178:

and the condensed water passes into the bottom of the oil reservoir and the sight-glass chambers. When the sight-glass chambers have filled with water the oil delivery for each feed, regulated by control valves, is released upwards into the water-filled sight-glass chambers. The rate of delivery, typically two or three drops of oil through each feed per minute, is monitored by watching the progress of the drops as they rise through the water. The oil gathers above the water and passes into the delivery tubes. The body is fitted with a drain for emptying the condensed water from the oil chamber before it is refilled with oil.

226:

262:

38:

163:

217:, which could be made to release oil back into the reservoir (instead of entering the feed tubes) at varying stages as the delivery stroke progressed. If the device were used to deliver heavy grade oil to the steam cylinders the reservoir was heated by a steam coil to allow the oil to pass more easily down the delivery tubes.

95:. It operates by allowing steam to enter a closed vessel containing oil. After condensing, the water sinks to the bottom of the vessel, causing the oil to rise and overflow into delivery pipes. The oil from the delivery pipes is introduced into the steam pipe, where it is atomised and carried to the valves and cylinders.

287:

The FSA type lubricator differs by each pump having two separate pistons to control the pumping & distribution of oil. The pistons are driven by cams on the driving shaft. The driving shaft is driven via a means of a roller ratchet assembly which converts the reciprocating motion of the operating

252:

The lubricator is driven by a rod from the expansion link in locomotives valve gear. The rocking motion of this drive is converted to a rotary motion by a series of driving pawls contained in a clutch box. The lubricators were also fitted with a priming hand wheel on the outer face of the lubricator.

177:

and incorporates the condensing chamber, the oil reservoir and the sight-glasses fitted at the front and back of the body. Passages within the body interconnect these areas. The body is fitted with a steam valve, a water valve and oil control valves. In operation, steam enters the condensing chamber

283:

The DV range was available in range of sizes with capacities ranging from 8 to 36 pints, and the number of feeds from 1 to 26. Each of the lubricators consist of a reservoir, a ratchet assembly, a sliding shaft assembly, and the pump units. A screwed oil filler cap is fitted to the lockable hinged

128:

The displacement lubricator was a useful stop-gap but had the disadvantage that it was difficult to accurately control over the rate of oil feed and lubrication was only supplied when the engine was doing work (when a locomotive is coasting with the regulator closed, no steam is present to operate

145:

in 1862 and patented in

British Patent 1337. It incorporated two improvements over the original Ramsbottom type, the ability to control the quantity of steam which entered the lubricator, via a control valve, and the addition of an air filled chamber within the oil reservoir. The chamber expanded

120:, a Canadian who moved to Michigan and became a U.S. citizen, received a patent for his automatic lubricator in 1872. Piping delivered oil by gravity from a central reservoir to where it was required. Later types of lubricator (from around 1887), referred to as the "sight-feed" type, allowed a

248:

The lubricator is a self-contained unit with the drive mechanism fitted at one end, with the drive shaft running through the cast iron oil reservoir. The drive shaft is fitted with 2 hardened steel eccentrics which provide movement to the drive frame which runs in machined grooves in the oil

316:

draws the oil over the lip of the pipe for delivery by gravity. Variation in delivery rates comes from adjusting the size and tightness of the worsted bundles. The bundles of wool are effective in filtering out harmful contamination but do not work properly should water enter the reservoir.

284:

lid of the reservoir and a sight glass for indicating the oil level is fitted to the front face of the reservoir. The pumps of the DV type lubricator are operated by a sliding shaft assembly, unlike the

Silverton or Wakefield lubricators which are operated by a rotating camshaft.

124:

to be positioned in the cab where the rate of oil feed could be observed. In 1898 McCoy's further patent added a glass tube mounted below the reservoir so that the rate of delivery could be monitored, with a bypass pipe available in case the main feed was seen to be blocked.

269:

The

Friedmann system of mechanical lubricators included the DV & FSA type lubricators. This style of mechanical lubricator was designed & produced by Alex Friedmann KG of Austria. The DV type were then made under licence by in the US by the

146:

when steam was cut off, the aim of which was to supply oil even when the locomotive was coasting. However, this proved ineffective in practice, particularly if the locomotive was coasting for a long time (e.g. down a hill).

137:

The Roscoe type lubricator improved the situation by providing a valve with which to regulate the flow of steam and hence lubricant. Setting the valve correctly required experience and depended on the speed of the train.

41:

Modern locomotive lubricators. The center item is a mechanical lubricator for the cylinders, operated by the connecting lever seen below it (or by the hand wheel, for priming). The smaller one to the right is a

245:, as well as by the various UK private locomotive builders for export overseas. Commonly 2 lubricators were fitted, one for lubricating the cylinders and the second for lubricating the axleboxes.

193:. This lubricator was commonly made with either 3,4 or 5 feeds, the center feed on the odd numbered lubricators was often used for supplying oil to the steam end of Westinghouse air compressors.

181:

This type of hydrostatic displacement lubricator was made by the

Detroit Lubricator Company of the USA. A British patent was granted in 1911 and this lubricator was then manufactured by the

154:

When more sophisticated lubricators, such as the

Wakefield and Detroit types, were developed, displacement lubricators fell out of use but they are still used on model steam engines.

110:

or one lubricator would be placed behind the smokebox. The behind-smokebox configuration has the advantage that a good connection can be made to the steam pipe and it was used by the

114:. It has the disadvantage that the lubricator's accessibility is reduced and additional drain pipes are required to be connected to the waste to avoid it dripping onto the boiler.

401:

498:

229:

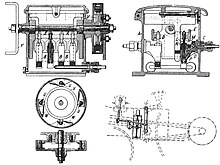

Patent drawing of the original

Midland Railway version of the Silverton mechanical lubricator as reproduced in the December 1911 issue of 'The Engineer' magazine.

74:

mountings as well. There are various types of automatic lubricator, which include various designs of displacement, hydrostatic and mechanical lubricators.

205:

in 1899. The company manufactured both hydrostatic and mechanical lubricators but it was best-known for its patent mechanical lubricator. Marketed as the

202:

585:

523:

300:, equipment using this method consists of reservoirs of oil with delivery pipes from the reservoir to the bearings, axleboxes, slide bars or

249:

reservoir. This drive frame reciprocates vertically which then drives the double acting independent oil pumps located in the oil reservoir.

280:

Both types of lubricator are of the 'valveless' type, having no ball valves, springs or oil seals used in the operation of the pump units.

238:

312:

yarn tied around narrow wire frames—are tucked into the open ends of the delivery pipes so that a "tail" of threads drapes into the oil.

405:

558:

502:

482:

301:

237:

in 1911 and from 1922 was commercially available from

Gresham and Craven. This style of mechanical lubricator was used by the

209:

it comprised a large oil chest (typically 1 imperial gallon (4.5 L; 1.2 US gal) for eight delivery tubes) with

436:

31:

595:

63:

271:

92:

590:

210:

111:

103:

600:

275:

304:, mounted so that the open top ends of the pipes are above the maximum oil level. Assemblies called

225:

265:

Nathan mechanical lubricator fitted to South

Maitland Railway ten class loco No.18 in preservation.

326:

182:

261:

554:

478:

440:

376:

351:

106:) would be positioned at the front of the boiler near the valves, often on either side of the

313:

99:

234:

37:

17:

201:

The

Wakefield Oil Company, a manufacturer of lubricating oils, was founded in London by

88:

579:

67:

213:

pumps submerged within it. Regulation of the oil feed was achieved by adjustment of

166:

Hydrostatic lubricator showing sight glasses with oil drops rising through the water

162:

402:"Stuart Models | Steam Engines | Model Engineering | Executive Toys"

242:

214:

142:

117:

55:

375:

Lubrication of

Locomotives, B.L. Ahrons 1922, The Locomotive Publishing Co. Ltd.

121:

355:

59:

444:

524:"Worsted Wool Instructions - Worsted Wool - Lubricators & Accessories"

380:

171:

107:

71:

309:

174:

260:

224:

186:

161:

36:

475:

Steam locomotive lubrication : its development and practice

350:. London: British Transport Commission. 1957. pp. 126–128.

233:

The Silvertown lubricator was designed and developed by the

27:

Device fitted to a steam engine to supply lubricating oil

102:, either two displacement lubricators (one for each

87:The displacement lubricator was introduced in the

433:Handbook for Railway Steam Locomotive Enginemen

274:& the type DV & FSA types in the UK by

8:

30:For other uses of automatic lubricator, see

468:

466:

464:

462:

460:

458:

456:

454:

371:

369:

367:

365:

43:

553:. Manila, Philippines: Rex. p. 2.

348:Handbook for steam locomotive enginemen

338:

257:Friedmann/Nathan mechanical lubricator

141:The Roscoe lubricator was invented by

426:

424:

422:

7:

239:London, Midland and Scottish Railway

170:The one-piece lubricator body is a

25:

221:Silvertown mechanical lubricator

528:www.heritagesteamsupplies.co.uk

1:

586:Steam locomotive technologies

437:British Transport Commission

32:Automatic lubrication system

391:US patents 129,843; 614,307

617:

477:. Barrow-in-Furness: MIC.

473:Skellon, Peter W. (1997).

288:linkage to rotary motion.

276:Davies & Metcalfe Ltd.

191:British Detroit Lubricator

44:§ syphonic lubricator

29:

18:Detroit Lubricator Company

530:. Heritage Steam Supplies

98:In early applications in

272:Nathan Manufacturing Co.

54:is a device fitted to a

78:Displacement lubricator

551:Industrial Lubrication

549:Niño, Emanuel (1997).

266:

230:

167:

158:Hydrostatic lubricator

47:

431:Harvey, R.F. (1957).

264:

228:

165:

112:Great Western Railway

40:

439:. pp. 127–134.

292:Wick feed lubricator

207:Wakefield Lubricator

197:Wakefield lubricator

66:and, sometimes, the

52:automatic lubricator

596:English inventions

499:"Castrol timeline"

327:Splash lubrication

298:syphon lubrication

267:

231:

211:eccentric-operated

183:Vacuum Oil Company

168:

48:

203:Charles Wakefield

129:the lubricator).

100:steam locomotives

16:(Redirected from

608:

591:Locomotive parts

565:

564:

546:

540:

539:

537:

535:

520:

514:

513:

511:

510:

501:. Archived from

495:

489:

488:

470:

449:

448:

428:

417:

416:

414:

413:

404:. Archived from

398:

392:

389:

383:

373:

360:

359:

343:

314:Capillary action

21:

616:

615:

611:

610:

609:

607:

606:

605:

576:

575:

574:

569:

568:

561:

548:

547:

543:

533:

531:

522:

521:

517:

508:

506:

497:

496:

492:

485:

472:

471:

452:

430:

429:

420:

411:

409:

400:

399:

395:

390:

386:

374:

363:

346:"Lubrication".

345:

344:

340:

335:

323:

294:

259:

235:Midland Railway

223:

199:

160:

152:

135:

93:John Ramsbottom

85:

83:Ramsbottom type

80:

60:lubricating oil

35:

28:

23:

22:

15:

12:

11:

5:

614:

612:

604:

603:

598:

593:

588:

578:

577:

573:

572:External links

570:

567:

566:

559:

541:

515:

490:

483:

450:

418:

393:

384:

361:

337:

336:

334:

331:

330:

329:

322:

319:

296:Known also as

293:

290:

258:

255:

241:and latter by

222:

219:

198:

195:

159:

156:

151:

148:

134:

131:

89:United Kingdom

84:

81:

79:

76:

26:

24:

14:

13:

10:

9:

6:

4:

3:

2:

613:

602:

599:

597:

594:

592:

589:

587:

584:

583:

581:

571:

562:

560:9789712321788

556:

552:

545:

542:

529:

525:

519:

516:

505:on 2009-05-17

504:

500:

494:

491:

486:

484:0-9530417-0-0

480:

476:

469:

467:

465:

463:

461:

459:

457:

455:

451:

446:

442:

438:

434:

427:

425:

423:

419:

408:on 2011-10-06

407:

403:

397:

394:

388:

385:

382:

378:

372:

370:

368:

366:

362:

357:

353:

349:

342:

339:

332:

328:

325:

324:

320:

318:

315:

311:

307:

303:

299:

291:

289:

285:

281:

278:

277:

273:

263:

256:

254:

250:

246:

244:

240:

236:

227:

220:

218:

216:

215:sleeve valves

212:

208:

204:

196:

194:

192:

188:

184:

179:

176:

173:

164:

157:

155:

149:

147:

144:

139:

132:

130:

126:

123:

119:

115:

113:

109:

105:

101:

96:

94:

90:

82:

77:

75:

73:

69:

65:

61:

57:

53:

45:

39:

33:

19:

550:

544:

532:. Retrieved

527:

518:

507:. Retrieved

503:the original

493:

474:

432:

410:. Retrieved

406:the original

396:

387:

347:

341:

308:—bundles of

305:

297:

295:

286:

282:

279:

268:

251:

247:

243:British Rail

232:

206:

200:

190:

180:

169:

153:

143:James Roscoe

140:

136:

127:

118:Elijah McCoy

116:

97:

86:

56:steam engine

51:

49:

601:Lubrication

302:horn blocks

150:Replacement

133:Roscoe type

122:sight glass

91:in 1860 by

580:Categories

534:14 October

509:2021-10-27

435:. London:

412:2009-01-09

333:References

58:to supply

356:505163269

306:trimmings

189:) as the

187:Mobil Oil

64:cylinders

381:12656163

321:See also

172:gunmetal

108:smokebox

104:cylinder

72:axle box

68:bearings

445:4431123

310:worsted

185:(later

175:casting

62:to the

557:

481:

443:

379:

354:

555:ISBN

536:2021

479:ISBN

441:OCLC

377:OCLC

352:OCLC

70:and

50:An

582::

526:.

453:^

421:^

364:^

563:.

538:.

512:.

487:.

447:.

415:.

358:.

46:.

34:.

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.