186:

piston rose within the cylinder, drawn upward by a counterbalance, it drew in steam at atmospheric pressure. At the top of the stroke the steam valve was closed, and cold water was briefly injected into the cylinder as a means of cooling the steam. This water condensed the steam and created a partial vacuum below the piston. The atmospheric pressure outside the engine was then greater than the pressure within the cylinder, thereby pushing the piston into the cylinder. The piston, attached to a chain and in turn attached to one end of the "rocking beam", pulled down the end of the beam, lifting the opposite end of the beam. Hence, the pump deep in the mine attached to opposite end of the beam via ropes and chains was driven. The pump pushed, rather than pulled the column of water upward, hence it could lift water any distance. Once the piston was at the bottom, the cycle repeated.

134:, which in turn produced new steam engine designs. Watt's early engines were like the original Newcomen designs in that they used low-pressure steam, and all of the power was produced by atmospheric pressure. When, in the early 1800s, other companies introduced high-pressure steam engines, Watt was reluctant to follow suit due to safety concerns. Wanting to improve on the performance of his engines, Watt began considering the use of higher-pressure steam, as well as designs using multiple cylinders in both the double-acting concept and the multiple-expansion concept. These double-acting engines required the invention of the

263:

the utilisation of steam expansion against the vacuum on the other side of the piston. The steam supply was cut during the stroke, and the steam expanded against the vacuum on the other side. This increased the efficiency of the engine, but also created a variable torque on the shaft which was undesirable for many applications, in particular pumping. Watt therefore limited the expansion to a ratio of 1:2 (i.e. the steam supply was cut at half stroke). This increased the theoretical efficiency from 6.4% to 10.6%, with only a small variation in piston pressure. Watt did not use high pressure steam because of safety concerns.

643:

244:. When the piston reached the top of the cylinder, the steam inlet valve closed and the valve controlling the passage to the condenser opened. The condenser being at a lower pressure, drew the steam from the cylinder into the condenser where it cooled and condensed from water vapour to liquid water, maintaining a partial vacuum in the condenser that was communicated to the space of the cylinder by the connecting passage. External atmospheric pressure then pushed the piston down the cylinder.

639:

non-toxic, non-flammable and non-corrosive. It works at pressure near and below atmospheric, so that sealing is not a problem. And it is a simple machine, implying cost effectiveness. Researchers from the

University of Southampton / UK are currently developing a modern version of Watt's engine in order to generate energy from waste steam and waste heat. They improved the theory, demonstrating that theoretical efficiencies of up to 17.4% (and actual efficiencies of 11%) are possible.

590:

255:. The condenser is located in a cold water bath below the cylinder. The volume of water entering the condenser as spray absorbed the latent heat of the steam, and was determined as seven times the volume of the condensed steam. The condensate and the injected water was then removed by the air pump, and the surrounding cold water served to absorb the remaining thermal energy to retain a condenser temperature of 30 °C to 45 °C and the equivalent pressure of 0.04 to 0.1 bar

574:

203:

33:

166:

346:'s practice was to help mine-owners and other customers to build engines, supplying men to erect them and some specialised parts. However, their main profit from their patent was derived from charging a licence fee to the engine owners, based on the cost of the fuel they saved. The greater fuel efficiency of their engines meant that they were most attractive in areas where fuel was expensive, particularly

613:

371:

417:

103:

cylinder causing the power stroke. The condensing cylinder was water cooled to keep the steam condensing. At the end of the power stroke, the valve was closed so the power cylinder could be filled with steam as the piston moved to the top. The result was the same cycle as

Newcomen's design, but without any cooling of the power cylinder which was immediately ready for another stroke.

1214:

563:

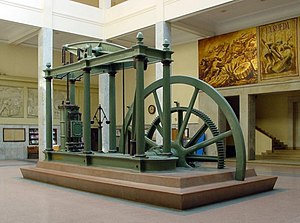

commissioned the replica engine from the

English manufacturer Charles Summerfield in 1932. The museum also holds an original Boulton and Watt atmospheric pump engine, originally used for canal pumping in Birmingham, illustrated below, and in use in situ at the Bowyer Street pumping station, from 1796

247:

The separation of the cylinder and condenser eliminated the loss of heat that occurred when steam was condensed in the working cylinder of a

Newcomen engine. This gave the Watt engine greater efficiency than the Newcomen engine, reducing the amount of coal consumed while doing the same amount of work

106:

Watt worked on the design over a period of several years, introducing the condenser, and introducing improvements to practically every part of the design. Notably, Watt performed a lengthy series of trials on ways to seal the piston in the cylinder, which considerably reduced leakage during the power

339:

invented a boring machine in which the shaft that held the cutting tool was supported on both ends and extended through the cylinder, unlike the cantilevered borers then in use. Boulton wrote in 1776 that "Mr. Wilkinson has bored us several cylinders almost without error; that of 50 inches diameter,

638:

The

Expansion Engine can offer significant advantages here, in particular for lower power ratings of 2 to 100 kW: with expansion ratios of 1:5, the theoretical efficiency reaches 15%, which is in the range of ORC systems. The Expansion Engine uses water as working fluid which is simple, cheap,

395:

Before the development of the double acting piston, the linkage to the beam and the piston rod had been by means of a chain, which meant that power could only be applied in one direction, by pulling. This was effective in engines that were used for pumping water, but the double action of the piston

189:

The

Newcomen engine was more powerful than the Savery engine. For the first time water could be raised from a depth of over 300 feet. The first example from 1712 was able to replace a team of 500 horses that had been used to pump out the mine. Seventy-five Newcomen pumping engines were installed

424:

Having the beam connected to the piston shaft by a means that applied force alternately in both directions also meant that it was possible to use the motion of the beam to turn a wheel. The simplest solution to transforming the action of the beam into a rotating motion was to connect the beam to a

262:

Watt's next improvement to the

Newcomen design was to seal the top of the cylinder and surround the cylinder with a jacket. Steam was passed through the jacket before being admitted below the piston, keeping the piston and cylinder warm to prevent condensation within it. The second improvement was

193:

While

Newcomen engines brought practical benefits, they were inefficient in terms of the use of energy to power them. The system of alternately sending jets of steam, then cold water into the cylinder meant that the walls of the cylinder were alternately heated, then cooled with each stroke. Each

787:

A new and complete dictionary of Art and sciences; comprehending all the branches of useful knowledge, with accurate descriptions as well of the various machines, tools, figures and schemes necessary for illustrating them, as of the classes, kinds, preparations, and uses of natural productions,

185:

that also worked on the vacuum principle. It employed a cylinder containing a movable piston connected by a chain to one end of a rocking beam that worked a mechanical lift pump from its opposite end. At the bottom of each stroke, steam was allowed to enter the cylinder below the piston. As the

102:

Watt realised that the heat needed to warm the cylinder could be saved by adding a separate condensing cylinder. After the power cylinder was filled with steam, a valve was opened to the secondary cylinder, allowing the steam to flow into it and be condensed, which drew the steam from the main

650:

In order to demonstrate the principle, a 25 watt experimental model engine was built and tested. The engine incorporates steam expansion as well as new features such as electronic control. The picture shows the model built and tested in 2016. Currently, a project to build and test a scaled-up

608:

In the 1880s, Hathorn Davey and Co / Leeds produced a 1 hp / 125 rpm atmospheric engine with external condenser but without steam expansion. It has been argued that this was probably the last commercial atmospheric engine to be manufactured. As an atmospheric engine, it did not have a

635:. In principle, these are steam turbines which do not use water but a fluid (a refrigerant) which evaporates at temperatures below 100 °C. Such systems are however fairly complex. They work with pressures of 6 to 20 bars, so that the whole system has to be completely sealed.

387:

development. An arrangement of valves could alternately admit low pressure steam to the cylinder and then connect with the condenser. Consequently, the direction of the power stroke might be reversed, making it easier to obtain rotary motion. Additional benefits of the

98:

noticed that it required significant amounts of heat to warm the cylinder back up to the point where steam could enter the cylinder without immediately condensing. When the cylinder was warm enough that it became filled with steam the next power stroke could commence.

162:, but it could only draw fluid up approximately 25 feet, meaning it had to be located within this distance of the mine floor being drained. As mines became deeper, this was often impractical. It also consumed a large amount of fuel compared with later engines.

630:

with temperatures between 100 and 150 °C generated by industry. In addition, solarthermal collectors, geothermal energy sources and biomass reactors produce heat in this temperature range. There are technologies to utilise this energy, in particular the

280:

The separate condenser showed dramatic potential for improvements on the

Newcomen engine but Watt was still discouraged by seemingly insurmountable problems before a marketable engine could be perfected. It was only after entering into partnership with

323:

Watt had tried unsuccessfully for several years to obtain an accurately bored cylinder for his steam engines, and was forced to use hammered iron, which was out of round and caused leakage past the piston. Joseph

Wickham Roe stated in 1916: "When

258:

At each stroke the warm condensate was drawn off from the condenser and sent to a hot well by a vacuum pump, which also helped to evacuate the steam from under the power cylinder. The still-warm condensate was recycled as feedwater for the boiler.

382:

The first Watt engines were atmospheric pressure engines, like the Newcomen engine but with the condensation taking place separate from the cylinder. Driving the engines using both low pressure steam and a partial vacuum raised the possibility of

444:

which, once set in motion, by its momentum maintained a constant power and smoothed the action of the alternating strokes. To its rotating central shaft, belts and gears could be attached to drive a great variety of machinery.

625:

Watt's Expansion Engine is generally considered as of historic interest only. There are however some recent developments which may lead to a renaissance of the technology. Today, there is an enormous amount of waste steam and

400:

to the beam, because while the rod moved vertically in a straight line, the beam was pivoted at its centre, with each side inscribing an arc. To bridge the conflicting actions of the beam and the piston, Watt developed his

90:, the weight of the object being moved by the engine pulled the piston to the top of the cylinder as steam was introduced. Then the cylinder was cooled by a spray of water, which caused the steam to condense, forming a

293:. At last Watt had access to facilities and the practical experience of craftsmen who were soon able to get the first engine working. As fully developed, it used about 75% less fuel than a similar Newcomen one.

478:

to measure steam pressure within the cylinder according to the position of the piston, enabling a diagram to be produced representing the pressure of the steam as a function of its volume throughout the cycle.

396:

meant that it could push as well as pull. This was not possible as long as the beam and the rod were connected by a chain. Furthermore, it was not possible to connect the piston rod of the sealed cylinder

122:

would have been used previously. This was a key moment in the industrial revolution, since power sources could now be located anywhere instead of, as previously, needing a suitable water source and

790:. Illustrated with above three hundred copper-plates engraved by Mr. Jefferys (The second edition, with many additions, and other improvements. ed.). London: W.Owen. p. 1073 (table).

521:; on certain weekends throughout the year the modern pumps are switched off and the two steam engines at Crofton still perform this function. The oldest extant rotative steam engine, the

440:, only later reverting, once the patent rights had expired, to the more familiar crank seen on most engines today. The main wheel attached to the crank was large and heavy, serving as a

328:

saw the first engine he reported to the Society of Engineers that 'Neither the tools nor the workmen existed who could manufacture such a complex machine with sufficient precision

1275:

194:

charge of steam introduced would continue condensing until the cylinder approached working temperature once again. So at each stroke part of the potential of the steam was lost.

1248:

158:

invented a pumping appliance that used steam to draw water directly from a well by means of a vacuum created by condensing steam. The appliance was also proposed for draining

118:

to turn the linear motion of the engines into rotary motion. This made it useful not only in the original pumping role, but also as a direct replacement in roles where a

142:

of the individual cylinders to move in straight lines, keeping the piston true in the cylinder, while the walking beam end moved through an arc, somewhat analogous to a

285:

that such became reality. Watt told Boulton about his ideas on improving the engine, and Boulton, an avid entrepreneur, agreed to fund development of a test engine at

1073:

801:

788:

whether animals, vegetables, minerals, fossils, or fluids; together with the kingdoms, provinces, cities, towns and other remarkable places throughout the world

470:

Watt was also concerned with fundamental research on the functioning of the steam engine. His most notable measuring device, still in use today, is the Watt

589:

463:

and horses as the main sources of power for British industry, thereby freeing it from geographical constraints and becoming one of the main drivers in the

509:). The oldest still in its original engine house and still capable of doing the job for which it was installed is the 1812 Boulton and Watt engine at the

506:

1268:

107:

stroke, preventing power loss. All of these changes produced a more reliable design which used half as much coal to produce the same amount of power.

2150:

413:

to produce the required straight line motion much more cheaply than if he had used a slider type of linkage. He was very proud of his solution.

903:

741:

929:

2240:

1261:

1059:

190:

at mines in Britain, France, Holland, Sweden and Russia. In the next fifty years only a few small changes were made to the engine design.

975:

849:

Hulse David K (1999): "The early development of the steam engine"; TEE Publishing, Leamington Spa, U.K., ISBN, 85761 107 1 p. 127 et seq.

429:, but because another party had patent rights on the use of the crank, Watt was obliged to come up with another solution. He adopted the

1725:

559:

houses a replica of a 1788 Watt rotative engine. It is a full-scale working model of a Boulton-Watt engine. The American industrialist

769:

573:

389:

130:

began developing a multitude of machines that made use of this rotary power, developing the first modern industrialized factory, the

2250:

1720:

1001:

2184:

2096:

680:

233:

were separate, condensation occurred without significant loss of heat from the cylinder. The condenser remained cold and below

2225:

2155:

1990:

1799:

1031:

336:

305:

48:

1110:

1045:

1443:

2230:

1829:

1819:

452:

which he adapted from those used to automatically control the speed of windmills. The centrifugal was not a true speed

1237:

251:

In Watt's design, the cold water was injected only into the condensation chamber. This type of condenser is known as a

2023:

1887:

1868:

1859:

1743:

1355:

1298:

182:

170:

79:

1637:

924:

Hulse David K (2001): "The development of rotary motion by the steam power"; TEE Publishing, Leamington Spa, U.K.,

2189:

2178:

1735:

226:

1963:

1895:

705:

538:

2255:

2199:

2194:

2115:

1839:

1784:

1506:

1462:

530:

510:

1095:

2204:

2102:

1943:

1824:

1475:

1413:

729:

642:

494:

488:

448:

Because factory machinery needed to operate at a constant speed, Watt linked a steam regulator valve to a

410:

37:

1218:

297:

2245:

2160:

2069:

1794:

1715:

1688:

1418:

1403:

1313:

632:

596:

552:

518:

502:

464:

215:

94:

in the cylinder. Atmospheric pressure on the top of the piston pushed it down, lifting the work object.

87:

72:

56:

2129:

1814:

1753:

1614:

1480:

1428:

1365:

1318:

1125:

665:

449:

406:

384:

234:

1158:

1017:

218:

when he was assigned the job of repairing a model Newcomen engine and noted how inefficient it was.

2235:

2123:

1657:

1531:

1448:

1438:

433:

115:

47:(London) in 1832, now in the lobby of the Superior Technical School of Industrial Engineers of the

836:

266:

These improvements led to the fully developed version of 1776 that actually went into production.

2056:

2050:

2044:

2036:

2031:

1619:

556:

114:

ironworks. Watt continued working to improve the engine, and in 1781 introduced a system using a

75:, and it was many years before significantly new designs began to replace the basic Watt design.

1243:

44:

355:

340:

which we have put up at Tipton, does not err on the thickness of an old shilling in any part".

1768:

1707:

1662:

1642:

1629:

1609:

1591:

1536:

1490:

1360:

997:

925:

899:

891:

882:

765:

737:

526:

471:

317:

230:

17:

1996:

1984:

1957:

1683:

1601:

1571:

1423:

1133:

542:

522:

498:

343:

286:

275:

1184:

202:

32:

2169:

1902:

1844:

1763:

1652:

1647:

1561:

1516:

546:

437:

402:

375:

282:

178:

135:

127:

83:

1225:

830:

709:

1129:

392:

engine were increased efficiency, higher speed (greater power) and more regular motion.

2088:

1937:

1909:

1586:

1485:

1408:

1398:

1308:

675:

534:

453:

430:

111:

110:

The new design was introduced commercially in 1776, with the first example sold to the

91:

165:

2219:

1876:

1849:

1748:

1667:

1503:

685:

646:

The 25 Watt Experimental Condensing Engine built and tested at Southampton University

155:

2077:

1834:

1581:

1566:

1521:

1375:

1370:

1284:

660:

325:

222:

131:

40:

1111:"Experimental investigation of the atmospheric steam engine with forced expansion"

950:

612:

370:

1137:

876:

688:

made a dual-piston steam engine in 1766, but died before he could mass-produce it

2002:

1976:

1929:

1526:

1500:

1470:

1348:

1343:

670:

460:

416:

119:

2008:

1951:

1576:

1511:

1495:

1433:

1390:

1380:

627:

580:

560:

426:

359:

351:

313:

290:

211:

139:

123:

95:

68:

762:

The Most Powerful Idea in the World: A Story of Steam, Industry and Invention

1804:

1789:

1231:

832:

A treatise on the steam engine : historical, practical, and descriptive

514:

475:

143:

835:. London : Printed for Longman, Rees, Orme, Brown and Green. pp.

1213:

1693:

441:

347:

309:

221:

In 1765, Watt conceived the idea of equipping the engine with a separate

529:

in Sydney, Australia. A Boulton-Watt engine of 1788 may be found in the

456:

because it could not hold a set speed in response to a change in load.

1809:

1546:

525:(from 1785, the third rotative engine ever built), is located in the

301:

241:

159:

52:

982:

This is the first edition. Modern paperback editions are available.

895:

1328:

641:

611:

415:

369:

201:

164:

1074:"A pumping station, glassworks and pottery kiln at Ashted Circus"

1253:

886:

1257:

1244:

Boulton and Watt Steam Engine at the Powerhouse Museum, Sydney

86:

in 1712, were of the "atmospheric" design. At the end of the

316:, which was at work the following month. A third engine, at

237:

at all times, while the cylinder remained hot at all times.

755:

753:

459:

These improvements allowed the steam engine to replace the

898:); and by Lindsay Publications, Inc., Bradley, Illinois, (

609:

pressurized boiler. It was intended for small businesses.

240:

Steam was drawn from the boiler to the cylinder under the

1249:

James Watt Steam Engine Act on the UK Parliament website

806:

University of Glasgow Hunterian Museum & Art Gallery

564:

until 1854, and afterwards removed to Dearborn in 1929.

350:, for which three engines were ordered in 1777, for the

890:. Reprinted by McGraw-Hill, New York and London, 1926 (

296:

In 1775, Watt designed two large engines: one for the

1234:– excerpts from Transactions of the Newcomen Society.

71:

that became synonymous with steam engines during the

567:

An other one is preserved at Fumel factory, France.

2143:

2114:

2087:

2068:

2022:

1975:

1928:

1919:

1886:

1867:

1858:

1777:

1734:

1706:

1676:

1628:

1600:

1554:

1545:

1461:

1389:

1336:

1327:

1291:

1228:– Michigan State University, Chemical Engineering

1018:"Rotative steam engine by Boulton and Watt, 1788"

996:. London: Peter Peregrinus Ltd. pp. 47, 22.

881:, New Haven, Connecticut: Yale University Press,

497:. The oldest working engine in the world is the

270:The partnership of Matthew Boulton and James Watt

177:The solution to draining deep mines was found by

802:"Model Newcomen Engine, repaired by James Watt"

710:"Technological Transformations and Long Waves"

501:, brought into service in May 1779 and now at

320:in east London, was also working that summer.

27:Industrial Revolution era stream engine design

1269:

604:Watt engine produced by Hathorn, Davey and Co

206:The major components of a Watt pumping engine

8:

764:. University of Chicago Press. p. 137.

55:). Steam engines of this kind propelled the

977:A History of the Growth of the Steam-Engine

860:James Watt: II The Years of Toil, 1775–1785

724:

722:

505:in Birmingham (formerly at the now defunct

1925:

1864:

1551:

1333:

1276:

1262:

1254:

994:A History of Control Engineering 1800-1930

736:. Cambridge University Press. p. 87.

541:ironworks of M W Grazebrook now decorates

507:Museum of Science and Industry, Birmingham

870:

868:

154:In 1698, the English mechanical designer

229:. Because the condenser and the working

31:

2151:Glossary of steam locomotive components

1758:

697:

651:2 kW engine is under preparation.

595:Watt atmospheric pump engine (1796) at

569:

545:, a traffic island at the start of the

304:, completed in March 1776, and one for

214:was working as instrument maker at the

517:. This was used to pump water for the

961:

7:

980:. D. Appleton & Co. p. 116.

824:

822:

487:The oldest surviving Watt engine is

862:(Landmark, Ashbourne, 2005), 58–65.

734:A Short History of the Steam Engine

2003:National Museum of Scotland engine

1240:at the National Museum of Scotland

878:English and American Tool Builders

25:

2185:List of steam technology patents

1212:

941:from 3rd edition Britannica 1797

588:

572:

436:system suggested by an employee

59:in Great Britain and the world.

2170:Murdoch's model steam carriage

2156:History of steam road vehicles

829:Farey, John (1 January 1827).

405:. This device used a four bar

1:

2097:Murray's Hypocycloidal Engine

1189:The Condensing Engine Project

1163:The Condensing Engine Project

785:Society of Gentlemen (1763).

18:Boulton and Watt steam engine

1820:Return connecting rod engine

1138:10.1016/j.renene.2014.09.061

974:Thurston, Robert H. (1875).

875:Roe, Joseph Wickham (1916),

173:upon which Watt experimented

2241:History of the steam engine

1744:Condensing steam locomotive

225:chamber, which he called a

67:design was an invention of

2272:

2051:"Coalbrookdale Locomotive"

273:

2057:"Pen-y-Darren" locomotive

1726:Single- and double-acting

1238:Boulton & Watt engine

1076:. Birmingham City Council

36:A late version of a Watt

2251:Stationary steam engines

1896:Newcomen Memorial Engine

1096:"Davey's engine of 1885"

146:in later steam engines.

2200:Timeline of steam power

2195:Stationary steam engine

2078:Woolf's compound engine

1985:Soho Manufactory engine

1840:Steeple compound engine

1507:straight line mechanism

1232:Watt's 'perfect engine'

1226:Watt atmospheric engine

1109:Müller, Gerald (2015).

760:Rosen, William (2012).

730:Dickinson, Henry Winram

537:, formerly used at the

511:Crofton Pumping Station

2205:Water-returning engine

2179:Lean's Engine Reporter

1952:Chacewater Mine engine

1825:Six-column beam engine

951:James Watt: Monopolist

681:Preserved beam engines

647:

617:

531:Science Museum, London

495:Science Museum, London

483:Preserved Watt engines

421:

379:

248:as a Newcomen engine.

207:

174:

60:

2226:Industrial Revolution

2045:London Steam Carriage

645:

633:Organic Rankine Cycle

615:

597:The Henry Ford Museum

553:The Henry Ford Museum

519:Kennet and Avon Canal

465:Industrial Revolution

419:

373:

216:University of Glasgow

205:

168:

73:Industrial Revolution

57:Industrial Revolution

35:

1991:Bradley Works engine

1815:Reciprocating engine

1638:Babcock & Wilcox

1481:Centrifugal governor

1222:at Wikimedia Commons

992:Bennett, S. (1979).

932: : p 58 et seq.

666:Corliss steam engine

493:of 1777, now in the

450:centrifugal governor

385:reciprocating engine

235:atmospheric pressure

183:"atmospheric" engine

138:, which allowed the

2231:Scottish inventions

1532:Sun and planet gear

1159:"Model tests, Mk 1"

1130:2015REne...75..348M

1060:"Rowington Records"

1046:"Henry Ford Museum"

1032:"Henry Ford Museum"

621:Recent developments

579:The 1817 engine in

434:sun and planet gear

378:on a pumping engine

298:Bloomfield Colliery

116:sun and planet gear

80:first steam engines

45:D. Napier & Son

2032:Richard Trevithick

1630:Water-tube boilers

1444:Gresley conjugated

1220:Watt steam engines

648:

618:

616:Daveys Engine 1885

557:Dearborn, Michigan

422:

380:

366:Later improvements

208:

198:Separate condenser

175:

61:

2213:

2212:

2139:

2138:

2018:

2017:

1702:

1701:

1602:Fire-tube boilers

1457:

1456:

1217:Media related to

1020:. Science Museum.

904:978-0-917914-73-7

743:978-1-108-01228-7

527:Powerhouse Museum

420:Watt steam engine

181:who developed an

126:. Watt's partner

65:Watt steam engine

16:(Redirected from

2263:

2163:fardier à vapeur

1997:Whitbread Engine

1958:Smethwick Engine

1926:

1865:

1684:Feedwater heater

1552:

1334:

1278:

1271:

1264:

1255:

1216:

1201:

1200:

1198:

1196:

1191:. 9 October 2016

1181:

1175:

1174:

1172:

1170:

1165:. 8 October 2016

1155:

1149:

1148:

1146:

1144:

1118:Renewable Energy

1115:

1106:

1100:

1099:

1092:

1086:

1085:

1083:

1081:

1070:

1064:

1063:

1056:

1050:

1049:

1042:

1036:

1035:

1028:

1022:

1021:

1014:

1008:

1007:

989:

983:

981:

971:

965:

964:, pp. 176–7

959:

953:

948:

942:

939:

933:

922:

916:

913:

907:

889:

872:

863:

856:

850:

847:

841:

840:

826:

817:

816:

814:

812:

798:

792:

791:

782:

776:

775:

757:

748:

747:

726:

717:

716:

714:

702:

592:

576:

543:Dartmouth Circus

533:, while an 1817

523:Whitbread Engine

499:Smethwick Engine

474:incorporating a

344:Boulton and Watt

331:

318:Stratford-le-Bow

308:'s ironworks at

276:Boulton and Watt

82:, introduced by

21:

2271:

2270:

2266:

2265:

2264:

2262:

2261:

2260:

2216:

2215:

2214:

2209:

2135:

2110:

2083:

2064:

2014:

1971:

1915:

1903:Fairbottom Bobs

1888:Newcomen engine

1882:

1854:

1800:Expansion valve

1773:

1759:Watt's separate

1730:

1698:

1672:

1624:

1596:

1541:

1517:Parallel motion

1453:

1404:Stephenson link

1385:

1323:

1292:Operating cycle

1287:

1282:

1219:

1209:

1204:

1194:

1192:

1185:"Crowd funding"

1183:

1182:

1178:

1168:

1166:

1157:

1156:

1152:

1142:

1140:

1113:

1108:

1107:

1103:

1098:. 27 June 2017.

1094:

1093:

1089:

1079:

1077:

1072:

1071:

1067:

1058:

1057:

1053:

1044:

1043:

1039:

1030:

1029:

1025:

1016:

1015:

1011:

1004:

991:

990:

986:

973:

972:

968:

960:

956:

949:

945:

940:

936:

923:

919:

914:

910:

874:

873:

866:

857:

853:

848:

844:

828:

827:

820:

810:

808:

800:

799:

795:

784:

783:

779:

772:

759:

758:

751:

744:

728:

727:

720:

712:

704:

703:

699:

695:

657:

623:

606:

599:

593:

584:

577:

549:in Birmingham.

547:A38(M) motorway

485:

438:William Murdoch

409:coupled with a

403:parallel motion

376:parallel motion

368:

329:

283:Matthew Boulton

278:

272:

200:

179:Thomas Newcomen

171:Newcomen engine

152:

136:parallel motion

128:Matthew Boulton

84:Thomas Newcomen

28:

23:

22:

15:

12:

11:

5:

2269:

2267:

2259:

2258:

2256:Thermodynamics

2253:

2248:

2243:

2238:

2233:

2228:

2218:

2217:

2211:

2210:

2208:

2207:

2202:

2197:

2192:

2187:

2182:

2175:

2174:

2173:

2167:

2153:

2147:

2145:

2141:

2140:

2137:

2136:

2134:

2133:

2127:

2120:

2118:

2112:

2111:

2109:

2108:

2100:

2093:

2091:

2085:

2084:

2082:

2081:

2074:

2072:

2066:

2065:

2063:

2062:

2061:

2060:

2054:

2048:

2042:

2028:

2026:

2020:

2019:

2016:

2015:

2013:

2012:

2006:

2000:

1994:

1988:

1981:

1979:

1973:

1972:

1970:

1969:

1961:

1955:

1949:

1941:

1938:Kinneil Engine

1934:

1932:

1923:

1917:

1916:

1914:

1913:

1910:Elsecar Engine

1907:

1899:

1892:

1890:

1884:

1883:

1881:

1880:

1873:

1871:

1862:

1856:

1855:

1853:

1852:

1847:

1842:

1837:

1832:

1830:Steeple engine

1827:

1822:

1817:

1812:

1807:

1802:

1797:

1792:

1787:

1781:

1779:

1775:

1774:

1772:

1771:

1766:

1761:

1756:

1751:

1746:

1740:

1738:

1732:

1731:

1729:

1728:

1723:

1718:

1712:

1710:

1704:

1703:

1700:

1699:

1697:

1696:

1691:

1689:Feedwater pump

1686:

1680:

1678:

1674:

1673:

1671:

1670:

1665:

1660:

1655:

1650:

1645:

1640:

1634:

1632:

1626:

1625:

1623:

1622:

1617:

1612:

1606:

1604:

1598:

1597:

1595:

1594:

1589:

1584:

1579:

1574:

1569:

1564:

1558:

1556:

1555:Simple boilers

1549:

1543:

1542:

1540:

1539:

1537:Watt's linkage

1534:

1529:

1524:

1519:

1514:

1509:

1498:

1493:

1488:

1486:Connecting rod

1483:

1478:

1473:

1467:

1465:

1459:

1458:

1455:

1454:

1452:

1451:

1446:

1441:

1436:

1431:

1426:

1421:

1416:

1411:

1406:

1401:

1395:

1393:

1387:

1386:

1384:

1383:

1378:

1373:

1368:

1363:

1358:

1353:

1352:

1351:

1340:

1338:

1331:

1325:

1324:

1322:

1321:

1316:

1311:

1306:

1301:

1295:

1293:

1289:

1288:

1283:

1281:

1280:

1273:

1266:

1258:

1252:

1251:

1246:

1241:

1235:

1229:

1223:

1208:

1207:External links

1205:

1203:

1202:

1176:

1150:

1101:

1087:

1065:

1051:

1037:

1023:

1009:

1002:

984:

966:

954:

943:

934:

917:

915:Hills, 96–105.

908:

864:

851:

842:

818:

793:

777:

771:978-0226726342

770:

749:

742:

718:

696:

694:

691:

690:

689:

683:

678:

676:Thermodynamics

673:

668:

663:

656:

653:

622:

619:

605:

602:

601:

600:

594:

587:

585:

578:

571:

535:blowing engine

484:

481:

367:

364:

337:John Wilkinson

306:John Wilkinson

274:Main article:

271:

268:

199:

196:

151:

148:

112:Carron Company

92:partial vacuum

26:

24:

14:

13:

10:

9:

6:

4:

3:

2:

2268:

2257:

2254:

2252:

2249:

2247:

2244:

2242:

2239:

2237:

2234:

2232:

2229:

2227:

2224:

2223:

2221:

2206:

2203:

2201:

2198:

2196:

2193:

2191:

2188:

2186:

2183:

2181:

2180:

2176:

2171:

2168:

2165:

2164:

2159:

2158:

2157:

2154:

2152:

2149:

2148:

2146:

2142:

2131:

2128:

2125:

2122:

2121:

2119:

2117:

2113:

2106:

2105:

2101:

2098:

2095:

2094:

2092:

2090:

2086:

2079:

2076:

2075:

2073:

2071:

2067:

2058:

2055:

2052:

2049:

2046:

2043:

2040:

2039:

2038:Puffing Devil

2035:

2034:

2033:

2030:

2029:

2027:

2025:

2024:High-pressure

2021:

2010:

2007:

2004:

2001:

1998:

1995:

1992:

1989:

1986:

1983:

1982:

1980:

1978:

1977:Rotative beam

1974:

1967:

1966:

1962:

1959:

1956:

1953:

1950:

1947:

1946:

1942:

1939:

1936:

1935:

1933:

1931:

1927:

1924:

1922:

1918:

1911:

1908:

1905:

1904:

1900:

1897:

1894:

1893:

1891:

1889:

1885:

1878:

1877:Savery Engine

1875:

1874:

1872:

1870:

1866:

1863:

1861:

1857:

1851:

1850:Working fluid

1848:

1846:

1843:

1841:

1838:

1836:

1833:

1831:

1828:

1826:

1823:

1821:

1818:

1816:

1813:

1811:

1808:

1806:

1803:

1801:

1798:

1796:

1793:

1791:

1788:

1786:

1783:

1782:

1780:

1776:

1770:

1767:

1765:

1762:

1760:

1757:

1755:

1752:

1750:

1747:

1745:

1742:

1741:

1739:

1737:

1733:

1727:

1724:

1722:

1719:

1717:

1714:

1713:

1711:

1709:

1705:

1695:

1692:

1690:

1687:

1685:

1682:

1681:

1679:

1675:

1669:

1666:

1664:

1661:

1659:

1656:

1654:

1651:

1649:

1646:

1644:

1641:

1639:

1636:

1635:

1633:

1631:

1627:

1621:

1618:

1616:

1613:

1611:

1608:

1607:

1605:

1603:

1599:

1593:

1590:

1588:

1585:

1583:

1580:

1578:

1575:

1573:

1570:

1568:

1565:

1563:

1560:

1559:

1557:

1553:

1550:

1548:

1544:

1538:

1535:

1533:

1530:

1528:

1527:Rotative beam

1525:

1523:

1520:

1518:

1515:

1513:

1510:

1508:

1505:

1504:hypocycloidal

1502:

1499:

1497:

1494:

1492:

1489:

1487:

1484:

1482:

1479:

1477:

1474:

1472:

1469:

1468:

1466:

1464:

1460:

1450:

1447:

1445:

1442:

1440:

1437:

1435:

1432:

1430:

1427:

1425:

1422:

1420:

1417:

1415:

1412:

1410:

1407:

1405:

1402:

1400:

1397:

1396:

1394:

1392:

1388:

1382:

1379:

1377:

1374:

1372:

1369:

1367:

1364:

1362:

1359:

1357:

1354:

1350:

1347:

1346:

1345:

1342:

1341:

1339:

1335:

1332:

1330:

1326:

1320:

1317:

1315:

1312:

1310:

1307:

1305:

1302:

1300:

1297:

1296:

1294:

1290:

1286:

1285:Steam engines

1279:

1274:

1272:

1267:

1265:

1260:

1259:

1256:

1250:

1247:

1245:

1242:

1239:

1236:

1233:

1230:

1227:

1224:

1221:

1215:

1211:

1210:

1206:

1190:

1186:

1180:

1177:

1164:

1160:

1154:

1151:

1139:

1135:

1131:

1127:

1123:

1119:

1112:

1105:

1102:

1097:

1091:

1088:

1075:

1069:

1066:

1061:

1055:

1052:

1047:

1041:

1038:

1033:

1027:

1024:

1019:

1013:

1010:

1005:

1003:0-86341-047-2

999:

995:

988:

985:

979:

978:

970:

967:

963:

958:

955:

952:

947:

944:

938:

935:

931:

930:1 85761 119 5

927:

921:

918:

912:

909:

905:

901:

897:

893:

888:

884:

880:

879:

871:

869:

865:

861:

858:R. L. Hills,

855:

852:

846:

843:

838:

834:

833:

825:

823:

819:

807:

803:

797:

794:

789:

781:

778:

773:

767:

763:

756:

754:

750:

745:

739:

735:

731:

725:

723:

719:

715:. p. 13.

711:

707:

706:Ayres, Robert

701:

698:

692:

687:

686:Ivan Polzunov

684:

682:

679:

677:

674:

672:

669:

667:

664:

662:

659:

658:

654:

652:

644:

640:

636:

634:

629:

620:

614:

610:

603:

598:

591:

586:

582:

575:

570:

568:

565:

562:

558:

554:

550:

548:

544:

540:

536:

532:

528:

524:

520:

516:

512:

508:

504:

500:

496:

492:

491:

482:

480:

477:

473:

468:

466:

462:

457:

455:

451:

446:

443:

439:

435:

432:

428:

418:

414:

412:

408:

404:

399:

393:

391:

390:double acting

386:

377:

372:

365:

363:

361:

357:

353:

349:

345:

341:

338:

333:

327:

321:

319:

315:

311:

307:

303:

299:

294:

292:

288:

284:

277:

269:

267:

264:

260:

256:

254:

253:jet condenser

249:

245:

243:

238:

236:

232:

228:

224:

219:

217:

213:

204:

197:

195:

191:

187:

184:

180:

172:

167:

163:

161:

157:

156:Thomas Savery

149:

147:

145:

141:

137:

133:

129:

125:

121:

117:

113:

108:

104:

100:

97:

93:

89:

85:

81:

76:

74:

70:

66:

58:

54:

50:

46:

42:

39:

38:double-acting

34:

30:

19:

2246:Beam engines

2190:Modern steam

2177:

2162:

2124:Porter-Allen

2103:

2037:

1964:

1944:

1920:

1901:

1835:Safety valve

1764:"Pickle-pot"

1658:Thimble tube

1303:

1193:. Retrieved

1188:

1179:

1167:. Retrieved

1162:

1153:

1141:. Retrieved

1121:

1117:

1104:

1090:

1078:. Retrieved

1068:

1054:

1040:

1026:

1012:

993:

987:

976:

969:

957:

946:

937:

920:

911:

877:

859:

854:

845:

831:

809:. Retrieved

805:

796:

786:

780:

761:

733:

700:

661:Carnot cycle

649:

637:

624:

607:

566:

551:

489:

486:

469:

458:

447:

423:

397:

394:

381:

342:

334:

322:

295:

279:

265:

261:

257:

252:

250:

246:

239:

223:condensation

220:

209:

192:

188:

176:

153:

150:Introduction

132:Soho Foundry

109:

105:

101:

88:power stroke

77:

64:

62:

43:, built by

41:steam engine

29:

1921:Watt engine

1721:Oscillating

1677:Boiler feed

1522:Plate chain

1501:Tusi couple

1414:Walschaerts

1299:Atmospheric

1124:: 348–355.

1080:14 February

671:Heat engine

461:water wheel

425:wheel by a

227:"condenser"

140:piston rods

120:water wheel

2236:James Watt

2220:Categories

2130:Ljungström

2116:High-speed

2009:Lap Engine

1965:Resolution

1869:Precursors

1754:Kirchweger

1716:Locomotive

1663:Three-drum

1643:Field-tube

1610:Locomotive

1592:Lancashire

1512:Link chain

1496:Crankshaft

1463:Mechanisms

1391:Valve gear

962:Rosen 2012

693:References

628:waste heat

581:Birmingham

561:Henry Ford

454:controller

411:pantograph

360:Chacewater

352:Wheal Busy

314:Shropshire

291:Birmingham

212:James Watt

169:The model

124:topography

96:James Watt

69:James Watt

2161:Cugnot's

2104:Salamanca

1805:Hydrolock

1790:Crosshead

1736:Condenser

1572:Egg-ended

1195:25 August

1169:25 August

583:, England

539:Netherton

515:Wiltshire

503:Thinktank

476:manometer

472:indicator

431:epicyclic

356:Ting Tang

335:In 1774,

210:In 1763,

144:crosshead

2144:See also

2070:Compound

1945:Old Bess

1785:Blowback

1708:Cylinder

1694:Injector

1653:Stirling

1648:Sentinel

1562:Haystack

1476:Cataract

1449:Southern

1439:Caprotti

1314:Compound

896:27-24075

887:16011753

732:(1939).

708:(1989).

655:See also

490:Old Bess

442:flywheel

398:directly

348:Cornwall

310:Broseley

231:cylinder

1860:History

1769:Surface

1587:Cornish

1547:Boilers

1429:Corliss

1366:Corliss

1349:D slide

1319:Uniflow

1309:Cornish

1143:5 March

1126:Bibcode

407:linkage

374:Watt's

362:mines.

326:Smeaton

289:, near

2172:(1784)

2166:(1769)

2132:(1908)

2126:(1862)

2107:(1812)

2099:(1805)

2089:Murray

2080:(1803)

2059:(1804)

2053:(1803)

2047:(1803)

2041:(1801)

2011:(1788)

2005:(1786)

1999:(1785)

1993:(1783)

1987:(1782)

1968:(1781)

1960:(1779)

1954:(1778)

1948:(1777)

1940:(1768)

1912:(1795)

1906:(1760)

1898:(1725)

1879:(1698)

1845:Stroke

1810:Piston

1795:Cutoff

1668:Yarrow

1620:Launch

1615:Scotch

1376:Sleeve

1371:Poppet

1356:Piston

1337:Valves

1329:Valves

1000:

928:

902:

894:

885:

811:1 July

768:

740:

358:, and

302:Tipton

242:piston

53:Madrid

1778:Other

1582:Flued

1567:Wagon

1491:Crank

1434:Lentz

1424:Baker

1419:Allan

1344:Slide

1114:(PDF)

713:(PDF)

427:crank

160:mines

1930:Beam

1471:Beam

1381:Bash

1361:Drop

1304:Watt

1197:2019

1171:2019

1145:2018

1082:2024

998:ISBN

926:ISBN

900:ISBN

892:LCCN

883:LCCN

813:2014

766:ISBN

738:ISBN

287:Soho

78:The

63:The

1749:Jet

1577:Box

1409:Joy

1399:Gab

1134:doi

839:ff.

837:339

555:in

513:in

332:".

312:in

300:at

49:UPM

2222::

1187:.

1161:.

1132:.

1122:75

1120:.

1116:.

906:).

867:^

821:^

804:.

752:^

721:^

467:.

354:,

1277:e

1270:t

1263:v

1199:.

1173:.

1147:.

1136::

1128::

1084:.

1062:.

1048:.

1034:.

1006:.

815:.

774:.

746:.

330:'

51:(

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.