1449:(the xz shear strain along the xz-GB plane must be equivalent for A and B). In addition, this GB constraint requires that five independent slip systems be activated per crystallite constituting the GB. Notably, because independent slip systems are defined as slip planes on which dislocation migrations cannot be reproduced by any combination of dislocation migrations along other slip system’s planes, the number of geometrical slip systems for a given crystal system - which by definition can be constructed by slip system combinations - is typically greater than that of independent slip systems. Significantly, there is a maximum of five independent slip systems for each of the seven crystal systems, however, not all seven crystal systems acquire this upper limit. In fact, even within a given crystal system, the composition and Bravais lattice diversifies the number of independent slip systems (see the table below). In cases for which crystallites of a polycrystal do not obtain five independent slip systems, the GB condition cannot be met, and thus the time-independent deformation of individual crystallites results in cracks and voids at the GBs of the polycrystal, and soon fracture is realized. Hence, for a given composition and structure, a single crystal with less than five independent slip systems is stronger (exhibiting a greater extent of plasticity) than its polycrystalline form.

1338:) is low, representative of a small amount of applied shear stress necessary to induce a large amount of shear strain. Facile dislocation glide and corresponding flow is attributed to dislocation migration along parallel slip planes only (i.e. one slip system). Moderate impedance to dislocation migration along parallel slip planes is exhibited according to the weak stress field interactions between these dislocations, which heightens with smaller interplanar spacing. Overall, these migrating dislocations within a single slip system act as weak obstacles to flow, and a modest rise in stress is observed in comparison to the yield stress. During the linear hardening stage 2 of flow, the work hardening rate becomes high as considerable stress is required to overcome the stress field interactions of dislocations migrating on non-parallel slip planes (i.e. multiple slip systems), acting as strong obstacles to flow. Much stress is required to drive continual dislocation migration for small strains. The shear flow stress is directly proportional to the square root of the dislocation density (τ

1346:), irrespective of the evolution of dislocation configurations, displaying the reliance of hardening on the number of dislocations present. Regarding this evolution of dislocation configurations, at small strains the dislocation arrangement is a random 3D array of intersecting lines. Moderate strains correspond to cellular dislocation structures of heterogeneous dislocation distribution with large dislocation density at the cell boundaries, and small dislocation density within the cell interior. At even larger strains the cellular dislocation structure reduces in size until a minimum size is achieved. Finally, the work hardening rate becomes low again in the exhaustion/saturation of hardening stage 3 of plastic flow, as small shear stresses produce large shear strains. Notably, instances when multiple slip systems are oriented favorably with respect to the applied stress, the τ

1526:~d ). Therefore, the flow stress of a polycrystal, and hence the polycrystal’s strength, increases with small grain size. The reason for this is that smaller grains have a relatively smaller number of slip planes to be activated, corresponding to a fewer number of dislocations migrating to the GBs, and therefore less stress induced on adjacent grains due to dislocation pile up. In addition, for a given volume of polycrystal, smaller grains present more strong obstacle grain boundaries. These two factors provide an understanding as to why the onset of macroscopic flow in fine-grained polycrystals occurs at larger applied stresses than in coarse-grained polycrystals.

981:

1218:

1505:

governing single crystal time-independent yielding. Eventually, the activated slip planes within the grain interiors will permit dislocation migration to the GB where many dislocations then pile up as geometrically necessary dislocations. This pile up corresponds to strain gradients across individual grains as the dislocation density near the GB is greater than that in the grain interior, imposing a stress on the adjacent grain in contact. When considering the AB bicrystal as a whole, the most favorably oriented slip system in A will not be the that in B, and hence τ

1323:

1633:

132:

1400:

cannot pass from one grain to another across the grain boundary. The following sections explore specific GB requirements for extensive plastic deformation of polycrystals prior to fracture, as well as the influence of microscopic yielding within individual crystallites on macroscopic yielding of the polycrystal. The critical resolved shear stress for polycrystals is defined by Schmid’s law as well (τ

1757:

1540:

38:

1107:

modeling the foam as beams is only valid if the ratio of the density of the foam to the density of the matter is less than 0.3. This is because beams yield axially instead of bending. In closed cell foams, the yield strength is increased if the material is under tension because of the membrane that spans the face of the cells.

1106:

These materials plastically deform when the bending moment exceeds the fully plastic moment. This applies to open cell foams where the bending moment is exerted on the cell walls. The foams can be made of any material with a plastic yield point which includes rigid polymers and metals. This method of

1314:, however plastic flow will still occur due to thermally activated high temperature time-dependent plastic deformation mechanisms such as Nabarro–Herring (NH) and Coble diffusional flow through the lattice and along the single crystal surfaces, respectively, as well as dislocation climb-glide creep.

997:

Most metals show more plasticity when hot than when cold. Lead shows sufficient plasticity at room temperature, while cast iron does not possess sufficient plasticity for any forging operation even when hot. This property is of importance in forming, shaping and extruding operations on metals. Most

993:

Plasticity in a crystal of pure metal is primarily caused by two modes of deformation in the crystal lattice: slip and twinning. Slip is a shear deformation which moves the atoms through many interatomic distances relative to their initial positions. Twinning is the plastic deformation which takes

1517:

between grains A and B is achieved, according to the GB constraint. Thus, for a given composition and structure, a polycrystal with five independent slip systems is stronger (greater extent of plasticity) than its single crystalline form. Correspondingly, the work hardening rate will be higher for

1424:

The GB constraint for polycrystals can be explained by considering a grain boundary in the xz plane between two single crystals A and B of identical composition, structure, and slip systems, but misoriented with respect to each other. To ensure that voids do not form between individually deforming

1083:

materials, the discussion of "dislocations" is inapplicable, since the entire material lacks long range order. These materials can still undergo plastic deformation. Since amorphous materials, like polymers, are not well-ordered, they contain a large amount of free volume, or wasted space. Pulling

1504:

Although the two crystallites A and B discussed in the above section have identical slip systems, they are misoriented with respect to each other, and therefore misoriented with respect to the applied force. Thus, microscopic yielding within a crystallite interior may occur according to the rules

1399:

Plasticity in polycrystals differs substantially from that in single crystals due to the presence of grain boundary (GB) planar defects, which act as very strong obstacles to plastic flow by impeding dislocation migration along the entire length of the activated slip plane(s). Hence, dislocations

1350:

for these systems may be similar and yielding may occur according to dislocation migration along multiple slip systems with non-parallel slip planes, displaying a stage 1 work-hardening rate typically characteristic of stage 2. Lastly, distinction between time-independent plastic deformation in

1012:

Crystalline materials contain uniform planes of atoms organized with long-range order. Planes may slip past each other along their close-packed directions, as is shown on the slip systems page. The result is a permanent change of shape within the crystal and plastic deformation. The presence of

934:

applied to a sample will cause it to behave in an elastic manner. Each increment of load is accompanied by a proportional increment in extension. When the load is removed, the piece returns to its original size. However, once the load exceeds a threshold – the yield strength – the

1139:

Inelastic deformations of rocks and concrete are primarily caused by the formation of microcracks and sliding motions relative to these cracks. At high temperatures and pressures, plastic behavior can also be affected by the motion of dislocations in individual grains in the microstructure.

941:, however, is an approximation and its quality depends on the time frame considered and loading speed. If, as indicated in the graph opposite, the deformation includes elastic deformation, it is also often referred to as "elasto-plastic deformation" or "elastic-plastic deformation".

2019:

Again, a visual representation of the yield surface may be constructed using the above equation, which takes the shape of an ellipse. Inside the surface, materials undergo elastic deformation. Reaching the surface means the material undergoes plastic deformations.

1188:

is the Schmid factor. The Schmid factor comprises two variables λ and φ, defining the angle between the slip plane direction and the tensile force applied, and the angle between the slip plane normal and the tensile force applied, respectively. Notably, because

1045:

The presence of other defects within a crystal may entangle dislocations or otherwise prevent them from gliding. When this happens, plasticity is localized to particular regions in the material. For crystals, these regions of localized plasticity are called

952:, may need increasingly higher stresses to deform further. Generally, plastic deformation is also dependent on the deformation speed, i.e. higher stresses usually have to be applied to increase the rate of deformation. Such materials are said to deform

856:, a non-reversible change of shape in response to applied forces. For example, a solid piece of metal being bent or pounded into a new shape displays plasticity as permanent changes occur within the material itself. In engineering, the transition from

1747:

may be constructed, which provides a visual representation of this concept. Inside of the yield surface, deformation is elastic. On the surface, deformation is plastic. It is impossible for a material to have stress states outside its yield surface.

1355:

Comparison between the time-independent plastic deformation of body centered cubic transition metals and face centered cubic metals, highlighting the critical resolved shear stress, work hardening rate, and necking strain during tensile testing.

1559:(of order d-1 in d dimensions) is a function of the strain tensor. Although this description is accurate when a small part of matter is subjected to increasing loading (such as strain loading), this theory cannot account for irreversibility.

1298:

remains so until region 3 is defined. Notably, in region 2 moderate temperature time-dependent plastic deformation (creep) mechanisms such as solute-drag should be considered. Furthermore, in the high temperature region 3

1650:

criteria are commonly used to determine whether a material has yielded. However, these criteria have proved inadequate for a large range of materials and several other yield criteria are also in widespread use.

1782:

under uniaxial loading, subtracting out hydrostatic stresses, and states that all effective stresses greater than that which causes material failure in uniaxial loading will result in plastic deformation.

1659:

The Tresca criterion is based on the notion that when a material fails, it does so in shear, which is a relatively good assumption when considering metals. Given the principal stress state, we can use

1646:

If the stress exceeds a critical value, as was mentioned above, the material will undergo plastic, or irreversible, deformation. This critical stress can be tensile or compressive. The Tresca and the

1260:*) shear stresses, arising from the stress required to move dislocations in the presence of other dislocations, and the resistance of point defect obstacles to dislocation migration, respectively. At

1717:

1416:

is the weighted Schmid factor. The weighted Schmid factor reflects the least favorably oriented slip system among the most favorably oriented slip systems of the grains constituting the GB.

1161:), initiating dislocation migration along parallel slip planes of a single slip system, thereby defining the transition from elastic to plastic deformation behavior in crystalline materials.

2014:

267:

1624:, uses a set of non-linear, non-integrable equations to describe the set of changes on strain and stress with respect to a previous state and a small increase of deformation.

1121:

Soils, particularly clays, display a significant amount of inelasticity under load. The causes of plasticity in soils can be quite complex and are strongly dependent on the

984:

Plasticity under a spherical nanoindenter in (111) copper. All particles in ideal lattice positions are omitted and the color code refers to the von Mises stress field.

98:

1774:

The Huber–von Mises criterion is based on the Tresca criterion but takes into account the assumption that hydrostatic stresses do not contribute to material failure.

74:

1290:* → 0, representing the elimination of point defect impedance to dislocation migration. Thus the temperature-independent critical resolved shear stress τ

2339:

1518:

the polycrystal than the single crystal, as more stress is required in the polycrystal to produce strains. Importantly, just as with single crystal flow stress, τ

816:

944:

Perfect plasticity is a property of materials to undergo irreversible deformation without any increase in stresses or loads. Plastic materials that have been

1247:

which is required to initiate dislocation glide and equivalently plastic flow. In region 1, the critical resolved shear stress has two components: athermal (

2619:

895:. Such defects are relatively rare in most crystalline materials, but are numerous in some and part of their crystal structure; in such cases,

1125:, chemical composition, and water content. Plastic behavior in soils is caused primarily by the rearrangement of clusters of adjacent grains.

2544:

2308:

2214:

2161:

2107:

2082:

1225:

There are three characteristic regions of the critical resolved shear stress as a function of temperature. In the low temperature region 1 (

2605:

2582:

2563:

2525:

2494:

2400:

2246:

Maaß, Robert; Derlet, Peter M. (January 2018). "Micro-plasticity and recent insights from intermittent and small-scale plasticity".

2189:

2136:

809:

1616:, roughly simultaneously, realized that the plastic deformation of ductile materials could be explained in terms of the theory of

2650:

1760:

The von Mises yield surfaces in principal stress coordinates circumscribes a cylinder around the hydrostatic axis. Also shown is

935:

extension increases more rapidly than in the elastic region; now when the load is removed, some degree of extension will remain.

1669:

782:

1330:

During the easy glide stage 1, the work hardening rate, defined by the change in shear stress with respect to shear strain (

483:

320:

1217:

1084:

these materials in tension opens up these regions and can give materials a hazy appearance. This haziness is the result of

2640:

1116:

1453:

The number of independent slip systems for a given composition (primary material class) and structure (Bravais lattice).

802:

523:

409:

478:

387:

1789:

270:

1567:

2044:

1769:

1663:

to solve for the maximum shear stresses our material will experience and conclude that the material will fail if

1647:

1150:

Time-independent plastic flow in both single crystals and polycrystals is defined by a critical/maximum resolved

853:

394:

223:

148:

2645:

1007:

904:

689:

684:

299:

473:

466:

136:

41:

2442:

2039:

1775:

752:

747:

416:

1513:. Paramount is the fact that macroscopic yielding of the bicrystal is prolonged until the higher value of τ

1621:

1613:

1599:

1583:

304:

2124:

896:

727:

345:

167:

110:

2420:

2362:

2265:

1556:

1134:

1063:

857:

565:

382:

350:

294:

2593:

2029:

1641:

1544:

1221:

The three characteristic regions of the critical resolved shear stress as a function of temperature

1098:. The material may go from an ordered appearance to a "crazy" pattern of strain and stretch marks.

1022:

938:

861:

767:

615:

508:

214:

153:

45:

2480:

2333:

2281:

2255:

2049:

1095:

1030:

787:

421:

377:

372:

105:

77:

53:

2054:

1033:

such as

Nitinol wire also exhibit a reversible form of plasticity which is more properly called

1551:

There are several mathematical descriptions of plasticity. One is deformation theory (see e.g.

1322:

83:

2615:

2601:

2578:

2559:

2540:

2521:

2490:

2484:

2416:

2396:

2304:

2210:

2185:

2157:

2132:

2103:

2078:

834:

404:

355:

49:

59:

2513:

2370:

2273:

2034:

1779:

1660:

1059:

1034:

916:

742:

717:

630:

605:

600:

555:

161:

140:

1632:

1609:

1351:

body-centered cubic transition metals and face centered cubic metals is summarized below.

953:

931:

732:

656:

570:

501:

435:

337:

887:. However, the physical mechanisms that cause plastic deformation can vary widely. At a

620:

490:

2457:

2366:

2269:

1547:

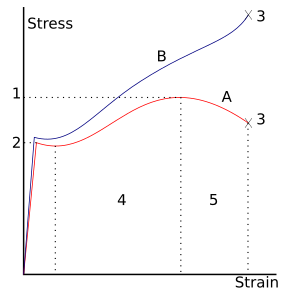

showing elastic and plastic deformation regimes for the deformation theory of plasticity

1213:

Critical resolved shear stress dependence on temperature, strain rate, and point defects

2229:

Ziegenhain, Gerolf; and

Urbassek, Herbert M.; "Reversible Plasticity in fcc metals" in

1579:

1571:

1552:

1369:

Critical resolved shear stress = high (relatively) & strongly temperature-dependent

1122:

945:

876:

737:

595:

560:

461:

367:

121:

1522:~ρ, but is also inversely proportional to the square root of average grain diameter (τ

980:

131:

2634:

2285:

1744:

1372:

Critical resolved shear stress = low (relatively) & weakly temperature-dependent

777:

610:

115:

2353:

Groves, Geoffrey W.; Kelly, Anthony (1963). "Independent Slip

Systems in Crystals".

1761:

1617:

1151:

969:

949:

762:

757:

722:

454:

2277:

1778:

was the first who proposed the criterion of shear energy. Von Mises solves for an

1169:

The critical resolved shear stress for single crystals is defined by Schmid’s law

903:

materials such as rock, concrete and bone, plasticity is caused predominantly by

2388:

2177:

1605:

1237:

900:

892:

888:

772:

675:

2234:

919:, plasticity is mainly a consequence of bubble or cell rearrangements, notably

30:"Plastic material" redirects here. For the material used in manufacturing, see

2374:

1047:

1026:

994:

place along two planes due to a set of forces applied to a given metal piece.

920:

908:

694:

590:

1756:

1587:

1539:

1080:

965:

666:

661:

495:

27:

Non-reversible deformation of a solid material in response to applied forces

17:

1326:

The three stages of time-independent plastic deformation of single crystals

1025:

metals is reversible, as long as there is no material transport in form of

1563:

880:

849:

645:

550:

530:

516:

37:

2445:(1904). "Właściwa praca odkształcenia jako miara wytezenia materiału".

1575:

1091:

1086:

927:

830:

399:

31:

2100:

Nonlinear Solid

Mechanics: Bifurcation Theory and Material Instability

540:

1743:

is the stress under which the material fails in uniaxial loading. A

1441:(the z-axial strain at the GB must be equivalent for A and B), and ε

2260:

1144:

Time-independent yielding and plastic flow in crystalline materials

1755:

1631:

1538:

1321:

1216:

979:

912:

868:

846:

444:

1562:

Ductile materials can sustain large plastic deformations without

2425:

Nachrichten von der

Gesellschaft der Wissenschaften zu Göttingen

1433:(the x-axial strain at the GB must be equivalent for A and B), ε

884:

872:

867:

Plastic deformation is observed in most materials, particularly

1058:

Microplasticity is a local phenomenon in metals. It occurs for

2303:(Second ed.). Long Grove, Illinois: Waveland Press, Inc.

580:

2421:"Mechanik der festen Körper im plastisch-deformablen Zustand"

1500:

Implications of the grain boundary constraint in polycrystals

1165:

Time-independent yielding and plastic flow in single crystals

998:

metals are rendered plastic by heating and hence shaped hot.

964:

The plasticity of a material is directly proportional to the

1425:

grains, the GB constraint for the bicrystal is as follows: ε

1021:

On the nanoscale the primary plastic deformation in simple

1395:

Time-independent yielding and plastic flow in polycrystals

2458:"Specific Work of Strain as a Measure of Material Effort"

2180:; Ma, Guo-Wei; Qiang, Hong-Fu; Zhang, Yong-Qiang (2006).

1066:

domain while some local areas are in the plastic domain.

2326:

Deformation and

Fatigue of Hexagonal Close Packed Metals

891:

scale, plasticity in metals is usually a consequence of

1712:{\displaystyle \sigma _{1}-\sigma _{3}\geq \sigma _{0}}

1566:. However, even ductile metals will fracture when the

1286:) is defined, where the thermal shear stress component

2537:

Plasticity: Mathematical Theory and

Numerical Analysis

1812:

1318:

Stages of time-independent plastic flow, post yielding

2520:. Vol. 7. Oxford: Elsevier. pp. 7068–7071.

2516:(2001). "Plastic Deformation of Cellular Materials".

1792:

1672:

1636:

Comparison of Tresca criterion to Von Mises criterion

226:

86:

62:

1469:

Metal: 5, ceramic (covalent): 5, ceramic (ionic): 2

1461:Primary material class: # Independent slip systems

2008:

1711:

1094:are formed within the material in regions of high

261:

92:

68:

2518:Encyclopedia of Materials: Science and Technology

1590:of a worked piece, so that shaping can continue.

1013:dislocations increases the likelihood of planes.

1184:is the yield strength of the single crystal and

2009:{\displaystyle \sigma _{v}^{2}={\tfrac {1}{2}}}

1412:is the yield strength of the polycrystal and

1377:Work hardening rate = temperature-independent

810:

8:

1570:becomes large enough—this is as a result of

1380:Work hardening rate = temperature-dependent

1008:Slip (materials science) § Slip systems

1574:of the material, which causes it to become

262:{\displaystyle J=-D{\frac {d\varphi }{dx}}}

2338:: CS1 maint: location missing publisher (

1620:. The mathematical theory of plasticity,

1388:Necking strain decreases with temperature

1268:*, the moderate temperature region 2 (0.25

1062:values where the metal is globally in the

817:

803:

650:

440:

283:

205:

2259:

1994:

1989:

1976:

1971:

1958:

1953:

1934:

1924:

1911:

1895:

1885:

1872:

1856:

1846:

1833:

1811:

1802:

1797:

1791:

1703:

1690:

1677:

1671:

1420:Grain boundary constraint in polycrystals

1385:Necking strain increases with temperature

860:behavior to plastic behavior is known as

239:

225:

85:

61:

2626:. Massachusetts Institute of Technology.

2556:Fundamentals of the Theory of Plasticity

1451:

1353:

130:

36:

2573:Khan, Akhtar S.; Huang, Sujian (1995).

2065:

911:. In cellular materials such as liquid

674:

629:

579:

539:

443:

312:

286:

213:

2489:. New York: McGraw-Hill. p. 369.

2331:

2427:. Mathematisch-Physikalische Klasse.

2393:The Mathematical Theory of Plasticity

1361:Body-centered cubic transition metals

1310:) έ can be low, contributing to low τ

7:

2539:(2nd ed.). New York: Springer.

2535:Han, Weimin; Reddy, B. Daya (2013).

2554:Kachanov, Lazar' Markovich (2004).

2620:"Mechanical Behavior of Materials"

2154:Limit Analysis and Soil Plasticity

1736:is the minimum normal stress, and

25:

2207:Plasticity in Reinforced Concrete

2486:History of Strength of Materials

2301:Mechanical Behavior of Materials

2129:Inelastic analysis of structures

2575:Continuum Theory of Plasticity

2231:Philosophical Magazine Letters

2102:. Cambridge University Press.

2003:

2000:

1946:

1931:

1904:

1892:

1865:

1853:

1826:

1823:

1729:is the maximum normal stress,

948:by prior deformation, such as

1:

2278:10.1016/j.actamat.2017.06.023

2235:DOI 10.1080/09500830903272900

1493:Metal: 2, ceramic (mixed): 2

1240:must be high to achieve high

1117:critical state soil mechanics

154:Yield strength (yield point)

2395:. Oxford University Press.

1764:'s hexagonal yield surface.

1364:Face-centered cubic metals

2667:

2598:Computational Inelasticity

1767:

1639:

1597:

1132:

1114:

1005:

29:

2375:10.1080/14786436308213843

2324:Partridge, Peter (1969).

2299:Courtney, Thomas (2005).

2045:Deformation (engineering)

1770:Von Mises yield criterion

1752:Huber–von Mises criterion

1530:Mathematical descriptions

93:{\displaystyle \epsilon }

76:, shown as a function of

2443:Huber, Maksymilian Tytus

2073:Lubliner, Jacob (2008).

321:Clausius–Duhem (entropy)

271:Fick's laws of diffusion

2651:Deformation (mechanics)

2624:MIT Course Number 3.032

2328:. University of Surrey.

2233:, 89(11):717-723, 2009

2131:. John Wiley and Sons.

2098:Bigoni, Davide (2012).

2040:Deformation (mechanics)

960:Contributing properties

479:Navier–Stokes equations

417:Material failure theory

69:{\displaystyle \sigma }

2481:Timoshenko, Stephen P.

2355:Philosophical Magazine

2209:. J. Ross Publishing.

2205:Chen, Wai-Fah (2007).

2182:Generalized Plasticity

2156:. J. Ross Publishing.

2152:Chen, Wai-Fah (2008).

2010:

1765:

1713:

1637:

1622:flow plasticity theory

1614:Geoffrey Ingram Taylor

1600:Flow plasticity theory

1594:Flow plasticity theory

1548:

1543:An idealized uniaxial

1327:

1222:

985:

845:) is the ability of a

263:

203:

128:

94:

70:

2616:Van Vliet, Krystyn J.

2462:Archives of Mechanics

2447:Czasopismo Techniczne

2011:

1759:

1714:

1635:

1542:

1325:

1220:

1017:Reversible plasticity

983:

897:plastic crystallinity

852:to undergo permanent

474:Bernoulli's principle

467:Archimedes' principle

264:

134:

111:Proportionality limit

100:):

95:

71:

40:

2641:Plasticity (physics)

2594:Hughes, Thomas J. R.

1790:

1670:

1557:Cauchy stress tensor

1135:rock mass plasticity

566:Cohesion (chemistry)

388:Infinitesimal strain

224:

84:

60:

2367:1963PMag....8..877G

2270:2018AcMat.143..338M

2030:Yield (engineering)

1999:

1981:

1963:

1807:

1642:Yield (engineering)

1545:stress-strain curve

1485:Ceramic (ionic): 3

1474:Body centered cubic

1466:Face centered cubic

1454:

1357:

1279: < 0.7

1070:Amorphous materials

1031:Shape-memory alloys

1023:face-centered cubic

976:Physical mechanisms

939:Elastic deformation

843:plastic deformation

484:Poiseuille equation

215:Continuum mechanics

209:Part of a series on

137:stress–strain curve

42:Stress–strain curve

2417:von Mises, Richard

2006:

1985:

1967:

1949:

1821:

1793:

1766:

1709:

1638:

1549:

1535:Deformation theory

1452:

1354:

1328:

1223:

1129:Rocks and concrete

1102:Cellular materials

1096:hydrostatic stress

986:

917:biological tissues

690:Magnetorheological

685:Electrorheological

422:Fracture mechanics

259:

204:

129:

106:True elastic limit

90:

66:

2546:978-1-4614-5939-2

2514:Ashby, Michael F.

2310:978-1-57766-425-3

2216:978-1-932159-74-5

2163:978-1-932159-73-8

2125:Bažant, Zdeněk P.

2109:978-1-107-02541-7

2084:978-0-486-46290-5

2075:Plasticity theory

1820:

1497:

1496:

1392:

1391:

972:of the material.

954:visco-plastically

835:materials science

827:

826:

702:

701:

636:

635:

405:Contact mechanics

328:

327:

257:

177:Apparent stress (

149:Ultimate strength

50:nonferrous alloys

16:(Redirected from

2658:

2627:

2611:

2588:

2569:

2550:

2531:

2501:

2500:

2476:

2470:

2469:

2468:: 173–190. 2004.

2454:

2439:

2433:

2432:

2413:

2407:

2406:

2385:

2379:

2378:

2350:

2344:

2343:

2337:

2329:

2321:

2315:

2314:

2296:

2290:

2289:

2263:

2243:

2237:

2227:

2221:

2220:

2202:

2196:

2195:

2174:

2168:

2167:

2149:

2143:

2142:

2123:Jirásek, Milan;

2120:

2114:

2113:

2095:

2089:

2088:

2070:

2035:Atterberg limits

2015:

2013:

2012:

2007:

1998:

1993:

1980:

1975:

1962:

1957:

1939:

1938:

1929:

1928:

1916:

1915:

1900:

1899:

1890:

1889:

1877:

1876:

1861:

1860:

1851:

1850:

1838:

1837:

1822:

1813:

1806:

1801:

1780:effective stress

1718:

1716:

1715:

1710:

1708:

1707:

1695:

1694:

1682:

1681:

1655:Tresca criterion

1586:can restore the

1455:

1358:

1303: ≥ 0.7

1275: <

1035:pseudoelasticity

819:

812:

805:

651:

616:Gay-Lussac's law

606:Combined gas law

556:Capillary action

441:

284:

268:

266:

265:

260:

258:

256:

248:

240:

206:

162:Strain hardening

141:structural steel

99:

97:

96:

91:

75:

73:

72:

67:

44:showing typical

21:

2666:

2665:

2661:

2660:

2659:

2657:

2656:

2655:

2646:Solid mechanics

2631:

2630:

2614:

2608:

2592:Simo, Juan C.;

2591:

2585:

2572:

2566:

2558:. Dover Books.

2553:

2547:

2534:

2528:

2512:

2509:

2507:Further reading

2504:

2497:

2479:

2477:

2473:

2456:

2441:

2440:

2436:

2415:

2414:

2410:

2403:

2387:

2386:

2382:

2361:(89): 877–887.

2352:

2351:

2347:

2330:

2323:

2322:

2318:

2311:

2298:

2297:

2293:

2248:Acta Materialia

2245:

2244:

2240:

2228:

2224:

2217:

2204:

2203:

2199:

2192:

2176:

2175:

2171:

2164:

2151:

2150:

2146:

2139:

2122:

2121:

2117:

2110:

2097:

2096:

2092:

2085:

2072:

2071:

2067:

2063:

2055:Poisson's ratio

2026:

1930:

1920:

1907:

1891:

1881:

1868:

1852:

1842:

1829:

1788:

1787:

1772:

1754:

1742:

1735:

1728:

1699:

1686:

1673:

1668:

1667:

1657:

1644:

1630:

1610:Michael Polanyi

1602:

1596:

1537:

1532:

1525:

1521:

1516:

1512:

1508:

1502:

1458:Bravais lattice

1448:

1444:

1440:

1436:

1432:

1428:

1422:

1411:

1407:

1403:

1397:

1349:

1341:

1320:

1313:

1309:

1297:

1293:

1285:

1274:

1256:) and thermal (

1255:

1246:

1235:

1215:

1208:

1201:

1183:

1179:

1175:

1167:

1160:

1146:

1137:

1131:

1119:

1113:

1104:

1077:

1072:

1056:

1054:Microplasticity

1043:

1019:

1010:

1004:

991:

978:

962:

932:tensile loading

899:can result. In

841:(also known as

823:

794:

793:

792:

712:

704:

703:

657:Viscoelasticity

648:

638:

637:

625:

575:

571:Surface tension

535:

438:

436:Fluid mechanics

428:

427:

426:

340:

338:Solid mechanics

330:

329:

281:

273:

249:

241:

222:

221:

202:

191:Actual stress (

187:

173:

144:

127:

126:

82:

81:

58:

57:

35:

28:

23:

22:

15:

12:

11:

5:

2664:

2662:

2654:

2653:

2648:

2643:

2633:

2632:

2629:

2628:

2612:

2606:

2589:

2583:

2570:

2564:

2551:

2545:

2532:

2526:

2508:

2505:

2503:

2502:

2495:

2471:

2455:Translated as

2434:

2408:

2401:

2380:

2345:

2316:

2309:

2291:

2238:

2222:

2215:

2197:

2190:

2169:

2162:

2144:

2137:

2115:

2108:

2090:

2083:

2064:

2062:

2059:

2058:

2057:

2052:

2047:

2042:

2037:

2032:

2025:

2022:

2017:

2016:

2005:

2002:

1997:

1992:

1988:

1984:

1979:

1974:

1970:

1966:

1961:

1956:

1952:

1948:

1945:

1942:

1937:

1933:

1927:

1923:

1919:

1914:

1910:

1906:

1903:

1898:

1894:

1888:

1884:

1880:

1875:

1871:

1867:

1864:

1859:

1855:

1849:

1845:

1841:

1836:

1832:

1828:

1825:

1819:

1816:

1810:

1805:

1800:

1796:

1768:Main article:

1753:

1750:

1740:

1733:

1726:

1720:

1719:

1706:

1702:

1698:

1693:

1689:

1685:

1680:

1676:

1656:

1653:

1640:Main article:

1629:

1628:Yield criteria

1626:

1598:Main article:

1595:

1592:

1580:Heat treatment

1572:work hardening

1536:

1533:

1531:

1528:

1523:

1519:

1514:

1510:

1506:

1501:

1498:

1495:

1494:

1491:

1487:

1486:

1483:

1479:

1478:

1475:

1471:

1470:

1467:

1463:

1462:

1459:

1446:

1442:

1438:

1434:

1430:

1426:

1421:

1418:

1409:

1405:

1401:

1396:

1393:

1390:

1389:

1386:

1382:

1381:

1378:

1374:

1373:

1370:

1366:

1365:

1362:

1347:

1339:

1319:

1316:

1311:

1307:

1295:

1291:

1283:

1272:

1251:

1244:

1233:

1214:

1211:

1206:

1197:

1181:

1177:

1173:

1166:

1163:

1158:

1145:

1142:

1133:Main article:

1130:

1127:

1123:microstructure

1115:Main article:

1112:

1111:Soils and sand

1109:

1103:

1100:

1076:

1073:

1071:

1068:

1055:

1052:

1042:

1039:

1018:

1015:

1006:Main article:

1003:

1000:

990:

987:

977:

974:

961:

958:

825:

824:

822:

821:

814:

807:

799:

796:

795:

791:

790:

785:

780:

775:

770:

765:

760:

755:

750:

745:

740:

735:

730:

725:

720:

714:

713:

710:

709:

706:

705:

700:

699:

698:

697:

692:

687:

679:

678:

672:

671:

670:

669:

664:

659:

649:

644:

643:

640:

639:

634:

633:

627:

626:

624:

623:

618:

613:

608:

603:

598:

593:

587:

584:

583:

577:

576:

574:

573:

568:

563:

561:Chromatography

558:

553:

547:

544:

543:

537:

536:

534:

533:

514:

513:

512:

493:

481:

476:

464:

451:

448:

447:

439:

434:

433:

430:

429:

425:

424:

419:

414:

413:

412:

402:

397:

392:

391:

390:

385:

375:

370:

365:

360:

359:

358:

348:

342:

341:

336:

335:

332:

331:

326:

325:

324:

323:

315:

314:

310:

309:

308:

307:

302:

297:

289:

288:

282:

279:

278:

275:

274:

269:

255:

252:

247:

244:

238:

235:

232:

229:

218:

217:

211:

210:

201:

200:

189:

185:

174:

172:

171:

165:

159:

156:

151:

145:

125:

124:

122:yield strength

118:

113:

108:

102:

101:

89:

65:

26:

24:

14:

13:

10:

9:

6:

4:

3:

2:

2663:

2652:

2649:

2647:

2644:

2642:

2639:

2638:

2636:

2625:

2621:

2617:

2613:

2609:

2607:0-387-97520-9

2603:

2599:

2595:

2590:

2586:

2584:0-471-31043-3

2580:

2576:

2571:

2567:

2565:0-486-43583-0

2561:

2557:

2552:

2548:

2542:

2538:

2533:

2529:

2527:0-08-043152-6

2523:

2519:

2515:

2511:

2510:

2506:

2498:

2496:9780486611877

2492:

2488:

2487:

2482:

2475:

2472:

2467:

2463:

2459:

2452:

2448:

2444:

2438:

2435:

2431:(1): 582–592.

2430:

2426:

2422:

2418:

2412:

2409:

2404:

2402:0-19-850367-9

2398:

2394:

2390:

2384:

2381:

2376:

2372:

2368:

2364:

2360:

2356:

2349:

2346:

2341:

2335:

2327:

2320:

2317:

2312:

2306:

2302:

2295:

2292:

2287:

2283:

2279:

2275:

2271:

2267:

2262:

2257:

2253:

2249:

2242:

2239:

2236:

2232:

2226:

2223:

2218:

2212:

2208:

2201:

2198:

2193:

2191:3-540-25127-8

2187:

2183:

2179:

2173:

2170:

2165:

2159:

2155:

2148:

2145:

2140:

2138:0-471-98716-6

2134:

2130:

2126:

2119:

2116:

2111:

2105:

2101:

2094:

2091:

2086:

2080:

2076:

2069:

2066:

2060:

2056:

2053:

2051:

2048:

2046:

2043:

2041:

2038:

2036:

2033:

2031:

2028:

2027:

2023:

2021:

1995:

1990:

1986:

1982:

1977:

1972:

1968:

1964:

1959:

1954:

1950:

1943:

1940:

1935:

1925:

1921:

1917:

1912:

1908:

1901:

1896:

1886:

1882:

1878:

1873:

1869:

1862:

1857:

1847:

1843:

1839:

1834:

1830:

1817:

1814:

1808:

1803:

1798:

1794:

1786:

1785:

1784:

1781:

1777:

1771:

1763:

1758:

1751:

1749:

1746:

1745:yield surface

1739:

1732:

1725:

1704:

1700:

1696:

1691:

1687:

1683:

1678:

1674:

1666:

1665:

1664:

1662:

1661:Mohr's circle

1654:

1652:

1649:

1643:

1634:

1627:

1625:

1623:

1619:

1615:

1611:

1607:

1601:

1593:

1591:

1589:

1585:

1581:

1577:

1573:

1569:

1565:

1560:

1558:

1554:

1546:

1541:

1534:

1529:

1527:

1499:

1492:

1489:

1488:

1484:

1481:

1480:

1476:

1473:

1472:

1468:

1465:

1464:

1460:

1457:

1456:

1450:

1419:

1417:

1415:

1394:

1387:

1384:

1383:

1379:

1376:

1375:

1371:

1368:

1367:

1363:

1360:

1359:

1352:

1345:

1337:

1333:

1324:

1317:

1315:

1306:

1302:

1289:

1282:

1278:

1271:

1267:

1263:

1259:

1254:

1250:

1243:

1239:

1232:

1228:

1219:

1212:

1210:

1205:

1200:

1196:

1192:

1187:

1172:

1164:

1162:

1157:

1153:

1148:

1143:

1141:

1136:

1128:

1126:

1124:

1118:

1110:

1108:

1101:

1099:

1097:

1093:

1089:

1088:

1082:

1074:

1069:

1067:

1065:

1061:

1053:

1051:

1049:

1041:Shear banding

1040:

1038:

1036:

1032:

1028:

1024:

1016:

1014:

1009:

1001:

999:

995:

988:

982:

975:

973:

971:

967:

959:

957:

955:

951:

947:

942:

940:

936:

933:

929:

924:

922:

918:

914:

910:

906:

902:

898:

894:

890:

886:

882:

878:

874:

870:

865:

863:

859:

855:

851:

848:

844:

840:

836:

832:

820:

815:

813:

808:

806:

801:

800:

798:

797:

789:

786:

784:

781:

779:

776:

774:

771:

769:

766:

764:

761:

759:

756:

754:

751:

749:

746:

744:

741:

739:

736:

734:

731:

729:

726:

724:

721:

719:

716:

715:

708:

707:

696:

693:

691:

688:

686:

683:

682:

681:

680:

677:

673:

668:

665:

663:

660:

658:

655:

654:

653:

652:

647:

642:

641:

632:

628:

622:

619:

617:

614:

612:

609:

607:

604:

602:

601:Charles's law

599:

597:

594:

592:

589:

588:

586:

585:

582:

578:

572:

569:

567:

564:

562:

559:

557:

554:

552:

549:

548:

546:

545:

542:

538:

532:

529:

525:

522:

518:

515:

510:

509:non-Newtonian

507:

503:

499:

498:

497:

494:

492:

489:

485:

482:

480:

477:

475:

472:

468:

465:

463:

460:

456:

453:

452:

450:

449:

446:

442:

437:

432:

431:

423:

420:

418:

415:

411:

408:

407:

406:

403:

401:

398:

396:

395:Compatibility

393:

389:

386:

384:

383:Finite strain

381:

380:

379:

376:

374:

371:

369:

366:

364:

361:

357:

354:

353:

352:

349:

347:

344:

343:

339:

334:

333:

322:

319:

318:

317:

316:

311:

306:

303:

301:

298:

296:

293:

292:

291:

290:

287:Conservations

285:

277:

276:

272:

253:

250:

245:

242:

236:

233:

230:

227:

220:

219:

216:

212:

208:

207:

198:

194:

190:

184:

180:

176:

175:

169:

166:

163:

160:

157:

155:

152:

150:

147:

146:

142:

138:

133:

123:

119:

117:

116:Elastic limit

114:

112:

109:

107:

104:

103:

87:

79:

63:

55:

51:

48:behavior for

47:

43:

39:

33:

19:

2623:

2600:. Springer.

2597:

2574:

2555:

2536:

2517:

2485:

2474:

2465:

2461:

2450:

2446:

2437:

2428:

2424:

2411:

2392:

2389:Hill, Rodney

2383:

2358:

2354:

2348:

2325:

2319:

2300:

2294:

2251:

2247:

2241:

2230:

2225:

2206:

2200:

2184:. Springer.

2181:

2178:Yu, Mao-Hong

2172:

2153:

2147:

2128:

2118:

2099:

2093:

2074:

2068:

2018:

1773:

1737:

1730:

1723:

1721:

1658:

1645:

1618:dislocations

1603:

1561:

1555:) where the

1550:

1503:

1482:Simple cubic

1423:

1413:

1408:/ṁ), where σ

1398:

1343:

1335:

1331:

1329:

1304:

1300:

1287:

1280:

1276:

1269:

1265:

1261:

1257:

1252:

1248:

1241:

1230:

1226:

1224:

1203:

1198:

1194:

1190:

1185:

1170:

1168:

1155:

1152:shear stress

1149:

1147:

1138:

1120:

1105:

1085:

1078:

1057:

1044:

1020:

1011:

1002:Slip systems

996:

992:

970:malleability

963:

950:cold forming

943:

937:

925:

921:T1 processes

893:dislocations

866:

842:

838:

828:

676:Smart fluids

621:Graham's law

527:

520:

505:

491:Pascal's law

487:

470:

458:

362:

313:Inequalities

196:

192:

182:

178:

18:Plastic flow

2254:: 338–363.

2050:Plastometer

1776:M. T. Huber

1606:Egon Orowan

1553:Hooke's law

1238:strain rate

1180:/m, where σ

1048:shear bands

909:microcracks

889:crystalline

854:deformation

695:Ferrofluids

596:Boyle's law

368:Hooke's law

346:Deformation

139:typical of

2635:Categories

2261:1704.07297

2061:References

1027:cross-slip

839:plasticity

748:Gay-Lussac

711:Scientists

611:Fick's law

591:Atmosphere

410:frictional

363:Plasticity

351:Elasticity

2577:. Wiley.

2334:cite book

2286:119387816

2077:. Dover.

1987:σ

1969:σ

1951:σ

1922:σ

1918:−

1909:σ

1883:σ

1879:−

1870:σ

1844:σ

1840:−

1831:σ

1795:σ

1701:σ

1697:≥

1688:σ

1684:−

1675:σ

1648:von Mises

1604:In 1934,

1588:ductility

1584:annealing

1490:Hexagonal

1477:Metal: 5

1081:amorphous

989:In metals

966:ductility

926:For many

788:Truesdell

718:Bernoulli

667:Rheometer

662:Rheometry

502:Newtonian

496:Viscosity

246:φ

234:−

88:ϵ

64:σ

2618:(2006).

2596:(1998).

2483:(1953).

2419:(1913).

2391:(1998).

2127:(2002).

2024:See also

1582:such as

1564:fracture

1193:> 1,

1090:, where

946:hardened

930:metals,

881:concrete

862:yielding

850:material

646:Rheology

551:Adhesion

531:Pressure

517:Buoyancy

462:Dynamics

300:Momentum

2453:. Lwów.

2363:Bibcode

2266:Bibcode

1576:brittle

1264:=

1236:), the

1092:fibrils

1087:crazing

1075:Crazing

1064:elastic

928:ductile

901:brittle

858:elastic

831:physics

733:Charles

541:Liquids

455:Statics

400:Bending

168:Necking

158:Rupture

120:Offset

80:,

56:,

32:Plastic

2604:

2581:

2562:

2543:

2524:

2493:

2399:

2307:

2284:

2213:

2188:

2160:

2135:

2106:

2081:

1762:Tresca

1722:where

1568:strain

1229:≤ 0.25

1060:stress

883:, and

869:metals

783:Stokes

778:Pascal

768:Navier

763:Newton

753:Graham

728:Cauchy

631:Plasma

526:

524:Mixing

519:

504:

486:

469:

457:

445:Fluids

378:Strain

373:Stress

356:linear

305:Energy

170:region

164:region

78:strain

54:stress

2282:S2CID

2256:arXiv

1202:>

913:foams

885:foams

877:rocks

873:soils

847:solid

758:Hooke

738:Euler

723:Boyle

581:Gases

46:yield

2602:ISBN

2579:ISBN

2560:ISBN

2541:ISBN

2522:ISBN

2491:ISBN

2478:See

2429:1913

2397:ISBN

2340:link

2305:ISBN

2211:ISBN

2186:ISBN

2158:ISBN

2133:ISBN

2104:ISBN

2079:ISBN

1612:and

1524:flow

1520:flow

1515:CRSS

1511:CRSS

1507:CRSS

1402:CRSS

1348:CRSS

1340:flow

1312:CRSS

1292:CRSS

1245:CRSS

1207:CRSS

1174:CRSS

1159:CRSS

968:and

905:slip

833:and

773:Noll

743:Fick

295:Mass

280:Laws

2371:doi

2274:doi

2252:143

1578:.

1509:≠ τ

1445:= ε

1437:= ε

1429:= ε

1294:= τ

1079:In

915:or

907:at

829:In

2637::

2622:.

2466:56

2464:.

2460:.

2451:22

2449:.

2423:.

2369:.

2357:.

2336:}}

2332:{{

2280:.

2272:.

2264:.

2250:.

1991:12

1973:31

1955:23

1926:33

1913:11

1887:33

1874:22

1848:22

1835:11

1608:,

1447:xz

1443:xz

1439:zz

1435:zz

1431:xx

1427:xx

1404:=σ

1336:dγ

1332:dτ

1209:.

1176:=σ

1050:.

1037:.

1029:.

956:.

923:.

879:,

875:,

871:,

864:.

837:,

135:A

2610:.

2587:.

2568:.

2549:.

2530:.

2499:.

2405:.

2377:.

2373::

2365::

2359:8

2342:)

2313:.

2288:.

2276::

2268::

2258::

2219:.

2194:.

2166:.

2141:.

2112:.

2087:.

2004:]

2001:)

1996:2

1983:+

1978:2

1965:+

1960:2

1947:(

1944:6

1941:+

1936:2

1932:)

1905:(

1902:+

1897:2

1893:)

1866:(

1863:+

1858:2

1854:)

1827:(

1824:[

1818:2

1815:1

1809:=

1804:2

1799:v

1741:0

1738:σ

1734:3

1731:σ

1727:1

1724:σ

1705:0

1692:3

1679:1

1414:ṁ

1410:y

1406:y

1344:ρ

1342:~

1334:/

1308:m

1305:T

1301:T

1299:(

1296:a

1288:τ

1284:m

1281:T

1277:T

1273:m

1270:T

1266:T

1262:T

1258:τ

1253:a

1249:τ

1242:τ

1234:m

1231:T

1227:T

1204:τ

1199:y

1195:σ

1191:m

1186:m

1182:y

1178:y

1171:τ

1156:τ

1154:(

818:e

811:t

804:v

528:·

521:·

511:)

506:·

500:(

488:·

471:·

459:·

254:x

251:d

243:d

237:D

231:=

228:J

199:)

197:A

195:/

193:F

188:)

186:0

183:A

181:/

179:F

143::

52:(

34:.

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.