, similar to what is found in home air filtration systems. This allows much greater surface area for higher flow at the cost of additional complexity in manufacture and cleaning.

390:

394:

393:

389:

388:

55:, where performance may vary significantly depending on process and electrical conditions, functioning baghouses typically have a particulate collection efficiency of 99% or better, even when particle size is very small.

395:

252:

makes the bags collapse partially, causing the dust cake to crack and fall into the hopper below. At the end of the cleaning cycle, reverse airflow is discontinued, and the compartment is returned to the main stream.

337:

When shaken, the dust collected on the inside of the bag is freed. No dirty gas flows through a bag while it is being cleaned. This redirection of air flow illustrates why baghouses must be compartmentalized.

409:

483:

that occurs as a result of the particles in a gas stream. Opacity is not an exact measurement of the concentration of particles; however, it is a good indicator of the amount of dust leaving the baghouse.

75:

Baghouses are very efficient particulate collectors because of the dust cake formed on the surface of the bags. The fabric provides a surface on which dust collects through the following four mechanisms:

392:

470:

Gas temperature – Fabrics are designed to operate within a certain temperature range. Fluctuation outside of these limits, even for a small period of time, can weaken, damage, or ruin the bags.

255:

The flow of the dirty gas helps maintain the shape of the bag. However, to prevent total collapse and fabric chafing during the cleaning cycle, rigid rings are sewn into the bags at intervals.

239:

for shaker baghouses is relatively low, hence the space requirements are quite high. However, because of the simplicity of design, they are popular in the minerals processing industry.

103:

A combination of these mechanisms results in formation of the dust cake on the filter, which eventually increases the resistance to gas flow. The filter must be cleaned periodically.

72:

cleaning process begins. Cleaning can take place while the baghouse is online (filtering) or is offline (in isolation). When the compartment is clean, normal filtering resumes.

520:

Fabric filter bags are oval or round tubes, typically 15–30 feet (4.6–9.1 m) long and 5 to 12 inches (130 to 300 mm) in diameter, made of woven or felted material.

945:

717:

408:

784:

391:

375:, are turned on just before or at the start of the cleaning cycle to help break the bonds between particles on the filter media surface and aid in dust removal.

533:

filters have a definite repeated pattern. Low energy cleaning methods such as shaking or reverse air allow for woven filters. Various weaving patterns such as

429:

force that dislodges the particulates as the cage moves. This rotating action can be as adjusted to meet desired whipping effect on the inside of the bag.

658:

80:

Inertial collection – Dust particles strike the fibers placed perpendicular to the gas-flow direction instead of changing direction with the gas stream.

473:

Pressure drop – Baghouses operate most effectively within a certain pressure drop range. This spectrum is based on a specific gas volumetric flow rate.

68:

267:

pulse-jet baghouse was invented by MikroPul (currently part of the

Nederman group and still a major supplier of filtration solutions) in the 1950s.

940:

631:

201:

Baghouses are classified by the cleaning method used. The three most common types of baghouses are mechanical shakers, reverse gas, and pulse jet.

965:

511:

The air-to-cloth ratio (ft/min or cm/s) is defined as the amount of gas entering the baghouse divided by the surface area of the filter cloth.

258:

Space requirements for a reverse-air baghouse are comparable to those of a shaker baghouse; however, maintenance needs are somewhat greater.

48:

the invention of high-temperature fabrics (for use in the filter media) capable of withstanding temperatures over 350 °F (177 °C).

579:

605:

760:

897:

791:

724:

496:

Pressure drop, filter drag, air-to-cloth ratio, and collection efficiency are essential factors in the design of a baghouse.

89:– Submicrometre particles are diffused, increasing the probability of contact between the particles and collecting surfaces.

213:

Cleaning a mechanical-shaker baghouse is accomplished by shaking the top horizontal bar from which the bags are suspended.

975:

225:

compartmentalized baghouses; when one compartment is being cleaned, the airflow can be diverted to other compartments.

83:

Interception – Particles that do not cross the fluid streamlines come in contact with fibers because of the fiber size.

232:

inside the bags during the shake cycle. Pressures as low as 5 pascals (0.00073 psi) can interfere with cleaning.

52:

559:

694:

367:

installed to provide supplementary vibration to increase dust cleaning. The horns, which generate high intensity

950:

669:

872:

36:

459:

294:

turns on the solenoid valve at set intervals to inject air into the blow pipe and clean the filters.

96:

92:

635:

378:

Sonic cleaning is commonly combined with another method of cleaning to ensure thorough cleaning.

236:

609:

840:

756:

541:

side of the fabric, keeping dust particles from becoming embedded in the filter media fibers.

466:, and particle loading and size distribution of the gas stream are essential factors as well.

274:

injected through a common manifold over a row of bags. The compressed air is accelerated by a

229:

86:

583:

970:

480:

476:

451:

364:

319:

area. This makes shutting down the production process unnecessary during cleaning cycles.

218:

659:"Pleated cartridges provide increased baghouse capacity and improved filter performance"

450:

Baghouse performance is dependent upon inlet and outlet gas temperature, pressure drop,

841:"Air filtration - Industrial Bag Filters and cartridges - Industrial Dedusting Filters"

554:

505:

275:

271:

40:

959:

323:

prevent complete shutdown during bag maintenance and failures to the primary system.

905:

857:

438:

results in a reduced air to media ratio, pressure drop, and overall collector size.

422:

44:

816:

750:

534:

368:

154:

372:

399:

a mechanical cage inside a dusty bag moving to beat off the built-up material

463:

214:

455:

416:

Actuation of a rotating mechanical cage for dust removal on filter media

363:

The least common type of cleaning method is sonic. Some baghouses have

186:

170:

580:"Baghouse filter installation manifold – US Patent 5636422 Description"

935:

930:

402:

385:

291:

279:

cake, and the dislodged dust falls into a storage hopper below.

902:

Midwesco Filter

Resources, Inc. Midwesco Filter Resources, Inc

871:

Beachler, David S.; Joseph, Jerry; Pompelia, Mick (1995).

783:

Beachler, David S.; Joseph, Jerry; Pompelia, Mick (1995).

716:

Beachler, David S.; Joseph, Jerry; Pompelia, Mick (1995).

99:

on the particles and the filter can increase dust capture.

307:

Two main sequence types are used to clean baghouses:

221:

creates waves in the bags to shake off the dust cake.

657:

Courtenay, John; Bryant, Michaek (July–August 2008).

115:Fabric filters generally have the following parts:

67:Dust-laden gas or air enters the baghouse through

790:. North Carolina State University. Archived from

723:. North Carolina State University. Archived from

508:is the resistance across the fabric-dust layer.

951:Guide To Choosing The Correct Baghouse Filter

287:ratios, so the space requirements are lower.

8:

487:velocity, two factors that shorten bag life.

946:Baghouse / Fabric Filter Glossary of Terms

632:"Baghouse / Fabric Filters KnowledgeBase"

752:Handbook of Pollution Control Processes

571:

858:"Hunze LLC – Rotating Mechanical Cage"

785:"Lesson 2: Fabric Filter Bag Cleaning"

228:In shaker baghouses, there must be no

852:

850:

527:as pulse jet require felted fabrics.

270:Bags are cleaned by a short burst of

217:produced by a motor-driven shaft and

7:

931:Baghouse Dust Collector Information

479:– Opacity measures the quantity of

873:"Lesson 4:Fabric Filter Materials"

718:"Fabric Filter Operation Overview"

14:

878:. North Carolina State University

898:"Pleat+Plus Pleated Filter Bags"

634:. Neundorfer.com. Archived from

582:. Patentstorm.us. Archived from

425:and beating the dust out of it.

311:Intermittent (periodic) cleaning

185:

169:

153:

283:usually not compartmentalized.

966:Pollution control technologies

697:. Baghouse.com. 5 January 2011

608:. Baghouse.net. Archived from

1:

936:Baghouse Technical Drawings

125:Bag, cage, venturi assembly

53:electrostatic precipitators

992:

560:Electrostatic precipitator

161:Mechanical Shaker Baghouse

821:www.nedermanmikropul.com

16:Pollution control device

941:Baghouse Knowledgebase

755:. Noyes Publications.

749:Noyes, Robert (1991).

695:"Cartridge Collectors"

417:

400:

371:at the low end of the

817:"About Us | Nederman"

415:

398:

290:A digital sequential

134:Compressed air header

95:– The presence of an

37:air pollution control

606:"What is a Baghouse"

460:chemical composition

433:Cartridge collectors

177:Reverse Air Baghouse

97:electrostatic charge

93:Electrostatic forces

976:Particulate control

373:ultrasonic spectrum

314:Continuous cleaning

797:on 9 November 2013

730:on 9 November 2013

586:on 13 October 2012

418:

401:

303:Cleaning sequences

237:air-to-cloth ratio

205:Mechanical shakers

193:Pulse Jet Baghouse

140:Housing and hopper

23:, also known as a

462:, moisture, acid

413:

396:

230:positive pressure

87:Brownian movement

983:

918:

917:

915:

913:

904:. Archived from

894:

888:

887:

885:

883:

877:

868:

862:

861:

854:

845:

844:

837:

831:

830:

828:

827:

813:

807:

806:

804:

802:

796:

789:

780:

774:

773:

771:

769:

746:

740:

739:

737:

735:

729:

722:

713:

707:

706:

704:

702:

691:

685:

684:

682:

680:

675:on 28 March 2012

674:

668:. Archived from

663:

654:

648:

647:

645:

643:

628:

622:

621:

619:

617:

602:

596:

595:

593:

591:

576:

492:Design variables

481:light scattering

414:

397:

365:ultrasonic horns

189:

173:

157:

991:

990:

986:

985:

984:

982:

981:

980:

956:

955:

927:

922:

921:

911:

909:

896:

895:

891:

881:

879:

875:

870:

869:

865:

856:

855:

848:

839:

838:

834:

825:

823:

815:

814:

810:

800:

798:

794:

787:

782:

781:

777:

767:

765:

763:

748:

747:

743:

733:

731:

727:

720:

715:

714:

710:

700:

698:

693:

692:

688:

678:

676:

672:

666:Aluminium Times

661:

656:

655:

651:

641:

639:

630:

629:

625:

615:

613:

612:on 24 July 2013

604:

603:

599:

589:

587:

578:

577:

573:

568:

551:

518:

494:

448:

435:

403:

386:

384:

361:

352:

343:

334:

329:

305:

300:

264:

245:

207:

199:

198:

197:

196:

195:

190:

181:

180:

179:

174:

165:

164:

163:

158:

147:

113:

61:

25:baghouse filter

17:

12:

11:

5:

989:

987:

979:

978:

973:

968:

958:

957:

954:

953:

948:

943:

938:

933:

926:

925:External links

923:

920:

919:

908:on 2 June 2013

889:

863:

846:

832:

808:

775:

761:

741:

708:

686:

649:

623:

597:

570:

569:

567:

564:

563:

562:

557:

555:Dust collector

550:

547:

517:

514:

513:

512:

509:

502:

493:

490:

489:

488:

484:

474:

471:

447:

444:

434:

431:

383:

380:

360:

357:

351:

348:

342:

339:

333:

330:

328:

325:

316:

315:

312:

304:

301:

299:

296:

272:compressed air

263:

260:

244:

241:

206:

203:

191:

184:

183:

182:

175:

168:

167:

166:

159:

152:

151:

150:

149:

148:

146:

143:

142:

141:

138:

135:

132:

129:

126:

123:

120:

112:

109:

101:

100:

90:

84:

81:

60:

57:

41:dust collector

15:

13:

10:

9:

6:

4:

3:

2:

988:

977:

974:

972:

969:

967:

964:

963:

961:

952:

949:

947:

944:

942:

939:

937:

934:

932:

929:

928:

924:

907:

903:

899:

893:

890:

874:

867:

864:

859:

853:

851:

847:

842:

836:

833:

822:

818:

812:

809:

793:

786:

779:

776:

764:

762:9780815512905

758:

754:

753:

745:

742:

726:

719:

712:

709:

696:

690:

687:

671:

667:

660:

653:

650:

638:on 2013-08-07

637:

633:

627:

624:

611:

607:

601:

598:

585:

581:

575:

572:

565:

561:

558:

556:

553:

552:

548:

546:

542:

538:

536:

532:

528:

525:

521:

515:

510:

507:

503:

499:

498:

497:

491:

485:

482:

478:

475:

472:

469:

468:

467:

465:

461:

457:

453:

445:

443:

439:

432:

430:

426:

424:

382:Rotating cage

381:

379:

376:

374:

370:

366:

358:

356:

349:

347:

340:

338:

331:

326:

324:

320:

313:

310:

309:

308:

302:

297:

295:

293:

288:

284:

280:

277:

273:

268:

261:

259:

256:

253:

249:

242:

240:

238:

233:

231:

226:

222:

220:

216:

211:

204:

202:

194:

188:

178:

172:

162:

156:

144:

139:

136:

133:

130:

127:

124:

121:

118:

117:

116:

110:

108:

104:

98:

94:

91:

88:

85:

82:

79:

78:

77:

73:

70:

65:

58:

56:

54:

49:

46:

43:that removes

42:

38:

34:

33:fabric filter

30:

26:

22:

910:. Retrieved

906:the original

901:

892:

880:. Retrieved

866:

835:

824:. Retrieved

820:

811:

799:. Retrieved

792:the original

778:

766:. Retrieved

751:

744:

732:. Retrieved

725:the original

711:

699:. Retrieved

689:

677:. Retrieved

670:the original

665:

652:

640:. Retrieved

636:the original

626:

614:. Retrieved

610:the original

600:

588:. Retrieved

584:the original

574:

543:

539:

530:

529:

523:

522:

519:

516:Filter media

495:

449:

440:

436:

427:

423:clothes line

419:

377:

362:

353:

344:

335:

321:

317:

306:

298:Bag cleaning

289:

285:

281:

269:

265:

257:

254:

250:

246:

234:

227:

223:

212:

208:

200:

192:

176:

160:

122:Dusty plenum

119:Clean plenum

114:

105:

102:

74:

66:

62:

50:

45:particulates

32:

28:

24:

20:

18:

535:plain weave

446:Performance

369:sound waves

341:Reverse air

243:Reverse air

39:device and

960:Categories

826:2021-07-21

566:References

454:, and gas

29:bag filter

464:dew point

350:Pulse jet

262:Pulse jet

215:Vibration

137:Blow pipe

131:RAV/SCREW

128:Tubeplate

59:Operation

912:6 August

882:6 August

801:6 August

768:6 August

734:6 August

701:6 August

679:6 August

642:6 August

616:6 August

590:6 August

549:See also

524:Nonwoven

456:velocity

21:baghouse

971:Filters

504:Filter

501:outlet.

477:Opacity

452:opacity

332:Shaking

327:Methods

276:venturi

69:hoppers

51:Unlike

759:

458:. The

64:bags.

35:is an

876:(PDF)

795:(PDF)

788:(PDF)

728:(PDF)

721:(PDF)

673:(PDF)

662:(PDF)

531:Woven

359:Sonic

292:timer

145:Types

111:Parts

31:, or

914:2013

884:2013

803:2013

770:2013

757:ISBN

736:2013

703:2013

681:2013

644:2013

618:2013

592:2013

506:drag

235:The

219:cam

962::

900:.

849:^

819:.

664:.

27:,

19:A

916:.

886:.

860:.

843:.

829:.

805:.

772:.

738:.

705:.

683:.

646:.

620:.

594:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.