980:—railwaymen usually call their track a road. Initially, Brunel had the track tied down to timber piles to prevent lateral movement and bounce, but he had overlooked the fact that the made ground, on which his track was supported between piles, would settle. The piles remained stable and the ground between them settled so that his track soon had an unpleasant undulation, and he had to have the piles severed, so that the track could settle more or less uniformly. A variant of the baulk road can still be seen today on many older under-bridges where no ballast was provided. The design varies considerably, but in many cases longitudinal timbers are supported directly on the cross-girders, with transoms and tiebars to retain the gauge, but of course with modern rails and base-plates or chairs. The longitudinal sleepers are somewhat similar to modern-day

1095:

became inadequate. Consequently, on main lines, the rails in use were made progressively heavier (and stronger). Metallurgical processes improved and better rails, including some of steel, came into use. From a maintenance point of view, the rail joints were the source of most of the work, and as steel-making techniques improved it became possible to roll steel rails of increased length—reducing the number of joints per mile. The standard length became 30 ft (9,144 mm), then 45 ft (13,720 mm) and finally 60 ft (18,290 mm) rails became the norm. For main line use, the standard rail section became the 95BH section, weighing 95 lb/yd (47 kg/m). For secondary routes, a lighter 85BH, 85 lb/yd (42 kg/m), section was used.

1080:

1500:

actual installation work tends to be done at cooler temperatures. Originally the rails were physically heated to the stress-free temperature with propane gas heaters; they were then rattled with hand bars to eliminate any binding, preventing even expansion, and then clipped down. Since about 1963 however hydraulic jacks are used to physically stretch the rails while they are supported on temporary rollers. By stretching the rails to the length they would be if they were at the stress-free temperature, then there is no need to heat them; they can just be clipped down before the jacks are released.

1168:, resting on rubber pads to resist rail creep. In this pioneering stage, some catastrophic mistakes in detailed design were made, but from about 1968 continuous welded rail became a reliable standard for universal installation on main and secondary routes. The form adopted used pre-stressed concrete sleepers and a 110A rail section—a slight improvement on the 109 rails previously used—the A was to distinguish it from the British Standard 110 lb/yd (55 kg/m) rail section, which was unsuitable. Rail fastenings eventually converged onto a proprietary spring clip made by the

1107:, measuring 8 ft 6 in (2.59 m) long by 10 in (250 mm) by 5 in (130 mm). Chairs were secured to the sleepers by trenails (steel spikes driven through a timber sleeve) or three chair-screws on first class routes. The GWR alone among the main line railways kept to its own standard, the 00 rail at 97.5 lb/yd (48.4 kg/m), and with two fangbolts securing each chair to the sleeper, with the head of the bolt under the sleeper and a nut above the chair—more secure but much more difficult to adjust.

1496:

limited lengths only because of technological limitations. However at the end of the CWR section where it abutted older, ordinary jointed track, that track would be unable to resist the expansive force and the jointed track might be forced to buckle. To prevent that, special expansion switches, sometimes called breathers, were installed. The expansion switches could accommodate a considerable expansive movement—typically 4 in (100 mm) or so—in the end section of the CWR without passing the movement on to the jointed track.

75:

288:(or strap rail) and was widely used on pre-steam railways in the United States. Although relatively cheap and quick to build, they were unsuited to heavy loads and required 'excessive maintenance'. Train wheels rolling over the spikes loosened them, allowing the rail to break free and curve upwards sufficiently that a car wheel could get beneath it and force the end of the rail up through the floor of the car, writhing and twisting, endangering passengers. These broken rails became known as "snake heads".

1151:

stiffness of flat-bottom was an advantage, but it tended to straighten out between the joints on curves; and flat bottom’s rigidity led to high vertical impact forces at badly maintained joints and this resulted in high volumes of fatigue fractures at the joints. Moreover, the elastic rail fastenings had little resistance to rail creep—the propensity of the rails to move gradually in the direction of traffic, and the workload of pulling back the rails to regulate the joints was surprisingly high.

949: in (1.435 m) gauge had been fine for small mineral trucks on a horse-drawn tramway, but he wanted something more stable for his high speed railway. The large diameter wheels used in stage coaches gave better ride quality over rough ground, and Brunel originally intended to have his passenger carriages carried in the same way—on large diameter wheels placed outside the bodies of the carriages. To achieve this he needed a wider track gauge and he settled on the famous 7 feet (2.1 m)

633:

67:

309:

1367:

than 20 mph (32 km/h) except in very special designs, and great ingenuity was employed to give a good ride to vehicles passing through at speed on the main line. A difficulty was the common crossing where continuous support to wheels passing was difficult, and the point rail was planed to protect it from direct impact in the facing direction, so that a designed irregularity in support was introduced.

301:

548:. This was strong enough to bear the weight of a locomotive and of a train of wagons (or carriages) pulled by it. This marks the beginning of the modern rail era. This system was instantly successful, although some false starts took place. Some early rails were made in a T cross section, but the lack of metal at the foot limited the bending strength of the rail, which has to act as a beam between supports.

906:) gauge he used was therefore the most widespread. As early notions of linking up different railway systems evolved, this gauge secured general adoption. It is more or less an accident of history that this gauge—which suited the wagons already in use at the colliery where George Stephenson had been an engine man—became the British standard gauge: it was exported to most of Europe and North America.

32:

1442:

1389:

1291:

1022:

802:

646:

476:

624:. A boom in rail production followed, but a banking crisis in America slowed the rate at which railways were built there and orders to British rail producers. The British iron and steel industry went into a recession, which particularly affected the wrought iron sector. When demand for rails began to grow again, it was largely for steel rails, which were more durable than those of iron.

1352:

1249: in (1,432 mm). In practice this change caused more problems than it cured and it was returned on renewals to 1435 mm with effect from 1996. The gauge is set by the positioning of the cast-in fixings, so it is not a simple task to re-gauge existing track; it also creates problems with spot replacement of sleepers. Many sleepers were made with the reduced track gauge but

1231:). In the later 1950s, general track maintenance standards deteriorated rapidly due to labour shortages and, on some routes, faster freight train speeds. Freight trains consisted almost entirely of short wheelbase (10 ft or 3.0 m) four-wheeled wagons carried on a very stiff elliptical leaf spring suspension, and these wagons showed a rapid rate of increase in derailments.

726:

forged chairs riveted direct. However steel sleepers seem not to have enjoyed widespread adoption until about 1995. Their dominant usage now is for life extension of existing track on secondary routes. They have a significant advantage on weak formations and poor ballast conditions, as the bearing area is at a high level, immediately under the rail seat.

913:, and these are often asserted to be about the same as Stephenson's gauge. Of course the ruts were made by the wheels of carts, and the carts were of a sensible size for horse-drawn carts prior to the industrial era, pretty much the same as the size of the pre-railway carts at the colliery where Stephenson worked: that is the only connection.

967: in or 2.140 m). When the time came to build the passenger carriages, they were designed conventionally with smaller wheels under the bodies after all, but with a seven-foot track gauge the bodies could be much wider than on the standard gauge. His original intention to have the wheels outside the width of the bodies was abandoned.

560:

tie, partly vitiating the cost saving. However, in main line situations, this form found almost universal adoption in North

America and Australia, and in much of continental Europe. The United Kingdom persisted with bullhead rail in main line use, with widespread introduction of flat-bottom rail only starting in about 1947.

1449:

Continuous Welded Rail (CWR) was developed in response to the observation that the bulk of track maintenance work takes place at the joints. As steel production and manufacturing processes improved, the rail lengths installed were progressively increased, and the logical extension of this would be to

1110:

Some experiments were made before 1945 with reinforced concrete sleepers, in most cases with bullhead chairs mounted on them. This was in response to the very high price of the best (most durable) timber, but reinforced concrete sleepers were never successful in main line use. Concrete pots were also

740:

The early cast iron rails of the 18th century and before used integral fixings for nailing or bolting to the railroad ties. Strap rails introduced in the late 18th century, of cast and later rolled iron were nailed to wooden supports via countersunk holes in the metal. The introduction of rolled rail

194:

The earliest use of a railway track seems to have been in connection with mining in

Germany in the 12th century. Mine passageways were usually wet and muddy, and moving barrows of ore along them was extremely difficult. Improvements were made by laying timber planks so that wheeled containers could

1524:

The original SmW process was very sensitive to operator skill, and as the welding was usually the final process before returning the track to traffic, time pressure was sometimes applied resulting in unwanted improper welds. The improved SkV process was less sensitive and over the years weld quality

1468:

If the long thin piece of metal could be constrained to prevent it from buckling (e.g. by being contained inside a tube) then it can resist a much higher compressive force. If the rails can be constrained in a similar way, they can be prevented from buckling. The weight of the track resists buckling

1150:

The new designs were successful, but they introduced many challenges, especially as the availability of experienced track maintenance staff became acutely difficult, and poorly maintained flat bottom track seemed more difficult to keep in good order than poorly maintained bullhead track. The greater

757:

in 1830 was initially spiked directly to wooden sleepers, later tie plates were used to spread the load and also keep the rail in gauge with inbuilt shoulders in the plate. Outside North

America a wide variety of spring based fastening systems were later introduced in combination with baseplates and

340:

town. These rails are referred to as plates, and the railway is sometimes called a plateway. The term "platelayer" also derives from this origin. In theory, the unflanged wheels could have been used on ordinary highways, but in practice this was probably rarely done, because the wagon wheels were so

1374:

About 1971, this trend was reversed with the so-called vertical S&C, in which the rails were held vertical, rather than at the customary 1 in 20 inclination. With other simplifications, this considerably reduced the stockholding required for a wide range of S&C speeds, although the vertical

1362:

Early S&C allowed only a very slow speed on the subsidiary route (the "turnout"), so geometrical design was not too important. Many older S&C units had a loose joint at the heel so that the switch rail could turn to close to the stock rail or open from it. When the switch rail was closed, a

714:

did not disrupt the all-important track gauge. The alignment of the track could be adjusted by shifting the sleepers bodily, without loss of gauge. Softwood was widely used, but its life was limited if it was not treated with preservative, and some railways set up creosoting plants for the purpose.

559:

Many railways preferred a flat bottom rail section, where the rails could be laid directly on the sleepers, representing a marked cost saving. Indenting of the sleeper was the problem; where the traffic was heavy, it became necessary to provide a sole plate under the rails to spread the load on the

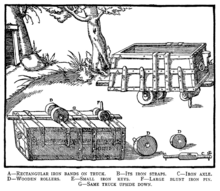

344:

The system found wide adoption in

Britain. Often, the plates were mounted on stone blocks, and sometimes without sleepers, but that was liable to cause the rails to spread apart, increasing the gauge. Railways of this kind were widely used in south Wales, particularly to transport limestone down to

1464:

If a small cube of metal is compressed between the jaws of a press, it will contract—that is it will be squashed somewhat—and a very large force can be resisted by it without ultimate failure. However, if a long piece of metal of the same cross section is compressed, it will deform sideways into a

1366:

As speeds rose, this was no longer feasible and the switch rails were fixed at the heel end, and their flexibility enabled the toe end to open and close. Manufacture of the switch rails was a complex process, and that of the crossings even more so. Speeds on the subsidiary route were rarely higher

1194:

in 1958. The two lengths were loaded on ten wagons, attached to the existing track by a steel rope and drawn back at 30 ft/min (9.1 m/min). As the train moved back, the old rails were levered out and the new ones dropped into the chairs. A hoist on the rear wagon dropped the last part of

555:

At first, the rail section was almost symmetrical top-to-bottom, and was described as a double-headed rail. The intention was to invert the rail after the top surface had become worn, but rails tend to develop chair gall, an attrition of the rail where it is supported in the chairs, and this would

551:

As metal technologies improved, these wrought iron rails were made progressively somewhat longer, and with a heavier, and therefore stronger, cross-section. By providing more metal in the foot of the rail, a stronger beam was created, achieving much better strength and stiffness, and a section was

146:

Developments in manufacturing technologies has led to changes to the design, manufacture and installation of rails, sleepers and the means of attachments. Cast iron rails, 4 feet (1.2 m) long, began to be used in the 1790s and by 1820, 15-foot-long (4.6 m) wrought iron rails were in use.

1499:

The CWR is installed and fastened down at an optimum temperature, to ensure that the highest possible expansive force is limited. This temperature is called the stress-free temperature, and in the UK it is 27 °C (81 °F). It is in the upper range of ordinary outdoor temperatures, and the

267:

Wear of the timber rails was a problem. They could be renewed by turning them over, but had to be regularly replaced. Sometimes, the rail was made in two parts, so that the top portion could easily be replaced when worn out. The rails were held together by wooden sleepers, covered with ballast to

1528:

The issue of buckling is not restricted to CWR, and jointed track has suffered buckles in the past. The fish-plates at joints need to be removed and greased annually (the requirement was relaxed to bi-annually in 1993) and where this was omitted or where ballast conditions were especially weak,

1495:

If the rail is held so that it cannot expand at all, then there is no limit on the length of rail that can be handled. (The expansive force in a one-foot length of rail at a certain temperature is the same as in a mile or 100 mile length of rail.) Early continuous welded rail was installed in

1159:

Much of the work of maintaining the track was at the joints, especially as the stiff rails became dipped, and the joint sleepers took a hammering. Pre-war experiments with long welded rail lengths were built upon, and in the years from 1960 long rail lengths were installed, at first on hardwood

1094:

bullhead rails supported in cast iron chairs on timber sleepers, laid in some form of ballast. In North

America, the standard was T-rails and tie plates fastened to timber crossties with cut spikes. Many railways were using very light rails and, as locomotive weights and speeds increased, these

725:

Steel sleepers were tried as an alternative to timber; Acworth writing in 1889 describes the production of steel sleepers on the London & North

Western Railway, and there is an illustration showing rolled channel section (shallow upturned "U" shapes) with no shaped ends, and with three-part

1503:

The CWR rails are made by welding ordinary rails together. For many years, rails could only be made in lengths of up to 60 ft (18 m) (18.288 m) in

Britain, and the factory welding process made them into 600 ft (180 m), 900 ft (270 m), or 1,200 ft (370 m)

975:

for the purpose. The wider, flat foot also meant that the chair needed by the bullhead section could be dispensed with. The longitudinal timbers needed to be kept at the proper spacing to retain the gauge correctly, and Brunel achieved this by using timber transoms—transverse spacers—and iron

772:

Track was originally laid directly on the ground, but this quickly proved unsatisfactory and some form of ballast was essential to ensure good drainage, spread the load and retain the track in position. The natural ground is rarely strong enough to accept the loading from locomotives without

102:

or ties embedded in ballast, intended to carry the ordinary trains of a railway. It is described as a permanent way because, in the earlier days of railway construction, contractors often laid a temporary track to transport spoil and materials about the site; when this work was substantially

1182:

A further enhancement to the rail profile produced the 113A section, which was the universal standard until about 1998; detail improvements to the sleepers and ballast profile completed the picture and the general form of the track had stabilised. This format is now in place over 99% of the

1098:

Flat bottom rails were still seen as undesirable for

British main line railway use, despite their successful use in North America, although some lightly operated British railways used them, generally spiked direct to the sleepers. Under heavy usage, they indent the sleepers severely and the

995:

was appointed to determine national policy. The Broad Gauge was technically superior but conversion of the standard gauge routes to broad would have meant reconstructing every tunnel, bridge and station platform, whereas universal adoption of the standard gauge only required the progressive

1512:

The long rails could be conveyed to site by a special train, and unloaded on to the ground (by chaining the end in position and pulling the train out from underneath the rails). The long rails had to be welded together (or to adjacent track) using a site welding process; and, after initial

1370:

As faster speeds were required, more configurations of S&C were designed, and a very large number of components, each specific to only one type of S&C, was required. At faster speeds on the turnout road, the divergence from the main route is much more gradual, and therefore a very

1119:

At the end of the Second World War in 1945, the

British railways were worn out, having been patched up following war damage without the availability of much new material. The country was economically in a weak situation also, and for nearly a decade after the war, materials—especially

1234:

In response to the dynamic behaviour ("hunting") of the wagons, the permitted speed of the wagons was reduced to 45 mph (72 km/h) and, on new installations of continuously welded track on concrete sleepers, to reduce the track gauge by one-eighth of an inch to 4 ft

139:), but this arrangement was expensive and Brunel soon replaced it with what became the classic broad gauge track, in which the piles were forgone and transoms, similar to sleepers, maintained the rail gauge. Today, most rail track uses the standard system of rail and sleepers;

1102:

Timber sleepers were expensive and not durable, and the railways’ engineers had strong—and conflicting—views about the best wood species and the best preservative treatments. The railways moved towards standardisation on a softwood sleeper preserved by pressure injection of

352:

and causing derailments. Another problem was that the running surface was liable to become obstructed by stones, displaced from the ballast. An alternative was to use an iron tie bar to keep the rails to the proper gauge, incorporating a shoe in which the rail was fixed.

147:

The first steel rails were made in 1857 and standard rail lengths increased over time from 30 to 60 feet (9.1–18.3 m). Rails were typically specified by units of weight per linear length and these also increased. Railway sleepers were traditionally made of

865:

The early railways were almost exclusively local concerns involved with conveying minerals to some waterway; for them the gauge of the track was adopted to suit the wagons intended to be used, and it was typically in the range 4 ft (1,200 mm) to 4 ft

1529:

buckling took place in hot weather. In addition, if rails were allowed to creep, it was always possible that several successive joints might close up, so that the expansion gap was lost, with inevitable results at the onset of hot weather.

345:

the ironworks, and then to take the iron to a canal, sometimes several miles away, which took the products to market. The rails were at first made of cast iron, typically in lengths of 3 feet (0.91 m), spanning between stone blocks.

970:

Brunel also looked at novel track forms, and decided to use a continuously supported rail. Using longitudinal timbers under each rail, he achieved a smoother profile while not requiring such a strong rail section, and he used a shallow

552:

created similar to the bullhead rail section still visible today. This was expensive, however, and the promoters of early railways struggled with decisions about the appropriate weight (and therefore strength, and cost) of their rails.

118:

as L-shaped plate rails). Rails were also individually fixed to rows of stone blocks, without any cross ties to maintain correct separation. This system also led to problems, as the blocks could individually move. The first version of

1189:

have now replaced labour-intensive permanent way gangs. Long welded rail was hard to install manually. An early demonstration of mechanised track-laying with two 600 ft (180 m) lengths of long welded rail took place on the

174:

1183:

first-class main lines in

Britain, although the CEN60 (60 kg/m) rail section was introduced in the UK during the 1990s. This has a wider rail foot and is taller than the 113A section so is incompatible with standard sleepers.

1508:

in which high electrical currents are used to soften the rail end, and the ends are then forced together by rams. The flash-butt process is very reliable, providing that the factory ensured good geometry of the rail ends.

773:

excessive settlement, more so in wet conditions; a layer of ballast under sleepers reduces the bearing pressure on the ground, tends to keep them in place and resist displacement, and keeps the permanent way well-drained.

556:

have made running on the former bottom surface impossibly noisy and irregular. It was better to provide the extra metal on the top surface and gain extra wear there without the need to invert the rail at its half life.

991:. But, as the British railway network spread, the incompatibility of the two systems became a serious blockage, as a wagon could not be sent from one system to the other without transshipping the goods by hand. A

709:

Timber sleepers, that is transverse beams supporting the two rails that form the track, replaced the individual stone blocks formerly used. This system has the major advantage that maintenance adjustments to the

999:

The existing broad gauge routes could continue, but as they had no development potential it was only a matter of time before they were eventually converted to standard. In the meantime, an extensive mileage of

291:

When wrought iron became available, wrought iron plates provided an even more durable surface. The rails had projecting lugs (or ears) with a hole to enable them to be fixed to the underlying wooden rail.

1139:

sleepers, it was to be the universal standard. The fastenings were to be of a resilient steel type, and for secondary routes a 98 lb/yd rail was adopted. Regional variations still persisted, and

1008:

being run, where wagons of each gauge were run in a single train. The legacy of the broad gauge can still be seen where there seems to be an unnecessarily wide space between station platforms.

722:

By that time, relatively long (perhaps 20 ft or 6.1 m) wrought iron rails supported in chairs on timber cross-sleepers, were in use—a track form recognisable today in older track.

1111:

used in sidings; they are sometimes called twin-block sleepers, and consisted of two concrete blocks each mounted with a chair, and an angle iron connecting them and retaining the gauge.

276:

Cast iron strips could be laid on top of timber rails, and the use of such materials probably occurred in 1738, but there are claims that this technology went back to 1716. In 1767,

211:

of Grasmere, Newlands and Caldbeck. Where space permitted round-section wooden tracks to take trucks with flanged wheels were installed: a painting from 1544 by the Flemish artist

446:

in 1798, which enabled rails to have a longer span between blocks. These were T-section edge rails, three feet long and laid on transverse stone sleepers. These were still made of

1131:

The railway companies became persuaded that the traditional bullhead forms of track needed revision, and after some experimentation a new flat bottom rail format was adopted. The

155:

and this continued through to modern times. Continuous welded rail was introduced into Britain in the mid 1960s and this was followed by the introduction of concrete sleepers.

195:

be dragged along by manpower. By the 16th century, the difficulty of keeping the wagon running straight had been solved by having a pin going into a gap between the planks.

1135:

sections were unsuitable and a new profile, a 109 lb/yd (54 kg/m) rail, was made the new standard. In 60 ft (18 m) lengths, laid on steel baseplates on

336:(who became a partner in them in 1790). These were used to transport goods for relatively short distances down to canals, though Curr's ran between the manor colliery and

1491:

taking precautions when track maintenance work is performed in hot weather, and making sure ballast is sufficiently consolidated before full-speed operation is resumed.

1461:

to expand. If prevented from expanding, they develop a force of 1.7 tonnes (17 kN) for every 1 degree Celsius of temperature change in a practical rail section.

199:

describes box-shaped carts, called "dogs", about half as large again as a wheelbarrow, fitted with a blunt vertical pin and wooden rollers running on iron axles. An

1457:: the rails expand in higher temperatures. Without joints, there is no room for the rails to expand; as the rails get warmer, they will develop an enormous force in

256:

In Shropshire, the gauge was usually narrow, to enable the wagons to be taken underground in drift mines. However, by far the greatest number of wagonways were near

1726:

880: in (1,435 mm), and at first there was no idea of the need for any conformity with the gauge of other lines. When the first public railways developed,

106:

The earliest tracks consisted of wooden rails on transverse wooden sleepers, which helped maintain the spacing of the rails. Various developments followed, with

1406:

1312:

1039:

819:

663:

493:

987:

The group of railways that had Brunel as their engineer were successful and the broad gauge track spread throughout the west of England, South Wales, and the

788:, a by-product of steel making, and ash from steam locomotives was used. Modern practice is to employ sharp-edged stone crushed within a narrow size range.

1521:

was the fuel and a metallurgically appropriate composition of molten steel descended into the gap between the rail ends, contained in refractory moulds.

612:

in 1860. Several other companies began producing steel rails in the following years. The transition to steel rails was hastened by the introduction of

348:

The stone blocks had been assumed to be permanent, but experience quickly showed that they settled and gradually moved under traffic, creating chaotic

1482:

heating the rails when they are installed and fastened in cool or cold weather, so that the expansion on the hottest days is less than otherwise

135:

system used rails laid on longitudinal sleepers whose rail gauge and elevation were pinned down by being tied to piles (conceptually akin to a

1902:

1175:

The welded track was to be laid on 6 to 12 inches (15 to 30 cm) of crushed stone ballast, although this was not always achieved, and the

2228:

1488:

making sure that curves do not line themselves inward during cold weather sufficiently to make buckling more likely when warm weather returns

935:(GWR), he sought an improved design for his railway track and accepted none of the previous received wisdom without challenge. The 4 ft

407:) in width with a depth of 3 inches (76 mm) and 4 feet (1.2 m) in length, and required flanges on the wagon wheels. The same year,

182:

260:, where a single wagon was hauled by a horse on a wagonway of about the modern standard gauge. These took coal from the pithead down to a

284:

plates, which were fixed to the top of wooden rails with nails, to provide a more durable running surface. This construct was known as

2731:

1144:

776:

Ballast in early days was usually locally available mineral product, such as gravel or reject material from coal and iron mining. The

2181:

2024:

1946:

1428:

1338:

1061:

841:

685:

515:

2701:

605:

324:'s colliery there. This had a L-shaped rail, so that the flange was on the rail rather than on the wheel. This was also used by

1191:

777:

545:

1160:

sleepers but soon on concrete sleepers. For example, the first long welded rail (almost 1 mi or 1.6 km) on the UK's

1410:

1316:

1043:

823:

667:

497:

23:

1079:

78:

Reconstruction of flat wooden track for transporting silver ore; guidance was by a vertical pin running between the timbers

589:

1004:

track was installed, where each line had three rails to accommodate trains of either gauge. There were some instances of

996:

conversion of the track itself. The broad gauge was doomed, and no further independent broad gauge lines could be built.

2309:

1963:

372:

1301:

1399:

1359:

Terminology is difficult for "switches and crossings" (S&C) previously "points and crossings", or "fittings".

1320:

1305:

1032:

812:

656:

486:

2424:

2221:

2658:

1476:

ensuring that the sleepers are well supported on consolidated ballast to enable the generation of the friction

74:

2696:

2409:

2250:

2172:

Key, A. J., Frederick C. O. and Round D. J. (1983). "Thermit Rail Welding Development on British Rail". In:

928:

120:

40:

1517:

welding process was used. This was an alumino-thermic process in which a powder 'portion' was ignited; the

2726:

2568:

2392:

2324:

1485:

making sure that any rail added if rail breaks during cold weather is removed before warm weather returns.

988:

735:

577:

573:

432:

208:

1465:

bow shape; the process is called buckling, and the compressive force it can withstand is very much less.

1375:

rail imposes a loss of the steering effect and the ride through new vertical S&C is often irregular.

249:. This, probably a rope-hauled incline plane, had existed 'long before' 1605. This probably preceded the

2548:

2528:

2294:

932:

621:

1938:

Trains and Technology: The American Railroad in the Nineteenth Century - Volume 3: Track and Structures

1858:

New, J. R. (November 2004), "400 years of English railways – Huntingdon Beaumont and the early years",

600:. The rails proved far more durable than the iron rails they replaced and remained in use until 1873.

2498:

2214:

1544:

1161:

533:

360:

357:

2133:

1179:

of the formation was not always taken into account, leading to some spectacular formation failures.

632:

2573:

2345:

1910:

1363:

reasonable alignment was secured; when it was open, no wheel could run on it so it did not matter.

1186:

1099:

incremental cost of a base-plate appeared at this early date, to rule the flat bottom section out.

613:

443:

396:

388:

257:

2681:

2618:

2604:

2558:

2488:

1707:

1090:

At the beginning of the twentieth century, the form of British track had converged on the use of

384:

364:

39:. The wagons were guided by the pronounced flange on the wooden wheels, and the narrow gauge of

458:

The earliest rails had square butt joints, which were weak and difficult to keep in alignment.

66:

2686:

2431:

2177:

2040:

2020:

1942:

1801:

1695:

1641:

1479:

providing consolidated ballast around the sides of the sleepers to provide additional friction

1454:

909:

Reference is sometimes made to the "gauge" of ruts in stone roadways at ancient sites such as

881:

754:

459:

329:

250:

173:

1936:

749:

required the use of chairs, keys to hold the rail, and bolts or spikes to fix the chair. The

2643:

2613:

2608:

2279:

1841:

1793:

1595:

1590:

1176:

1165:

1132:

581:

242:

2691:

2563:

2518:

2458:

2360:

2284:

2274:

1719:

1605:

1600:

1579:

1280:

704:

617:

593:

529:

408:

325:

321:

285:

200:

99:

2553:

2538:

2463:

2436:

2365:

2238:

1691:

1683:

992:

711:

601:

537:

428:

412:

349:

333:

308:

196:

91:

2720:

2653:

2648:

2638:

2599:

2543:

2451:

2446:

2414:

2397:

2264:

2246:

1953:– This section describes strap rails, their uses and problems in considerable detail.

1615:

1574:

1554:

1549:

1539:

1505:

767:

233:

A different system was developed in England, probably in the late 16th century, near

19:

2202:. The Industrial Archaeology of the British Isles. Newtown Abbot: David and Charles.

2064:

300:

2583:

2533:

2513:

2473:

2375:

2355:

2340:

2319:

2314:

2304:

2161:

General Instructions for the Installation and Maintenance of Continuous Welded Rail

1569:

1564:

1469:

upwards, so buckling is most likely to take place laterally. This is prevented by:

1091:

981:

972:

541:

416:

246:

212:

186:

140:

111:

95:

36:

31:

1172:

company which was the exclusive form of fastening in Britain for about 30 years.

1128:—were in very short supply. Labour too was seriously restricted in availability.

784:, which does not constrain movement as much as sharp-edged stone. In later years

2508:

2468:

2380:

1585:

1441:

1388:

1290:

1021:

950:

801:

645:

475:

136:

132:

1351:

758:

flat bottomed rail, these are now ubiquitous on main line high speed railways.

70:

Contemporary illustration of guided truck used in 16th-century mines in Germany

2665:

2631:

2626:

2578:

2503:

2478:

2419:

2385:

2269:

2122:

Railway Magazine March 1958 pp. 176–177 Laying Long Welded Rails in the N.E.R.

1845:

1610:

1559:

1204:

1001:

977:

922:

860:

404:

368:

238:

115:

1699:

636:

NZR Half Kilometer peg, 70 lb/yd track and track fishplate. Weka Pass Railway

103:

completed, the temporary track was taken up and the permanent way installed.

2404:

2370:

2350:

2299:

2289:

1797:

1518:

1271:) standard gauge versions have also been manufactured in more recent times.

585:

447:

423:

line in 1794, and his sons used I-shaped beams in 1813–15 on a railway from

420:

392:

337:

317:

281:

107:

1805:

1645:

442:

profile, first used by Thomas Barnes (1765–1801) at Walker Colliery, near

2441:

2259:

2017:

A biographical dictionary of civil engineers in Great Britain and Ireland

1140:

1136:

1104:

716:

424:

234:

228:

152:

148:

1514:

1413: in this section. Unsourced material may be challenged and removed.

1169:

1046: in this section. Unsourced material may be challenged and removed.

910:

826: in this section. Unsourced material may be challenged and removed.

670: in this section. Unsourced material may be challenged and removed.

597:

500: in this section. Unsourced material may be challenged and removed.

462:

introduced lapped joints, which maintained their alignment quite well.

261:

204:

2206:

1941:(illustrated ed.). University of Delaware Press. pp. 85–88.

1754:

62:) allowed the points to be altered by swinging the single switch rail.

2523:

1125:

781:

719:-treated hardwood is now widely used in North America and elsewhere.

277:

884:'s skilful innovation meant that his railways were dominant and the

2019:. Vol. 1. London: Institution of Civil Engineers. p. 44.

1473:

providing heavy sleepers, that generate friction on the ballast bed

1445:

Continuous welded track with conductor rail installed in the 1970s

1440:

1350:

1121:

1078:

631:

609:

569:

307:

299:

73:

65:

30:

2163:; Civil Engineering Handbook No 11; British Railways; March 1988.

1964:"The Hist The History of Wrought and Cast Ir ought and Cast Iron"

1832:

Smith, R. S. (1960), "England's First Rails: A reconsideration",

1765:(3). Matlock, England: Peak District Mines Historical Society: 3

1371:

considerable length of planning of the switch rail is required.

785:

400:

216:

2210:

544:

rails in 1820 in 15 feet (4.6 m) lengths, as used for the

375:, but the engine was so heavy that it broke many of the rails.

1382:

1284:

1015:

795:

639:

469:

215:

shows a coppermine with rails of this type emerging from an

207:, England, and they were probably also in use in the nearby

1640:(2 ed.). London: The Railway Gazette. pp. 18–19.

620:

set up his Landore steelworks partly to supply rail to the

264:, where the coal was loaded into river boats called keels.

1504:

lengths, depending on the factory. The process used was a

35:

Section of timber track from a 16th-century gold mine in

1818:

Peter King, 'First Shropshire Railways', Paper given at

1792:(3). London: Society of Occupational Medicine: 159–160.

1143:

sleepers and Mills clip fastenings were favoured on the

253:

of 1604, which has hitherto been regarded as the first.

18:

For the current status of permanent way technology, see

2074:

2072:

341:

narrow that they would have dug into the road surface.

1759:

Bulletin of the Peak District Mines Historical Society

312:

A long fish bellied rail supported over several chairs

203:

example of this has been discovered at Silvergill in

2015:

Skepton, Alec (2002). "Barnes, Thomas (1765–1801)".

1784:

McKiernan, Mick (2008). "Lucas Gassel, Coppermine".

976:

tie-bars. The whole assembly was referred to as the

415:. T-shaped beams were used by William Jessop on the

2674:

2592:

2487:

2333:

2245:

1907:(Includes illustration of a length of strap rail.)

1209:As stated, the general track gauge in Britain was

189:'s 1544 painting The Coppermine depicting railway

110:plates laid on top of the wooden rails and later

1930:

1928:

2004:. Devon:David & Charles. pp. 171–172.

2222:

8:

268:provide a surface for the horse to walk on.

1982:

1980:

1319:. Unsourced material may be challenged and

588:ironworks, and were laid experimentally at

2229:

2215:

2207:

2104:, Second Edition 1889, John Murray, London

2055:(London: Institute of materials 1990), 66.

2039:Lives of the Engineers, by Samuel Smiles,

1429:Learn how and when to remove this message

1339:Learn how and when to remove this message

1083:World's railways in 1908 as presented by

1062:Learn how and when to remove this message

842:Learn how and when to remove this message

686:Learn how and when to remove this message

604:supplied 500 tons of steel blooms to the

516:Learn how and when to remove this message

431:. Samples of these rails are held in the

237:for conveying coal from mines, sometimes

2000:Charles Hadfield; Alec Skempton (1979).

1755:"Early Surface Features of Metal Mining"

371:in 1804, using one of his high pressure

1725:CS1 maint: location missing publisher (

1628:

2200:Stone Blocks and Iron Rails (Tramways)

2156:

2154:

1889:

1715:

1705:

580:remelted scrap steel from an abortive

2113:Railway Magazine December 1957 p. 882

2089:History of the British steel Industry

399:in 1793. These were rectangular, 2.5

114:plates or wrought iron angle plates (

7:

1411:adding citations to reliable sources

1317:adding citations to reliable sources

1044:adding citations to reliable sources

824:adding citations to reliable sources

668:adding citations to reliable sources

498:adding citations to reliable sources

953:. (It was later eased to 7 ft

1668:Lewis, M J T (1970), "Chapter 2",

741:profiles in the 1820s such as the

438:A short-lived alternative was the

383:Cast iron edge rails were used by

14:

1822:Conference (publication awaited).

1743:Conference (publication awaited).

1513:experimentation, the proprietary

1450:eliminate the joints altogether.

1085:The Harmsworth atlas and Gazetter

320:of Sheffield, the manager of the

2138:Manchester Model Railway Society

1990:(Newcomen Society, London, 2001.

1453:A major obstacle to doing so is

1387:

1289:

1164:was laid in 1957, just south of

1020:

800:

644:

606:London and North Western Railway

474:

316:An alternative was developed by

172:

1694:(trans.). London. p. 156.

1672:, London: Routledge Keegan Paul

1398:needs additional citations for

1031:needs additional citations for

811:needs additional citations for

778:Great North of Scotland Railway

655:needs additional citations for

546:Stockton and Darlington Railway

485:needs additional citations for

304:Section of L-shaped plate rails

143:is used in a few applications.

1935:Bianculli, Anthony J. (2003).

1834:Renaissance and Modern Studies

747:double flanged T parallel rail

743:single flanged T parallel rail

94:lines: generally the pairs of

24:Permanent way (disambiguation)

1:

1909:. Past Tracks. Archived from

2091:(Oxford 1962: Blackwell), 81

1012:Twentieth century and beyond

528:The breakthrough came when

356:An example of this was the

2748:

2437:Transfer table (traverser)

1278:

1202:

920:

858:

765:

733:

702:

568:The first rails made from

226:

17:

2732:History of rail transport

2425:ground-level power supply

2087:J.C. Carr and W. Taplin,

1846:10.1080/14735786009391434

1753:Cranstone, David (1994).

1638:The Evolution of Railways

367:to demonstrate a pioneer

2198:Baxter, Bertram (1966).

2134:"Modern Permanent Way 3"

2002:William Jessop, Engineer

1988:Early limestone railways

2410:Railway electrification

2102:The Railways of England

929:Isambard Kingdom Brunel

614:open hearth steelmaking

584:trial, in crucibles at

411:used edge rails on the

121:Isambard Kingdom Brunel

1903:"What was a Railroad?"

1446:

1379:Continuous welded rail

1356:

1275:Switches and crossings

1087:

736:Rail fastening systems

637:

578:Robert Forester Mushet

433:Science Museum, London

313:

305:

159:Wooden tracked systems

98:typically laid on the

79:

71:

63:

22:. For other uses, see

2549:Platform screen doors

2132:Craig, Colin (n.d.).

2078:Barraclough 1990, 67.

2053:Steelmaking 1850–1900

1798:10.1093/occmed/kqn038

1786:Occupational Medicine

1670:Early Wooden Railways

1636:Lee, Charles (1943).

1444:

1354:

1195:the rail into place.

1192:Fighting Cocks branch

1115:Post-war developments

1082:

933:Great Western Railway

635:

622:Great Western Railway

590:Derby railway station

358:Penydarren or Merthyr

311:

303:

241:down the side of the

77:

69:

34:

2499:Anti-trespass panels

1692:Herbert Clark Hoover

1545:List of track gauges

1407:improve this article

1313:improve this section

1187:Track renewal trains

1162:East Coast Main Line

1040:improve this article

820:improve this article

664:improve this article

534:Bedlington Ironworks

494:improve this article

2346:Classification yard

780:used rounded river

628:Associated features

454:Butt and lap joints

397:Monmouthshire canal

363:. This was used by

330:Butterley Ironworks

258:Newcastle upon Tyne

90:is the elements of

2605:Motive power depot

2559:Signalling control

1684:Agricola, Georgius

1506:flash-butt process

1447:

1357:

1088:

1006:mixed gauge trains

855:Early track gauges

751:flat bottomed rail

638:

387:when building the

385:Thomas Dadford Jr.

365:Richard Trevithick

314:

306:

80:

72:

64:

2714:

2713:

2432:Railway turntable

2253:

2041:The Folio Society

1455:thermal expansion

1439:

1438:

1431:

1349:

1348:

1341:

1155:Long welded rails

1072:

1071:

1064:

917:Broad gauge track

882:George Stephenson

852:

851:

844:

755:Robert L. Stevens

696:

695:

688:

540:developed rolled

526:

525:

518:

466:Modern edge rails

460:George Stephenson

251:Wollaton Wagonway

2739:

2609:Railway workshop

2325:Transition curve

2295:Fastening system

2249:

2231:

2224:

2217:

2208:

2203:

2185:

2176:. British Rail.

2170:

2164:

2158:

2149:

2148:

2146:

2144:

2129:

2123:

2120:

2114:

2111:

2105:

2098:

2092:

2085:

2079:

2076:

2067:

2062:

2056:

2051:K. Barraclough,

2049:

2043:

2037:

2031:

2030:

2012:

2006:

2005:

1997:

1991:

1984:

1975:

1974:

1972:

1970:

1960:

1954:

1952:

1932:

1923:

1922:

1920:

1918:

1899:

1893:

1887:

1881:

1874:

1868:

1867:

1855:

1849:

1848:

1829:

1823:

1820:Early Railways 4

1816:

1810:

1809:

1781:

1775:

1774:

1772:

1770:

1750:

1744:

1741:Early Railways 4

1737:

1731:

1730:

1723:

1717:

1713:

1711:

1703:

1680:

1674:

1673:

1665:

1659:

1656:

1650:

1649:

1633:

1596:Railway platform

1591:Rail terminology

1434:

1427:

1423:

1420:

1414:

1391:

1383:

1355:Railway turnouts

1344:

1337:

1333:

1330:

1324:

1293:

1285:

1270:

1268:

1267:

1263:

1260:

1252:

1248:

1247:

1243:

1240:

1230:

1226:

1224:

1223:

1219:

1216:

1177:bearing capacity

1166:Carlton-on-Trent

1133:British Standard

1067:

1060:

1056:

1053:

1047:

1024:

1016:

993:Gauge Commission

966:

965:

961:

958:

948:

947:

943:

940:

905:

901:

899:

898:

894:

891:

879:

878:

874:

871:

847:

840:

836:

833:

827:

804:

796:

691:

684:

680:

677:

671:

648:

640:

608:'s rail mill at

521:

514:

510:

507:

501:

478:

470:

379:Early edge rails

280:began producing

278:Ketley ironworks

272:Early iron rails

176:

130:

126:

61:

59:

58:

54:

51:

43:

2747:

2746:

2742:

2741:

2740:

2738:

2737:

2736:

2717:

2716:

2715:

2710:

2670:

2588:

2564:Structure gauge

2519:Defect detector

2491:

2483:

2329:

2285:Clip and scotch

2275:Breather switch

2241:

2235:

2197:

2194:

2189:

2188:

2174:Rail Technology

2171:

2167:

2159:

2152:

2142:

2140:

2131:

2130:

2126:

2121:

2117:

2112:

2108:

2099:

2095:

2086:

2082:

2077:

2070:

2063:

2059:

2050:

2046:

2038:

2034:

2027:

2014:

2013:

2009:

1999:

1998:

1994:

1985:

1978:

1968:

1966:

1962:

1961:

1957:

1949:

1934:

1933:

1926:

1916:

1914:

1901:

1900:

1896:

1888:

1884:

1875:

1871:

1857:

1856:

1852:

1831:

1830:

1826:

1817:

1813:

1783:

1782:

1778:

1768:

1766:

1752:

1751:

1747:

1739:Paper given at

1738:

1734:

1724:

1716:|magazine=

1714:

1704:

1688:De Re Metallica

1682:

1681:

1677:

1667:

1666:

1662:

1657:

1653:

1635:

1634:

1630:

1625:

1620:

1606:Structure gauge

1601:Strap iron rail

1580:Railroad switch

1535:

1435:

1424:

1418:

1415:

1404:

1392:

1381:

1345:

1334:

1328:

1325:

1310:

1294:

1283:

1281:Railroad switch

1277:

1265:

1261:

1258:

1256:

1255:4 ft

1254:

1250:

1245:

1241:

1238:

1236:

1228:

1221:

1217:

1214:

1212:

1211:4 ft

1210:

1207:

1201:

1157:

1147:, for example.

1117:

1077:

1068:

1057:

1051:

1048:

1037:

1025:

1014:

963:

959:

956:

954:

945:

941:

938:

936:

925:

919:

903:

896:

892:

889:

887:

886:4 ft

885:

876:

872:

869:

867:

863:

857:

848:

837:

831:

828:

817:

805:

794:

770:

764:

738:

732:

730:Rail fastenings

707:

705:Railway sleeper

701:

692:

681:

675:

672:

661:

649:

630:

618:William Siemens

594:Midland Railway

566:

530:John Birkinshaw

522:

511:

505:

502:

491:

479:

468:

456:

409:Benjamin Outram

381:

326:Benjamin Outram

322:Duke of Norfolk

298:

286:strap-iron rail

274:

231:

225:

201:Elizabethan era

192:

191:

190:

184:

179:

178:

177:

166:

161:

128:

124:

56:

52:

49:

47:

46:

41:

27:

12:

11:

5:

2745:

2743:

2735:

2734:

2729:

2719:

2718:

2712:

2711:

2709:

2708:

2707:

2706:

2705:

2704:

2689:

2684:

2678:

2676:

2672:

2671:

2669:

2668:

2663:

2662:

2661:

2656:

2651:

2646:

2636:

2635:

2634:

2629:

2621:

2616:

2611:

2602:

2596:

2594:

2590:

2589:

2587:

2586:

2581:

2576:

2571:

2566:

2561:

2556:

2554:Railway signal

2551:

2546:

2541:

2539:Level crossing

2536:

2531:

2526:

2521:

2516:

2511:

2506:

2501:

2495:

2493:

2485:

2484:

2482:

2481:

2476:

2471:

2466:

2464:Track geometry

2461:

2456:

2455:

2454:

2444:

2439:

2434:

2429:

2428:

2427:

2422:

2417:

2415:overhead lines

2407:

2402:

2401:

2400:

2390:

2389:

2388:

2378:

2373:

2368:

2366:Gauntlet track

2363:

2358:

2353:

2348:

2343:

2337:

2335:

2331:

2330:

2328:

2327:

2322:

2317:

2312:

2310:Minimum radius

2307:

2302:

2297:

2292:

2287:

2282:

2277:

2272:

2267:

2262:

2256:

2254:

2243:

2242:

2239:infrastructure

2236:

2234:

2233:

2226:

2219:

2211:

2205:

2204:

2193:

2190:

2187:

2186:

2165:

2150:

2124:

2115:

2106:

2100:Acworth, W M,

2093:

2080:

2068:

2057:

2044:

2032:

2025:

2007:

1992:

1976:

1955:

1947:

1924:

1913:on 23 May 2011

1894:

1882:

1869:

1850:

1824:

1811:

1776:

1745:

1732:

1675:

1660:

1658:Lee (1943: 11)

1651:

1627:

1626:

1624:

1621:

1619:

1618:

1613:

1608:

1603:

1598:

1593:

1588:

1583:

1577:

1572:

1567:

1562:

1557:

1555:Overhead lines

1552:

1547:

1542:

1536:

1534:

1531:

1493:

1492:

1489:

1486:

1483:

1480:

1477:

1474:

1437:

1436:

1395:

1393:

1386:

1380:

1377:

1347:

1346:

1297:

1295:

1288:

1279:Main article:

1276:

1273:

1203:Main article:

1200:

1197:

1156:

1153:

1145:Eastern Region

1116:

1113:

1076:

1073:

1070:

1069:

1028:

1026:

1019:

1013:

1010:

931:conceived the

921:Main article:

918:

915:

859:Main article:

856:

853:

850:

849:

808:

806:

799:

793:

790:

766:Main article:

763:

760:

734:Main article:

731:

728:

712:track geometry

703:Main article:

700:

697:

694:

693:

652:

650:

643:

629:

626:

602:Henry Bessemer

565:

562:

538:Northumberland

524:

523:

482:

480:

473:

467:

464:

455:

452:

429:Belvoir Castle

413:Cromford Canal

380:

377:

350:track geometry

334:William Jessop

297:

296:Iron plateways

294:

273:

270:

227:Main article:

224:

221:

197:Georg Agricola

181:

180:

171:

170:

169:

168:

167:

165:

162:

160:

157:

13:

10:

9:

6:

4:

3:

2:

2744:

2733:

2730:

2728:

2727:Permanent way

2725:

2724:

2722:

2703:

2700:

2699:

2698:

2695:

2694:

2693:

2690:

2688:

2685:

2683:

2680:

2679:

2677:

2673:

2667:

2664:

2660:

2657:

2655:

2652:

2650:

2647:

2645:

2642:

2641:

2640:

2637:

2633:

2630:

2628:

2625:

2624:

2622:

2620:

2617:

2615:

2612:

2610:

2606:

2603:

2601:

2600:Coaling tower

2598:

2597:

2595:

2591:

2585:

2582:

2580:

2577:

2575:

2572:

2570:

2569:Signal bridge

2567:

2565:

2562:

2560:

2557:

2555:

2552:

2550:

2547:

2545:

2544:Loading gauge

2542:

2540:

2537:

2535:

2532:

2530:

2527:

2525:

2522:

2520:

2517:

2515:

2512:

2510:

2507:

2505:

2502:

2500:

2497:

2496:

2494:

2490:

2486:

2480:

2477:

2475:

2472:

2470:

2467:

2465:

2462:

2460:

2457:

2453:

2452:refuge siding

2450:

2449:

2448:

2445:

2443:

2440:

2438:

2435:

2433:

2430:

2426:

2423:

2421:

2418:

2416:

2413:

2412:

2411:

2408:

2406:

2403:

2399:

2398:tramway track

2396:

2395:

2394:

2391:

2387:

2384:

2383:

2382:

2379:

2377:

2374:

2372:

2369:

2367:

2364:

2362:

2359:

2357:

2354:

2352:

2349:

2347:

2344:

2342:

2339:

2338:

2336:

2332:

2326:

2323:

2321:

2318:

2316:

2313:

2311:

2308:

2306:

2303:

2301:

2298:

2296:

2293:

2291:

2288:

2286:

2283:

2281:

2278:

2276:

2273:

2271:

2268:

2266:

2263:

2261:

2258:

2257:

2255:

2252:

2248:

2244:

2240:

2232:

2227:

2225:

2220:

2218:

2213:

2212:

2209:

2201:

2196:

2195:

2191:

2183:

2182:0-9508596-0-5

2179:

2175:

2169:

2166:

2162:

2157:

2155:

2151:

2139:

2135:

2128:

2125:

2119:

2116:

2110:

2107:

2103:

2097:

2094:

2090:

2084:

2081:

2075:

2073:

2069:

2066:

2061:

2058:

2054:

2048:

2045:

2042:

2036:

2033:

2028:

2026:0-7277-2939-X

2022:

2018:

2011:

2008:

2003:

1996:

1993:

1989:

1986:J. van Laun,

1983:

1981:

1977:

1965:

1959:

1956:

1950:

1948:0-87413-802-7

1944:

1940:

1939:

1931:

1929:

1925:

1912:

1908:

1904:

1898:

1895:

1892:, p. 39.

1891:

1886:

1883:

1879:

1873:

1870:

1866:(11): 660–665

1865:

1861:

1854:

1851:

1847:

1843:

1839:

1835:

1828:

1825:

1821:

1815:

1812:

1807:

1803:

1799:

1795:

1791:

1787:

1780:

1777:

1764:

1760:

1756:

1749:

1746:

1742:

1736:

1733:

1728:

1721:

1709:

1701:

1697:

1693:

1689:

1685:

1679:

1676:

1671:

1664:

1661:

1655:

1652:

1647:

1643:

1639:

1632:

1629:

1622:

1617:

1616:Tramway track

1614:

1612:

1609:

1607:

1604:

1602:

1599:

1597:

1594:

1592:

1589:

1587:

1584:

1581:

1578:

1576:

1575:Rail sabotage

1573:

1571:

1568:

1566:

1563:

1561:

1558:

1556:

1553:

1551:

1550:Loading gauge

1548:

1546:

1543:

1541:

1540:Clearance car

1538:

1537:

1532:

1530:

1526:

1522:

1520:

1516:

1510:

1507:

1501:

1497:

1490:

1487:

1484:

1481:

1478:

1475:

1472:

1471:

1470:

1466:

1462:

1460:

1456:

1451:

1443:

1433:

1430:

1422:

1412:

1408:

1402:

1401:

1396:This section

1394:

1390:

1385:

1384:

1378:

1376:

1372:

1368:

1364:

1360:

1353:

1343:

1340:

1332:

1322:

1318:

1314:

1308:

1307:

1303:

1298:This section

1296:

1292:

1287:

1286:

1282:

1274:

1272:

1251:1,435 mm

1232:

1229:1,435 mm

1206:

1198:

1196:

1193:

1188:

1184:

1180:

1178:

1173:

1171:

1167:

1163:

1154:

1152:

1148:

1146:

1142:

1138:

1134:

1129:

1127:

1123:

1114:

1112:

1108:

1106:

1100:

1096:

1093:

1086:

1081:

1074:

1066:

1063:

1055:

1045:

1041:

1035:

1034:

1029:This section

1027:

1023:

1018:

1017:

1011:

1009:

1007:

1003:

997:

994:

990:

989:West Midlands

985:

983:

979:

974:

968:

952:

934:

930:

924:

916:

914:

912:

907:

904:1,435 mm

883:

862:

854:

846:

843:

835:

825:

821:

815:

814:

809:This section

807:

803:

798:

797:

791:

789:

787:

783:

779:

774:

769:

768:Track ballast

761:

759:

756:

752:

748:

744:

737:

729:

727:

723:

720:

718:

713:

706:

698:

690:

687:

679:

669:

665:

659:

658:

653:This section

651:

647:

642:

641:

634:

627:

625:

623:

619:

615:

611:

607:

603:

599:

595:

591:

587:

583:

579:

575:

572:were made in

571:

563:

561:

557:

553:

549:

547:

543:

539:

535:

531:

520:

517:

509:

499:

495:

489:

488:

483:This section

481:

477:

472:

471:

465:

463:

461:

453:

451:

449:

445:

441:

436:

434:

430:

426:

422:

418:

414:

410:

406:

402:

398:

395:lines to the

394:

390:

386:

378:

376:

374:

373:steam engines

370:

366:

362:

359:

354:

351:

346:

342:

339:

335:

331:

327:

323:

319:

310:

302:

295:

293:

289:

287:

283:

279:

271:

269:

265:

263:

259:

254:

252:

248:

244:

240:

236:

230:

222:

220:

218:

214:

210:

206:

202:

198:

188:

183:

175:

163:

158:

156:

154:

150:

144:

142:

138:

134:

129:2,134 mm

122:

117:

113:

109:

104:

101:

97:

93:

89:

88:permanent way

85:

84:railway track

76:

68:

44:

38:

33:

29:

25:

21:

20:Railway track

16:

2584:Wayside horn

2534:Interlocking

2514:Catch points

2474:Water trough

2376:Passing loop

2356:Pocket track

2341:Balloon loop

2305:Ladder track

2199:

2173:

2168:

2160:

2141:. Retrieved

2137:

2127:

2118:

2109:

2101:

2096:

2088:

2083:

2060:

2052:

2047:

2035:

2016:

2010:

2001:

1995:

1987:

1967:. Retrieved

1958:

1937:

1915:. Retrieved

1911:the original

1906:

1897:

1885:

1877:

1872:

1863:

1859:

1853:

1837:

1833:

1827:

1819:

1814:

1789:

1785:

1779:

1767:. Retrieved

1762:

1758:

1748:

1740:

1735:

1687:

1678:

1669:

1663:

1654:

1637:

1631:

1570:Rail profile

1565:Rail lengths

1527:

1523:

1511:

1502:

1498:

1494:

1467:

1463:

1458:

1452:

1448:

1425:

1416:

1405:Please help

1400:verification

1397:

1373:

1369:

1365:

1361:

1358:

1335:

1326:

1311:Please help

1299:

1233:

1208:

1185:

1181:

1174:

1158:

1149:

1130:

1118:

1109:

1101:

1097:

1092:wrought iron

1089:

1084:

1075:1900 to 1945

1058:

1049:

1038:Please help

1033:verification

1030:

1005:

998:

986:

982:Ladder track

969:

926:

908:

864:

838:

829:

818:Please help

813:verification

810:

775:

771:

753:invented by

750:

746:

742:

739:

724:

721:

708:

682:

673:

662:Please help

657:verification

654:

567:

558:

554:

550:

542:wrought iron

527:

512:

503:

492:Please help

487:verification

484:

457:

440:fish-bellied

439:

437:

417:Loughborough

382:

355:

347:

343:

315:

290:

275:

266:

255:

247:River Severn

243:Severn Gorge

232:

213:Lucas Gassel

193:

187:Lucas Gassel

185:Fragment of

145:

141:ladder track

112:wrought iron

105:

87:

83:

81:

37:Transylvania

28:

15:

2509:Buffer stop

2469:Water crane

2381:Track gauge

2320:Tie/Sleeper

1890:Baxter 1966

1840:: 119–134,

1586:Rail tracks

1199:Track gauge

1002:mixed gauge

973:bridge rail

951:broad gauge

564:Steel rails

239:drift mines

223:Edged rails

209:Mines Royal

137:pile bridge

133:broad gauge

42:480 mm

2721:Categories

2682:Industrial

2666:Water stop

2627:for trains

2619:Roundhouse

2593:Structures

2579:Train stop

2529:Guard rail

2504:Block post

2492:and safety

2489:Signalling

2420:third rail

2393:Rail track

2386:dual gauge

2270:Baulk road

1969:19 January

1917:1 February

1623:References

1611:Third rail

1560:Rail gauge

1525:improved.

1419:April 2021

1329:April 2021

1205:Rail gauge

1052:April 2021

978:baulk road

923:Baulk road

861:Rail gauge

832:April 2021

745:and later

676:April 2021

506:April 2021

369:locomotive

164:Plank ways

116:angle iron

2632:for goods

2574:Tell-tale

2405:Rail yard

2371:Guide bar

2351:Headshunt

2334:Trackwork

2300:Fishplate

2290:Date nail

2251:(history)

1860:Backtrack

1769:25 August

1718:ignored (

1708:cite book

1700:181688102

1519:aluminium

1300:does not

586:Ebbw Vale

448:cast iron

444:Newcastle

421:Nanpantan

403:(64

393:Blaenavon

338:Sheffield

318:John Curr

282:cast iron

153:hardwoods

151:-treated

125:7 ft

108:cast iron

2687:Military

2644:building

2614:Platform

2524:Derailer

2442:Roll way

2361:Junction

2260:Axe ties

2065:fweb.org

1806:18441363

1686:(1912).

1582:(points)

1533:See also

1269: in

1225: in

1141:hardwood

1137:softwood

1105:creosote

900: in

717:Creosote

699:Sleepers

582:Bessemer

425:Grantham

389:Beaufort

235:Broseley

229:wagonway

149:Creosote

100:sleepers

60: in

2697:station

2692:Private

2639:Station

2315:Profile

2265:Ballast

2192:Sources

2143:20 July

1876:Lewis,

1646:1591369

1515:Thermit

1321:removed

1306:sources

1264:⁄

1244:⁄

1220:⁄

1170:Pandrol

962:⁄

944:⁄

911:Pompeii

895:⁄

875:⁄

762:Ballast

598:England

592:on the

576:, when

361:tramway

262:staithe

245:to the

205:Cumbria

92:railway

55:⁄

2459:Switch

2447:Siding

2247:Tracks

2180:

2023:

1945:

1878:passim

1804:

1698:

1644:

1459:trying

1126:timber

792:Gauges

782:gravel

401:inches

2675:Types

2654:ghost

2649:clock

2623:Shed

2237:Rail

1122:steel

927:When

610:Crewe

570:steel

96:rails

2702:list

2659:list

2280:Cant

2178:ISBN

2145:2022

2021:ISBN

1971:2024

1943:ISBN

1919:2011

1802:PMID

1771:2009

1727:link

1720:help

1696:OCLC

1642:OCLC

1304:any

1302:cite

1124:and

786:slag

574:1857

391:and

332:and

217:adit

82:The

2479:Wye

1842:doi

1794:doi

1409:by

1315:by

1042:by

822:by

666:by

596:in

536:in

532:of

496:by

427:to

328:of

123:'s

86:or

2723::

2153:^

2136:.

2071:^

1979:^

1927:^

1905:.

1864:18

1862:,

1838:IV

1836:,

1800:.

1790:58

1788:.

1763:12

1761:.

1757:.

1712::

1710:}}

1706:{{

1690:.

984:.

616:.

450:.

435:.

405:mm

219:.

131:)

48:18

2607:/

2230:e

2223:t

2216:v

2184:.

2147:.

2029:.

1973:.

1951:.

1921:.

1880:.

1844::

1808:.

1796::

1773:.

1729:)

1722:)

1702:.

1648:.

1432:)

1426:(

1421:)

1417:(

1403:.

1342:)

1336:(

1331:)

1327:(

1323:.

1309:.

1266:2

1262:1

1259:+

1257:8

1253:(

1246:8

1242:3

1239:+

1237:8

1227:(

1222:2

1218:1

1215:+

1213:8

1065:)

1059:(

1054:)

1050:(

1036:.

964:4

960:1

957:+

955:0

946:2

942:1

939:+

937:8

902:(

897:2

893:1

890:+

888:8

877:2

873:1

870:+

868:8

845:)

839:(

834:)

830:(

816:.

689:)

683:(

678:)

674:(

660:.

519:)

513:(

508:)

504:(

490:.

419:-

127:(

57:8

53:7

50:+

45:(

26:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.