99:. More recently, foam concrete is being made with a continuous foam generator. The foam is produced by agitating a foaming agent with compressed air to make "aircrete" or "foamcrete". This material is fireproof, insect proof, and waterproof. It offers significant thermal and acoustic insulation and can be cut, carved, drilled and shaped with wood-working tools. This construction material can be used to make foundations, subfloors, building blocks, walls, domes, or even arches that can be reinforced with a construction fabric.

19:

245:

that is just 7.5% of water. The enzyme consists of highly active proteins of biotechnological origin not based on protein hydrolysis. In recent years foamed concrete has been used extensively in highways, commercial buildings, disaster rehabilitation buildings, schools, apartments and housing developments in countries such as

Germany, USA, Brazil, Singapore, India, Malaysia, Kuwait, Nigeria, Bangladesh, Botswana, Mexico, Indonesia, Libya, Saudi Arabia, Algeria, Iraq, Egypt, and Vietnam.

148:

75:

1194:

160:

1,600 kg/m depending on the application. Lighter density products may be cut into different sizes. While the product is considered a form of concrete (with air bubbles replacing aggregate), its high thermal and acoustical insulating qualities make it a very different application than conventional concrete.

94:

were developed in the late 1970s and early 80s, which led to the commercial use of foamed concrete in construction projects. Initially, it was used in the

Netherlands for filling voids and for ground stabilisation. Further research carried out in the Netherlands helped bring about the more widespread

181:

Foamed concrete can be produced with dry densities of 400 to 1600 kg/m (25 lb/ft to 100 lb/ft), with 7-day strengths of approximately 1 to 10 N/mm (145 to 1450 psi) respectively. Foam concrete is fire resistant, and its thermal and acoustical insulation properties make it ideal for a wide range

244:

The development of synthetic-enzyme based foaming agents; foam stability enhancing admixtures; and specialized foam generating, mixing, and pumping equipment has improved the stability of the foam and hence foam concrete, making it possible to manufacture as light as 75 kg/m density, a density

138:

cured with temperatures up to 70 °C to accelerate the process.), depending on variables including ambient temperature and humidity. Once solidified, the formed product may be released from its mold. A new application in foam concrete manufacturing is to cut large concrete cakes into blocks of

240:

Until the mid-1990s, foam concrete was regarded as weak and non-durable with high shrinkage characteristics. This is due to the unstable foam bubbles resulted in foam concrete having properties unsuitable for producing very low density (Less than 300 kg/m dry density) as well as load bearing

159:

with a simple production method that is relatively inexpensive compared to autoclave aerated concrete. Foam concrete compounds utilising fly ash in the slurry mix is cheaper still, and has less environmental impact. Foam concrete is produced in a variety of densities from 200 kg/m to

241:

structural applications. It is therefore important to ensure that the air entrained into the foamed concrete is contained in stable, very tiny, uniform bubbles that remain intact and isolated, and do not thus increase the permeability of the cement paste between the voids.

269:

The energy absorption capacity of foamed concrete was approximated from drop testing and found to vary from 4 to 15 MJ/m depending on its density. With optimum absorption estimated from a 1000 kg/m moderate density mix at water to cement (w/c) ratios from 0·6 to 0·7.

57:

instead of concrete; it may be called "foamed cement" as well. The density of foam concrete usually varies from 400 kg/m to 1600 kg/m. The density is normally controlled by substituting all or part of the fine aggregate with the foam.

261:

being fielded by the U.S. Army Corps of

Engineers, which when worn out, can be shipped directly to metal recycling facilities without requiring the separation of the trapped bullets, as the calcium carbonate in the concrete acts as a

111:

and sand and water, although some suppliers recommend pure cement and water with the foaming agent for very lightweight mixes. This slurry is further mixed with a synthetic aerated

134:

behavior of the foam bubbles, allowing it to be easily poured into the chosen form or mold. The viscous material requires up to 24 hours to solidify (or as little as two hours if

90:. A detailed study concerning the composition, physical properties and production of foamed concrete was first carried out in the 1950s and 60s. Following this research, new

1132:

305:

Sach J and

Seifert H (1999). Foamed concrete technology: possibilities for thermal insulation at high temperatures. CFI Forum of Technology, DKG 76, No. 9, pp 23–30.

123:, mixed with water and air from a generator. The foaming agent must be able to produce air bubbles with a high level of stability, resistant to the physical and

293:

130:

Foamed concrete mixture may be poured or pumped into molds, or directly into structural elements. The foam enables the slurry to flow freely due to the

870:

580:

1021:

695:

66:

It is also called foamed concrete, foam concrete, aerated concrete, aircrete, cellular lightweight concrete, or reduced density concrete.

1112:

139:

different sizes by a cutting machine using special steel wires. The cutting action takes place before the concrete has fully cured.

880:

500:

497:

Proceedings of the Tri-Service

Environmental Technology Workshop, "Enhancing Readiness Through Environmental QualityTechnology"

610:

489:

Use of Shock-Absorbing

Concrete (SACON) as an Environmentally Compatible Bullet-Trapping Medium on Small-Arms Training Ranges

653:

573:

182:

of purposes, from insulating floors and roofs to void filling. It is also particularly useful for trench reinstatement.

169:

In terms of thermal conductivity, foam concrete is not inferior to wood. A 40 cm wall is able to withstand -30°C frost.

1127:

1102:

1016:

983:

83:

895:

1081:

605:

87:

1117:

978:

918:

733:

648:

566:

517:

461:

890:

675:

988:

865:

789:

680:

398:

British Cement

Association, Foamed Concrete Composition and Properties, British Cement Association, 1994.

172:

Foam concrete withstands one-sided exposure to fire for at least three hours, and on average, five hours.

1071:

814:

116:

1107:

1008:

1003:

963:

875:

738:

91:

29:, also known as Lightweight Cellular Concrete (LCC) and Low Density Cellular Concrete (LDCC), and by

314:

Valore RC. (1954). Cellular concrete part 1 composition and methods of production, ACI j ;50:773-96.

1086:

1054:

973:

743:

685:

18:

532:

1059:

968:

885:

473:

1218:

1197:

1153:

953:

948:

923:

905:

819:

799:

635:

620:

323:

Valore RC. (1954). Cellular RC, Cellular concrete part 2 physical properties. ACI J;50:817-36.

263:

156:

147:

96:

1223:

1049:

958:

824:

784:

663:

625:

544:

54:

50:

46:

993:

844:

748:

658:

257:

in high intensity US military firearm training ranges. This work resulted in the product

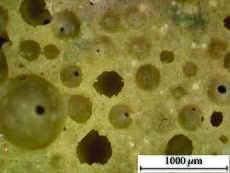

74:

1066:

998:

839:

758:

728:

723:

615:

487:

1212:

1039:

938:

834:

120:

1076:

943:

829:

804:

82:

The history of foam concrete dates back to the early 1920s and the production of

1044:

763:

700:

254:

131:

486:

Fabian, Gene L.; O'Donnell, Richard H.; Tom, Joe G.; Malone, Philip G. (1996).

421:"Aerated Concrete, Lightweight Concrete, Cellular Concrete and Foamed Concrete"

370:"Aerated Concrete, Lightweight Concrete, Cellular Concrete and Foamed Concrete"

1148:

933:

913:

705:

447:

1179:

548:

1163:

1158:

794:

753:

715:

597:

589:

420:

351:

124:

53:

is used for production of foam concrete the correct term would be called

1122:

690:

108:

849:

809:

643:

211:

38:

34:

369:

768:

670:

407:

146:

135:

73:

17:

533:"Energy absorption of foamed concrete from low-velocity impacts"

457:

455:

410:

Luca

Industries International GmbH, Retrieved on 22 January 2015

112:

42:

562:

341:

Van Deijk. Foam concrete. Concrete, July/August 1991, pp 49–54.

332:

Rudnai G. (1963). Lightweight concretes. Budapest, Akademikiado

78:

The 1930s-era Smithy bridge used foamed concrete for infilling.

476:

Luca

Industries International GmbH, Retrieved on 29 March 2016

464:

Luca

Industries International GmbH, Retrieved on 29 March 2016

107:

Foamed concrete typically consists of a slurry of cement or

558:

289:

287:

285:

283:

1172:

1141:

1095:

1032:

904:

858:

777:

714:

634:

596:

253:Foamed concrete has been investigated for use as a

448:8 ADVANTAGES OF FOAM CONCRETE OVER OTHER MATERIALS

531:Jones, M. Roderick; Zheng, Li (1 February 2013).

151:A sample of foamed concrete used for measurement.

1133:International Federation for Structural Concrete

185:A few of the applications of foam concrete are:

574:

127:processes of mixing, placing, and hardening.

8:

518:"Shock-Absorbing Concrete SACON Bullet Trap"

551:– via icevirtuallibrary.com (Atypon).

443:

441:

581:

567:

559:

462:LithoPore™ Aerated Concrete 75 – 150 Kg/m

279:

394:

392:

390:

296:The Concrete Institute, Midrand, 2021

41:, with a minimum of 20% (per volume)

7:

696:Ground granulated blast-furnace slag

506:from the original on 20 August 2015.

1113:Institution of Structural Engineers

192:pipeline abandonment / annular fill

204:cast-in-situ / cast-in-place walls

14:

1193:

1192:

30:

499:. pp. 187–196. ADP017714.

231:prefabricated insulation boards

189:bridge approaches / embankments

611:Roman architectural revolution

207:insulating compensation laying

201:precast wall elements / panels

119:. The foam is created using a

1:

537:Magazine of Concrete Research

155:Foam concrete is a versatile

22:A cylinder of foam concrete.

1128:Portland Cement Association

1103:American Concrete Institute

86:, which was used mainly as

84:autoclaved aerated concrete

45:entrained into the plastic

1240:

606:Ancient Roman architecture

474:LithoPore™ True Technology

408:LithoPore Aerated Concrete

95:use of foam concrete as a

1188:

1118:Indian Concrete Institute

228:filling of hollow blocks

294:Foamed Concrete leaflet

216:insulation roof screeds

896:Alkali–silica reaction

654:Energetically modified

236:Trends and development

219:sunken portion filling

152:

79:

23:

549:10.1680/macr.12.00054

520:. Terran Corporation.

150:

117:concrete mixing plant

77:

21:

881:Environmental impact

739:Reversing drum mixer

225:sub-base in highways

222:trench reinstatement

984:Self-consolidating

676:Water–cement ratio

153:

80:

33:, is defined as a

24:

1206:

1205:

1198:Category:Concrete

979:Roller-compacting

800:Climbing formwork

649:Calcium aluminate

621:Roman engineering

210:insulation floor

157:building material

97:building material

1231:

1196:

1195:

1108:Concrete Society

919:Fiber-reinforced

734:Volumetric mixer

626:Roman technology

583:

576:

569:

560:

553:

552:

528:

522:

521:

514:

508:

507:

505:

494:

483:

477:

471:

465:

459:

450:

445:

436:

435:

433:

431:

417:

411:

405:

399:

396:

385:

384:

382:

380:

366:

360:

359:

348:

342:

339:

333:

330:

324:

321:

315:

312:

306:

303:

297:

291:

249:Shock-absorption

51:coarse aggregate

1239:

1238:

1234:

1233:

1232:

1230:

1229:

1228:

1209:

1208:

1207:

1202:

1184:

1168:

1137:

1091:

1028:

900:

854:

773:

749:Flow table test

710:

630:

592:

587:

557:

556:

530:

529:

525:

516:

515:

511:

503:

492:

485:

484:

480:

472:

468:

460:

453:

446:

439:

429:

427:

419:

418:

414:

406:

402:

397:

388:

378:

376:

368:

367:

363:

350:

349:

345:

340:

336:

331:

327:

322:

318:

313:

309:

304:

300:

292:

281:

276:

251:

238:

195:trench backfill

179:

166:

145:

105:

72:

64:

49:. As mostly no

12:

11:

5:

1237:

1235:

1227:

1226:

1221:

1211:

1210:

1204:

1203:

1201:

1200:

1189:

1186:

1185:

1183:

1182:

1176:

1174:

1170:

1169:

1167:

1166:

1161:

1156:

1151:

1145:

1143:

1139:

1138:

1136:

1135:

1130:

1125:

1120:

1115:

1110:

1105:

1099:

1097:

1093:

1092:

1090:

1089:

1084:

1079:

1074:

1069:

1067:Concrete block

1064:

1063:

1062:

1057:

1055:voided biaxial

1052:

1047:

1036:

1034:

1030:

1029:

1027:

1026:

1025:

1024:

1019:

1011:

1006:

1001:

996:

991:

986:

981:

976:

971:

966:

961:

956:

951:

946:

941:

936:

931:

926:

921:

916:

910:

908:

902:

901:

899:

898:

893:

888:

883:

878:

873:

868:

862:

860:

856:

855:

853:

852:

847:

842:

837:

832:

827:

822:

817:

812:

807:

802:

797:

792:

787:

781:

779:

775:

774:

772:

771:

766:

761:

759:Concrete cover

756:

751:

746:

741:

736:

731:

729:Concrete mixer

726:

720:

718:

712:

711:

709:

708:

703:

698:

693:

688:

683:

678:

673:

668:

667:

666:

661:

656:

651:

640:

638:

632:

631:

629:

628:

623:

618:

616:Roman concrete

613:

608:

602:

600:

594:

593:

588:

586:

585:

578:

571:

563:

555:

554:

543:(4): 209–219.

523:

509:

478:

466:

451:

437:

412:

400:

386:

361:

343:

334:

325:

316:

307:

298:

278:

277:

275:

272:

250:

247:

237:

234:

233:

232:

229:

226:

223:

220:

217:

214:

208:

205:

202:

199:

198:precast blocks

196:

193:

190:

178:

175:

174:

173:

170:

165:

162:

144:

141:

104:

101:

71:

68:

63:

60:

13:

10:

9:

6:

4:

3:

2:

1236:

1225:

1222:

1220:

1217:

1216:

1214:

1199:

1191:

1190:

1187:

1181:

1178:

1177:

1175:

1171:

1165:

1162:

1160:

1157:

1155:

1152:

1150:

1147:

1146:

1144:

1140:

1134:

1131:

1129:

1126:

1124:

1121:

1119:

1116:

1114:

1111:

1109:

1106:

1104:

1101:

1100:

1098:

1096:Organizations

1094:

1088:

1085:

1083:

1080:

1078:

1075:

1073:

1070:

1068:

1065:

1061:

1060:slab on grade

1058:

1056:

1053:

1051:

1048:

1046:

1043:

1042:

1041:

1038:

1037:

1035:

1031:

1023:

1020:

1018:

1015:

1014:

1012:

1010:

1007:

1005:

1002:

1000:

997:

995:

992:

990:

989:Self-leveling

987:

985:

982:

980:

977:

975:

972:

970:

967:

965:

962:

960:

957:

955:

952:

950:

947:

945:

942:

940:

937:

935:

932:

930:

927:

925:

922:

920:

917:

915:

912:

911:

909:

907:

903:

897:

894:

892:

889:

887:

884:

882:

879:

877:

874:

872:

869:

867:

864:

863:

861:

857:

851:

848:

846:

843:

841:

838:

836:

833:

831:

828:

826:

823:

821:

818:

816:

813:

811:

808:

806:

803:

801:

798:

796:

793:

791:

790:Cast-in-place

788:

786:

783:

782:

780:

776:

770:

767:

765:

762:

760:

757:

755:

752:

750:

747:

745:

742:

740:

737:

735:

732:

730:

727:

725:

722:

721:

719:

717:

713:

707:

704:

702:

699:

697:

694:

692:

689:

687:

686:Reinforcement

684:

682:

679:

677:

674:

672:

669:

665:

662:

660:

657:

655:

652:

650:

647:

646:

645:

642:

641:

639:

637:

633:

627:

624:

622:

619:

617:

614:

612:

609:

607:

604:

603:

601:

599:

595:

591:

584:

579:

577:

572:

570:

565:

564:

561:

550:

546:

542:

538:

534:

527:

524:

519:

513:

510:

502:

498:

491:

490:

482:

479:

475:

470:

467:

463:

458:

456:

452:

449:

444:

442:

438:

426:

425:litebuilt.com

422:

416:

413:

409:

404:

401:

395:

393:

391:

387:

375:

374:litebuilt.com

371:

365:

362:

357:

353:

347:

344:

338:

335:

329:

326:

320:

317:

311:

308:

302:

299:

295:

290:

288:

286:

284:

280:

273:

271:

267:

265:

260:

256:

248:

246:

242:

235:

230:

227:

224:

221:

218:

215:

213:

209:

206:

203:

200:

197:

194:

191:

188:

187:

186:

183:

176:

171:

168:

167:

163:

161:

158:

149:

142:

140:

137:

133:

128:

126:

122:

121:foaming agent

118:

114:

110:

103:Manufacturing

102:

100:

98:

93:

89:

85:

76:

69:

67:

61:

59:

56:

52:

48:

44:

40:

36:

32:

28:

27:Foam concrete

20:

16:

1072:Step barrier

1033:Applications

944:Nanoconcrete

928:

830:Power trowel

815:Power screed

805:Slip forming

778:Construction

540:

536:

526:

512:

496:

488:

481:

469:

430:12 September

428:. Retrieved

424:

415:

403:

379:12 September

377:. Retrieved

373:

364:

356:Domegaia.com

355:

346:

337:

328:

319:

310:

301:

268:

258:

252:

243:

239:

184:

180:

177:Applications

154:

129:

106:

81:

65:

26:

25:

15:

1050:hollow-core

1009:Waste light

1004:Translucent

964:Prestressed

891:Segregation

876:Degradation

764:Cover meter

701:Silica fume

636:Composition

255:bullet trap

132:thixotropic

62:Terminology

31:other names

1213:Categories

1149:Eurocode 2

1087:Structures

974:Reinforced

934:Lunarcrete

914:AstroCrete

871:Durability

866:Properties

744:Slump test

716:Production

706:Metakaolin

352:"AirCrete"

274:References

164:Advantages

143:Properties

92:admixtures

88:insulation

1180:Hempcrete

1142:Standards

969:Ready-mix

886:Recycling

681:Aggregate

664:Rosendale

1219:Concrete

1173:See also

1164:EN 10080

1159:EN 206-1

1154:EN 197-1

1013:Aerated

954:Polished

949:Pervious

924:Filigree

820:Finisher

795:Formwork

659:Portland

590:Concrete

501:Archived

125:chemical

1224:Masonry

1123:Nanocem

1082:Columns

959:Polymer

859:Science

825:Grinder

785:Precast

691:Fly ash

598:History

212:screeds

109:fly ash

70:History

37:-based

1045:waffle

994:Sulfur

850:Tremie

845:Sealer

810:Screed

754:Curing

644:Cement

55:mortar

47:mortar

39:slurry

35:cement

1077:Roads

999:Tabby

906:Types

840:Float

769:Rebar

724:Plant

671:Water

504:(PDF)

493:(PDF)

259:SACON

136:steam

115:in a

1040:Slab

1022:RAAC

939:Mass

929:Foam

835:Pump

432:2015

381:2015

264:flux

113:foam

43:foam

1017:AAC

545:doi

1215::

541:65

539:.

535:.

495:.

454:^

440:^

423:.

389:^

372:.

354:.

282:^

266:.

582:e

575:t

568:v

547::

434:.

383:.

358:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.