391:

about the type of equipment in use, and how it was used, the HSE looked back at the results from its annual testing of portable appliances across its estate over the last five years. Using the results of the previous tests, the HSE decided that further portable appliance tests are not needed within the foreseeable future or at all for certain types of portable equipment. Also, they decided to continue to monitor any faults reported as a result of user checks and visual inspections and review its maintenance system if evidence suggests that it needs revising. Electrical equipment will continue to be maintained by a series of user checks and visual inspections by staff that have had some training.

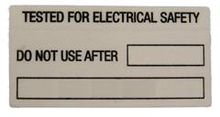

411:. In some cases testing was conducted on a three-month (high-risk) and six-month (low-risk) cycle from the early 1960s onwards. Extensive record-keeping was made into log-books and generally the equipment used was an insulation resistance tester, simple hand tools and visual inspection. Evidence of testing was clearly visible to workers in the form of "passed," "tested for electrical safety," and "do not use after..." labels affixed to various parts of the electrical equipment used. This early testing and inspection was done under a planned maintenance scheme and pre-dated both the

751:

by a tester is actually producing microwaves. After checking for leakage the door is required to be opened by whatever means is provided and the measurement device is not to record a level above the given limit. In some scenarios a known quantity of water is heated for a known period of time and the temperature rise over the period of operation is used to generate an indication of the effective power output of the magnetron. This can be helpful to determine whether the oven is operating at the expected power levels indicated by labelling.

139:

535:

simulate a fault condition: if a live part contacts the earthed metalwork, the earth conductor should be able to carry sufficient current to blow the fuse and render the appliance safe, without the earth conductor itself burning out. On the other hand, some equipment (especially IT equipment) could be damaged by this test, as the earth connection is only for functional purposes and is not meant to be relied upon for safety.

895:

376:(HSE) recommends that a competent person must inspect the installation regularly in any public building or a place that people work. They suggest initial intervals for combined inspection and testing that range from three months (for construction equipment) to one year, and in many cases, longer periods for re-testing (certain types of appliance in schools, hotels, offices and shops).

43:

801:

It has become accepted practice, however, for individuals operating as PAT Testers to hold a 2377–22 (or a later version, such as 2377-77) City and Guilds qualification. PAT Testers in the UK do not need to be electricians or have a background in the electrical industry. An example of a nationally recognised qualification of competence in PAT testing is offered by

830:

under test, for example, a protective conductor current or touch current tests. The main kind for businesses are simple PASS/FAIL testers that are easy to use, and are aimed at in-house PAT testing with minimal interpretation of results. Advanced PAT testers can give much more information and testing features but are mainly aimed at more highly skilled users.

84:

800:

In the UK, there is no requirement to have a formal qualification for persons carrying out PAT Testing. The

Electricity at Work regulations of 1989 simply state that where required, inspecting and testing must be carried out by a competent person, however does not mention a benchmark for competency.

750:

whilst the unit is operating. As microwave ovens are not normally designed to be operated without a load this will usually take the form of an open container containing a quantity of water which is used to absorb the energy and as it gets warmed gives an indication that a unit not previously examined

440:

This can be done by hiring an external company to test all the electrical products in a business (someone who has had some PAT training, either by an official qualification or by attending a health and safety course offered by some electrical health and safety companies) or it can be done in-house by

423:

In the UK there is no legal instrument that requires a sub-contractor to ensure that all tools and equipment are PAT inspected before bringing onto a site of work. Neither is there any legal instrument which obliges the site owner to ensure third-party equipment is PAT inspected either by themselves

941:

Dual purpose check boxes (which are essentially known resistances either side of the test limits) have also been introduced, which are capable of validating the accuracy of both electrical installation testers and portable appliance testers in the field, reducing the risk of a tester being used when

916:

As PAT testers are sophisticated instruments, it is important to make sure that they are continuing to measure correctly. If a company fails to check and maintain calibration, it could face difficulty substantiating any measurements in the event of a claim. It is usually recommended that calibration

865:

Earth continuity resistance (aka Earth Bond) tests with a measurement range of 0 – 1.99 Ω at high test currents (usually 8 A, 10 A or 25 A) and lower test currents (in the range 20 mA to 200 mA), enabling a complete range of appliances including personal computers to be

791:

The earth lead is connected to metal parts on both Class I and Class II appliances. For "Class I" during the earth test to prove continuity between earth pin and metal parts on the appliance. For "Class II" during the insulation test to prove the insulation between active-neutral and the metal parts

774:

Class II – Double insulated wiring, The earth clamp is still connected during the insulation test. The appliance may or may not have an earth connection (some appliances have a functional earth), but the safety of the appliance does not depend on the earth connection. Class II is indicated by double

427:

The internal policies of many UK businesses and educational establishments make mistaken reference to PAT inspection being a legal requirement under the

Electricity at Work Regulations, which is false. Having such a policy is legitimate for internal reasons, but it is not underwritten by law; it is

394:

Annual portable appliance testing is not always necessary in low risk environments. You do not need to be qualified as an electrician to carry out visual inspections. Regular user checks and visual inspections can be a good method of maintaining portable electric equipment. For landlords maintaining

390:

Recent HSE publications have relaxed their tone somewhat to acknowledge this, and now point out that in many situations an annual PAT test is disproportionate to the risks and is often not required. In 2011, the HSE reviewed its approach to portable appliance maintenance in its own offices. Thinking

907:

Some advanced PAT testers can download information to a computer. Bluetooth enabled computerised PAT testers make the two way transfer of test data between the tester and PC-based record keeping systems much simpler, and can be used with other test accessories such as label printers. Records can be

816:

In New

Zealand it is not a legal requirement to attend a training course, however persons undertaking Portable Appliance Testing must be deemed Competent by a Responsible person (being the owner of the premises electrical equipment or someone with a legal responsibility for the safety of electrical

466:

At periodic intervals, the portable appliances are tested to measure that the degree of protection to ensure that it is adequate. At these intervals, a formal visual inspection is carried out and then followed by electrical testing. Note the inside of the plug should be checked unless it is moulded

812:

In

Australia it is not a legal requirement to have attended a course or gained a qualification in order to PAT - AS/NZS 3760 2010 stipulates a competent person may Test and Tag, and that a person may be a competent person through formal training (i.e. a test and tag course), experience on the job,

617:

In countries where the sockets are polarised, polarity testing is a simple test that can be carried out using a polarity tester to determine whether the active and neutral of the plug end are correctly connected to the corresponding terminals at the socket end. Note: The earth is tested during the

449:

Advising the user of potential danger signs can result in problems being picked up before they can result in any danger. For example, if the power cable is frayed or the plug is cracked, users need to be advised not to use the appliance and report the fault to a supervisor. This information can be

303:

regulations require that electrical appliances are safe and well maintained to prevent harm to workers. Many equipment manufacturers recommend testing at regular intervals to ensure continual safety, with the interval between tests varying based on both the type of appliance and the environment in

599:

A deficiency of the insulation resistance (500 V /250 V DC) test is that the DC voltage will not activate electromagnetic switches or internal relays etc. that are common in many modern power tools, computers, TVs etc. and therefore it can only test the appliance up to that point. Appliances with

534:

The choice of which of the tests to use is at the operator's discretion as there is merit in each test for given situations. Later model testers that are battery powered are limited to doing the "screen test". Older mains powered units can do all tests. The purpose of the high current test is to

319:

and

European product standards relevant to that type of appliance. This in turn allows testing and the interpretation of results to be de-skilled to a large extent. The inspection of the appliances can largely be carried out in-house in many organisations. This can result in cost savings and more

829:

At the basic level, PAT test instruments carry out basic safety checks. Most are equipped with an earth continuity test, insulation resistance test and the ability to check the wiring of detachable mains cords. Many do not however include tests which involve applying mains power to the appliance

838:

These are the simple-to-use and comparatively much cheaper portable appliance testers for most businesses who will test in-house to carry out the testing and suitable for a wide range of businesses. They simply say PASS or FAIL when a test is carried out. Mains powered testers require AC power.

379:

Although the

Electricity at Work Regulations 1989 is an obligation on UK businesses, there is no obligation to undertake PAT inspection. In reality neither act nor their corresponding regulations and associated statutory instruments detail PAT inspection as an obligation, but rather impose a

741:

The first is that the device immediately ceases production of the microwave radiation when the door is opened, which checks that the safety interlock systems are functional; and the second is that any leakage when operating is less than 5 mWcm which indicates that the door and casing are not

608:

AS/NZS 3760:2010 section 2.3.3.2 requires a leakage test to be carried out if equipment being tested must be energised to close the circuit or operate a switching device. Leakage testing does require the item being tested to be powered up thus meaning the item will switch on and operate.

308:

governs the manufacture or importation of electrical appliances. Compliance with these standards has to be declared and indicated by the display of the CE mark on the product. The responsibility for testing lies with the manufacturer or the importer and is policed by

Trading Standards.

653:) of the socket apertures of a three pin flat pin socket, to their connections, shall be Earth (radial pin – green/yellow wire), Active (brown wire) and then Neutral (light blue wire), in a clockwise direction, when viewed from the front of the socket looking at the apertures.

745:

A piece of calibrated equipment is required for these tests to detect and measure leakage of the 2.4 GHz microwave radiation, it is usually a hand-held device with a sensing antenna that can be scanned over the areas where the door meets the casing to find any radiation

825:

PAT testing can be conducted manually, using a collection of standard test gear, including a high-voltage insulation tester and a low resistance ohm meter for earth continuity. But generally it is conducted with an automatic tester that applies a sequence of tests in turn.

305:

787:

are not legal in the UK and other countries. By treating all appliances without Class II or III markings as Class I by default, Class 0 appliances will fail testing as a Class I device. Similarly, Class II or III with stickers that have fallen off will also fail.

882:

These readings require interpretation by an electrician or someone with electrical understanding. Advanced PAT testers are effective as facilities management tools because they can record the location and test status of electrical equipment and appliances.

805:: 2377-77 Level 3 Award in the In-service Inspection and Testing of Electrical Equipment (603/6790/8), while the current (2023) guidance is the 'Code of Practice for In-service Inspection and Testing of Electrical Equipment – 5th Edition' published by the

639:) of the pins of a three pin flat pin plug, to their connections, shall be Earth (radial pin – green/yellow wire), Neutral (light blue wire) and then Active (brown wire), in a clockwise direction, when viewed from the front of the plug looking at the pins.

431:

The HSE recommend policies use phrases such as "equipment that is brought onto site for an event must be in a safe condition" and refrain from overzealous statements such as "must be PAT inspected" which can be restrictive without improving safety.

479:

and subject to a risk assessment by the technician. e.g. it may not be safe to perform a leakage current test which powers up the appliance, such as a grinder, if it cannot be secured to a bench; an insulation resistance test may be a safe option.

565:

Leakage current testing is performed using a PAT by applying a nominal voltage to the live conductors (active and neutral) of an appliance, and placing 0 volt reference on the earthed parts of a Class I appliance or the external metal parts of a

578:

Insulation resistance testing is performed using an ohmmeter or portable appliance tester by applying a nominal voltage to the live conductors (active and neutral) of an appliance, and placing 0 volt reference on the earthed parts of a

214:

778:

Class III – These are appliances that are supplied at a low voltage called

Separated Extra Low Voltage (SELV) which must be less than 50 V. These appliances are supplied with a transformer supply that is also marked as an SELV

352:) requires that all electrical systems (including electrical appliances) are maintained (so far as it is reasonable and practicable) to prevent risk of injury or danger. Private houses are not covered by this legislation, although

1297:

754:

Microwave leakage testing was removed in version 4 of the IET Code of

Practice, to revert microwave oven testing to the same as any other appliance, but with emphasis put on the visual inspection of the door seal.

488:

This test shows the resistance offered by the earthing rods with the connection leads. Various testing instruments are available for earthing resistance tests. The earthing resistance ideally is less than

711:

A current, equal to the rated tripping current, shall be "suddenly" applied between active and protective earth and the operating time measured with maximum trip time 40 ms for Type I and 300 ms for Type

681:(the TEST button referred to here is the test button on the RCD tester not the TEST button on the RCD itself. If the RCD is live, pressing the RCD's own test button should always trip the RCD).

395:

legal requirements it is not compulsory for them to have all appliances tested, but they do need to show a "duty of care" and most letting agents recommend that a test certificate is obtained.

450:

put across, say by the use of a poster or in a memo. User checks are always carried out before the operation, and the results are generally not recorded unless a defect is identified.

771:

Class I – Single insulated wiring, which requires an earth connection for safety. If the appliance has no symbol on it, then it is to be treated as Class I for the purpose of testing.

328:

Portable appliance testing is abbreviated as PAT. The correct term for the whole process is "In-service

Inspection & Testing of Electrical Equipment" (as defined by IET/IEE and

356:

requires householders not to deliberately expose occupants or visitors to unreasonable risks. The HSE and the local authority are responsible for the policing of this legislation.

458:

This is a process of simply inspecting the appliance, the cable and the plug for any obvious signs of damage. According to the HSE, this process can find more than 90% of faults.

387:

Today a great many private companies and other organizations do meet their legal obligations to protect their workers by an enforced PAT regime, but it is not the only route.

428:

only their interpretation. Therefore, it is not a legal requirement to have a PAT inspection sticker or certificate, rather the obligation is that equipment must be safe.

927:

Calibrating the unit back to national standards. This is best performed by the product manufacturer (if they offer a calibration service) or a laboratory accredited by

441:

a competent person. In a low-risk environment most dangerous defects can be found simply by checking the appliances for obvious signs of damage such as frayed cables.

1442:

959:

558:(IR) values are not less than 1MΩ for Class I and Class II appliances at 500 V d.c., or at 250 V d.c. to avoid the equipment apparently failing the test because the

891:

Some units can also test RCDs, following the recommendation in the current IEE Code of Practice to test any RCD fitted on an extension lead or multiway adapter.

842:

These testers have a simple "lights" system. They have a "Pass" light, a "Fail" light, options for Class I metal / plastic or Class II. They also will show:

56:

315:

Testing equipment has been specifically developed for PAT inspections, based on the testing equipment used by manufacturers to ensure compliance with the

261:

of the equipment and verification that power cables are in good condition. Additionally, other tests may be done when required, such as a verification of

562:(MOVs) or electro-magnetic interference (EMI) suppression triggered, for equipment containing voltage limiting devices such as MOVs or EMI suppression.

806:

365:

1117:

1452:

353:

467:

or there is an unbroken seal covering the screws (bad internal wiring or an unsuitable fuse would cause the item to be classed as dangerous).

738:

Specific microwave leakage testing was recommended for microwave ovens in the United Kingdom up until version 3 of the IET Code of Practice.

408:

928:

349:

160:

102:

94:

1031:

802:

369:

1328:

412:

335:

In Australia and New Zealand, the common name for PAT is simply 'Test and Tag.' The regulatory guidelines are set out in AS/NZS 3760.

1281:

403:

The first official appliance-testing equipment in the UK was used for government housing estates. This was under the control of the

316:

200:

182:

120:

70:

626:, the phase ('Live' or 'Hot') cable should connect with the right hand side terminal of the socket (if we face the socket outlet).

1007:

983:

924:

Ensuring the resistance readout is accurate and correcting for any drift arising from ageing of components inside the PAT tester,

730:

Best Practice is to test the RCD under 1/2, 1X and 5X rated tripping current, each at both the 0 degree and 180 degree phases.

62:

528:

12V maximum, 1.5 times rated current of appliance or 25A, whichever is greater - commonly known as "type test" or "bond test".

1258:

1167:

667:

872:

Protective conductor/touch current measurement (sometimes referred to as "earth leakage tests" on some older PAT units);

257:. The formal term for the process is "in-service inspection & testing of electrical equipment". Testing involves a

1462:

1354:

839:

Battery operated PAT testers are self-contained and convenient to use. They usually come with rechargeable batteries.

373:

792:

of the appliance. i.e. there is no leakage from mains coming into the appliance to the metal parts that are exposed.

153:

147:

691:

Select half delta range, and press TEST button - the RCD should not operate, this ensures against nuisance tripping.

1099:

694:

Select delta range, and press TEST button - The RCD should operate, within ms for 50 Hz, 230 V system (as per

1447:

767:

are differentiated by a series of IEC protection classes. The protocols for PAT Testing vary by appliance class:

222:

31:

164:

1457:

404:

920:

When a PAT tester is calibrated, it is internally trimmed to match the original specification. This includes:

723:

using 5 times rated tripping current, with trip times reduced accordingly, to simulate high current exposure.

663:

509:

270:

522:

12V maximum, test current range 100mA to 200mA - commonly known as "earth continuity test" or "screen test"

742:

distorted and any seals are intact so that there is no hazard to those in the vicinity of the equipment.

1121:

1053:

555:

1407:

1402:

277:-carrying parts, and a check for any exposed metal that could be touched. The formal limits for a pass/

241:) is a process by which electrical appliances are routinely checked for safety, commonly used in the

650:

636:

475:

The tests an appliance is required to undergo will depend on the type of appliance, its electrical

381:

1100:"Electrical Landlord Certificates: What you need to know | Blog Post | Premier Electrical Company"

505:

or the earthing conductor of an extension cord or appliance cord set, which does not exceed 1Ω.

1324:

1277:

937:

A calibration certificate should be issued to prove the PAT unit has been electrically tested.

764:

584:

580:

567:

548:

544:

476:

300:

258:

281:

of these electrical tests vary somewhat depending on the category of equipment being tested.

1321:

Code of Practice for In-service Inspection and Testing of Electrical Equipment – 5th Edition

502:

274:

1428:

Memorandum of guidance on the Electricity at Work Regulations 1989. Guidance on Regulations

1412:

592:

574:

Nominal voltage is 230 V AC. (therefore it can not be performed with a digital multimeter)

559:

329:

266:

262:

1422:

942:

not operating correctly - this also allows the re-calibration interval to be increased.

284:

Other countries have similar procedures, for example, testing of equipment according to

242:

17:

1423:

IET/IEE Code of practice for in-service inspection and testing of electrical equipment

1436:

1343:

543:

A leakage current test performed at rated voltage with values not exceeding 5mA for

1376:

1365:

894:

250:

869:

Insulation resistance tests at test voltages of 500 V DC or 250 V DC.

1427:

684:

The RCD tester should be connected with the socket, with earth terminal and

254:

600:

these components / design should be tested using the leakage current test.

591:

Nominal voltage is 500 V DC (250 V DC may be used for equipment containing

1418:

UK Health and Safety Executive – Portable appliance testing myths debunked

1087:

1076:

861:

These testers display more information than just pass or fail, including:

27:

Procedure in which electrical appliances are routinely checked for safety

720:

using 1/2 (half) the rated tripping current to detect nuisance tripping.

688:

select the testing range 'delta' (10 mA, 30 mA, 100 mA, 300 mA, 500 mA).

213:

1191:

1054:"PAT (Portable appliance testing) - HSE's answers to popular questions"

784:

707:

This test requires specialised test equipment, knowledge and training;

695:

623:

289:

246:

1417:

893:

212:

1319:

The Institution of Engineering and Technology (21 October 2020).

525:

12V maximum, test current 10A - commonly known as "routine test"

278:

1204:

Best Practices in Testing & Tagging of Electrical Equipment

1088:

Maintaining portable electric equipment in low-risk environment

934:

If it is mains powered, then a safety test must be carried out.

490:

312:

In Australia and New Zealand the standard used is AS/NZS3760.

132:

77:

36:

217:

A common label for certifying that a device has been tested.

1032:"Corded and electric? Test it and tag it with AS/NZS 3760"

1243:

In-service inspection and testing of electrical equipment

1230:

In-service inspection and testing of electrical equipment

1217:

In-service inspection and testing of electrical equipment

1180:

In-service inspection and testing of electrical equipment

1156:

In-service inspection and testing of electrical equipment

1143:

In-service inspection and testing of electrical equipment

1387:

678:

This test requires specific test equipment RCD tester:

1077:

Health and Safety Executive, Electrical safety and you

501:

The equipment shall have a measured resistance of the

1298:"Electrical Equipment Maintenance and Testing (2377)"

1206:

to AS/NZS 3760:2003. (Zahra & Virieux 2007) 5.8.1

380:

requirement of maintenance of safety and evidence of

320:

flexibility as to exactly when a PAT is carried out.

908:

maintained using PAT software such as PATorganiser.

419:

Site and campus requirements, events and contractors

960:"Low Voltage Directive (LVD) - European Commission"

519:Using a PAT tester under the following conditions:

384:for all hand-held, portable and plug-in equipment.

1323:. The Institution of Engineering and Technology.

1259:"How do I PAT test a microwave? | PAT FAQ's"

716:In addition to this, many technicians also test;

917:is carried out annually on a PAT testing unit.

670:(ELCB), there are two test methods to be used:

30:"PAT Test" redirects here. For other uses, see

8:

1413:HSE Maintaining electrical equipment safety

1168:Understanding Insulation Resistance Testing

583:appliance or the external metal parts of a

71:Learn how and when to remove these messages

1253:

1251:

619:

508:Testing is performed using an ohmmeter or

807:Institution of Engineering and Technology

366:Institution of Engineering and Technology

201:Learn how and when to remove this message

183:Learn how and when to remove this message

121:Learn how and when to remove this message

1388:The United Kingdom Accreditation Service

146:This article includes a list of general

1443:Electrical safety in the United Kingdom

951:

813:qualification, or combination thereof.

516:Using the ohmmeter to produce a reading

1274:Handbook of Portable Appliance Testing

898:Modern PAT testers include an RCD test

415:and the Electricity at Work Act 1989.

409:Ministry of Public Building and Works

7:

929:United Kingdom Accreditation Service

726:under 0 degree and 180 degree phases

350:Electricity at Work Regulations 1989

1408:HSE Portable appliance testing FAQs

964:single-market-economy.ec.europa.eu

413:Health and Safety at Work Act 1974

152:it lacks sufficient corresponding

93:tone or style may not reflect the

25:

317:British Standard Code of Practice

52:This article has multiple issues.

137:

103:guide to writing better articles

82:

41:

1300:. City&Guilds. 25 July 2022

796:PAT training and qualifications

60:or discuss these issues on the

1453:Occupational safety and health

1118:"Faults and electrical safety"

658:RCDs / ELCBs / safety switches

306:European Low Voltage Directive

1:

1104:electricians-portsmouth.co.uk

668:earth-leakage circuit breaker

269:, a test of the soundness of

462:Combined inspections and PAT

304:which it is to be used. The

1403:HSE guidance on PAT testing

1241:Standard: AS/NZS 3760:2003

1228:Standard: AS/NZS 3760:2003

1215:Standard: AS/NZS 3760:2003

1178:Standard: AS/NZS 3760:2003

1154:Standard: AS/NZS 3760:2003

1141:Standard: AS/NZS 3760:2003

374:Health and Safety Executive

1479:

1377:Insulation Resistance Test

539:Insulation resistance test

368:(IET, published under the

227:portable appliance testing

29:

454:Formal visual inspections

360:Fixed wiring in buildings

223:electrical safety testing

32:PAT Test (disambiguation)

1276:. Ohm Books Publishing.

903:Computerised PAT testers

664:residual-current devices

554:Alternatively, measured

503:protective earth circuit

424:or the equipment owner.

405:Property Services Agency

1272:Segaran, Seggy (2022).

1232:Sec 2.3.3.5(b). General

1219:Sec 2.3.3.5(a). General

1182:Sec 2.3.3.2(b). General

834:Pass / fail PAT testers

167:more precise citations.

97:used on Knowledge (XXG)

18:Portable Appliance Test

1355:Commercial Electrician

912:Calibration of testers

899:

644:Cord extension sockets

547:appliances or 1mA for

218:

101:See Knowledge (XXG)'s

1366:Earth Continuity Test

897:

849:insulation resistance

759:Class of construction

620:earth continuity test

560:metal oxide varistors

556:insulation resistance

497:Earth continuity test

484:Earth resistance test

216:

1345:What Is AS/NZS 3760?

1012:www.standards.org.au

988:www.standards.org.au

857:Advanced PAT testers

821:Types of PAT testers

622:. In the UK, as per

407:– prior to 1972 the

354:occupiers' liability

339:UK legal obligations

382:routine maintenance

1463:Safety engineering

900:

666:(RCDs), a type of

364:Guidance from the

219:

809:in October 2021.

803:City & Guilds

765:appliance classes

348:British law (the

301:Health and safety

286:DGUV Vorschrift 3

259:visual inspection

211:

210:

203:

193:

192:

185:

131:

130:

123:

95:encyclopedic tone

75:

16:(Redirected from

1470:

1448:Electrical tests

1390:

1385:

1379:

1374:

1368:

1363:

1357:

1352:

1346:

1341:

1335:

1334:

1316:

1310:

1309:

1307:

1305:

1294:

1288:

1287:

1269:

1263:

1262:

1255:

1246:

1239:

1233:

1226:

1220:

1213:

1207:

1201:

1195:

1189:

1183:

1176:

1170:

1165:

1159:

1152:

1146:

1139:

1133:

1132:

1130:

1129:

1120:. Archived from

1114:

1108:

1107:

1096:

1090:

1085:

1079:

1074:

1068:

1067:

1065:

1064:

1050:

1044:

1043:

1041:

1039:

1034:. August 8, 2022

1028:

1022:

1021:

1019:

1018:

1008:"Catalogue Item"

1004:

998:

997:

995:

994:

984:"Catalogue Item"

980:

974:

973:

971:

970:

956:

846:earth continuity

783:Classes such as

595:/ EMI filtering)

436:Carrying out PAT

206:

199:

188:

181:

177:

174:

168:

163:this article by

154:inline citations

141:

140:

133:

126:

119:

115:

112:

106:

105:for suggestions.

86:

85:

78:

67:

45:

44:

37:

21:

1478:

1477:

1473:

1472:

1471:

1469:

1468:

1467:

1458:Product testing

1433:

1432:

1399:

1394:

1393:

1386:

1382:

1375:

1371:

1364:

1360:

1353:

1349:

1342:

1338:

1331:

1318:

1317:

1313:

1303:

1301:

1296:

1295:

1291:

1284:

1271:

1270:

1266:

1257:

1256:

1249:

1240:

1236:

1227:

1223:

1214:

1210:

1202:

1198:

1190:

1186:

1177:

1173:

1166:

1162:

1158:Sec 2. 3.3.2(a)

1153:

1149:

1140:

1136:

1127:

1125:

1116:

1115:

1111:

1098:

1097:

1093:

1086:

1082:

1075:

1071:

1062:

1060:

1052:

1051:

1047:

1037:

1035:

1030:

1029:

1025:

1016:

1014:

1006:

1005:

1001:

992:

990:

982:

981:

977:

968:

966:

958:

957:

953:

948:

914:

905:

889:

859:

836:

823:

798:

761:

736:

734:Microwave ovens

705:

703:Applied current

676:

660:

646:

632:

615:

606:

541:

499:

486:

473:

464:

456:

447:

438:

421:

401:

372:brand) and the

362:

346:

341:

330:City and Guilds

326:

298:

207:

196:

195:

194:

189:

178:

172:

169:

159:Please help to

158:

142:

138:

127:

116:

110:

107:

100:

91:This article's

87:

83:

46:

42:

35:

28:

23:

22:

15:

12:

11:

5:

1476:

1474:

1466:

1465:

1460:

1455:

1450:

1445:

1435:

1434:

1431:

1430:

1425:

1420:

1415:

1410:

1405:

1398:

1397:External links

1395:

1392:

1391:

1380:

1369:

1358:

1347:

1336:

1330:978-1785619663

1329:

1311:

1289:

1282:

1264:

1247:

1234:

1221:

1208:

1196:

1184:

1171:

1160:

1147:

1134:

1109:

1091:

1080:

1069:

1058:www.hse.gov.uk

1045:

1023:

999:

975:

950:

949:

947:

944:

939:

938:

935:

932:

925:

913:

910:

904:

901:

888:

885:

880:

879:

878:Lead polarity.

876:

873:

870:

867:

858:

855:

854:

853:

850:

847:

835:

832:

822:

819:

797:

794:

781:

780:

776:

772:

760:

757:

735:

732:

728:

727:

724:

721:

714:

713:

704:

701:

700:

699:

692:

689:

675:

672:

659:

656:

655:

654:

645:

642:

641:

640:

631:

628:

614:

613:Polarity check

611:

605:

602:

597:

596:

576:

575:

540:

537:

532:

531:

530:

529:

526:

523:

517:

498:

495:

485:

482:

472:

469:

463:

460:

455:

452:

446:

443:

437:

434:

420:

417:

400:

397:

361:

358:

345:

342:

340:

337:

325:

324:Origin of name

322:

297:

294:

243:United Kingdom

235:PAT inspection

209:

208:

191:

190:

145:

143:

136:

129:

128:

90:

88:

81:

76:

50:

49:

47:

40:

26:

24:

14:

13:

10:

9:

6:

4:

3:

2:

1475:

1464:

1461:

1459:

1456:

1454:

1451:

1449:

1446:

1444:

1441:

1440:

1438:

1429:

1426:

1424:

1421:

1419:

1416:

1414:

1411:

1409:

1406:

1404:

1401:

1400:

1396:

1389:

1384:

1381:

1378:

1373:

1370:

1367:

1362:

1359:

1356:

1351:

1348:

1344:

1340:

1337:

1332:

1326:

1322:

1315:

1312:

1299:

1293:

1290:

1285:

1283:9798771096926

1279:

1275:

1268:

1265:

1260:

1254:

1252:

1248:

1245:Appendix D D3

1244:

1238:

1235:

1231:

1225:

1222:

1218:

1212:

1209:

1205:

1200:

1197:

1193:

1188:

1185:

1181:

1175:

1172:

1169:

1164:

1161:

1157:

1151:

1148:

1144:

1138:

1135:

1124:on 2016-01-12

1123:

1119:

1113:

1110:

1105:

1101:

1095:

1092:

1089:

1084:

1081:

1078:

1073:

1070:

1059:

1055:

1049:

1046:

1033:

1027:

1024:

1013:

1009:

1003:

1000:

989:

985:

979:

976:

965:

961:

955:

952:

945:

943:

936:

933:

930:

926:

923:

922:

921:

918:

911:

909:

902:

896:

892:

886:

884:

877:

874:

871:

868:

864:

863:

862:

856:

851:

848:

845:

844:

843:

840:

833:

831:

827:

820:

818:

814:

810:

808:

804:

795:

793:

789:

786:

777:

773:

770:

769:

768:

766:

758:

756:

752:

749:

743:

739:

733:

731:

725:

722:

719:

718:

717:

710:

709:

708:

702:

697:

693:

690:

687:

686:

685:

682:

679:

673:

671:

669:

665:

657:

652:

648:

647:

643:

638:

634:

633:

629:

627:

625:

621:

612:

610:

603:

601:

594:

590:

589:

588:

586:

582:

573:

572:

571:

569:

563:

561:

557:

552:

550:

546:

538:

536:

527:

524:

521:

520:

518:

515:

514:

513:

511:

506:

504:

496:

494:

492:

483:

481:

478:

470:

468:

461:

459:

453:

451:

444:

442:

435:

433:

429:

425:

418:

416:

414:

410:

406:

399:Origins in UK

398:

396:

392:

388:

385:

383:

377:

375:

371:

367:

359:

357:

355:

351:

343:

338:

336:

333:

331:

323:

321:

318:

313:

310:

307:

302:

295:

293:

291:

287:

282:

280:

276:

272:

268:

264:

260:

256:

252:

248:

244:

240:

236:

232:

228:

224:

215:

205:

202:

187:

184:

176:

166:

162:

156:

155:

149:

144:

135:

134:

125:

122:

114:

111:November 2011

104:

98:

96:

89:

80:

79:

74:

72:

65:

64:

59:

58:

53:

48:

39:

38:

33:

19:

1383:

1372:

1361:

1350:

1339:

1320:

1314:

1304:18 September

1302:. Retrieved

1292:

1273:

1267:

1242:

1237:

1229:

1224:

1216:

1211:

1203:

1199:

1194:wiring rules

1187:

1179:

1174:

1163:

1155:

1150:

1142:

1137:

1126:. Retrieved

1122:the original

1112:

1103:

1094:

1083:

1072:

1061:. Retrieved

1057:

1048:

1036:. Retrieved

1026:

1015:. Retrieved

1011:

1002:

991:. Retrieved

987:

978:

967:. Retrieved

963:

954:

940:

919:

915:

906:

890:

881:

860:

841:

837:

828:

824:

817:equipment).

815:

811:

799:

790:

782:

762:

753:

747:

744:

740:

737:

729:

715:

706:

683:

680:

677:

674:Press button

661:

616:

607:

604:Leakage test

598:

577:

564:

553:

551:appliances.

542:

533:

507:

500:

487:

474:

465:

457:

448:

439:

430:

426:

422:

402:

393:

389:

386:

378:

363:

347:

334:

327:

314:

311:

299:

285:

283:

273:between the

265:(grounding)

238:

234:

230:

226:

220:

197:

179:

173:October 2018

170:

151:

117:

108:

92:

68:

61:

55:

54:Please help

51:

1145:Sec 2.3.3.1

1038:November 2,

887:RCD testing

763:Electrical

649:The order (

635:The order (

587:appliance;

570:appliance;

445:User checks

251:New Zealand

239:PAT testing

165:introducing

1437:Categories

1128:2015-12-29

1063:2023-10-04

1017:2024-04-07

993:2024-04-07

969:2024-04-07

946:References

875:Fuse test;

344:Appliances

271:insulation

267:continuity

148:references

57:improve it

852:polarity.

748:hot-spots

255:Australia

63:talk page

651:polarity

637:polarity

585:Class II

568:Class II

549:Class II

263:earthing

1192:BS 7671

866:tested;

785:Class 0

696:BS 7671

624:BS 7671

581:Class I

545:Class I

512:tester

471:Testing

296:Purpose

290:Germany

275:current

247:Ireland

161:improve

1327:

1280:

931:(UKAS)

150:, but

630:Plugs

477:class

1325:ISBN

1306:2023

1278:ISBN

1040:2023

779:PSU.

775:box.

662:For

593:MOVs

279:fail

253:and

712:II.

510:PAT

370:IEE

332:).

288:in

237:or

231:PAT

221:In

1439::

1250:^

1102:.

1056:.

1010:.

986:.

962:.

493:.

292:.

249:,

245:,

233:,

225:,

66:.

1333:.

1308:.

1286:.

1261:.

1131:.

1106:.

1066:.

1042:.

1020:.

996:.

972:.

698:)

491:Ω

489:1

229:(

204:)

198:(

186:)

180:(

175:)

171:(

157:.

124:)

118:(

113:)

109:(

99:.

73:)

69:(

34:.

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.