707:

other optical polymers, that is, they have refractive indices of between 1.5 and 1.7 and provide good propagation of light between approximately 400 nm and 1700 nm. Close refractive index (RI) matching between materials is important for proper propagation of light through them. Because of the ease of RI matching, PPEs are used in many optical devices as optical fluids. Extreme resistance to ionizing radiation gives PPEs an added advantage in the manufacture of solar cells and solid-state UV/blue emitters and telecommunication equipment made from high-index glasses and semiconductors.

689:

avoided, such as in certain electronic devices. A thin film of polyphenyl ether on a surface is not a thin contiguous film as one would envision, but rather comprises tiny droplets. This PPE property tends to keep the film stationary, or at least to cause it to remain in the area where the lubrication is needed, rather than migrating away by spreading and forming a new surface. As a result, contamination of other components and equipment, which do not require a lubricant, is avoided. The high surface tension of PPEs, therefore, makes them useful in lubricating electronic contacts.

724:

Due to the low volatility and excellent high-temperature thermo-oxidative stability, PPEs have also found use as a lubricant for chains used in and around kilns, metal fabrication plants, and glass molding and manufacturing equipment. In these high-temperature applications, PPEs do not form any sludge and hard deposits. The low soft-carbon residue that is left behind is removed easily by wiping. PPEs' low volatility, low flammability, and good thermodynamic properties make them ideally suited for use as heat transfer fluids and in heat sink applications as well.

720:

also used as base fluids for radiation-resistant greases used in nuclear power plant mechanisms. PPEs and their derivatives have also found use as vapor phase lubricants in gas turbines and custom bearings, and wherever extreme environmental conditions exist. Vapor phase lubrication is achieved by heating the liquid lubricant above its boiling point. The resultant vapors are then transported to the hot bearing surface. If the temperatures of the bearing surface are kept below the lubricant’s boiling point, the vapors re-condense to provide liquid lubrication.

109:

82:

1081:

28:

224:. PPEs have the disadvantage of having somewhat high pour points. For example, PPEs that contain two and three benzene rings are actually solids at room temperatures. The melting points of the ordinarily solid PPEs are lowered if they contain more m-phenylene rings, alkyl groups, or are mixtures of isomers. PPEs that contain only o- and p-substituted rings have the highest melting points.

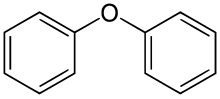

145:(DPE), also called diphenyl oxide, the structure of which is provided in Figure 4. Low molecular weight polyphenyl ethers and thioethers are used in a variety of applications, and include high-vacuum devices, optics, electronics, and in high-temperature and radiation-resistant fluids and greases. Figure 5 shows the structure of the sulfur analogue of 3-R polyphenyl ether shown in Figure 3.

98:

20:

1087:

746:. See Figure 2 for the PPO structure. PPO polymers can be classified as plastic resins. They and their composites with polystyrene, glass, and nylon are used as high-strength, moisture-resistant engineering plastics in a number of industries, including computer, telecommunication, and automotive parts. PPOs are marketed by

706:

Polyphenyl ethers (PPEs) possess good optical clarity, a high refractive index, and other beneficial optical properties. Because of these, PPEs have the ability to meet the rigorous performance demands of signal processing in advanced photonics systems. Optical clarity of PPEs resembles that of the

419:

10 ergs/gram of radiation at 99 °C (210 °F) was compared with synthetic ester, synthetic hydrocarbon, and silicone fluids. PPE showed a viscosity increase of only 35%, while all other fluids showed a viscosity increase of 1700% and gelled. Further tests have shown PPEs to be resistant

719:

PPEs were developed for use in jet engines that involved high speed-related frictional temperatures of as high as 320 °C (608 °F). While the use of PPEs in lubricating jet engines has somewhat subsided due to their higher cost, they are still used in some aerospace applications. PPEs are

801:

Bolt, R. O., "Radiation

Effects on Lubricants," CRC Handbook of Lubrication, Vol. I, Theory and Practice of Tribology: Applications and Maintenance, pp. 3–44 , Richard E. Booser Editor, CRC Press, Boca Raton, 1983. Carroll, J. G. and Bolt. R. O., Radiation Effects on Organic Materials, Bolt. R. O.

387:

PPEs have excellent high temperature properties and good oxidation stability. With respect to volatilities, p-derivatives have the lowest volatilities, and the o-derivatives have the highest volatilities. The opposite is true for flash points and fire points. Spontaneous ignition temperatures of

723:

Polyphenyl ether technology can also provide superior fire safety and fatigue life, depending on the specific bearing design. In this application, PPEs have the advantage of providing lubrication both as a liquid at low temperatures and as a vapor at temperatures above 315 °C (599 °F).

388:

polyphenyl ethers lie between 550 and 595 °C (1,022 and 1,103 °F), alkyl substitution reduces this value by ~50 °C (122 °F). PPEs are compatible with most metals and elastomers that are commonly used in high-temperature applications. They typically swell common seal materials.

692:

Polyphenyl ether lubricants have a 30-year history of commercial service for connectors with precious and base metal contacts in telecom, automotive, aerospace, instrumentation and general-purpose applications. In addition to maintaining the current flow and providing long-term lubrication, PPEs

688:

5R4E PPE has a surface tension of 49.9 dynes/cm, which is amongst the highest in pure organic liquids. Because of this, this PPE and the other PPEs do not effectively wet metal surfaces. This property is useful when migration of a lubricant from one part of the equipment to another part must be

137:

equal to 1 is identified as pmp5P4E, indicating para, meta, para substitution of the three middle rings, a total of 5 rings, and 4 ether linkages. Meta substitution of the aryl rings in these materials is most common and often desired. Longer chain analogues with up to 10 benzene rings are also

72:

s). The phenoxy groups in the former class of polymers do not contain any substituents whereas those in the latter class contain 2 to 4 alkyl groups on the phenyl ring. The structure of an oxygen-containing PPE is provided in Figure 1 and that of a 2, 6-xylenol derived PPO is shown in Figure 2.

470:

10 torr at 25 °C. Such high vacuums are necessary in equipment such as electron microscopes, mass spectrometers and that used for various surface physics studies. Vacuum pumps are also used in the production of electric lamps, vacuum tubes, and cathode ray tubes (CRTs), semiconductor

432:

PPEs have high surface tension; hence these fluids have a lower tendency to wet metal surfaces. The surface tension of the commercially available 5R4E is 49.9 dynes/cm, one of the highest in pure organic liquids. This property is useful in applications where migration of the lubricant into the

403:

Ionizing radiation affects all organic compounds, causing a change in their properties because radiation disrupts covalent bonds that are most prevalent in organic compounds. One result of ionization is that the organic molecules disproportionate to form smaller hydrocarbon molecules as well as

216:

Typical physical properties of polyphenyl ethers are provided in Table 2. Physical properties of a particular PPE depend upon the number of aromatic rings, their substitution pattern, and whether it is an ether or a thioether. In the case of products of mixed structures, properties are hard to

715:

PPEs, being of excellent thermo-oxidative stability and radiation resistance, have found extensive use in high temperature applications that also require radiation resistance. In addition, PPEs demonstrate better wear control and load-carrying ability than mineral oils, especially when used in

462:

in combination with a fore pump are amongst the most popular. Diffusion pumps use a high boiling liquid of low vapor pressure to create a high-speed jet that strikes the gaseous molecules in the system to be evacuated and direct them into space that is being evacuated by the fore pump. A good

132:

PPEs of up to 6 phenyl rings, both oxy and thio ethers, are commercially available. See Table 1. They are characterized by indicating the substitution pattern of each ring, followed by the number of phenyl rings and the number of ether linkages. Thus, the structure in Figure 1 with

441:

While originally PPEs were developed for use in extreme environments that were experienced in aerospace applications, they are now used in other applications requiring low volatility and excellent thermo-oxidative and ionizing radiation stability. Such applications include use as

463:

diffusion fluid must therefore reflect low vapor pressure, high flash point, high thermal and oxidative stability and chemical resistance. If the diffusion pump is operating in the proximity of ionizing radiation source, good radiation stability is also desired.

693:

offer protection to connectors against aggressive acidic and oxidative environments. By providing a protective surface film, polyphenyl ethers not only protect connectors against corrosion but also against vibration-related wear and abrasion that leads to

415:) the polyphenyl ethers are the most radiation resistant. Excellent radiation stability of PPEs can be ascribed to the limited number of ionizable carbon-carbon and carbon-hydrogen bonds. In one study, the performance of PPE under the influence of 1

446:

fluids; high vacuum fluids; and in formulating jet engine lubricants, high-temperature hydraulic lubricants and greases, and heat transfer fluids. In addition, because of excellent optical properties these fluids have found use in optical devices.

697:

wear. The devices that benefit from the specialized properties of PPEs include cell phones, printers, and a variety of other electronic appliances. The protection lasts for decades or for the life of the equipment.

1688:

404:

larger hydrocarbons molecules. This is reflected by increased evaporation loss, lowering of the flash and fire points, and increased viscosity. Other chemical reactions caused by radiation include oxidation and

116:

The proper name for a phenyl ether polymer is poly(phenyl ether) or polyphenyl polyether, but the name polyphenyl ether is widely accepted. Polyphenyl ethers (PPEs) are obtained by repeated application of the

866:

Hamid, S. and Burian, S. A., "Polyphenyl Ether

Lubricants," published in Synthetics, Mineral Oils, and Bio-based Lubricants: Chemistry and Technology, Leslie R. Rudnick Editor, pp. 175–199, Taylor and Francis

847:

Using

Lubricants to Avoid Failures in Medical Electronic Connectors," by Sibtain Hamid in Medical Electronics Manufacturing, Spring 2004 and SANTOLUBES Brochure on Stationary lubricants prevent connector

877:

2002grc087 High Heat PPO.: 13C and 31P NMR Methods for

Characterizing End Groups and Chain Structures in Poly(2,6-dimethyl-1,4-phenylene oxide)/Poly(2,3,6-trimethyl-1,4-phenylene oxide) Copolymers

792:"Synthetic Lubricants," Chapter 6, pp. 96–153, Lubricants and Related Products: Synthesis, Properties, Applications, International Standards by Dieter Klamann, Verlag Chemie Gmbh publisher (1984)

783:

Joaquim, M., "Polyphenyl Ether

Lubricants" Synthetic Lubricants and High-performance Functional Fluids", R. L. Rudnick and R. L. Shubkin, Eds., p. 239, Marcel Dekker, Inc., NY, 1999

391:

Oxidation stability of un-substituted PPEs is quite good, partly because they lack easily oxidizable carbon-hydrogen bonds. Thermal decomposition temperature, as measured by the

1412:

466:

Data presented in Table 3 demonstrates polyphenyl ether to be superior to other fluids that are commonly used in diffusion pumps. PPEs help achieve the highest vacuum of 4

738:

These polymers are made through oxidative coupling of substituted phenol in the presence of oxygen and copper and amine containing catalysts, such as

1405:

1288:

1747:

1698:

1667:

1398:

905:

408:. The former leads to increased acidity, corrosivity, and coke formation; the latter causes a change in viscosity and volatility.

930:

1683:

1662:

1559:

1313:

1737:

1657:

411:

PPEs have extremely high radiation resistance. Of all classes of synthetic lubricants (with the possible exception of

1730:

1652:

1468:

1065:

995:

970:

1770:

1504:

1390:

1303:

1128:

945:

935:

811:

Joaquim, M. E. and J. F. Herber, "Lubrication of

Electronic Connectors and Equipment in Radiation Environments,

220:

The important attributes of PPEs include their thermal and oxidative stability and stability in the presence of

1574:

1564:

1426:

1113:

1060:

950:

823:

The

Surface Tension of Pure Liquid Compounds, Joseph J. Jasper, J. Phys. Chem. Ref. Data, Vol. 1, No. 4, 1972;

765:"The Ullmann Ether Condensation," by A A Moroz and Mark S Shvartsberg, 1974, Russ. Chem. Rev. 43 (8), 679-689

1164:

1055:

1040:

1020:

733:

64:

1579:

1457:

1212:

940:

898:

1759:

1463:

1108:

876:

1479:

1474:

1447:

1365:

812:

118:

86:

1799:

1794:

1609:

1370:

1293:

1207:

1159:

108:

1624:

1542:

1283:

1257:

1227:

1187:

1169:

1118:

1070:

1050:

412:

221:

1789:

1754:

1720:

1640:

1452:

1274:

1192:

891:

217:

predict from only the structural features; hence, they must be determined via measurement.

1645:

1340:

1242:

1217:

1149:

1010:

955:

81:

1509:

1495:

1360:

1247:

1237:

1005:

739:

1080:

1538:

1350:

1252:

1123:

459:

443:

142:

102:

73:

Either class can have the oxygen atoms attached at various positions around the rings.

1783:

1725:

1532:

1318:

1308:

1298:

1202:

1103:

1025:

975:

458:

are devices that remove gases from an enclosed space to greatly reduce pressure. Oil

405:

1345:

1335:

1197:

1045:

990:

965:

392:

27:

836:

1528:

1500:

1435:

1355:

1154:

1035:

1030:

824:

455:

126:

19:

1604:

1232:

1222:

1086:

47:

1693:

1599:

1569:

1439:

1000:

985:

960:

97:

54:

linkages. Commercial phenyl ether polymers belong to two chemical classes:

1614:

743:

694:

1742:

1619:

1591:

1520:

1422:

1144:

914:

857:

SANTOLUBES Brochure on

Stationary lubricants prevent connector failures

835:"Inside a Vacuum Diffusion Pump," by Manuel E. Joaquim and Bill Foley;

122:

39:

43:

813:

http://www.chemassociates.com/products/findett/PPEs_Radiation2.pdf

747:

51:

395:

procedure, is between 440 and 465 °C (824 and 869 °F).

980:

1394:

887:

424:

10 erg/g at temperatures up to 315 °C (599 °F).

31:

Figure 2: Representative

Structure of Polyphenylene Oxide (PPO)

186:

Three- and four-ring oxy- and thioethers; trade name: MCS-293

23:

Figure 1: Representative

Structure of Polyphenyl Ether (PPE)

883:

194:

Three-ring polyphenyl ether (3P2E); trade name: MCS-2167

802:

and Carroll, J. G., Eds., Academic Press, New York, 1963

420:

to gamma and associated neutron radiation dosages of 1

178:

Four-ring polyphenyl ether (4P3E); trade name: MCS-210

170:

Five-ring polyphenyl ether (5P4E); trade name: OS-124

162:

Six-ring polyphenyl ether (6P5E); trade name: OS-138

149:

Table 1: commercial polyphenyl ether products (PPEs)

1713:

1676:

1633:

1590:

1552:

1519:

1488:

1434:

1383:

1328:

1273:

1266:

1178:

1137:

1094:

921:

711:

High-temperature and radiation-resistant lubricants

228:Table 2: physical properties of polyphenyl ethers

141:The simplest member of the phenyl ether family is

112:Figure 5: structure of 3R2TE polyphenyl thioether

205:Diphenyl ether, diphenyl oxide, phenoxybenzene

837:http://www.xtronix.ch/pdf/Diffusion%20Pump.pdf

1406:

899:

825:https://www.nist.gov/srd/PDFfiles/jpcrd13.pdf

475:Table 3: diffusion fluid property comparison

93:-diphenoxybenzene), a simple polyphenyl ether

8:

612:Refractive index at 25 °C, 589 nm

1413:

1399:

1391:

1270:

906:

892:

884:

433:surrounding environment must be avoided.

473:

226:

189:Thiobis and bis (phenylmercapto)benzene

147:

107:

96:

80:

26:

18:

758:

996:Polyethylene terephthalate (PET, PETE)

936:Cross-linked polyethylene (PEX, XLPE)

931:Acrylonitrile butadiene styrene (ABS)

750:under the trademarked name of Noryl.

7:

1748:List of environmental health hazards

1668:List of environmental health hazards

471:processing, and vacuum engineering.

500:Vapor pressure, Torr at 25 °C

1553:Miscellaneous additives incl. PHCs

14:

1085:

1079:

971:Polybutylene terephthalate (PBT)

946:Poly(methyl methacrylate) (PMMA)

50:group as the repeating group in

951:Poly(ethyl methacrylate) (PEMA)

774:SANTOLUBES LLC Product Brochure

684:Electronic connector lubricants

584:Viscosity (cSt) at 100 °C

202:Two-ring diphenyl ether (2P1E)

173:m-Bis(m-phenoxyphenoxy)benzene

1314:Category:Plastics applications

1061:Styrene maleic anhydride (SMA)

1056:Polyvinylidene chloride (PVDC)

1041:Polytetrafluoroethylene (PTFE)

570:Viscosity (cSt) at 25 °C

556:Boiling point at 1.3 mbar, °C

121:: reaction of an alkali-metal

1:

1021:Poly(p-phenylene oxide) (PPO)

129:benzene catalyzed by copper.

1738:Persistent organic pollutant

1699:Toxic Substances Control Act

1658:Persistent organic pollutant

941:Ethylene vinyl acetate (EVA)

256:at 210 °F (99 °C)

251:at 100 °F (38 °C)

181:Bis (m-phenoxyphenyl) ether

101:Figure 4: Structure of 2R1E

1731:Great Pacific garbage patch

1653:Great Pacific garbage patch

1066:Styrene-acrylonitrile (SAN)

981:Polyetheretherketone (PEEK)

728:Polyphenylene oxides (PPOs)

1816:

1694:Japan Toxic Substances Law

1489:Miscellaneous plasticizers

731:

598:Surface tension, dynes/cm

383:Thermo-oxidative stability

1768:

1689:European REACH regulation

1684:California Proposition 65

1427:polyhalogenated compounds

1304:High-performance plastics

1129:High-performance plastics

1077:

748:SABIC Innovative Plastics

1114:Fibre-reinforced plastic

1051:Polyvinyl chloride (PVC)

451:Ultra-high-vacuum fluids

1165:Biodegradable additives

734:Poly(p-phenylene oxide)

119:Ullmann Ether Synthesis

87:Ullmann Ether Synthesis

77:Structure and synthesis

1580:Perfluorooctanoic acid

1016:Polyphenyl ether (PPE)

1011:Polyoxymethylene (POM)

956:Polyacrylic acid (PAA)

528:Density at 25 °C

321:3- and 4-ring oxythio

154:Common and trade name

113:

105:

94:

32:

24:

1760:Biodegradable plastic

1109:Thermosetting polymer

1006:Polylactic acid (PLA)

668:Radiation resistance

640:Oxidation resistance

111:

100:

84:

36:Phenyl ether polymers

30:

22:

1771:Identification codes

1371:Foam food containers

1294:Engineering plastics

654:Chemical resistance

65:polyphenylene oxides

1610:Endocrine disruptor

1208:Compression molding

1160:Polymer stabilizers

476:

413:perfluoropolyethers

399:Radiation stability

229:

212:Physical properties

197:m-Diphenoxybenzene

150:

1625:Polymer fume fever

1284:Commodity plastics

1258:Rotational molding

1228:Fiberglass molding

1188:Injection moulding

1170:Filler (materials)

1119:Corrugated plastic

1071:Tritan copolyester

1026:Polypropylene (PP)

976:Polycarbonate (PC)

626:Thermal stability

474:

244:Thermal stability

227:

222:ionizing radiation

148:

114:

106:

95:

33:

25:

1777:

1776:

1755:Plastic recycling

1721:Plastic pollution

1707:

1706:

1641:Plastic pollution

1421:Health issues of

1379:

1378:

1275:Plastics industry

1193:Plastic extrusion

1046:Polyurethane (PU)

1036:Polysulfone (PES)

991:Polyethylene (PE)

966:Polybutylene (PB)

681:

680:

514:Molecular weight

483:Polyphenyl ether

380:

379:

254:Viscosity (cSt),

249:Viscosity (cSt),

233:Polyphenyl ether

209:

208:

56:polyphenyl ethers

16:Class of polymers

1807:

1646:Rubber pollution

1496:Organophosphates

1415:

1408:

1401:

1392:

1271:

1243:Filament winding

1218:Transfer molding

1145:Polymer additive

1089:

1083:

1031:Polystyrene (PS)

908:

901:

894:

885:

879:

874:

868:

864:

858:

855:

849:

845:

839:

833:

827:

821:

815:

809:

803:

799:

793:

790:

784:

781:

775:

772:

766:

763:

542:Flash point, °C

493:Hydrocarbon oil

477:

469:

423:

418:

230:

151:

1815:

1814:

1810:

1809:

1808:

1806:

1805:

1804:

1780:

1779:

1778:

1773:

1764:

1709:

1708:

1703:

1672:

1629:

1586:

1548:

1515:

1484:

1430:

1419:

1385:

1375:

1324:

1262:

1248:Solvent bonding

1238:Plastic welding

1180:

1174:

1133:

1096:

1090:

1084:

1075:

986:Polyester (PEs)

923:

917:

912:

882:

875:

871:

865:

861:

856:

852:

846:

842:

834:

830:

822:

818:

810:

806:

800:

796:

791:

787:

782:

778:

773:

769:

764:

760:

756:

740:cuprous bromide

736:

730:

713:

704:

686:

494:

489:

484:

480:Fluid property

467:

460:diffusion pumps

453:

439:

430:

428:Surface tension

421:

416:

401:

385:

255:

250:

245:

240:

214:

79:

42:that contain a

38:are a class of

17:

12:

11:

5:

1813:

1811:

1803:

1802:

1797:

1792:

1782:

1781:

1775:

1774:

1769:

1766:

1765:

1763:

1762:

1757:

1752:

1751:

1750:

1745:

1740:

1735:

1734:

1733:

1717:

1715:

1711:

1710:

1705:

1704:

1702:

1701:

1696:

1691:

1686:

1680:

1678:

1674:

1673:

1671:

1670:

1665:

1660:

1655:

1650:

1649:

1648:

1637:

1635:

1631:

1630:

1628:

1627:

1622:

1617:

1612:

1607:

1602:

1596:

1594:

1588:

1587:

1585:

1584:

1583:

1582:

1572:

1567:

1562:

1556:

1554:

1550:

1549:

1547:

1546:

1539:Vinyl chloride

1536:

1533:Polycarbonates

1525:

1523:

1517:

1516:

1514:

1513:

1507:

1498:

1492:

1490:

1486:

1485:

1483:

1482:

1477:

1472:

1466:

1461:

1455:

1450:

1444:

1442:

1432:

1431:

1420:

1418:

1417:

1410:

1403:

1395:

1389:

1387:

1381:

1380:

1377:

1376:

1374:

1373:

1368:

1363:

1358:

1353:

1348:

1346:Packaging film

1343:

1338:

1332:

1330:

1329:Specific goods

1326:

1325:

1323:

1322:

1316:

1311:

1306:

1301:

1296:

1291:

1286:

1280:

1278:

1268:

1264:

1263:

1261:

1260:

1255:

1253:Vacuum forming

1250:

1245:

1240:

1235:

1230:

1225:

1220:

1215:

1210:

1205:

1200:

1195:

1190:

1184:

1182:

1176:

1175:

1173:

1172:

1167:

1162:

1157:

1152:

1147:

1141:

1139:

1135:

1134:

1132:

1131:

1126:

1124:Polymeric foam

1121:

1116:

1111:

1106:

1100:

1098:

1092:

1091:

1078:

1076:

1074:

1073:

1068:

1063:

1058:

1053:

1048:

1043:

1038:

1033:

1028:

1023:

1018:

1013:

1008:

1003:

1001:Polyimide (PI)

998:

993:

988:

983:

978:

973:

968:

963:

961:Polyamide (PA)

958:

953:

948:

943:

938:

933:

927:

925:

919:

918:

913:

911:

910:

903:

896:

888:

881:

880:

869:

859:

850:

840:

828:

816:

804:

794:

785:

776:

767:

757:

755:

752:

732:Main article:

729:

726:

712:

709:

703:

700:

685:

682:

679:

678:

675:

672:

669:

665:

664:

661:

658:

655:

651:

650:

647:

644:

641:

637:

636:

633:

630:

627:

623:

622:

619:

616:

613:

609:

608:

605:

602:

599:

595:

594:

591:

588:

585:

581:

580:

577:

574:

571:

567:

566:

563:

560:

557:

553:

552:

549:

546:

543:

539:

538:

535:

532:

529:

525:

524:

521:

518:

515:

511:

510:

507:

504:

501:

497:

496:

491:

486:

481:

452:

449:

444:diffusion pump

438:

435:

429:

426:

400:

397:

384:

381:

378:

377:

374:

371:

368:

365:

362:

358:

357:

354:

351:

348:

345:

342:

338:

337:

334:

331:

328:

325:

322:

318:

317:

314:

311:

308:

305:

302:

298:

297:

294:

291:

288:

285:

282:

278:

277:

274:

271:

268:

265:

262:

258:

257:

252:

247:

242:

237:

234:

213:

210:

207:

206:

203:

199:

198:

195:

191:

190:

187:

183:

182:

179:

175:

174:

171:

167:

166:

163:

159:

158:

157:Chemical name

155:

143:diphenyl ether

103:diphenyl ether

78:

75:

15:

13:

10:

9:

6:

4:

3:

2:

1812:

1801:

1798:

1796:

1793:

1791:

1788:

1787:

1785:

1772:

1767:

1761:

1758:

1756:

1753:

1749:

1746:

1744:

1741:

1739:

1736:

1732:

1729:

1728:

1727:

1726:Garbage patch

1724:

1723:

1722:

1719:

1718:

1716:

1712:

1700:

1697:

1695:

1692:

1690:

1687:

1685:

1682:

1681:

1679:

1675:

1669:

1666:

1664:

1661:

1659:

1656:

1654:

1651:

1647:

1644:

1643:

1642:

1639:

1638:

1636:

1632:

1626:

1623:

1621:

1618:

1616:

1613:

1611:

1608:

1606:

1603:

1601:

1598:

1597:

1595:

1593:

1592:Health issues

1589:

1581:

1578:

1577:

1576:

1573:

1571:

1568:

1566:

1563:

1561:

1558:

1557:

1555:

1551:

1544:

1540:

1537:

1534:

1530:

1527:

1526:

1524:

1522:

1518:

1511:

1508:

1506:

1502:

1499:

1497:

1494:

1493:

1491:

1487:

1481:

1478:

1476:

1473:

1470:

1467:

1465:

1462:

1459:

1456:

1454:

1451:

1449:

1446:

1445:

1443:

1441:

1437:

1433:

1428:

1424:

1416:

1411:

1409:

1404:

1402:

1397:

1396:

1393:

1388:

1382:

1372:

1369:

1367:

1366:Shopping bags

1364:

1362:

1359:

1357:

1354:

1352:

1349:

1347:

1344:

1342:

1339:

1337:

1334:

1333:

1331:

1327:

1321:(Agriculture)

1320:

1319:Plasticulture

1317:

1315:

1312:

1310:

1307:

1305:

1302:

1300:

1299:Geosynthetics

1297:

1295:

1292:

1290:

1287:

1285:

1282:

1281:

1279:

1276:

1272:

1269:

1265:

1259:

1256:

1254:

1251:

1249:

1246:

1244:

1241:

1239:

1236:

1234:

1231:

1229:

1226:

1224:

1221:

1219:

1216:

1214:

1211:

1209:

1206:

1204:

1203:Thermoforming

1201:

1199:

1196:

1194:

1191:

1189:

1186:

1185:

1183:

1177:

1171:

1168:

1166:

1163:

1161:

1158:

1156:

1153:

1151:

1148:

1146:

1143:

1142:

1140:

1136:

1130:

1127:

1125:

1122:

1120:

1117:

1115:

1112:

1110:

1107:

1105:

1104:Thermoplastic

1102:

1101:

1099:

1093:

1088:

1082:

1072:

1069:

1067:

1064:

1062:

1059:

1057:

1054:

1052:

1049:

1047:

1044:

1042:

1039:

1037:

1034:

1032:

1029:

1027:

1024:

1022:

1019:

1017:

1014:

1012:

1009:

1007:

1004:

1002:

999:

997:

994:

992:

989:

987:

984:

982:

979:

977:

974:

972:

969:

967:

964:

962:

959:

957:

954:

952:

949:

947:

944:

942:

939:

937:

934:

932:

929:

928:

926:

920:

916:

909:

904:

902:

897:

895:

890:

889:

886:

878:

873:

870:

863:

860:

854:

851:

844:

841:

838:

832:

829:

826:

820:

817:

814:

808:

805:

798:

795:

789:

786:

780:

777:

771:

768:

762:

759:

753:

751:

749:

745:

741:

735:

727:

725:

721:

717:

710:

708:

701:

699:

696:

690:

683:

676:

673:

670:

667:

666:

662:

659:

656:

653:

652:

648:

645:

642:

639:

638:

634:

631:

628:

625:

624:

620:

617:

614:

611:

610:

606:

603:

600:

597:

596:

592:

589:

586:

583:

582:

578:

575:

572:

569:

568:

564:

561:

558:

555:

554:

550:

547:

544:

541:

540:

536:

533:

530:

527:

526:

522:

519:

516:

513:

512:

508:

505:

502:

499:

498:

492:

487:

482:

479:

478:

472:

464:

461:

457:

450:

448:

445:

436:

434:

427:

425:

414:

409:

407:

406:isomerization

398:

396:

394:

389:

382:

375:

372:

370:316; >600

369:

366:

363:

360:

359:

355:

352:

349:

346:

343:

340:

339:

335:

332:

329:

326:

323:

320:

319:

315:

312:

309:

306:

304:Clear liquid

303:

300:

299:

295:

292:

289:

286:

284:Clear liquid

283:

280:

279:

275:

272:

269:

266:

264:Clear liquid

263:

260:

259:

253:

248:

243:

238:

235:

232:

231:

225:

223:

218:

211:

204:

201:

200:

196:

193:

192:

188:

185:

184:

180:

177:

176:

172:

169:

168:

164:

161:

160:

156:

153:

152:

146:

144:

139:

136:

130:

128:

124:

120:

110:

104:

99:

92:

88:

83:

76:

74:

71:

67:

66:

61:

57:

53:

49:

45:

41:

37:

29:

21:

1436:Plasticizers

1384:Environment

1336:Blister pack

1289:Construction

1198:Blow molding

1015:

872:

862:

853:

843:

831:

819:

807:

797:

788:

779:

770:

761:

737:

722:

718:

714:

705:

691:

687:

490:Dow Corning

465:

456:Vacuum pumps

454:

440:

437:Applications

431:

410:

402:

393:isoteniscope

390:

386:

361:2-ring 2P1E

341:3-ring 3P2E

324:Hazy liquid

301:4-ring 4P3E

281:5-ring 5P4E

261:6-ring 6P5E

219:

215:

140:

134:

131:

115:

90:

69:

63:

59:

55:

35:

34:

1677:Regulations

1529:Bisphenol A

1213:Calendering

1155:Plasticizer

1095:Mechanical

485:SANTOVAC 5

239:Pour point

236:Appearance

127:halogenated

48:thiophenoxy

1800:Lubricants

1795:Polyethers

1784:Categories

1605:Carcinogen

1570:Organotins

1440:Phthalates

1386:and health

1233:Pultrusion

1223:Laminating

1181:processing

754:References

716:bearings.

671:Excellent

657:Excellent

649:Poor-fair

646:Excellent

643:Excellent

629:Excellent

165:Bis ether

85:Figure 3:

1634:Pollution

1600:Teratogen

1531:(BPA, in

1179:Plastics

1150:Colorants

1138:Additives

922:Chemical

867:Publisher

488:Silicone

350:427; 800

330:367; 693

327:−29; −20

310:441; 825

290:453; 847

270:447; 836

246:(°C; °F)

241:(°C; °F)

89:of 4R2E (

1790:Plastics

1615:Diabetes

1521:Monomers

1501:Adipates

1423:plastics

1277:segments

1267:Products

915:Plastics

848:failures

744:pyridine

695:fretting

495:Apiezon

307:−12; 10

287:4.5; 40

40:polymers

1743:Dioxins

1663:Dioxins

1620:Obesity

1361:Cutlery

1351:Bottles

267:10; 50

138:known.

125:with a

123:phenate

62:s) and

44:phenoxy

1460:(BBzP)

1429:(PHCs)

1341:Chairs

1309:Nurdle

702:Optics

364:Solid

344:Solid

1714:Waste

1560:PBDEs

1471:(DOP)

1097:types

924:types

677:Fair

674:Good

663:Poor

660:Good

635:Poor

632:Good

621:1.48

618:1.56

615:1.67

607:30.5

604:30.5

601:49.9

587:12.0

573:1000

537:0.87

534:1.07

531:1.20

509:5×10

506:2×10

503:4×10

273:2000

52:ether

46:or a

1575:PFCs

1565:PCBs

1541:(in

1505:DEHA

1480:DINP

1475:DIDP

1469:DEHP

1464:DIHP

1448:DIBP

1425:and

1356:Bags

742:and

593:7.0

590:4.3

579:135

565:220

562:223

559:295

551:243

548:221

545:288

523:420

520:484

517:446

376:1.6

373:2.4

293:360

1543:PVC

1510:DOA

1458:BBP

1453:DBP

576:40

353:12

333:25

313:70

296:13

276:25

70:PPO

60:PPE

1786::

1438::

367:-

356:3

347:-

336:4

316:6

1545:)

1535:)

1512:)

1503:(

1414:e

1407:t

1400:v

907:e

900:t

893:v

468:×

422:×

417:×

135:n

91:p

68:(

58:(

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.