321:

309:

254:

266:

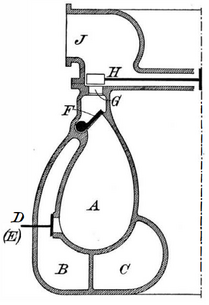

At this point the combustion chamber (A) is filled with pure, relatively cold air, into which the pure fuel (gas or atomized oil) is blown through the valve (E), thus forming the explosive mixture which is ignited by a spark. In order to make the impulses imparted to the turbine wheel more uniform, several combustion chambers working alternately are arranged in a circle around the turbine wheel (H).

136:, gas turbine in which combustion takes place cyclically in a combustion chamber closed off by valves. The Holzwarth gas turbine is named after its developer Dr Hans Holzwarth (1877-1953) who designed several prototype engines used for testing and experimental service in Germany and Switzerland between 1908 and 1943.

281:

The two

Holzwarth gas turbines built by Brown Boveri after 1928 used two stages of combustion chambers and a “two stoke” version of the cycle where gas admission and exhaust took place simultaneously. The first stage comprised the final charging of the combustion chamber, the explosion, the delivery

261:

The explosion chamber (A) is filled intermittently with a rich mixture supplied from the gas chamber (C) and the air chamber (B). The mixture is ignited by spark after which the explosion of the mixture causes and increase in pressure throwing open the nozzle valve (F), allowing the compressed gases

265:

When the expansion has been completed, air is blown, or drawn, in at a slight pressure through the valve (D). This scavenging air throws any residual gases left in the combustion chamber. through the nozzle, into the exhaust, after which the nozzle valve and the air valve (D) are positively closed.

236:

factory in 1938 for the

Hamborn steelworks. Fuel for combustion was blast-furnace gas compressed to about 6 bar (87 psi). The gas turbine had hydraulically operated valves working at 60-100 cycles per minute. The unit was only infrequently run and was not part of the steelwork's regular

262:

to flow through the nozzle (G) to the turbine wheel (H) on which the work is to be performed. While passing through the nozzle, the gases are expanded to the pressure of the exhaust (J). The nozzle valve (F) is kept open by fresh air throughout the expansion and subsequent scavenging and cooling.

212:

From 1928, Holzwarth once again collaborated with Brown Boveri to build a version of his gas turbine with two sets of combustion chambers connected in series. These two-stage machines used a compressor driven by a stream turbine which was fed from the evaporation of water from the cooling water

144:

At the start of the 20th century, designers across Europe were working on the development of the constant flow gas turbine. The biggest problem for these early pioneers was the design of the compressor. The low efficiency of the turbo compressors available at the time meant that the compressor

29:

145:

consumed all the energy supplied by the turbine. Holzwarth's design avoided this problem by having combustion take place cyclically in combustion chambers closed off by valves. Since the pressure rise took place in the sealed combustion chamber there was no need for a compressor.

269:

In early

Holzwarth machines, gas and air were supplied at a relatively low pressure around 0.1–1 bar (1–15 psi) in later models a gas compressor was used to supply fuel at pressures up to 6 bar (87 psi). The gas compressor was driven by a

190:

fuel which was found to burn acceptably in the combustion chamber but produced exhaust particles which damaged turbine blades. In 1927, Hans

Holzwarth left Thyssen & Co and founded his own company,

179:

to build a market-ready 1,000 hp (746 kW) gas turbine however output and efficiency were below expectations and Brown Boveri withdrew from the project in 1912.

282:

of heat and energy in the steam generator and gas turbine. The second stage comprised the scavenging and the pre-charging. The residual exhaust gases escaped through an

417:

182:

Holzwarth continued to work on his design while he was employed as chief engineer for gas turbines at

Thyssen. In 1923 a prototype machine was delivered to the

205:

Observations regarding the loss of waste heat to the cooling water led jacket led to the development, by Brown Boveri, of the commercially successful

201:

tested a 500 kW (671 hp) oil fired

Holzwarth gas turbine and found that only 8% of the fuel's energy was transformed into mechanical energy

320:

449:

395:

365:

186:

where it was used to drive a 350 kW (469 hp) generator for several years. During this period tests were carried out using

308:

152:

in the USA. Holzwarth returned to

Germany in 1908 where he designed and built a 25 hp (19 kW) machine while working for

213:

jacket. In 1933, a two-stage machine driving a 2,000 kW (2,682 hp) generator was installed at the

Thyssen

232:

The last

Holzwarth gas turbine was an experimental 5,000 kW (6,705 hp) machine built by Brown Boveri's

183:

149:

450:"Pressure Charging, Velox Boiler and Gas Turbine, a review of their origin and development by Brown Boveri"

238:

176:

120:

522:

274:

fed from the evaporation of water from the gas turbines cooling jacket which required the addition of a

148:

Holzwarth developed the theoretical concept for his gas turbine from 1905, while he was an employee of

527:

157:

112:

34:

28:

253:

391:

361:

275:

226:

133:

68:

295:

165:

257:

Diagrammatic section through one of the combustion chambers of a

Holzwarth gas turbine

516:

271:

198:

209:, which in turn led to the development of the first modern industrial gas turbines.

242:

206:

245:

ended, interest in the Holzwarth design declined and no further units were built.

46:

501:

Holzwarth, Hans (1912). "1 - General Description of the Gas Turbine Process".

283:

214:

153:

116:

187:

76:

233:

222:

72:

64:

218:

161:

299:

169:

418:"The Combustion Gas Turbine, Its History, Development and Prospects"

294:

This first prototype Holzwarth gas turbine is on display at the

241:

bombing raid after which no further test runs were made. After

237:

equipment. In 1943, the gas turbine was damaged during an

356:

Eckardt, Dietrich (2014). "3.3 - The Holzwarth Gas Turbine".

33:

A Holzwarth gas turbine prototype on the test bench at the

156:. This first machine was manufactured and tested at

505:. London, UK: Charles Griffin and Company. pp. 1–2.

388:

German Jet Engine and Gas Turbine Development 1930-1945

386:

Kay, Antony L (2002). "Holzwarth Gasturbinen GmbH".

108:

98:

90:

82:

60:

52:

42:

21:

463:. Baden, Switzerland: Brown Boveri and Company.

428:. Baden, Switzerland: Brown Boveri and Company.

360:. Oldenbourg Verlag Munchen. pp. 72–76.

8:

390:. Airlife Publishing Ltd. pp. 193–194.

252:

443:

441:

439:

437:

435:

411:

409:

407:

337:

304:

496:

494:

474:

472:

470:

381:

379:

377:

351:

349:

347:

345:

343:

341:

18:

221:where it was initially operated with

7:

14:

175:From 1909, Holzwarth worked with

319:

307:

27:

16:Early type of gas turbine engine

1:

164:and is now on display at the

487:(24): 543–544. 15 June 1912.

479:"What Inventors Are Doing".

193:Holzwarth Gasturbinen GmbH.

132:is a form of explosion, or

56:Electrical power generation

544:

26:

448:Noack, Walter G (1941).

457:The Brown Boveri Review

422:The Brown Boveri Review

177:Brown, Boveri & Cie

150:Hooven-Owens-Rentschler

358:Gas Turbine Powerhouse

258:

184:Prussian state railway

140:Design and Development

416:Meyer, Adolf (1939).

256:

130:Holzwarth gas turbine

22:Holzwarth gas turbine

481:Scientific American

286:to the atmosphere.

259:

290:Surviving example

276:surface condenser

227:blast furnace gas

126:

125:

69:Blast furnace gas

535:

507:

506:

498:

489:

488:

476:

465:

464:

454:

445:

430:

429:

413:

402:

401:

383:

372:

371:

353:

323:

311:

296:Deutsches Museum

166:Deutsches Museum

154:Thyssen & Co

113:Körting Brothers

37:workshop in 1908

35:Körting Brothers

31:

19:

543:

542:

538:

537:

536:

534:

533:

532:

513:

512:

511:

510:

503:The Gas Turbine

500:

499:

492:

478:

477:

468:

452:

447:

446:

433:

415:

414:

405:

398:

385:

384:

375:

368:

355:

354:

339:

334:

327:

326:Cutaway section

324:

315:

312:

292:

251:

225:and later with

160:'s workshop in

142:

134:constant volume

103:

38:

17:

12:

11:

5:

541:

539:

531:

530:

525:

515:

514:

509:

508:

490:

466:

431:

403:

396:

373:

366:

336:

335:

333:

330:

329:

328:

325:

318:

316:

313:

306:

291:

288:

250:

247:

141:

138:

124:

123:

110:

106:

105:

102:8 single-stage

100:

96:

95:

92:

88:

87:

86:Hans Holzwarth

84:

80:

79:

62:

58:

57:

54:

50:

49:

44:

43:Classification

40:

39:

32:

24:

23:

15:

13:

10:

9:

6:

4:

3:

2:

540:

529:

526:

524:

521:

520:

518:

504:

497:

495:

491:

486:

482:

475:

473:

471:

467:

462:

458:

451:

444:

442:

440:

438:

436:

432:

427:

423:

419:

412:

410:

408:

404:

399:

397:9781840372946

393:

389:

382:

380:

378:

374:

369:

367:9783486735710

363:

359:

352:

350:

348:

346:

344:

342:

338:

331:

322:

317:

310:

305:

303:

301:

297:

289:

287:

285:

279:

277:

273:

272:steam turbine

267:

263:

255:

248:

246:

244:

240:

235:

230:

228:

224:

220:

216:

210:

208:

207:Velox boilers

204:

200:

199:Aurel Stodola

195:

194:

189:

185:

180:

178:

173:

171:

167:

163:

159:

155:

151:

146:

139:

137:

135:

131:

122:

118:

114:

111:

109:Manufacturers

107:

101:

97:

93:

89:

85:

81:

78:

74:

70:

66:

63:

59:

55:

51:

48:

45:

41:

36:

30:

25:

20:

523:Gas turbines

502:

484:

480:

460:

456:

425:

421:

387:

357:

293:

280:

268:

264:

260:

243:World War II

231:

211:

202:

196:

192:

181:

174:

147:

143:

129:

127:

121:Brown Boveri

104:2 dual-stage

528:Gas engines

314:Gas Turbine

99:Total Units

61:Fuel source

53:Application

47:Gas turbine

517:Categories

332:References

284:economiser

215:steelworks

278:package.

249:Operation

188:coal dust

77:Coal dust

234:Mannheim

223:fuel oil

197:In 1927

91:Invented

83:Inventor

73:Fuel oil

65:Coal gas

219:Hamborn

162:Hanover

158:Körting

117:Thyssen

394:

364:

300:Munich

239:Allied

170:Munich

453:(PDF)

392:ISBN

362:ISBN

128:The

119:and

94:1908

485:106

298:in

217:in

168:in

75:or

519::

493:^

483:.

469:^

461:28

459:.

455:.

434:^

426:26

424:.

420:.

406:^

376:^

340:^

302:.

229:.

172:.

115:,

71:,

67:,

400:.

370:.

203:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.