112:

370:

214:

22:

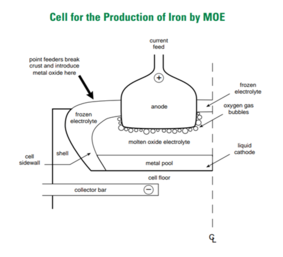

233:. For steel production, this method uses an inert anode (Carbon, Platinum, Iridium or Chromium-based alloy) and places iron ore in the cathode. The electrochemical reaction in this Molten Oxide cell can reach up to 1600 °C, a temperature that melts iron ore and electrolyte oxide. Then the molten iron ore decompose following this reaction.

392:

In electrorefining, decarburization process happened in electrochemical cell that composed of inert electrode, slag and steel. During the process, current passing through the cell and made slag and steel melted. Oxygen ion from slag decompose and oxidize carbon on steel and to form CO. That

1058:

D.R., George C. Marshall Space Flight Center

Marshall Space Flight Center, AL 35812, National Aeronautics and Space Administration Washington, DC 20546-0001 Curreri, P.A. Ethridge, E.C. Hudson, S.B. Miller, T.Y. Grugel, R.N. Sen, S. Sadoway.

138:. Electrolysis can be used as a final refining stage in pyrometallurgical metal production (electrorefining) and it is also used for reduction of a metal from an aqueous metal salt solution produced by hydrometallurgy (electrowinning).

951:

is come from the slag, based on the reaction above, beside producing CO gas, this method also producing pure silicon (depending on the slag). The benefit of this direct decarburization process is it does not produce

943:

358:. Moreover, if the electricity to run such cells comes from renewable sources, this process may have zero emissions. This technology also can be implemented for producing Nickel, Chromium, and Ferrochromium.

647:

521:

346:

791:

678:

1084:

1088:

350:

The electrolysis reaction will produce molten pure iron as a main product and oxygen as its by-product. Because this process does not add coke in the process, no CO

134:

operations. The electrolysis can be done on a molten metal oxide (smelt electrolysis) which is used for example to produce aluminium from aluminium oxide via the

377:

The purpose of this method is to reduce carbon content from steel. This process is suitable for secondary steelmaking industry which recycling steel

1062:

Process

Demonstration For Lunar In Situ Resource Utilization--Molten Oxide Electrolysis (MSFC Independent Research and Development Project No. 5-81)

1175:

Allanore, Antoine; Ortiz, Luis A; Sadoway, Donald R (2011-04-19), Neelameggham, Neale R.; Belt, Cynthia K.; Jolly, Mark; Reddy, Ramana G. (eds.),

32:

1196:

993:

126:

that uses electrical energy to produce metals by electrolysis. It is usually the last stage in metal production and is therefore preceded by

801:

527:

1034:

399:

1330:

172:

by electrodeposition is included in this category, or sometimes electrowinning, or a separate category depending on application.

90:

238:

62:

684:

381:

that has variety of carbon content in their feedstock. This method aim to replace current conventional method that utilizing

47:

69:

361:

Currently

Massachusetts-based Boston Metal company is in a process to scale up this technology to an industrial level.

135:

1320:

1177:"Molten Oxide Electrolysis for Iron Production: Identification of Key Process Parameters for Largescale Development"

147:

76:

382:

355:

58:

1325:

1264:

1115:

973:

385:(BOF) to reduce carbon content of iron by blowing oxygen to make it react with carbon and forming CO

111:

1296:

1176:

1157:

1078:

651:

393:

decarburizing reaction is occurred in three steps as follow. (ads) means adsorbed intermediate

83:

1288:

1280:

1192:

1149:

1141:

1066:

1040:

1030:

989:

169:

1029:. Djokić, Stojan S., Grgur, Branimir N., 1965-. New York: Kluwer Academic/Plenum Publishers.

1272:

1184:

1131:

1123:

981:

197:

187:

213:

165:

131:

1268:

1119:

369:

181:

175:

159:

127:

1314:

1300:

1252:

230:

1161:

222:

154:

226:

21:

1276:

1188:

985:

1103:

123:

1284:

1145:

1070:

1044:

39:

1292:

1153:

1024:

1136:

1127:

1104:"A new anode material for oxygen evolution in molten oxide electrolysis"

225:

in steelmaking is utilizing electrons as the reducing agent instead of

193:

184:, the manufacture of, usually thin, metal parts through electroplating

1060:

146:

Electrometallurgy is the field concerned with the processes of metal

1183:, Hoboken, NJ, USA: John Wiley & Sons, Inc., pp. 121–129,

938:{\displaystyle {\ce {C{}+1/2SiO2<=>CO_{(g)}{}+1/2Si_{(}l)}}}

378:

368:

110:

1251:

Judge, William D.; Paeng, Jaesuk; Azimi, Gisele (October 2022).

642:{\displaystyle {\ce {C(O_{(ads)}^{-})<=>C(O_{(ads)}^{})}}}

1220:

516:{\displaystyle {\ce {O2- + C <=> C(O^{-}_{(ads)}) +e-}}}

15:

1102:

Allanore, Antoine; Yin, Lan; Sadoway, Donald R. (May 2013).

1253:"Electrorefining for direct decarburization of molten iron"

796:

The total reaction from this cell is following this scheme

931:

895:

834:

779:

714:

631:

341:{\displaystyle {\ce {Fe2O3(l) + e- -> Fe(l) + O2(g)}}}

323:

266:

253:

786:{\displaystyle {\ce {C(O_{(ads)}^{})<=>CO_{(}g)}}}

43:

980:, John Wiley & Sons, Ltd, pp. 523–557, 2016,

903:

858:

814:

742:

587:

446:

804:

687:

654:

530:

402:

241:

190:, the removal of material from a metallic workpiece

178:, the deposition of a layer of one metal on another

956:but CO which is not considered as greenhouse gas.

937:

785:

672:

641:

515:

340:

150:. There are seven categories of these processes:

866:

865:

848:

847:

750:

749:

732:

731:

595:

594:

577:

576:

454:

453:

436:

435:

978:Physical Chemistry of Metallurgical Processes

8:

1083:: CS1 maint: multiple names: authors list (

1023:Popov, K. I. (Konstantin Ivanovich) (2002).

48:introducing citations to additional sources

1087:) CS1 maint: numeric names: authors list (

1135:

930:

918:

917:

898:

894:

882:

881:

867:

860:

859:

857:

849:

842:

840:

839:

837:

833:

828:

809:

805:

803:

778:

766:

765:

751:

744:

743:

741:

733:

726:

724:

723:

721:

713:

701:

700:

692:

688:

686:

663:

655:

653:

630:

618:

617:

609:

596:

589:

588:

586:

578:

571:

569:

568:

566:

556:

544:

543:

535:

531:

529:

506:

489:

477:

476:

468:

455:

448:

447:

445:

437:

430:

428:

427:

425:

413:

408:

403:

401:

326:

322:

317:

299:

287:

269:

265:

260:

252:

247:

242:

240:

1026:Fundamental aspects of electrometallurgy

212:

38:Relevant discussion may be found on the

965:

841:

725:

570:

429:

1076:

365:Direct Decarburization Electrorefining

196:, industrially known to Knowledge as

7:

1246:

1244:

1242:

1240:

1215:

1213:

1018:

1016:

1014:

1012:

1010:

162:, the extraction of metal from ores

115:Anodized titanium (detail) - a.jpg

14:

1221:"Decarbonizing Steel Production"

31:relies largely or entirely on a

20:

373:Direct Decarburization Reaction

168:, the purification of metals.

926:

919:

889:

883:

868:

843:

774:

767:

752:

727:

717:

708:

702:

693:

634:

625:

619:

610:

597:

572:

562:

551:

545:

536:

495:

484:

478:

469:

456:

431:

354:gas is produced. So no direct

333:

327:

306:

300:

293:

276:

270:

1:

673:{\displaystyle {\ce {+ e-}}}

1347:

1277:10.1038/s41563-021-01106-z

1189:10.1002/9781118061886.ch12

986:10.1002/9781119078326.ch12

209:Molten Oxide Electrolysis

1331:Metallurgical processes

356:greenhouse gas emission

170:Metal powder production

1181:Energy Technology 2011

939:

787:

674:

643:

517:

374:

342:

218:

116:

940:

788:

675:

644:

518:

372:

343:

216:

114:

802:

685:

652:

528:

400:

383:Basic Oxygen Furnace

239:

136:Hall-Hérault process

44:improve this article

1269:2022NatMa..21.1130J

1128:10.1038/nature12134

1120:2013Natur.497..353A

974:"Electrometallurgy"

933:

897:

854:

836:

781:

738:

716:

633:

583:

561:

494:

442:

418:

325:

268:

255:

229:as in conventional

59:"Electrometallurgy"

1321:Chemical processes

935:

913:

912:

877:

873:

824:

823:

783:

761:

757:

696:

670:

639:

613:

602:

539:

513:

472:

461:

404:

375:

338:

313:

256:

243:

219:

132:hydrometallurgical

117:

1263:(10): 1130–1136.

1198:978-1-118-06188-6

1114:(7449): 353–356.

995:978-1-119-07832-6

925:

916:

911:

888:

880:

875:

827:

822:

808:

773:

764:

759:

707:

699:

691:

662:

624:

616:

608:

604:

550:

542:

534:

505:

483:

475:

467:

463:

424:

407:

332:

316:

305:

298:

286:

275:

259:

246:

148:electrodeposition

128:pyrometallurgical

120:Electrometallurgy

109:

108:

94:

1338:

1305:

1304:

1257:Nature Materials

1248:

1235:

1234:

1232:

1231:

1217:

1208:

1207:

1206:

1205:

1172:

1166:

1165:

1139:

1099:

1093:

1092:

1082:

1074:

1055:

1049:

1048:

1020:

1005:

1004:

1003:

1002:

970:

944:

942:

941:

936:

934:

932:

929:

923:

922:

914:

904:

899:

896:

893:

892:

886:

878:

876:

874:

872:

871:

864:

856:

855:

853:

846:

838:

835:

832:

825:

815:

810:

806:

792:

790:

789:

784:

782:

780:

777:

771:

770:

762:

760:

758:

756:

755:

748:

740:

739:

737:

730:

722:

720:

715:

712:

711:

705:

697:

689:

679:

677:

676:

671:

669:

668:

667:

660:

648:

646:

645:

640:

638:

637:

632:

629:

628:

622:

614:

606:

605:

603:

601:

600:

593:

585:

584:

582:

575:

567:

565:

560:

555:

554:

548:

540:

532:

522:

520:

519:

514:

512:

511:

510:

503:

498:

493:

488:

487:

481:

473:

465:

464:

462:

460:

459:

452:

444:

443:

441:

434:

426:

422:

417:

412:

405:

347:

345:

344:

339:

337:

336:

330:

324:

321:

314:

309:

303:

296:

292:

291:

284:

279:

273:

267:

264:

257:

254:

251:

244:

198:chemical milling

188:Electropolishing

104:

101:

95:

93:

52:

24:

16:

1346:

1345:

1341:

1340:

1339:

1337:

1336:

1335:

1311:

1310:

1309:

1308:

1250:

1249:

1238:

1229:

1227:

1219:

1218:

1211:

1203:

1201:

1199:

1174:

1173:

1169:

1101:

1100:

1096:

1075:

1057:

1056:

1052:

1037:

1022:

1021:

1008:

1000:

998:

996:

972:

971:

967:

962:

955:

950:

800:

799:

683:

682:

659:

650:

649:

526:

525:

502:

398:

397:

388:

367:

353:

283:

237:

236:

211:

206:

204:Research trends

166:Electrorefining

144:

122:is a method in

105:

99:

96:

53:

51:

37:

25:

12:

11:

5:

1344:

1342:

1334:

1333:

1328:

1323:

1313:

1312:

1307:

1306:

1236:

1209:

1197:

1167:

1094:

1050:

1035:

1006:

994:

964:

963:

961:

958:

953:

948:

928:

921:

910:

907:

902:

891:

885:

870:

863:

852:

845:

831:

821:

818:

813:

794:

793:

776:

769:

754:

747:

736:

729:

719:

710:

704:

695:

680:

666:

658:

636:

627:

621:

612:

599:

592:

581:

574:

564:

559:

553:

547:

538:

523:

509:

501:

497:

492:

486:

480:

471:

458:

451:

440:

433:

421:

416:

411:

386:

366:

363:

351:

335:

329:

320:

312:

308:

302:

295:

290:

282:

278:

272:

263:

250:

210:

207:

205:

202:

201:

200:

191:

185:

182:Electroforming

179:

176:Electroplating

173:

163:

160:Electrowinning

157:

143:

140:

107:

106:

42:. Please help

28:

26:

19:

13:

10:

9:

6:

4:

3:

2:

1343:

1332:

1329:

1327:

1324:

1322:

1319:

1318:

1316:

1302:

1298:

1294:

1290:

1286:

1282:

1278:

1274:

1270:

1266:

1262:

1258:

1254:

1247:

1245:

1243:

1241:

1237:

1226:

1222:

1216:

1214:

1210:

1200:

1194:

1190:

1186:

1182:

1178:

1171:

1168:

1163:

1159:

1155:

1151:

1147:

1143:

1138:

1133:

1129:

1125:

1121:

1117:

1113:

1109:

1105:

1098:

1095:

1090:

1086:

1080:

1072:

1068:

1064:

1063:

1054:

1051:

1046:

1042:

1038:

1036:0-306-47564-2

1032:

1028:

1027:

1019:

1017:

1015:

1013:

1011:

1007:

997:

991:

987:

983:

979:

975:

969:

966:

959:

957:

945:

908:

905:

900:

861:

850:

829:

819:

816:

811:

797:

745:

734:

681:

664:

656:

590:

579:

557:

524:

507:

499:

490:

449:

438:

419:

414:

409:

396:

395:

394:

390:

384:

380:

371:

364:

362:

359:

357:

348:

318:

310:

288:

280:

261:

248:

234:

232:

231:blast furnace

228:

224:

221:Molten Oxide

215:

208:

203:

199:

195:

192:

189:

186:

183:

180:

177:

174:

171:

167:

164:

161:

158:

156:

153:

152:

151:

149:

141:

139:

137:

133:

129:

125:

121:

113:

103:

100:February 2019

92:

89:

85:

82:

78:

75:

71:

68:

64:

61: –

60:

56:

55:Find sources:

49:

45:

41:

35:

34:

33:single source

29:This article

27:

23:

18:

17:

1326:Electrolysis

1260:

1256:

1228:. Retrieved

1225:Boston Metal

1224:

1202:, retrieved

1180:

1170:

1137:1721.1/82073

1111:

1107:

1097:

1061:

1053:

1025:

999:, retrieved

977:

968:

946:

798:

795:

391:

376:

360:

349:

235:

223:Electrolysis

220:

155:Electrolysis

145:

119:

118:

97:

87:

80:

73:

66:

54:

30:

217:MOE scheme

1315:Categories

1230:2022-11-22

1204:2022-11-22

1001:2020-09-24

960:References

124:metallurgy

70:newspapers

1301:237947963

1285:1476-4660

1146:1476-4687

1079:cite book

1071:703646739

869:⇀

862:−

851:−

844:↽

753:⇀

746:−

735:−

728:↽

665:−

598:⇀

591:−

580:−

573:↽

558:−

508:−

491:−

457:⇀

450:−

439:−

432:↽

415:−

294:⟶

289:−

142:Processes

40:talk page

1293:34580434

1154:23657254

1045:51893969

1265:Bibcode

1162:4379353

1116:Bibcode

947:The SiO

194:Etching

84:scholar

1299:

1291:

1283:

1195:

1160:

1152:

1144:

1108:Nature

1069:

1043:

1033:

992:

86:

79:

72:

65:

57:

1297:S2CID

1158:S2CID

379:scrap

91:JSTOR

77:books

1289:PMID

1281:ISSN

1193:ISBN

1150:PMID

1142:ISSN

1089:link

1085:link

1067:OCLC

1041:OCLC

1031:ISBN

990:ISBN

227:coke

63:news

1273:doi

1185:doi

1132:hdl

1124:doi

1112:497

982:doi

826:SiO

706:ads

623:ads

549:ads

482:ads

130:or

46:by

1317::

1295:.

1287:.

1279:.

1271:.

1261:21

1259:.

1255:.

1239:^

1223:.

1212:^

1191:,

1179:,

1156:.

1148:.

1140:.

1130:.

1122:.

1110:.

1106:.

1081:}}

1077:{{

1065:.

1039:.

1009:^

988:,

976:,

952:CO

915:Si

879:CO

763:CO

389:.

297:Fe

245:Fe

1303:.

1275::

1267::

1233:.

1187::

1164:.

1134::

1126::

1118::

1091:)

1073:.

1047:.

984::

954:2

949:2

927:)

924:l

920:(

909:2

906:1

901:+

890:)

887:g

884:(

830:2

820:2

817:1

812:+

807:C

775:)

772:g

768:(

718:)

709:)

703:(

698:O

694:(

690:C

661:e

657:+

635:)

626:)

620:(

615:O

611:(

607:C

563:)

552:)

546:(

541:O

537:(

533:C

504:e

500:+

496:)

485:)

479:(

474:O

470:(

466:C

423:C

420:+

410:2

406:O

387:2

352:2

334:)

331:g

328:(

319:2

315:O

311:+

307:)

304:l

301:(

285:e

281:+

277:)

274:l

271:(

262:3

258:O

249:2

102:)

98:(

88:·

81:·

74:·

67:·

50:.

36:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.