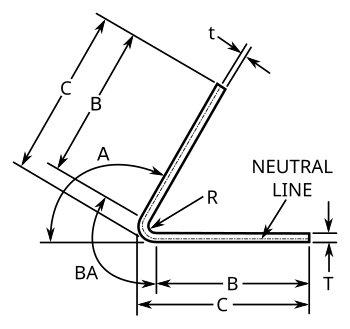

395:(the required length of the material prior to bending) and the formed bend. Subtracting them from the combined length of both flanges gives the flat pattern length. The question of which to use is determined by the dimensioning method used to define the flanges as shown in the two diagrams below. The flat pattern length is always shorter in length than the sum of all the flange length dimensions due to the geometric transformation. This gives rise to the common perspective that that material is stretching during bending and the bend deduction and bend allowance are the distance that each bend stretches. While a helpful way to look at it, a careful examination of the formulas and stresses involved show this to be false.

414:(BA) is the length of the arc of the neutral line between the tangent points of a bend in any material. Adding the length of each flange as dimensioned by B in the diagram to the BA gives the Flat Pattern length. This bend allowance formula is used to determine the flat pattern length when a bend is dimensioned from 1) the center of the radius, 2) a tangent point of the radius (B) or 3) the outside tangent point of the radius on an acute angle bend (C). When dimensioned to the outside tangent, the material thickness and bend radius are subtracted from it to find the dimension to the tangent point of the radius before adding in the bend allowance.

156:

a long rail form tool with a radiused tip that locates the inside profile of the bend is called a punch. Punches are usually attached to the ram of the machine by clamps and move to produce the bending force. A die with a long rail form tool that has concave or V-shaped lengthwise channel that locate the outside profile of the form is called a die. Dies are usually stationary and located under the material on the bed of the machine. Note that some locations do not differentiate between the two different kinds of dies (punches and dies). The other types of bending listed use specially designed tools or machines to perform the work.

502:

203:

T for 12 mm thick sheets. The bending radius must be at least 0.8 T to 2 T for sheet steel. Larger bend radii require about the same force for bottoming as they do for air bending, however, smaller radii require greater force—up to five times as much—than air bending. Advantages of bottoming include greater accuracy and less springback. A disadvantage is that a different tool set is needed for each bend angle, sheet thickness, and material. In general, air bending is the preferred technique.

38:

570:

145:

310:, is an offset bending process in which two opposite bends with equal angles are formed in a single action creating a small s-shape bend profile and an offset between the unbent face and the result flange that is typically less than 5 material thicknesses. Often the offset will be one material thickness, in order to allow a lap joint where the edge of one sheet of material is laid on top of the other.

296:

101:

46:

260:

180:

Air bending's angle accuracy is approximately ±0.5 deg. Angle accuracy is ensured by applying a value to the width of the V opening, ranging from 6 T (six times material thickness) for sheets to 3 mm thick to 12 T for sheets more than 10 mm thick. Springback depends on material properties,

164:

This bending method forms material by pressing a punch (also called the upper or top die) into the material, forcing it into a bottom V-die, which is mounted on the press. The punch forms the bend so that the distance between the punch and the side wall of the V is greater than the material thickness

757:

is a ratio of the location of the neutral line to the material thickness as defined by t/T where t = location of the neutral line and T = material thickness. The K-factor formula does not take the forming stresses into account but is simply a geometric calculation of the location of the neutral line

281:

In this method, the bottom V-die is replaced by a flat pad of urethane or rubber. As the punch forms the part, the urethane deflects and allows the material to form around the punch. This bending method has a number of advantages. The urethane will wrap the material around the punch and the end bend

229:

In folding, clamping beams hold the longer side of the sheet. The beam rises and folds the sheet around a bend profile. The bend beam can move the sheet up or down, permitting the fabricating of parts with positive and negative bend angles. The resulting bend angle is influenced by the folding angle

202:

In bottoming, the sheet is forced against the V opening in the bottom tool. U-shaped openings cannot be used. Space is left between the sheet and the bottom of the V opening. The optimum width of the V opening is 6 T (T stands for material thickness) for sheets about 3 mm thick, up to about 12

155:

There are three basic types of bending on a press brake, each is defined by the relationship of the end tool position to the thickness of the material. These three are Air

Bending, Bottoming and Coining. The configuration of the tools for these three types of bending are nearly identical. A die with

387:

during the bend. Its location in the material is a function of the forces used to form the part and the material yield and tensile strengths. This theoretical definition also coincides with the geometric definition of the plane representing the unbent flat pattern shape within the cross-section of

286:

with relieved areas on the urethane U-bends greater than 180° can be achieved in one hit, something that is not possible with conventional press tooling. Urethane tooling should be considered a consumable item and while they are not cheap, they are a fraction of the cost of dedicated steel. It also

211:

In coining, the top tool forces the material into the bottom die with 5 to 30 times the force of air bending, causing permanent deformation through the sheet. There is little, if any, spring back. Coining can produce an inside radius as low as 0.4 T, with a 5 T width of the V opening. While coining

1134:

Bending is a cost-effective near net shape process when used for low to medium quantities. Parts usually are lightweight with good mechanical properties. A disadvantage is that some process variants are sensitive to variations in material properties. For instance, differences in spring-back have a

176:

A disadvantage of air bending is that, because the sheet does not stay in full contact with the dies, it is not as precise as some other methods, and stroke depth must be kept very accurate. Variations in the thickness of the material and wear on the tools can result in defects in parts produced.

238:

In wiping, the longest end of the sheet is clamped, then the tool moves up and down, bending the sheet around the bend profile. Though faster than folding, wiping has a higher risk of producing scratches or otherwise damaging the sheet, because the tool is moving over the sheet surface. The risk

1138:

Broadly speaking, each bend corresponds with a set-up (although sometimes, multiple bends can be formed simultaneously). The relatively large number of set-ups and the geometrical changes during bending make it difficult to address tolerances and bending errors a priori during set-up planning,

318:

Many variations of these formulas exist and are readily available online. These variations may often seem to be at odds with one another, but they are invariably the same formulas simplified or combined. What is presented here are the unsimplified formulas. All formulas use the following keys:

758:

after the forces are applied and is thus the roll-up of all the unknown (error) factors for a given setup. The K-factor depends on many variables including the material, the type of bending operation (coining, bottoming, air-bending, etc.) the tools, etc. and is typically between 0.3 and 0.5.

250:

Rotary bending is similar to wiping but the top die is made of a freely rotating cylinder with the final formed shape cut into it and a matching bottom die. On contact with the sheet, the roll contacts on two points and it rotates as the forming process bends the sheet. This bending method is

220:

Three-point bending is a newer process that uses a die with an adjustable-height bottom tool, moved by a servo motor. The height can be set within 0.01 mm. Adjustments between the ram and the upper tool are made using a hydraulic cushion, which accommodates deviations in sheet thickness.

172:

Some of the newer bottom tools are adjustable, so, by using a single set of top and bottom tools and varying press-stroke depth, different profiles and products can be produced. Different materials and thicknesses can be bent in varying bend angles, adding the advantage of flexibility to air

190:

The flexibility and relatively low tonnage required by air bending are helping to make it a popular choice. Quality problems associated with this method are countered by angle-measuring systems, clamps and crowning systems adjustable along the x and y axes, and wear-resistant tools.

287:

has some drawbacks, this method requires tonnage similar to bottoming and coining and does not do well on flanges that are irregular in shape, that is where the edge of the bent flange is not parallel to the bend and is short enough to engage the urethane pad.

221:

Three-point bending can achieve bend angles with 0.25 deg. precision. While three-point bending permits high flexibility and precision, it also entails high costs and there are fewer tools readily available. It is being used mostly in high-value niche markets.

1124:

124:

towards its original position, so the sheet must be over-bent to achieve the proper bend angle. The amount of spring back is dependent on the material, and the type of forming. When sheet metal is bent, it stretches in length. The

388:

the bent part. Furthermore, the bend allowance (see below) in air bending depends primarily on the width of the opening of the bottom die. As a result, the bending process is more complicated than it appears to be at first sight.

496:

168:

Either a V-shaped or square opening may be used in the bottom die (dies are frequently referred to as tools or tooling). Because it requires less bend force, air bending tends to use smaller tools than other methods.

251:

typically considered a "non-marking" forming process suitable to pre-painted or easily marred surfaces. This bending process can produce angles greater than 90° in a single hit on standard press brakes process.

834:

662:

1135:

direct influence on the resulting bend angle. To mitigate this, various methods for in-process control have been developed. Other approaches include combining brakeforming with incremental forming.

744:

1258:

De Vin, L.J., Streppel, A.H., Singh, U.P. & Kals, H.J.J. A process model for air bending. Journal of

Materials Processing Technology, Volume 57, Issues 1–2, 1 February 1996, Pages 48-54

242:

This method will typically bottom or coin the material to set the edge to help overcome springback. In this bending method, the radius of the bottom die determines the final bending radius.

230:

of the beam, tool geometry, and material properties. Large sheets can be handled in this process, making the operation easily automated. There is little risk of surface damage to the sheet.

1489:

Lutters, D., Streppel, A. H., Kroeze, B. & Kals, H. J. J., Adaptive press brake control in air bending, Proc. of the Shemet97 Conference, Belfast, pp. 471–480, 1997.

282:

radius will be very close to the actual radius on the punch. It provides a non-marring bend and is suitable for pre-painted or sensitive materials. Using a special punch called a

108:

In press brake forming, the work piece is positioned over a die block and a punch then presses the sheet into the die block to form a shape. Usually bending has to overcome both

194:

The K-factor approximations given below are more likely to be accurate for air bending than the other types of bending due to the lower forces involved in the forming process.

1363:

De Vin, L.J., Expecting the unexpected, a must for accurate brakeforming, Journal of

Materials Processing Technology, Volume 117, Issues 1–2, 2 November 2001, Pages 244-248.

1289:

1028:

1576:

187:

Air bending does not require the bottom tool to have the same radius as the punch. Bend radius is determined by material elasticity rather than tool shape.

588:(BD) is twice the outside setback minus the bend allowance. BD is calculated using the following formula, where A is the angle in radians (=degrees*π/180):

1350:

1231:

423:

577:

The bend deduction BD is defined as the difference between the sum of the flange lengths (from the edge to the apex) and the initial flat length.

1537:

133:

refers to the inside radius. The formed bend radius is dependent upon the dies used, the material properties, and the material thickness.

1554:

1387:

1429:

767:

594:

1169:

1377:

1402:

673:

1457:

1319:

1602:

356:) is an imaginary profile that can be drawn through a cross-section of the workpiece that represents the locus where no

1286:

1164:

273:

The roll bending process induces a curve into bar or plate workpieces. There should be proper pre-punching allowance.

1597:

1242:

129:

is the amount the sheet metal will stretch when bent as measured from the outside edges of the bend. The

399:

361:

584:(OSSB) is the length from the tangent point of the radius to the apex of the outside of the bend. The

1502:. Journal of Materials Processing Technology. Volume 120, Issues 1–3, 15 January 2002, Pages 322–326.

85:

1305:

1174:

391:

Both bend deduction and bend allowance represent the difference between the neutral line or unbent

1179:

371:

stresses are at their maximum. In the bend region, the material between the neutral line and the

364:

113:

1582:

417:

The BA can be estimated using the following formula, which incorporates the empirical K-factor:

1550:

1533:

1383:

1344:

357:

73:

1119:{\displaystyle K={\frac {\log \min \left(100,{\frac {\max(20R,T)}{T}}\right)}{2\log 100}}.}

37:

1293:

184:

Depending on material properties, the sheet may be overbent to compensate for springback.

50:

1563:

109:

1435:

144:

17:

1591:

402:

has sheet metal functions or add-ons that performs these calculations automatically.

81:

61:

31:

64:

process that produces a V-shape, U-shape, or channel shape along a straight axis in

1154:

368:

353:

268:

1408:

1544:

1499:

1364:

1159:

295:

100:

89:

77:

69:

1466:

1326:

1259:

573:

Diagram showing standard dimensioning scheme when using bend deduction formulas

839:

The following table is a "rule of thumb". Actual results may vary remarkably.

491:{\displaystyle BA=A\left({\frac {\pi }{180}}\right)\left(R+(K\times T\right))}

45:

569:

501:

149:

344:

A = bend angle in degrees (the angle through which the material is bent)

212:

can attain high precision, higher costs mean that it is not often used.

1148:

299:

A joggle bend in sheet metal (at top of image) and a hand joggling tool

259:

173:

bending. There are also fewer tool changes, thus, higher productivity.

65:

1512:

1203:

Manufacturing

Processes Reference Guide, Industrial Press Inc., 1994.

116:. When bending is done, the residual stresses cause the material to

379:

during the bend while the material between the neutral line and the

761:

The following equation relates the K-factor to the bend allowance:

1018:

The following formula can be used in place of the table as a good

568:

500:

294:

258:

143:

99:

1530:

Press Brake

Technology: A Guide to Precision Sheet Metal Bending.

30:"Metal bending" redirects here. For the form of stage magic, see

84:. Typical products that are made like this are boxes such as

1379:

667:

For bends at 90 degrees this formula can be simplified to:

1225:

1223:

1221:

1219:

1217:

1215:

1213:

1211:

1209:

829:{\displaystyle K={\frac {-R+{\frac {BA}{\pi A/180}}}{T}}.}

657:{\displaystyle BD=2\left(R+T\right)\tan {\frac {A}{2}}-BA}

1513:

Tolerance

Reasoning and Set-Up Planning for Brakeforming

1515:, Int. J. Adv. Manuf. Technol., 1998, Vol. 14, 336–342.

1306:"Press Brake Training die Bending | Tooling U-SME"

1277:, 4th Edition, Society of Manufacturing Engineers, 1984

739:{\displaystyle BD=R\left(2-A\right)+T\left(2-KA\right)}

177:

Thus, the use of adequate process models is important.

1543:

Todd, Robert H.; Allen, Dell K.; Alting, Leo (1994),

1031:

770:

676:

597:

426:

1564:

https://prestigemetals.com/metal-bending-technology/

1404:

How to

Calculate Bend Allowance for Your Press Brake

1118:

828:

738:

656:

490:

341:t = distance from inside face to the neutral line

136:The U-punch forms a U-shape with a single punch.

27:Metalworking to produce a V-, U- or channel shape

1064:

1047:

1579:Fabricating & Metalworking, February 2010.

239:increases if sharp angles are being produced.

1511:L. J. De Vin & A. H. Streppel,

1365:https://doi.org/10.1016/S0924-0136(01)01140-2

1232:"Press Brake Bending: Methods and Challenges"

8:

1260:https://doi.org/10.1016/0924-0136(95)02043-8

1500:Process planning for laser-assisted forming

1532:Society of Manufacturing Engineers, 1997.

1271:Tool and Manufacturing Engineers Handbook

1061:

1038:

1030:

806:

789:

777:

769:

675:

635:

596:

443:

425:

841:

507:

44:

36:

1583:Bend allowance and deduction calculator

1546:Manufacturing Processes Reference Guide

1191:

1349:: CS1 maint: archived copy as title (

1342:

1199:

1197:

1195:

1139:although some attempts have been made

181:influencing the resulting bend angle.

7:

1498:J. Magee & L. J. De Vin,

72:. Commonly used equipment include

25:

1382:, Princeton Architectural Press,

1022:of the K-factor for air bending:

1170:Bending machine (manufacturing)

1082:

1067:

485:

468:

400:3D Solid Modeling CAD software

148:A schematic of coining with a

1:

1376:Iwamoto, Lisa (2 July 2013),

335:K = K-factor, which is t / T

323:Lf = flat length of the sheet

53:, a sample product of bending

1130:Advantages and disadvantages

1001:

987:

973:

952:

938:

924:

903:

889:

875:

1165:Brake (sheet metal bending)

1619:

1456:Diegel, Olaf (July 2002),

1431:Sheet metal bend deduction

1003:Greater than 3 × thickness

989:Thickness to 3 × thickness

954:Greater than 3 × thickness

940:Thickness to 3 × thickness

905:Greater than 3 × thickness

891:Thickness to 3 × thickness

266:

29:

1549:, Industrial Press Inc.,

967:

918:

869:

847:

68:materials, most commonly

1292:August 20, 2010, at the

80:, and other specialized

1241:: 38–43, archived from

338:T = material thickness

332:R = inside bend radius

1230:F., M. (August 2008),

1120:

830:

740:

658:

574:

505:

492:

300:

264:

152:

105:

54:

42:

18:K-factor (sheet metal)

1121:

831:

741:

659:

572:

504:

493:

383:radius will be under

375:radius will be under

298:

262:

147:

103:

86:electrical enclosures

48:

40:

1029:

768:

674:

595:

424:

114:compressive stresses

1603:Fabrication (metal)

1577:"Bending Made Easy"

1175:Hemming and seaming

329:BD = bend deduction

326:BA = bend allowance

216:Three-point bending

1287:3-81. DRAW FORMING

1180:Automotive hemming

1116:

826:

736:

654:

575:

506:

488:

301:

265:

153:

106:

74:box and pan brakes

55:

43:

1538:978-0-87263-483-1

1528:Benson, Steve D.

1111:

1089:

1016:

1015:

845:Generic K-factors

821:

815:

643:

562:

561:

451:

352:(also called the

277:Elastomer bending

16:(Redirected from

1610:

1560:

1516:

1509:

1503:

1496:

1490:

1487:

1481:

1480:

1478:

1477:

1471:

1465:, archived from

1464:

1453:

1447:

1446:

1444:

1443:

1434:, archived from

1426:

1420:

1419:

1417:

1416:

1407:, archived from

1399:

1393:

1392:

1373:

1367:

1361:

1355:

1354:

1348:

1340:

1338:

1337:

1331:

1325:. Archived from

1324:

1316:

1310:

1309:

1302:

1296:

1284:

1278:

1268:

1262:

1256:

1250:

1249:

1247:

1236:

1227:

1204:

1201:

1125:

1123:

1122:

1117:

1112:

1110:

1096:

1095:

1091:

1090:

1085:

1062:

1039:

862:Medium materials

842:

835:

833:

832:

827:

822:

817:

816:

814:

810:

798:

790:

778:

745:

743:

742:

737:

735:

731:

707:

703:

663:

661:

660:

655:

644:

636:

628:

624:

582:outside set back

508:

497:

495:

494:

489:

484:

480:

456:

452:

444:

367:are present but

306:, also known as

122:

121:

110:tensile stresses

88:and rectangular

21:

1618:

1617:

1613:

1612:

1611:

1609:

1608:

1607:

1588:

1587:

1572:

1557:

1542:

1525:

1520:

1519:

1510:

1506:

1497:

1493:

1488:

1484:

1475:

1473:

1469:

1462:

1455:

1454:

1450:

1441:

1439:

1428:

1427:

1423:

1414:

1412:

1401:

1400:

1396:

1390:

1375:

1374:

1370:

1362:

1358:

1341:

1335:

1333:

1329:

1322:

1320:"Archived copy"

1318:

1317:

1313:

1304:

1303:

1299:

1294:Wayback Machine

1285:

1281:

1269:

1265:

1257:

1253:

1245:

1234:

1229:

1228:

1207:

1202:

1193:

1188:

1145:

1132:

1097:

1063:

1054:

1050:

1040:

1027:

1026:

865:Hard materials

799:

791:

779:

766:

765:

752:

718:

714:

693:

689:

672:

671:

614:

610:

593:

592:

567:

461:

457:

439:

422:

421:

408:

316:

293:

279:

271:

257:

248:

236:

227:

218:

209:

200:

162:

142:

119:

118:

104:Bending process

98:

82:machine presses

51:chimney starter

35:

28:

23:

22:

15:

12:

11:

5:

1616:

1614:

1606:

1605:

1600:

1590:

1589:

1586:

1585:

1580:

1575:Latang, Paul.

1571:

1570:External links

1568:

1567:

1566:

1561:

1555:

1540:

1524:

1521:

1518:

1517:

1504:

1491:

1482:

1448:

1421:

1394:

1388:

1368:

1356:

1311:

1297:

1279:

1263:

1251:

1248:on 2011-07-14.

1205:

1190:

1189:

1187:

1184:

1183:

1182:

1177:

1172:

1167:

1162:

1157:

1152:

1144:

1141:

1131:

1128:

1127:

1126:

1115:

1109:

1106:

1103:

1100:

1094:

1088:

1084:

1081:

1078:

1075:

1072:

1069:

1066:

1060:

1057:

1053:

1049:

1046:

1043:

1037:

1034:

1014:

1013:

1010:

1007:

1004:

1000:

999:

996:

993:

990:

986:

985:

982:

979:

976:

975:0 to thickness

972:

971:

965:

964:

961:

958:

955:

951:

950:

947:

944:

941:

937:

936:

933:

930:

927:

926:0 to thickness

923:

922:

916:

915:

912:

909:

906:

902:

901:

898:

895:

892:

888:

887:

884:

881:

878:

877:0 to thickness

874:

873:

867:

866:

863:

860:

859:Soft materials

857:

853:

852:

849:

846:

837:

836:

825:

820:

813:

809:

805:

802:

797:

794:

788:

785:

782:

776:

773:

751:

748:

747:

746:

734:

730:

727:

724:

721:

717:

713:

710:

706:

702:

699:

696:

692:

688:

685:

682:

679:

665:

664:

653:

650:

647:

642:

639:

634:

631:

627:

623:

620:

617:

613:

609:

606:

603:

600:

586:bend deduction

566:

565:Bend deduction

563:

560:

559:

554:

552:Bend allowance

548:

547:

544:

540:

539:

536:

532:

531:

528:

524:

523:

520:

516:

515:

512:

499:

498:

487:

483:

479:

476:

473:

470:

467:

464:

460:

455:

450:

447:

442:

438:

435:

432:

429:

412:bend allowance

407:

406:Bend allowance

404:

346:

345:

342:

339:

336:

333:

330:

327:

324:

315:

312:

308:joggle bending

292:

289:

278:

275:

267:Main article:

256:

253:

247:

246:Rotary bending

244:

235:

232:

226:

223:

217:

214:

208:

205:

199:

196:

161:

158:

141:

138:

127:bend deduction

97:

94:

26:

24:

14:

13:

10:

9:

6:

4:

3:

2:

1615:

1604:

1601:

1599:

1598:Metal forming

1596:

1595:

1593:

1584:

1581:

1578:

1574:

1573:

1569:

1565:

1562:

1558:

1556:0-8311-3049-0

1552:

1548:

1547:

1541:

1539:

1535:

1531:

1527:

1526:

1522:

1514:

1508:

1505:

1501:

1495:

1492:

1486:

1483:

1472:on 2010-03-31

1468:

1461:

1460:

1452:

1449:

1438:on 2009-05-01

1437:

1433:

1432:

1425:

1422:

1411:on 2010-01-10

1410:

1406:

1405:

1398:

1395:

1391:

1389:9781616891787

1385:

1381:

1380:

1372:

1369:

1366:

1360:

1357:

1352:

1346:

1332:on 2010-03-31

1328:

1321:

1315:

1312:

1307:

1301:

1298:

1295:

1291:

1288:

1283:

1280:

1276:

1272:

1267:

1264:

1261:

1255:

1252:

1244:

1240:

1233:

1226:

1224:

1222:

1220:

1218:

1216:

1214:

1212:

1210:

1206:

1200:

1198:

1196:

1192:

1185:

1181:

1178:

1176:

1173:

1171:

1168:

1166:

1163:

1161:

1158:

1156:

1153:

1150:

1147:

1146:

1142:

1140:

1136:

1129:

1113:

1107:

1104:

1101:

1098:

1092:

1086:

1079:

1076:

1073:

1070:

1058:

1055:

1051:

1044:

1041:

1035:

1032:

1025:

1024:

1023:

1021:

1020:approximation

1011:

1008:

1005:

1002:

997:

994:

991:

988:

983:

980:

977:

974:

970:

966:

962:

959:

956:

953:

948:

945:

942:

939:

934:

931:

928:

925:

921:

917:

913:

910:

907:

904:

899:

896:

893:

890:

885:

882:

879:

876:

872:

868:

864:

861:

858:

855:

854:

850:

844:

843:

840:

823:

818:

811:

807:

803:

800:

795:

792:

786:

783:

780:

774:

771:

764:

763:

762:

759:

756:

749:

732:

728:

725:

722:

719:

715:

711:

708:

704:

700:

697:

694:

690:

686:

683:

680:

677:

670:

669:

668:

651:

648:

645:

640:

637:

632:

629:

625:

621:

618:

615:

611:

607:

604:

601:

598:

591:

590:

589:

587:

583:

578:

571:

564:

558:

555:

553:

550:

549:

545:

542:

541:

537:

534:

533:

529:

526:

525:

521:

518:

517:

513:

510:

509:

503:

481:

477:

474:

471:

465:

462:

458:

453:

448:

445:

440:

436:

433:

430:

427:

420:

419:

418:

415:

413:

405:

403:

401:

396:

394:

389:

386:

382:

378:

374:

370:

366:

363:

359:

355:

351:

343:

340:

337:

334:

331:

328:

325:

322:

321:

320:

313:

311:

309:

305:

297:

290:

288:

285:

276:

274:

270:

261:

254:

252:

245:

243:

240:

233:

231:

224:

222:

215:

213:

206:

204:

197:

195:

192:

188:

185:

182:

178:

174:

170:

166:

159:

157:

151:

146:

139:

137:

134:

132:

128:

123:

115:

111:

102:

95:

93:

91:

87:

83:

79:

78:brake presses

75:

71:

67:

63:

62:manufacturing

59:

52:

47:

39:

33:

32:Spoon bending

19:

1545:

1529:

1523:Bibliography

1507:

1494:

1485:

1474:, retrieved

1467:the original

1458:

1451:

1440:, retrieved

1436:the original

1430:

1424:

1413:, retrieved

1409:the original

1403:

1397:

1378:

1371:

1359:

1334:. Retrieved

1327:the original

1314:

1300:

1282:

1274:

1273:, Volume 2,

1270:

1266:

1254:

1243:the original

1239:Metalforming

1238:

1155:Tube bending

1137:

1133:

1019:

1017:

968:

919:

870:

838:

760:

754:

753:

666:

585:

581:

579:

576:

556:

551:

416:

411:

409:

397:

393:flat pattern

392:

390:

384:

380:

376:

372:

354:Neutral axis

350:neutral line

349:

347:

317:

314:Calculations

307:

303:

302:

284:radius ruler

283:

280:

272:

269:Roll bending

263:Roll bending

255:Roll bending

249:

241:

237:

228:

219:

210:

201:

193:

189:

186:

183:

179:

175:

171:

167:

163:

154:

135:

130:

126:

117:

107:

57:

56:

1160:Press brake

1151:(mechanics)

871:Air bending

377:compression

362:compressive

160:Air bending

131:bend radius

120:spring back

70:sheet metal

1592:Categories

1476:2010-02-24

1442:2010-02-24

1415:2010-02-24

1336:2010-02-24

1186:References

1459:BendWorks

1105:

1045:

920:Bottoming

801:π

781:−

723:−

698:−

646:−

633:

543:Thickness

475:×

446:π

198:Bottoming

150:backgauge

1345:cite web

1290:Archived

1143:See also

848:Aluminum

755:K-factor

750:K-factor

535:K-factor

304:Joggling

291:Joggling

90:ductwork

1275:Forming

1149:Bending

969:Coining

385:tension

381:outside

358:tensile

225:Folding

207:Coining

96:Process

66:ductile

58:Bending

41:Bending

1553:

1536:

1386:

856:Radius

851:Steel

527:Radius

522:3.142

373:inside

365:stress

234:Wiping

1470:(PDF)

1463:(PDF)

1330:(PDF)

1323:(PDF)

1246:(PDF)

1235:(PDF)

1012:0.50

998:0.47

984:0.44

963:0.50

949:0.48

935:0.46

914:0.50

900:0.45

886:0.40

557:20.89

538:0.33

530:10.0

511:Angle

398:Most

369:shear

165:(T).

140:Types

60:is a

1551:ISBN

1534:ISBN

1384:ISBN

1351:link

1009:0.50

1006:0.50

995:0.46

992:0.44

981:0.41

978:0.38

960:0.50

957:0.50

946:0.47

943:0.46

932:0.44

929:0.42

911:0.50

908:0.50

897:0.43

894:0.40

883:0.38

880:0.33

580:The

410:The

348:The

112:and

1108:100

1102:log

1065:max

1056:100

1048:min

1042:log

812:180

630:tan

546:10

514:90

449:180

360:or

1594::

1347:}}

1343:{{

1237:,

1208:^

1194:^

1071:20

519:Pl

92:.

76:,

49:A

1559:.

1479:.

1445:.

1418:.

1353:)

1339:.

1308:.

1114:.

1099:2

1093:)

1087:T

1083:)

1080:T

1077:,

1074:R

1068:(

1059:,

1052:(

1036:=

1033:K

824:.

819:T

808:/

804:A

796:A

793:B

787:+

784:R

775:=

772:K

733:)

729:A

726:K

720:2

716:(

712:T

709:+

705:)

701:A

695:2

691:(

687:R

684:=

681:D

678:B

652:A

649:B

641:2

638:A

626:)

622:T

619:+

616:R

612:(

608:2

605:=

602:D

599:B

486:)

482:)

478:T

472:K

469:(

466:+

463:R

459:(

454:)

441:(

437:A

434:=

431:A

428:B

34:.

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.