749:, performed with either 3 gf or 9 gf loads, preceded the development of microhardness testers using traditional indenters. In 1925, Smith and Sandland of the UK developed an indentation test that employed a square-based pyramidal indenter made from diamond. They chose the pyramidal shape with an angle of 136° between opposite faces in order to obtain hardness numbers that would be as close as possible to Brinell hardness numbers for the specimen. The Vickers test has a great advantage of using one hardness scale to test all materials. The first reference to the Vickers indenter with low loads was made in the annual report of the

716:. Due to their specificity, microhardness testing can be used to observe changes in hardness on the microscopic scale. Unfortunately, it is difficult to standardize microhardness measurements; it has been found that the microhardness of almost any material is higher than its macrohardness. Additionally, microhardness values vary with load and work-hardening effects of materials. The two most commonly used microhardness tests are tests that also can be applied with heavier loads as macroindentation tests:

104:

857:. For spherical indenters the indentation is known to stay symmetrical and spherical, but with a larger radius. For very hard materials the radius can be three times as large as the indenter's radius. This effect is attributed to the release of elastic stresses. Because of this effect the diameter and depth of the indentation do contain errors. The error from the change in diameter is known to be only a few percent, with the error for the depth being greater.

124:. One key factor of instrumented indentation test is that the tip needs to be controlled by force or displacement that can be measured simultaneously throughout the indentation cycle. Current technology can realize accurate force control in a wide range. Therefore hardness can be characterized at many different length scales, from hard materials like ceramics to soft materials like polymers.

704:" has been widely employed in the literature to describe the hardness testing of materials with low applied loads. A more precise term is "microindentation hardness testing." In microindentation hardness testing, a diamond indenter of specific geometry is impressed into the surface of the test specimen using a known applied force (commonly called a "load" or "test load") of 1 to 1000

734:

testing can be done using

Vickers as well as Knoop indenters. For the Vickers test, both the diagonals are measured and the average value is used to compute the Vickers pyramid number. In the Knoop test, only the longer diagonal is measured, and the Knoop hardness is calculated based on the projected area of the indent divided by the applied force, also giving test units in kgf/mm.

91:). Hardness, however, cannot be considered to be a fundamental material property. Classical hardness testing usually creates a number which can be used to provide a relative idea of material properties. As such, hardness can only offer a comparative idea of the material's resistance to plastic deformation since different hardness techniques have different scales.

1075:

52:, but it is an imperfect correlation often limited to small ranges of strength and hardness for each indentation geometry. This relation permits economically important nondestructive testing of bulk metal deliveries with lightweight, even portable equipment, such as hand-held Rockwell hardness testers.

634:(HV), which has one of the widest scales. Widely used to test hardness of all kinds of metal materials (steel, nonferrous metals, tinsel, cemented carbide, sheet metal, etc.); surface layer / coating (Carburization, nitriding, decarburization layer, surface hardening layer, galvanized coating, etc.).

737:

The

Vickers microindentation test is carried out in a similar manner welling to the Vickers macroindentation tests, using the same pyramid. The Knoop test uses an elongated pyramid to indent material samples. This elongated pyramid creates a shallow impression, which is beneficial for measuring the

687:

Indentation procedures can, however, be used to extract genuine stress-strain relationships. Certain criteria need to be met if reliable results are to be obtained. These include the need to deform a relatively large volume, and hence to use large loads. The methodologies involved are often grouped

822:

For any given load, the hardness increases rapidly at low diagonal lengths, with the effect becoming more pronounced as the load decreases. Thus at low loads, small measurement errors will produce large hardness deviations. Thus one should always use the highest possible load in any test. Also, in

849:

Surface finish of the part and the indenter do not have an effect on the hardness measurement, as long as the indentation is large compared to the surface roughness. This proves to be useful when measuring the hardness of practical surfaces. It also is helpful when leaving a shallow indentation,

733:

In microindentation testing, the hardness number is based on measurements made of the indent formed in the surface of the test specimen. The hardness number is based on the applied force divided by the surface area of the indent itself, giving hardness units in kgf/mm. Microindentation hardness

94:

The equation based definition of hardness is the pressure applied over the contact area between the indenter and the material being tested. As a result hardness values are typically reported in units of pressure, although this is only a "true" pressure if the indenter and surface interface is

756:

There is some disagreement in the literature regarding the load range applicable to microhardness testing. ASTM Specification E384, for example, states that the load range for microhardness testing is 1 to 1000 gf. For loads of 1 kgf and below, the

Vickers hardness (HV) is calculated with an

683:

for hard steels, for example, some materials show qualitatively different behaviors under the various measurement methods. The

Vickers and Brinell hardness scales correlate well over a wide range, however, with Brinell only producing overestimated values at high loads.

868:

of the surrounding material. If the metal is work hardened it has a tendency to pile up and form a "crater". If the metal is annealed it will sink in around the indentation. Both of these effects add to the error of the hardness measurement.

403:

972:

1373:

R.L. Smith and G.E. Sandland, "An

Accurate Method of Determining the Hardness of Metals, with Particular Reference to Those of a High Degree of Hardness," Proceedings of the Institution of Mechanical Engineers, Vol. I, 1922, p

207:

111:

Instrumented indentation basically indents a sharp tip into the surface of a material to obtain a force-displacement curve. The results provide a lot of information about the mechanical behavior of the material, including

78:

Hardness measurements quantify the resistance of a material to plastic deformation. Indentation hardness tests compose the majority of processes used to determine material hardness, and can be divided into three classes:

817:

610:

558:

75:

testing. As a result, techniques testing material "hardness" by indenting a material with a very small impression have been developed to attempt to estimate these properties.

1281:

Shnyrev, G.D., Bulychev, S.I. & Alekhin, V.P. & Shorshorov, M.K. & Ternovskii, A.P. (1975). "Determining Young's modulus from the indentor penetration diagram".

961:

922:

45:. Several such tests exist, wherein the examined material is indented until an impression is formed; these tests can be performed on a macroscopic or microscopic scale.

1070:{\displaystyle C\approx {\begin{cases}3&{\text{large }}E/\sigma _{y}{\text{ (ex. metals)}}\\1.5&{\text{small }}E/\sigma _{y}{\text{ (ex. glasses)}}\end{cases}}}

294:

1300:

518:

460:

491:

433:

285:

895:

846:

effect of the process. However, it has been experimentally determined through "strainless hardness tests" that the effect is minimal with smaller indentations.

254:

230:

853:

The indentation that is left after the indenter and load are removed is known to "recover", or spring back slightly. This effect is properly known as

137:

1434:

1489:

750:

1228:"An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments"

1088:. Indentation hardness on the other hand is constrained in three dimensions which prevent shear from dominating the failure.

771:

615:

Commonly used indentation techniques, as well as detailed calculation of each different method, are discussed as follows.

1513:

1084:

apply. A uni-axial test only constrains the material in one dimension, which allows the material to fail as a result of

742:

or thin components. Both the Knoop and

Vickers indenters require polishing of the surface to achieve accurate results.

1097:

842:

The main sources of error with indentation tests are poor technique, poor calibration of the equipment, and the

679:

There is, in general, no simple relationship between the results of different hardness tests. Though there are

1508:

689:

569:

34:

1461:

1294:

720:

637:

631:

523:

42:

1239:

1135:

1081:

924:, of many materials is proportional to the hardness by a constant known as the constrain factor, C.

823:

the vertical portion of the curves, small measurement errors will produce large hardness deviations.

672:

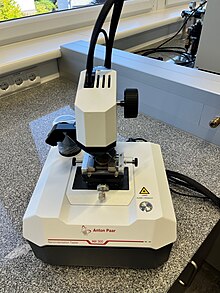

121:

987:

930:

1080:

The hardness differs from the uni-axial compressive yield stress of the material because different

746:

726:

680:

655:

649:

643:

103:

850:

because a finely etched indenter leaves a much easier to read indentation than a smooth indenter.

398:{\displaystyle {\frac {1}{E_{r}}}={\frac {1-\nu _{s}^{2}}{E_{s}}}+{\frac {1-\nu _{i}^{2}}{E_{i}}}}

127:

The earliest work was finished by

Bulychev, Alekhin, Shorshorov in the 1970s, who determined that

1263:

1153:

900:

131:

of a material can be determined from the slope of a force vs. displacement indentation curve as:

463:

128:

1485:

1440:

1430:

1255:

1194:

496:

438:

61:

1247:

1184:

1143:

897:, is defined as the mean contact pressure (load/ projected contact area), the yield stress,

843:

72:

49:

469:

411:

263:

832:

666:

117:

1173:"Indentation Hardness Measurements at Macro-, Micro-, and Nanoscale: A Critical Overview"

1243:

1139:

623:

The term "macroindentation" is applied to tests with a larger test load, such as 1

1102:

880:

660:

239:

215:

646:(HK), for measurement over small areas, widely used to test glass or ceramic material.

1502:

1267:

1157:

709:

87:

tests. Microindentation tests typically have forces less than 2 N (0.45 lb

1085:

753:

in 1932. Lips and Sack describes the first

Vickers tester using low loads in 1936.

739:

64:

at smaller scales. Measuring mechanical properties for materials, for instance, of

1479:

1227:

713:

663:(HR), principally used in the USA. HRA, HRB and HRC scales are most widely used.

202:{\displaystyle S={dP \over d\delta }={\frac {2}{\sqrt {\pi }}}E_{r}{\sqrt {A}}}

1189:

1172:

1148:

1123:

705:

65:

1444:

1259:

1198:

1124:"Correlation of Yield Strength and Tensile Strength with Hardness for Steels"

48:

When testing metals, indentation hardness correlates roughly linearly with

17:

1424:

1251:

113:

69:

38:

1216:

Meyers and Chawla (1999): "Mechanical

Behavior of Materials", 162–168.

102:

563:

The most critical information, hardness, can be calculated by:

627:

or more. There are various macroindentation tests, including:

624:

1063:

712:(roughly 200 gf) and produce indentations of about 50

708:. Microindentation tests typically have forces of 2

1362:

1350:

1338:

1326:

1314:

27:

Any measure of hardness based on indentation resistance

1429:(2nd ed.). New York: Springer. pp. 156–157.

860:

Another effect the load has on the indentation is the

812:{\displaystyle HV=0.0018544\times {\tfrac {L}{d^{2}}}}

791:

975:

933:

903:

883:

774:

572:

526:

499:

472:

441:

414:

297:

266:

242:

232:: material stiffness, which is the slope of the curve

218:

140:

761:) is in grams force and the mean of two diagonals (

669:, for polymers, widely used in the rubber industry.

1069:

955:

916:

889:

811:

604:

552:

512:

485:

454:

427:

397:

279:

248:

224:

201:

1128:Journal of Materials Engineering and Performance

1212:

1210:

1208:

8:

1299:: CS1 maint: multiple names: authors list (

692:, which is described in a separate article.

560:, the second term can typically be ignored.

520:are that of the indenter. Since typically,

60:Different techniques are used to quantify

1188:

1147:

1055:

1049:

1040:

1032:

1018:

1012:

1003:

995:

982:

974:

947:

932:

908:

902:

882:

800:

790:

773:

585:

579:

571:

544:

531:

525:

504:

498:

477:

471:

446:

440:

419:

413:

387:

376:

371:

358:

347:

336:

331:

318:

307:

298:

296:

271:

265:

241:

217:

192:

186:

170:

147:

139:

745:Scratch tests at low loads, such as the

1226:Oliver, W.C.; Pharr, G.M. (June 1992).

1114:

1292:

1122:Pavlina, E.J.; Van Tyne, C.J. (2008).

605:{\displaystyle H={\frac {P_{max}}{A}}}

1418:

1416:

7:

68:, cannot be done using conventional

1423:Fischer-Cripps, Anthony C. (2007).

1462:"Pinball Tester Reveals Hardness."

553:{\displaystyle E_{i}>>E_{s}}

25:

1426:Introduction to contact mechanics

640:(HB) BHN and HBW are widely used

1171:Broitman, Esteban (March 2017).

107:Instrumented Indentation Tester

956:{\displaystyle H=C\sigma _{y}}

287:: reduced modulus, defined as:

1:

1232:Journal of Materials Research

740:hardness of brittle materials

256:: the tip-sample contact area

1467:, November 1945, p. 75.

751:National Physical Laboratory

747:Bierbaum microcharacter test

462:are the Young's modulus and

1484:, Oxford University Press,

1349:EBP Rockwell hardness test

917:{\displaystyle \sigma _{y}}

681:practical conversion tables

1530:

1325:EBP Brinell hardness test

1313:EBP Vickers hardness test

1098:Leeb rebound hardness test

830:

675:, for composite materials.

1190:10.1007/s11249-016-0805-5

1149:10.1007/s11665-008-9225-5

1082:compressive failure modes

1361:EBP Shore hardness test

1337:EBP Knoop hardness test

873:Relation to yield stress

757:equation, wherein load (

513:{\displaystyle \nu _{i}}

455:{\displaystyle \nu _{s}}

99:Instrumented indentation

62:material characteristics

1283:Zavodskaya Laboratoriya

690:Indentation plastometry

1481:The Hardness of Metals

1071:

957:

918:

891:

813:

696:Microindentation tests

661:Rockwell hardness test

619:Macroindentation tests

606:

554:

514:

487:

456:

429:

399:

281:

250:

226:

203:

108:

35:mechanical engineering

1478:Tabor, David (2000),

1252:10.1557/JMR.1992.1564

1072:

958:

919:

892:

827:Nanoindentation tests

814:

765:) is in millimeters:

721:Vickers hardness test

638:Brinell hardness test

632:Vickers hardness test

607:

555:

515:

488:

486:{\displaystyle E_{i}}

457:

430:

428:{\displaystyle E_{s}}

400:

282:

280:{\displaystyle E_{r}}

251:

227:

204:

106:

1363:http://www.hiebp.com

1351:http://www.hiebp.com

1339:http://www.hiebp.com

1327:http://www.hiebp.com

1315:http://www.hiebp.com

973:

931:

901:

881:

772:

673:Barcol hardness test

570:

524:

497:

470:

439:

412:

295:

264:

240:

216:

138:

31:Indentation hardness

1514:Physical quantities

1244:1992JMatR...7.1564O

1140:2008JMEP...17..888P

1057: (ex. glasses)

727:Knoop hardness test

667:Shore hardness test

656:Meyer hardness test

650:Janka hardness test

644:Knoop hardness test

381:

341:

122:plastic deformation

1067:

1062:

1020: (ex. metals)

953:

914:

887:

809:

807:

602:

550:

510:

483:

466:of the sample, an

452:

425:

395:

367:

327:

277:

246:

222:

199:

109:

33:tests are used in

1465:Popular Mechanics

1436:978-0-387-68188-7

1401:Tabor, pp. 14-15.

1177:Tribology Letters

1058:

1035:

1021:

998:

890:{\displaystyle H}

806:

600:

393:

353:

313:

249:{\displaystyle A}

225:{\displaystyle S}

197:

180:

179:

165:

56:Material hardness

41:of a material to

37:to determine the

16:(Redirected from

1521:

1494:

1449:

1448:

1420:

1411:

1408:

1402:

1399:

1393:

1390:

1384:

1381:

1375:

1371:

1365:

1359:

1353:

1347:

1341:

1335:

1329:

1323:

1317:

1311:

1305:

1304:

1298:

1290:

1278:

1272:

1271:

1238:(6): 1564–1583.

1223:

1217:

1214:

1203:

1202:

1192:

1168:

1162:

1161:

1151:

1119:

1076:

1074:

1073:

1068:

1066:

1065:

1059:

1056:

1054:

1053:

1044:

1036:

1033:

1022:

1019:

1017:

1016:

1007:

999:

996:

962:

960:

959:

954:

952:

951:

923:

921:

920:

915:

913:

912:

896:

894:

893:

888:

844:strain hardening

838:Sources of error

818:

816:

815:

810:

808:

805:

804:

792:

611:

609:

608:

603:

601:

596:

595:

580:

559:

557:

556:

551:

549:

548:

536:

535:

519:

517:

516:

511:

509:

508:

492:

490:

489:

484:

482:

481:

461:

459:

458:

453:

451:

450:

434:

432:

431:

426:

424:

423:

404:

402:

401:

396:

394:

392:

391:

382:

380:

375:

359:

354:

352:

351:

342:

340:

335:

319:

314:

312:

311:

299:

286:

284:

283:

278:

276:

275:

255:

253:

252:

247:

231:

229:

228:

223:

208:

206:

205:

200:

198:

193:

191:

190:

181:

175:

171:

166:

164:

156:

148:

95:perfectly flat.

50:tensile strength

21:

1529:

1528:

1524:

1523:

1522:

1520:

1519:

1518:

1499:

1498:

1492:

1477:

1474:

1458:

1453:

1452:

1437:

1422:

1421:

1414:

1409:

1405:

1400:

1396:

1391:

1387:

1382:

1378:

1372:

1368:

1360:

1356:

1348:

1344:

1336:

1332:

1324:

1320:

1312:

1308:

1291:

1289:(9): 1137–1140.

1280:

1279:

1275:

1225:

1224:

1220:

1215:

1206:

1170:

1169:

1165:

1121:

1120:

1116:

1111:

1094:

1061:

1060:

1045:

1030:

1024:

1023:

1008:

993:

983:

971:

970:

943:

929:

928:

904:

899:

898:

879:

878:

877:When hardness,

875:

840:

835:

833:Nanoindentation

829:

796:

770:

769:

698:

688:under the term

621:

581:

568:

567:

540:

527:

522:

521:

500:

495:

494:

473:

468:

467:

464:Poisson's ratio

442:

437:

436:

415:

410:

409:

383:

360:

343:

320:

303:

293:

292:

267:

262:

261:

238:

237:

214:

213:

182:

157:

149:

136:

135:

129:Young's modulus

101:

90:

85:nanoindentation

58:

28:

23:

22:

15:

12:

11:

5:

1527:

1525:

1517:

1516:

1511:

1509:Hardness tests

1501:

1500:

1497:

1496:

1490:

1473:

1470:

1469:

1468:

1457:

1456:External links

1454:

1451:

1450:

1435:

1412:

1403:

1394:

1385:

1376:

1366:

1354:

1342:

1330:

1318:

1306:

1273:

1218:

1204:

1163:

1134:(6): 888–893.

1113:

1112:

1110:

1107:

1106:

1105:

1100:

1093:

1090:

1078:

1077:

1064:

1052:

1048:

1043:

1039:

1031:

1029:

1026:

1025:

1015:

1011:

1006:

1002:

994:

992:

989:

988:

986:

981:

978:

964:

963:

950:

946:

942:

939:

936:

911:

907:

886:

874:

871:

839:

836:

831:Main article:

828:

825:

820:

819:

803:

799:

795:

789:

786:

783:

780:

777:

731:

730:

724:

697:

694:

677:

676:

670:

664:

658:

653:

647:

641:

635:

620:

617:

613:

612:

599:

594:

591:

588:

584:

578:

575:

547:

543:

539:

534:

530:

507:

503:

480:

476:

449:

445:

422:

418:

406:

405:

390:

386:

379:

374:

370:

366:

363:

357:

350:

346:

339:

334:

330:

326:

323:

317:

310:

306:

302:

289:

288:

274:

270:

258:

257:

245:

234:

233:

221:

210:

209:

196:

189:

185:

178:

174:

169:

163:

160:

155:

152:

146:

143:

118:elastic moduli

100:

97:

88:

57:

54:

26:

24:

14:

13:

10:

9:

6:

4:

3:

2:

1526:

1515:

1512:

1510:

1507:

1506:

1504:

1493:

1491:0-19-850776-3

1487:

1483:

1482:

1476:

1475:

1471:

1466:

1463:

1460:

1459:

1455:

1446:

1442:

1438:

1432:

1428:

1427:

1419:

1417:

1413:

1410:Tabor, p. 15.

1407:

1404:

1398:

1395:

1392:Tabor, p. 14.

1389:

1386:

1383:Tabor, p. 16.

1380:

1377:

1370:

1367:

1364:

1358:

1355:

1352:

1346:

1343:

1340:

1334:

1331:

1328:

1322:

1319:

1316:

1310:

1307:

1302:

1296:

1288:

1284:

1277:

1274:

1269:

1265:

1261:

1257:

1253:

1249:

1245:

1241:

1237:

1233:

1229:

1222:

1219:

1213:

1211:

1209:

1205:

1200:

1196:

1191:

1186:

1182:

1178:

1174:

1167:

1164:

1159:

1155:

1150:

1145:

1141:

1137:

1133:

1129:

1125:

1118:

1115:

1108:

1104:

1101:

1099:

1096:

1095:

1091:

1089:

1087:

1083:

1050:

1046:

1041:

1037:

1027:

1013:

1009:

1004:

1000:

990:

984:

979:

976:

969:

968:

967:

948:

944:

940:

937:

934:

927:

926:

925:

909:

905:

884:

872:

870:

867:

863:

858:

856:

851:

847:

845:

837:

834:

826:

824:

801:

797:

793:

787:

784:

781:

778:

775:

768:

767:

766:

764:

760:

754:

752:

748:

743:

741:

735:

728:

725:

722:

719:

718:

717:

715:

711:

707:

703:

702:microhardness

695:

693:

691:

685:

682:

674:

671:

668:

665:

662:

659:

657:

654:

651:

648:

645:

642:

639:

636:

633:

630:

629:

628:

626:

618:

616:

597:

592:

589:

586:

582:

576:

573:

566:

565:

564:

561:

545:

541:

537:

532:

528:

505:

501:

478:

474:

465:

447:

443:

420:

416:

388:

384:

377:

372:

368:

364:

361:

355:

348:

344:

337:

332:

328:

324:

321:

315:

308:

304:

300:

291:

290:

272:

268:

260:

259:

243:

236:

235:

219:

212:

211:

194:

187:

183:

176:

172:

167:

161:

158:

153:

150:

144:

141:

134:

133:

132:

130:

125:

123:

119:

115:

105:

98:

96:

92:

86:

82:

76:

74:

71:

67:

63:

55:

53:

51:

46:

44:

40:

36:

32:

19:

1480:

1472:Bibliography

1464:

1425:

1406:

1397:

1388:

1379:

1369:

1357:

1345:

1333:

1321:

1309:

1295:cite journal

1286:

1282:

1276:

1235:

1231:

1221:

1180:

1176:

1166:

1131:

1127:

1117:

1079:

965:

876:

865:

861:

859:

854:

852:

848:

841:

821:

762:

758:

755:

744:

736:

732:

701:

699:

686:

678:

622:

614:

562:

407:

126:

110:

93:

84:

81:macro, micro

80:

77:

59:

47:

30:

29:

1103:Meyer's law

1034:small

997:large

43:deformation

18:Indent test

1503:Categories

1109:References

866:sinking-in

855:shallowing

700:The term "

652:, for wood

66:thin films

1445:187014877

1268:137098960

1260:0884-2914

1199:1023-8883

1183:(1): 23.

1158:135890256

1047:σ

1010:σ

980:≈

945:σ

906:σ

862:piling-up

788:×

785:0.0018544

502:ν

444:ν

369:ν

365:−

329:ν

325:−

177:π

162:δ

1374:623–641.

1092:See also

538:>>

116:, e.g.,

114:hardness

70:uniaxial

39:hardness

1240:Bibcode

1136:Bibcode

966:where:

73:tensile

1488:

1443:

1433:

1266:

1258:

1197:

1156:

408:Where

1264:S2CID

1154:S2CID

1086:shear

1486:ISBN

1441:OCLC

1431:ISBN

1301:link

1256:ISSN

1195:ISSN

729:(HK)

723:(HV)

493:and

435:and

120:and

83:and

1248:doi

1185:doi

1144:doi

1028:1.5

864:or

625:kgf

1505::

1439:.

1415:^

1297:}}

1293:{{

1287:41

1285:.

1262:.

1254:.

1246:.

1234:.

1230:.

1207:^

1193:.

1181:65

1179:.

1175:.

1152:.

1142:.

1132:17

1130:.

1126:.

714:μm

706:gf

1495:.

1447:.

1303:)

1270:.

1250::

1242::

1236:7

1201:.

1187::

1160:.

1146::

1138::

1051:y

1042:/

1038:E

1014:y

1005:/

1001:E

991:3

985:{

977:C

949:y

941:C

938:=

935:H

910:y

885:H

802:2

798:d

794:L

782:=

779:V

776:H

763:d

759:L

710:N

598:A

593:x

590:a

587:m

583:P

577:=

574:H

546:s

542:E

533:i

529:E

506:i

479:i

475:E

448:s

421:s

417:E

389:i

385:E

378:2

373:i

362:1

356:+

349:s

345:E

338:2

333:s

322:1

316:=

309:r

305:E

301:1

273:r

269:E

244:A

220:S

195:A

188:r

184:E

173:2

168:=

159:d

154:P

151:d

145:=

142:S

89:f

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.