205:

next ten years this amounted to the amount of nearly £58 000 on seemingly little security beyond the value of the business. It was the accepted practice for clerks in the Pay Office to temporarily use surplus funds for their own benefit. As part of the arrangement, Jellicoe's son Samuel became a partner in the

Fontley Works. The deal was later to have unfortunate repercussions for Cort.

214:

33:

305:

per ton. However, there were a series of production problems and the death of Adam

Jellicoe in 1789 precipitated legal actions by the Crown to recover the money lent by Adam Jellicoe to Cort. As a result of which, Cort was declared bankrupt and although he soon rectified his financial status he never

221:

Cort developed his ideas at the

Fontley Works (as he had renamed Titchfield Hammer) resulting in a 1783 patent for a simple reverberatory furnace to refine pig iron followed by a 1784 patent for his puddling furnace, with grooved rollers which mechanised the formerly laborious process. His work built

253:

hammer, after which it was rolled in the rolling mill. The original process of Cort was ineffectual until significant alterations were made by

Richard Crawshay and other Merthyr Tydfil ironmasters as Cort used iron from charcoal furnaces rather than the coke smelted pig iron in general production by

262:

When Adam

Jellicoe died suddenly on 30 August 1789, it became apparent that the £58 000 lent to Cort could not be repaid. As a result, the Crown seized all the Property of Adam Jellicoe as well as that of the partnership of Cort and Samuel Jellicoe. Cort was held responsible for Jellicoe's debt and

204:

at an existing iron mill in

Titchfield which was later used for the production of bar iron. Short of funds, he turned to Adam Jellicoe, at that time chief clerk in the Pay Office of the Royal Navy, who agreed to loan Cort funds to develop a new method of converting cast iron to bar iron, over the

314:

Cort's marriage to

Elizabeth Heysham produced 13 children. His business ventures did not bring him wealth, even though vast numbers of the puddling furnaces that he developed were eventually used (reportedly 8,200 by 1820), they used a modified version of his process and thus avoided payment of

395:

Evans, C., Jackson, O., and Ryden, G. ‘Baltic iron and the

British iron industry in the eighteenth century’. Econ. Hist. Rev. (2nd ser.), 55, 642–665. 2002: King, P. ‘The production and consumption of bar iron in early modern England and Wales’ Econ. Hist. Rev. (2nd ser.), 58, 1-33.

155:

but living in

Jamaica at the time of his (possible) father; another Henry Cort although his parents are not definitely known. Although his date of birth is traditionally given as 1740, this can not be confirmed and his early life remains an enigma. By 1765, Cort had become a

187:

whose estates included

Titchfield. Her uncle William Attwick, although a successful London attorney, had inherited the family ironmongery business in Gosport which supplied the navy with mooring chains, anchors and hundreds of different items of ironmongery.

629:

249:

while the "puddler" extracted a mass of iron from the furnace using an iron "rabbling bar". The extracted ball of metal was then processed into a "shingle" by a

675:

160:

pay agent, acting on commission collecting half pay and widows' pensions from an office in Crutched Friars near Aldgate in London. At that time, despite

670:

272:

419:

200:

reached an agreement with Cort, who had taken over Attwick's business, to convert scrap iron hoops for their barrels. He had recently taken over a

665:

552:

573:

480:

131:, for refining cast iron, although its commercial viability was only realised in the 1790s, through further innovations introduced by

358:

623:

680:

660:

271:

The importance of Cort's improvements to the process of bar purported iron making were recognised as early as 1786 by

617:

263:

declared bankrupt. The Crown later gave back to Samuel Jellicoe possession of the works at Titchfield and Gosport

315:

royalties. He was later awarded a government pension, but died a ruined man, and was buried in the churchyard of

238:' puddling process where iron is stirred to separate out impurities and extract the higher quality wrought iron.

197:

183:

In 1768, Cort's second marriage was to Elizabeth Heysham, the daughter of a Romsey solicitor and steward of the

176:

fuel, the resultant product was still only convertible to bar iron by a laborious process of decarburization in

151:

Little is known of Cort's early life other than that he was possibly born into a family coming originally from

504:

302:

123:(or bar iron) using innovative production systems. In 1784, he obtained a patent for an improved version of

250:

201:

91:

650:

423:

227:

152:

128:

112:

87:

111:(c. 1740 – 23 May 1800) was an English ironware producer who was formerly a Navy pay agent. During the

655:

316:

284:

136:

456:

444:

405:

337:

569:

563:

548:

529:

476:

470:

363:

294:

223:

184:

132:

161:

140:

637:- extensive research carried out by Eric Alexander on the life of the British inventor

644:

533:

231:

180:. As a result, bar iron imported from the Baltic undercut that produced in Britain.

173:

280:

235:

177:

124:

120:

382:

297:

whereby all iron manufactured according to the former's patents would result in a

288:

165:

213:

545:

The most powerful idea in the world: a story of steam, industry, and invention

367:

291:

276:

157:

352:

605:

The Case of Henry Cort and his Inventions in the Manufacture of British Iron

298:

246:

242:

505:

https://issuu.com/jeremygreenwood6/docs/the_early_life_and_times_of_henry_c

169:

116:

32:

230:(where heat is applied from above, rather than through the use of

212:

634:

457:

https://salthistory.yolasite.com/early-life-of-henry-cort.php

445:

https://salthistory.yolasite.com/early-life-of-henry-cort.php

406:

https://salthistory.yolasite.com/early-life-of-henry-cort.php

338:

https://salthistory.yolasite.com/early-life-of-henry-cort.php

241:

The puddling furnace lowered the carbon content of the

475:. Books for Libraries; Reprint edition. p. 110.

98:

82:

74:

66:

58:

42:

23:

568:. Europ Ischer Hochschulverlag Gmbh & Co. Kg.

565:Industrial Biography: Iron Workers and Tool Makers

351:

459:The early life and times of Henry Cort.

447:The early life and times of Henry Cort

408:The early life and times of Henry Cort

340:The early life and times of Henry Cort

589:Dickinson, H. W. Henry Cort's Bicentenary, in

164:'s improvements in the smelting of iron using

8:

362:(online ed.). Oxford University Press.

287:. In 1787, Cort came to an agreement with

115:in England, Cort began refining iron from

20:

593:, Transactions 1940–41, volume XXI, 1943.

422:. Fareham Borough Council. Archived from

306:again engaged in industrial activities.

630:The Gosport Iron Foundry and Henry Cort

359:Oxford Dictionary of National Biography

330:

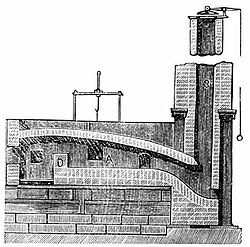

217:Schematic drawing of a puddling furnace

507:Henry Cort ; a revised biography

78:Inventor, pioneer in the iron industry

538:. London: Simpkin Marshall, & Co.

7:

635:Henry Cort, Father of the Iron Trade

676:People of the Industrial Revolution

600:, The Metals Society, London 1983)

14:

671:People from Lancaster, Lancashire

209:Rolling mill and puddling furnace

192:Partnership with Samuel Jellicoe

31:

16:English ironmaster (c.1740-1800)

469:Matschoss, Conrad (June 1970).

234:from below) and (particularly)

666:18th-century British inventors

1:

596:Mott, R. A. (ed. P. Singer),

275:who regarded them along with

222:on the existing ideas of the

383:UK public library membership

607:, Mechanics' Magazine, 1859

598:Henry Cort: the Great Finer

283:as more important than the

94:in the manufacture of iron.

697:

547:. New York: Random House.

353:"Cort, Henry (1741?–1800)"

196:In 1780, the Royal Navy's

626:– another brief biography

198:Victualling Commissioners

30:

495:Espinasse (1877), p. 233

562:Smiles, Samuel (2010).

543:Rosen, William (2010).

516:Espinasse (1877), p.225

420:"History of Henry Cort"

86:Inventions relating to

258:Death of Adam Jellicoe

218:

681:British metallurgists

368:10.1093/ref:odnb/6359

350:Evans, Chris (2006).

267:Patents and royalties

228:reverberatory furnace

216:

113:Industrial Revolution

591:The Newcomen Society

317:St John-at-Hampstead

661:British ironmasters

535:Lancashire Worthies

137:Cyfarthfa Ironworks

135:and Homfray of the

530:Espinasse, Francis

219:

62:Friday 23 May 1800

620:– brief biography

554:978-0-679-60361-0

381:(Subscription or

106:

105:

688:

603:Webster, Thomas

579:

558:

539:

517:

514:

508:

502:

496:

493:

487:

486:

466:

460:

454:

448:

442:

436:

435:

433:

431:

426:on 19 March 2012

415:

409:

403:

397:

393:

387:

386:

378:

376:

374:

355:

347:

341:

335:

295:Richard Crawshay

224:Cranege brothers

185:Duke of Portland

133:Richard Crawshay

129:puddling process

35:

21:

696:

695:

691:

690:

689:

687:

686:

685:

641:

640:

614:

586:

584:Further reading

576:

561:

555:

542:

528:

525:

520:

515:

511:

503:

499:

494:

490:

483:

472:Great Engineers

468:

467:

463:

455:

451:

443:

439:

429:

427:

417:

416:

412:

404:

400:

394:

390:

380:

372:

370:

349:

348:

344:

336:

332:

328:

322:

312:

285:loss of America

279:'s work on the

269:

260:

245:charge through

211:

194:

149:

54:

51:

49:

48:

38:

26:

17:

12:

11:

5:

694:

692:

684:

683:

678:

673:

668:

663:

658:

653:

643:

642:

639:

638:

632:

627:

621:

613:

612:External links

610:

609:

608:

601:

594:

585:

582:

581:

580:

575:978-3867414654

574:

559:

553:

540:

524:

521:

519:

518:

509:

497:

488:

482:978-0836918373

481:

461:

449:

437:

410:

398:

388:

342:

329:

327:

324:

311:

308:

273:Lord Sheffield

268:

265:

259:

256:

210:

207:

193:

190:

148:

145:

141:Merthyr Tydfil

104:

103:

100:

96:

95:

84:

83:Known for

80:

79:

76:

72:

71:

68:

64:

63:

60:

56:

55:

52:

46:

44:

40:

39:

36:

28:

27:

24:

15:

13:

10:

9:

6:

4:

3:

2:

693:

682:

679:

677:

674:

672:

669:

667:

664:

662:

659:

657:

654:

652:

649:

648:

646:

636:

633:

631:

628:

625:

622:

619:

616:

615:

611:

606:

602:

599:

595:

592:

588:

587:

583:

577:

571:

567:

566:

560:

556:

550:

546:

541:

537:

536:

531:

527:

526:

522:

513:

510:

506:

501:

498:

492:

489:

484:

478:

474:

473:

465:

462:

458:

453:

450:

446:

441:

438:

425:

421:

414:

411:

407:

402:

399:

392:

389:

384:

369:

365:

361:

360:

354:

346:

343:

339:

334:

331:

325:

323:

320:

318:

310:Personal life

309:

307:

304:

300:

296:

293:

290:

286:

282:

278:

274:

266:

264:

257:

255:

252:

248:

244:

239:

237:

233:

229:

225:

215:

208:

206:

203:

199:

191:

189:

186:

181:

179:

178:finery forges

175:

174:blast furnace

171:

167:

163:

162:Abraham Darby

159:

154:

146:

144:

142:

138:

134:

130:

126:

122:

118:

114:

110:

101:

97:

93:

89:

85:

81:

77:

75:Occupation(s)

73:

69:

65:

61:

57:

45:

41:

34:

29:

22:

19:

651:1740s births

604:

597:

590:

564:

544:

534:

512:

500:

491:

471:

464:

452:

440:

428:. Retrieved

424:the original

413:

401:

391:

371:. Retrieved

357:

345:

333:

321:

313:

281:steam engine

270:

261:

240:

236:Peter Onions

220:

202:rolling mill

195:

182:

150:

125:Peter Onions

121:wrought iron

108:

107:

102:Richard Cort

18:

656:1800 deaths

418:Pam Moore.

301:of 10

289:South Wales

168:instead of

67:Nationality

645:Categories

624:Henry Cort

618:Henry Cort

523:References

385:required.)

319:, London.

292:ironmaster

277:James Watt

232:forced air

226:and their

158:Royal Navy

109:Henry Cort

50:Circa 1740

47:Henry Cort

37:Henry Cort

25:Henry Cort

303:shillings

251:shingling

247:oxidation

243:cast iron

153:Lancaster

147:Biography

532:(1877).

373:5 August

170:charcoal

117:pig iron

99:Children

88:puddling

299:royalty

92:rolling

70:English

53:Unknown

572:

551:

479:

430:6 June

379:

254:then.

396:2005:

326:Notes

570:ISBN

549:ISBN

477:ISBN

432:2012

375:2010

166:coke

90:and

59:Died

43:Born

364:doi

172:as

139:in

127:'s

119:to

647::

356:.

143:.

578:.

557:.

485:.

434:.

377:.

366::

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.