17:

141:

105:

160:(LEL). This allows Honda Alabama's paint shop to switch from oxidizing 100,000 CFM of VOCs in a regenerative thermal oxidizer (RTO), to oxidizing only 1,500 CFM of VOCs in a small thermal oxidizer, at a much higher concentration. Reducing the volume of air to be oxidized from 100,000 CFM to 1,500 CFM (66:1 concentration ratio), allows for a much lower energy usage and consequently, fewer CO

48:. Differently from the fixed-bed or carbon rotor concentrators, the FBC system forces the VOC-laden air through several perforated steel trays, increasing the velocity of the air and allowing the sub-millimeter carbon beads to fluidize, or behave as if suspended in a liquid. This increases the surface area of the carbon-gas interaction, making it more effective at capturing VOCs.

57:

116:

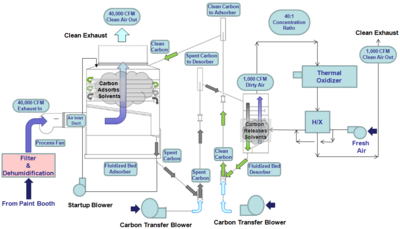

The saturated carbon beads are passed from the adsorber tower to the desorber tower, where the beads are heated to 350 °F and the VOCs are released. Typically the adsorber tower is many times larger than the desorber tower, leading to an air volume reduction and an increase in VOC concentration.

112:

Industrial processes requiring ventilation, including paint booths, printing, and chemical production, exhaust the ventilated air to the fluidized bed concentrator at room temperature. The air first passes into the adsorption tower, where it moves through six perforated trays of clean carbon beads.

172:

Despite an increase in Line 2 production, Honda is realizing a reduction in plant VOC emissions of nearly 60 metric tons annually as a result of the installation of the FBC system. Also, the new system uses approximately 20% of the energy of an RTO system. - Honda

Manufacturing of

183:

120:

The concentrated VOC gas stream is sent from the desorb tower to a thermal oxidizer, where the organic compounds are heated to 1400 °F and oxidized, or broken down into carbon dioxide (CO

250:

436:

446:

327:

426:

421:

416:

306:

156:

The primary advantage of the FBC over traditional rotor concentrators lies in its ability to achieve any concentration ratio up to the

255:

349:

431:

21:

16:

451:

371:

285:

245:

41:

441:

117:

The ratio of adsorber size to desorber size is called the concentration ratio, and ranges from 10:1 to 100:1.

113:

The 0.7 mm bead activated carbon (BAC) fluidizes in the trays and captures the VOCs as they intermix.

140:

223:

456:

157:

144:

Members of the Honda

Alabama Environmental Air Quality team are honored for their efforts to reduce CO

191:

128:

O), and by-products. In some cases, small amounts of carbon monoxide (CO), nitrogen oxide (NO

260:

182:

83:

37:

233:

206:

211:

36:) is an industrial process for the treatment of exhaust air. The system uses a bed of

410:

265:

228:

104:

45:

196:

92:

77:

71:

61:

401:

201:

56:

395:

218:

108:

A flow schematic of process gas in the fluidized bed concentrator system.

286:"Honda Manufacturing Alabama Honored As Air Conservationist of the Year"

67:

The fluidized bed concentrator consists of five primary components:

181:

139:

103:

55:

15:

398:

plus further links to relevant rules, reports, and programs.

186:

The adsorber tower and stack of a fluidized bed concentrator

251:

National

Emissions Standards for Hazardous Air Pollutants

307:"Toyota named Low-Carbon Auto Manufacturing of the Year"

328:"VOC Emissions from Industrial Painting Processes"

60:A 3D design of the fluidized bed concentrator in

372:"HMA Honored As Air Conservationist of the Year"

20:A fluidized bed concentrator for VOC control at

170:

437:United States Environmental Protection Agency

8:

95:, inlet desorber, outlet oxidizer to stack

277:

7:

447:Volatile organic compound abatement

427:Air pollution in the United States

350:"Ford Environmental VOC Emissions"

256:Air pollution in the United States

14:

132:), and other gases are produced.

422:Pollution control technologies

22:Honda Manufacturing of Alabama

1:

417:Air pollution control systems

473:

136:Emissions and energy usage

42:volatile organic compounds

30:fluidized bed concentrator

246:Volatile organic compound

432:Hazardous air pollutants

88:Carbon transport system

187:

175:

153:

109:

64:

25:

185:

158:lower explosive limit

143:

107:

59:

19:

452:Industrial processes

91:Process fans: inlet

224:Chemical production

188:

154:

110:

65:

26:

330:. Metal Finishing

178:Industries served

464:

383:

382:

380:

378:

368:

362:

361:

359:

357:

346:

340:

339:

337:

335:

324:

318:

317:

315:

313:

303:

297:

296:

294:

292:

282:

261:Activated carbon

84:Thermal oxidizer

44:(VOCs) from the

40:beads to adsorb

38:activated carbon

472:

471:

467:

466:

465:

463:

462:

461:

442:Chemical safety

407:

406:

392:

387:

386:

376:

374:

370:

369:

365:

355:

353:

348:

347:

343:

333:

331:

326:

325:

321:

311:

309:

305:

304:

300:

290:

288:

284:

283:

279:

274:

242:

234:Food processing

207:Heavy machinery

192:Paint finishing

180:

167:

163:

151:

147:

138:

131:

127:

123:

102:

54:

12:

11:

5:

470:

468:

460:

459:

454:

449:

444:

439:

434:

429:

424:

419:

409:

408:

405:

404:

402:Organic NESHAP

399:

391:

390:External links

388:

385:

384:

363:

341:

319:

298:

276:

275:

273:

270:

269:

268:

263:

258:

253:

248:

241:

238:

237:

236:

231:

226:

221:

216:

215:

214:

212:Transportation

209:

204:

199:

179:

176:

165:

161:

149:

145:

137:

134:

129:

125:

121:

101:

98:

97:

96:

89:

86:

81:

75:

53:

50:

13:

10:

9:

6:

4:

3:

2:

469:

458:

455:

453:

450:

448:

445:

443:

440:

438:

435:

433:

430:

428:

425:

423:

420:

418:

415:

414:

412:

403:

400:

397:

396:Clean Air Act

394:

393:

389:

373:

367:

364:

351:

345:

342:

329:

323:

320:

308:

302:

299:

287:

281:

278:

271:

267:

266:Air pollution

264:

262:

259:

257:

254:

252:

249:

247:

244:

243:

239:

235:

232:

230:

229:Semiconductor

227:

225:

222:

220:

217:

213:

210:

208:

205:

203:

200:

198:

195:

194:

193:

190:

189:

184:

177:

174:

169:

159:

142:

135:

133:

118:

114:

106:

99:

94:

90:

87:

85:

82:

79:

76:

73:

70:

69:

68:

63:

58:

51:

49:

47:

43:

39:

35:

31:

23:

18:

457:Fluidization

375:. Retrieved

366:

354:. Retrieved

344:

332:. Retrieved

322:

310:. Retrieved

301:

289:. Retrieved

280:

171:

155:

119:

115:

111:

100:How it works

66:

33:

29:

27:

168:emissions.

124:), water (H

46:exhaust gas

411:Categories

377:7 November

356:7 November

334:7 November

312:7 November

291:7 November

272:References

197:Automotive

152:emissions.

78:Desorption

72:Adsorption

62:SolidWorks

52:Components

202:Aerospace

240:See also

219:Printing

93:adsorber

173:Alabama

352:. Ford

164:and NO

148:and NO

80:tower

74:tower

379:2014

358:2014

336:2014

314:2014

293:2014

34:FBC

413::

28:A

381:.

360:.

338:.

316:.

295:.

166:X

162:2

150:x

146:2

130:X

126:2

122:2

32:(

24:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.