253:, did this task. The ring frame was idle until it was completed. Harold Partington (1906 - 1994) of Chadderton, England, patented a 'Means for Doffing Ring Frames' in September 1953 (US Patent 2,653,440). The machine removed full bobbins from the ring frame spindles, and placed empty bobbins onto the spindles in their place; eight spindles at a time. It was traversable along the front of the ring frame step by step through successive operations, and thereby reduced the period of stoppage of the ring frame as well as reducing the labour required for removing all the filled bobbins on a frame and replacing them with empty bobbins. The Partington autodoffer was developed with assistance from Platt Brothers (Oldham) and worked perfectly in ideal conditions: flat horizontal floor and ring frame parallel to the floor and standing vertically. Sadly, these conditions were unobtainable in most Lancashire cotton mills at the time and so the autodoffer did not go into production. The Partington autodoffer was unique and the only one to work properly as an add-on to a ring frame. A more modern mechanical doffer system fitted as an integral part of the ring frame, reduced the doffing time to 30–35 seconds.

1234:

968:

209:

84:

31:

289:

Textile firms united to reduce capacity rather than to add to it. It wasn't until the late 1940s that some replacement spindles started to be ordered and ring frames became dominant. Debate still continues in academic papers on whether the

Lancashire entrepreneurs made the right purchases decisions in the 1890s. The engine house and steam engine of the

339:

288:

for the New

Ladyhouse Cotton Spinning Company (registered 26 April 1877). A cluster of smaller mills developed which between 1884 and 1914 out performed the ring mills of Oldham. After 1926, the Lancashire industry went into sharp decline, the Indian export market was lost, Japan was self-sufficient.

413:

share the same axis but rotate at different speeds. The spindle is driven and the traveller drags behind thus distributing the rotation between winding up on the spindle and twist into the yarn. The bobbin is fixed on the spindle. In a ring frames, the different speed was achieved by drag caused by

384:

loaded with bobbins of roving. The roving (unspun thread) passes downwards from the bobbins to the draughting rollers. Here the back roller steadied the incoming thread, while the front rollers rotated faster, pulling the roving out and making the fibres more parallel. The rollers are individually

276:

Technologically mules were more versatile. The mules were more easily changed to spin the larger variety of qualities of cotton then found in

Lancashire. While Lancashire concentrated on "Fines" for export, it also spun a wider range, including the very coarse wastes. The existence of the Liverpool

280:

The wage cost per spindle is higher for ring spinning. In the states, where cotton staple was cheap, the additional labour costs of running mules could be absorbed, but

Lancashire had to pay shipment costs. The critical factor was the availability of labour, when skilled labour was scarce then the

224:

Manchester was convinced of the viability of the method. After a fact-finding tour to the States by his agent Blakey, he started to work on improving the frame. It was still too primitive to compete with the highly developed mule frames, let alone supersede them. He first started on improving the

241:

by attaching an open ring to the traverse or ring rail. This device controlled the thread, and consequently a lighter traveller could be made which could operate at higher speeds. Another problem was the accumulation of fluff on the traveller breaking the thread - this was eliminated by a device

103:

was developed and patented by

Arkwright in the 1770s. The roving was attenuated (stretched) by draughting rollers and twisted by winding it onto a spindle. It was heavy large-scale machine that needed to be driven by power, which in the late 18th century meant by a water wheel. Cotton mills were

432:

is a separate process. An attendant (or robot in an automated system) winds down the ring rails to the bottom. The machine stops. The thread guides are hinged up. The completed bobbin coils (yarn packages) are removed from the spindles. The new bobbin tube is placed on the spindle trapping the

324:

in the years preceding 1967. It was far faster than ring spinning, and did away with many preparatory processes. Put simply, the thread was ejected spinning from a nozzle, and on exiting hooked onto other loose fibres in the chamber behind. It was first introduced into the United

Kingdom at the

176:

The

Rabbeth spindle was self-lubricating and capable of running without vibration at over 7500 rpm. The Draper Co. bought the patent and expanded the Sawyer Spindle Co. to manufacture it. They licensed it to Fales & Jenks Machine Co., the Hopedale Machine Co., and later, other machine

159:

At the time of the

American Civil War, the American industry boasted 1,091 mills with 5,200,000 spindles processing 800,000 bales of cotton. The largest mill, Naumkeag Steam Cotton Co. in Salem, Mass.had 65,584 spindles. The average mill housed only 5,000 to 12,000 spindles, with mule spindles

123:

was a descendant of the water frame. It used the same principles, was better engineered and driven by steam. In 1828 the

Danforth throstle frame was invented in the United States. The heavy flyer caused the spindle to vibrate, and the yarn snarled every time the frame was stopped. Not a

69:

is first attenuated by using drawing rollers, then spun and wound around a rotating spindle which in its turn is contained within an independently rotating ring flyer. Traditionally ring frames could only be used for the coarser counts, but they could be attended by semi-skilled labour.

167:

Jacob Sawyer vastly improved spindle for the ring frame in 1871, taking the speed from 5000rpm to 7500rpm and reducing the power needed, formerly 100 spindles would need 1 hp but now 125 could be driven. This also led to production of fine yarns. During the next ten years, the

172:

protected its patent through the courts. One infringee was Jenks, who was marketing a spindle known after its designer, Rabbeth. When they lost the case, Mssrs. Fales and Jenks, revealed a new patent free spindle also designed by

Rabbeth, and also named the Rabbeth spindle.

393:

that is adjusted to be centred above the spindle. Thread guides are on a thread rail which allows them to be hinged out of the way for doffing or piecing a broken thread. The attenuated roving passes down to the spindle assembly, where it is threaded though a small

269:. They were constantly trying to improve the speed and quality of their product. The US market was relatively small, the total number of spindles in the entire United States was barely more than the number of spindles in one Lancashire town,

433:

thread between it and the cup in the wharf of the spindle, the thread guides are lowered and the machine restarted. Now all the processes are done automatically. The yarn is taken to a cone winder. Currently, machines are manufactured by

228:

Brooks and other manufacturers now worked on improving the spinning frame. The principal cause for concern was the design of the Booth-Sawyer spindle. The bobbin did not fit tightly on the spindle and vibrated wildly at higher speeds.

1773:

163:

After the war, mill building started in the south, it was seen as a way of providing employment. Almost exclusively these mills used ring technology to produce coarse counts, and the New England mills moved into fine counts.

1803:

193:. The ring frame was reliable for coarser counts while Lancashire spun fine counts as well. The ring frame was heavier, requiring structural alteration in the mills and needed more power. These were not problems in the

414:

air resistance and friction (lubrication of the contact surface between the traveller and the ring was a necessity). Spindles could rotate at speeds up to 25,000 rpm, this spins the yarn. The up and down

225:

doubling frame, constructing the necessary tooling needed to improve the precision of manufacture. This was profitable and machines offering 180,000 spindle were purchased by a sewing thread manufacturer.

1880:

237:

used the Rabbath spindle, which solved these problems. Another problem was ballooning, where the thread built up in an uneven manner. This was addressed by Furniss and Young of Mellor Bottom Mill,

148:

Machine shops experimented with ring frames and components in the 1830s. The success of the ring frame, however, was dependent on the market it served and it was not until industry leaders like

205:: skilled spinners were plentiful in Lancashire. In the main the requirements on the two continents were different, and the ring frame was not the method of choice for Europe at that moment.

1818:

1813:

441:(Japan), Zinser, Suessen, (Germany) and Marzoli (Italy)LMW (India). LMW Rieter and Toyota as have machines with up to 1824 spindles. All require controlled atmospheric conditions.

261:

The ring frame was extensively used in the United States, where coarser counts were manufactured. Many of frame manufacturers were US affiliates of the Lancashire firms, such as

1778:

490:

1915:

1783:

245:

A major time constraint was doffing, or changing the spindles. Three hundred or more spindles had to be removed, and replaced. The machine had to be stopped while the

736:

1833:

500:

1823:

1717:

1167:

2063:

1540:

1788:

607:

281:

ring became advantageous. This had always been so in New England, and when it became so in Lancashire, ring frames started to be adopted.

1793:

894:

583:

177:

builders. From 1883 to 1890 this was the standard spindle, and William Draper spent much of his time in court defending this patent.

1950:

1895:

1808:

839:

784:

1333:

1233:

967:

1288:

1160:

217:

1971:

1500:

684:"Can profitable arbitrage opportunities in the raw cotton market explain Britain's continued preference for mule spinning?"

1626:

1600:

1409:

402:. It is this that gives the ring frame its name. From here the thread is attached to the existing thread on the spindle.

2058:

1590:

1469:

1910:

1905:

1900:

1565:

1323:

1404:

1303:

1298:

1651:

1308:

2073:

1935:

1621:

1389:

1153:

290:

238:

186:

2032:

2027:

1940:

1925:

1672:

1203:

1074:

460:

273:. When production in Lancashire peaked in 1926 Oldham had 17.669 million spindles and the UK had 58.206 million.

109:

302:

The search for faster and more reliable ring spinning techniques continues. In 2005, a PhD paper was written at

1930:

1920:

1520:

1208:

54:

1859:

1273:

1099:

208:

1885:

1636:

1368:

1318:

1263:

1198:

132:

96:. The spindle rotated faster than the traveller in a ratio of 8:6, drawing was done by the spinners fingers.

1258:

1945:

1682:

1677:

1646:

1474:

1444:

1394:

1343:

1094:

1089:

887:

470:

465:

311:

83:

1293:

153:

1890:

1828:

1798:

1667:

1454:

1419:

1414:

694:

495:

266:

1358:

30:

1981:

1479:

1464:

1424:

1348:

1338:

1134:

562:"Investigating Disruptive Technology The Emergence Of Ring Spinning In The American Textile Industry"

262:

230:

149:

136:

721:

Toms (1998). "Growth profit and Technological Choice. The case for the Lancashire Cotton Industry".

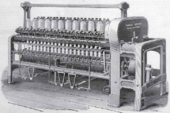

1854:

1570:

1560:

1555:

1530:

1278:

1223:

1058:

903:

611:

480:

307:

202:

46:

1253:

683:

1510:

1328:

1048:

861:

423:

326:

169:

42:

1631:

1399:

858:- Describes the blow room, carding, Ring spinning, OE, fibre testing, textile calculations etc.

2068:

2002:

1976:

1757:

1687:

1575:

1515:

1439:

1384:

1084:

932:

880:

835:

780:

475:

438:

317:

303:

221:

561:

2017:

1986:

1525:

1495:

1313:

1283:

1268:

2007:

1864:

1732:

1616:

1429:

1193:

1104:

992:

707:

105:

53:. The ring frame developed from the throstle frame, which in its turn was a descendant of

156:

in the 1850s began to manufacture ring frames that the technology started to take hold.

2012:

1702:

1697:

1585:

1459:

1353:

1248:

1218:

1124:

1114:

1109:

1053:

1012:

772:

485:

321:

194:

120:

93:

185:

The new method was compared with the self-acting spinning mule which was developed by

2052:

1966:

1737:

1707:

1449:

1363:

1119:

1028:

937:

795:

62:

813:

2022:

1742:

1727:

1595:

1535:

277:

cotton exchange meant that mill owners had access to a wider selection of staples.

250:

128:

2037:

1747:

1722:

1550:

1545:

1505:

1179:

1129:

1038:

947:

455:

198:

100:

58:

1849:

1752:

1641:

1580:

1176:

1043:

1007:

867:

234:

190:

113:

1002:

997:

1774:

Amalgamated Association of Beamers, Twisters and Drawers (Hand and Machine)

284:

The first known mill in Lancashire dedicated to ring spinning was built in

737:"Ring-spinning-system-for-making-yarn-having-a-magnetically-elevated-ring"

1434:

942:

17:

1712:

1033:

987:

982:

957:

450:

285:

246:

381:

952:

927:

434:

270:

66:

1804:

General Union of Lancashire and Yorkshire Warp Dressers' Association

1145:

584:"Textile Industry Meets Demand Of Booming U.S. Population 1887–1900"

1213:

922:

338:

337:

207:

82:

29:

864:- Articles on Ring Spinning machines, processes and technologies.

368:

was constructed from cast iron, and later pressed steel. On each

917:

855:

50:

1149:

876:

872:

201:. It fulfilled New England's difficulty in finding skilled

426:. The lifting must be adjusted for different yarn counts.

385:

adjustable, originally by mean of levers and weights. The

797:

Cotton Spinning: its development, principles and practice

398:

ring called the traveller. The traveller moves along the

65:

which uses an intermittent action. In ring spinning, the

1819:

North East Lancashire Amalgamated Weavers' Association

1814:

Lancashire Amalgamated Tape Sizers' Friendly Society

1779:

Amalgamated Association of Operative Cotton Spinners

491:

Textile manufacture during the Industrial Revolution

1995:

1959:

1873:

1842:

1766:

1660:

1609:

1488:

1377:

1241:

1186:

1067:

1021:

975:

910:

779:(Elibron Classics ed.). London: John Heywood.

189:using the more advanced engineering techniques in

61:. Ring spinning is a continuous process, unlike

49:fibres, such as cotton, flax or wool, to make a

777:Recent Cotton Mill Construction and Engineering

212:Brooks and Doxey Ring Spinning Frame about 1890

1784:Amalgamated Textile Warehousemen's Association

667:

533:

1161:

888:

8:

1314:B. Hick and Sons / Hick, Hargreaves & Co

501:Timeline of clothing and textiles technology

127:The Ring frame is credited to John Thorp in

1834:United Textile Factory Workers' Association

1824:Northern Counties Textile Trades Federation

92:The Saxony wheel was a double band treadle

1168:

1154:

1146:

895:

881:

873:

602:

600:

310:to reduce friction, a techniques known as

677:

675:

131:in 1828/9 and developed by Mr. Jencks of

564:. Harvard Business School, Baker Library

160:out-numbering ring spindles two-to-one.

756:

655:

643:

631:

548:

518:

511:

104:designed for the purpose by Arkwright,

703:

692:

544:

542:

1354:Yates & Thom / Yates of Blackburn

689:. London: London School of Economics.

529:

527:

7:

116:. Water frames could only spin weft.

34:A ring spinning machine in the 1920s

1789:Amalgamated Textile Workers' Union

1334:William Roberts & Co of Nelson

832:Cotton Mills of Greater Manchester

25:

1809:General Union of Loom Overlookers

682:Leunig, Timothy (November 2002).

144:Developments in the United States

1794:Amalgamated Weavers' Association

1232:

966:

422:into the shape required: i.e. a

2064:History of the textile industry

1224:Sidney Stott (later Sir Philip)

830:Williams, Mike; Farnie (1992).

1652:Amalgamated Cotton Mills Trust

1:

1627:Lancashire Cotton Corporation

1601:Thomas Whitehead and Brothers

1304:W & J Galloway & Sons

723:Journal of Industrial History

378:draughting (drafting) rollers

1405:John Hetherington & Sons

1289:Clayton, Goodfellow & Co

818:. Manchester: Marsden and Co

242:called a traveller cleaner.

1390:Butterworth & Dickinson

856:A complete spinning website

800:. George Bell and Sons 1903

2090:

1622:Fine Spinners and Doublers

1230:

668:Williams & Farnie 1992

534:Williams & Farnie 1992

343:Modern ring spinning frame

87:Arkwright's spinning frame

2033:John Kay (spinning frame)

2028:John Kay (flying shuttle)

1673:Cotton-spinning machinery

1445:Parr, Curtis & Madely

1395:Curtis, Parr & Walton

1274:Browett, Lindley & Co

1075:Cotton-spinning machinery

964:

794:Marsden, Richard (1884).

461:Cotton-spinning machinery

27:Method of spinning fibres

1470:Textile Machinery Makers

1450:British Northrop Loom Co

1369:Woolstenhulmes & Rye

1319:John Musgrave & Sons

1199:Bradshaw Gass & Hope

1987:Quarry Bank Mill, Styal

1647:James Burton & Sons

1637:Combined Egyptian Mills

1475:Tweedales & Smalley

834:. Carnegie Publishing.

139:names as the inventor.

133:Pawtucket, Rhode Island

1683:Magnetic ring spinning

1678:DREF friction spinning

1359:Willans & Robinson

1264:Bateman & Sherratt

1095:Magnetic ring spinning

1090:DREF friction spinning

702:Cite journal requires

471:Magnetic ring spinning

466:Dref Friction Spinning

420:thread onto the bobbin

361:

354:5 Anti-ballooning ring

312:Magnetic ring spinning

249:, who were often very

213:

88:

35:

1860:Mule spinners' cancer

1829:The Textile Institute

1799:Cardroom Amalgamation

1668:Textile manufacturing

1480:T. Wildman & Sons

1465:Taylor, Lang & Co

1425:Howard & Bullough

1415:John Pilling and Sons

1349:Urmson & Thompson

1259:Ashworth & Parker

1100:Mule spinners' cancer

812:Marsden, ed. (1910).

496:Textile manufacturing

389:now passes through a

372:of the frame are the

341:

267:Tweedales and Smalley

263:Howard & Bullough

231:Howard & Bullough

211:

152:in the 1840s and the

108:and others along the

86:

33:

1843:Employment practices

1661:Industrial processes

1279:Buckley & Taylor

1204:F.W. Dixon & Son

1135:Wool combing machine

815:Cotton Yearbook 1910

608:"Hopedale inventors"

582:Gilkerson, Yancy S.

150:Whitin Machine Works

2059:American inventions

1855:Kissing the shuttle

1632:Bagley & Wright

1571:George Augustus Lee

1561:William Houldsworth

1531:Nathaniel Eckersley

1400:Dobson & Barlow

1344:Scott & Hodgson

1309:Benjamin Goodfellow

1294:Earnshaw & Holt

1068:Industrial spinning

1022:Hand spinning tools

868:Auto-doffing videos

418:motion guides the

350:3 Attenuated roving

308:magnetic levitation

306:, Alabama on using

291:Ellenroad Ring Mill

197:cotton industry in

154:Lowell Machine Shop

1511:Hugh Hornby Birley

1455:Pemberton & Co

1440:Mather & Platt

1420:Harling & Todd

1385:Brooks & Doxey

1329:Petrie of Rochdale

1324:J & W McNaught

1269:Boulton & Watt

362:

360:8 Thread on bobbin

346:1 Drafting rollers

327:Maple Mill, Oldham

222:Brooks & Doxey

214:

181:Adoption in Europe

170:Draper Corporation

89:

36:

2074:Textile machinery

2046:

2045:

2003:Richard Arkwright

1982:Weavers' Triangle

1977:Queen Street Mill

1758:Lancashire boiler

1688:Open-end spinning

1610:Limited companies

1576:Charles Macintosh

1516:Joseph Brotherton

1143:

1142:

1085:Open-end spinning

476:Open end spinning

387:attenuated roving

376:, above them are

320:was developed in

318:Open end spinning

304:Auburn University

45:-based method of

16:(Redirected from

2081:

2018:James Hargreaves

1916:Oldham (borough)

1526:Peter Drinkwater

1496:Elkanah Armitage

1378:Machinery makers

1236:

1170:

1163:

1156:

1147:

1059:Spinner's weasel

970:

897:

890:

883:

874:

845:

826:

824:

823:

808:

806:

805:

790:

760:

754:

748:

747:

745:

743:

733:

727:

726:

718:

712:

711:

705:

700:

698:

690:

688:

679:

670:

665:

659:

653:

647:

641:

635:

629:

623:

622:

620:

619:

610:. Archived from

604:

595:

594:

592:

591:

579:

573:

572:

570:

569:

558:

552:

546:

537:

531:

522:

516:

380:and on top is a

297:New technologies

21:

2089:

2088:

2084:

2083:

2082:

2080:

2079:

2078:

2049:

2048:

2047:

2042:

2008:Samuel Crompton

1991:

1972:Helmshore Mills

1955:

1869:

1865:Piece-rate list

1838:

1762:

1733:Lancashire Loom

1656:

1617:Oldham Limiteds

1605:

1556:Richard Howarth

1484:

1430:Geo. Hattersley

1373:

1237:

1228:

1194:David Bellhouse

1182:

1174:

1144:

1139:

1105:Piece-rate list

1063:

1017:

971:

962:

906:

901:

852:

842:

829:

821:

819:

811:

803:

801:

793:

787:

773:Nasmith, Joseph

771:

768:

763:

755:

751:

741:

739:

735:

734:

730:

720:

719:

715:

701:

691:

686:

681:

680:

673:

666:

662:

654:

650:

642:

638:

630:

626:

617:

615:

606:

605:

598:

589:

587:

586:. Textile World

581:

580:

576:

567:

565:

560:

559:

555:

547:

540:

532:

525:

517:

513:

509:

447:

437:(Switzerland),

359:

357:

355:

353:

352:4 Thread guides

351:

349:

347:

345:

336:

299:

293:are preserved.

259:

257:Rings and mules

187:Richard Roberts

183:

146:

137:Richard Marsden

106:Jedediah Strutt

81:

76:

28:

23:

22:

15:

12:

11:

5:

2087:

2085:

2077:

2076:

2071:

2066:

2061:

2051:

2050:

2044:

2043:

2041:

2040:

2035:

2030:

2025:

2020:

2015:

2013:Peter Foxcroft

2010:

2005:

1999:

1997:

1993:

1992:

1990:

1989:

1984:

1979:

1974:

1969:

1963:

1961:

1957:

1956:

1954:

1953:

1948:

1943:

1938:

1933:

1928:

1923:

1918:

1913:

1908:

1903:

1898:

1893:

1888:

1883:

1877:

1875:

1874:Lists of mills

1871:

1870:

1868:

1867:

1862:

1857:

1852:

1846:

1844:

1840:

1839:

1837:

1836:

1831:

1826:

1821:

1816:

1811:

1806:

1801:

1796:

1791:

1786:

1781:

1776:

1770:

1768:

1764:

1763:

1761:

1760:

1755:

1750:

1745:

1740:

1735:

1730:

1725:

1720:

1715:

1710:

1705:

1703:Spinning jenny

1700:

1698:Spinning frame

1695:

1690:

1685:

1680:

1675:

1670:

1664:

1662:

1658:

1657:

1655:

1654:

1649:

1644:

1639:

1634:

1629:

1624:

1619:

1613:

1611:

1607:

1606:

1604:

1603:

1598:

1593:

1588:

1586:Samuel Oldknow

1583:

1578:

1573:

1568:

1563:

1558:

1553:

1548:

1543:

1538:

1533:

1528:

1523:

1518:

1513:

1508:

1503:

1501:Henry Ashworth

1498:

1492:

1490:

1486:

1485:

1483:

1482:

1477:

1472:

1467:

1462:

1460:Platt Brothers

1457:

1452:

1447:

1442:

1437:

1432:

1427:

1422:

1417:

1412:

1410:Joseph Hibbert

1407:

1402:

1397:

1392:

1387:

1381:

1379:

1375:

1374:

1372:

1371:

1366:

1364:J & E Wood

1361:

1356:

1351:

1346:

1341:

1336:

1331:

1326:

1321:

1316:

1311:

1306:

1301:

1296:

1291:

1286:

1281:

1276:

1271:

1266:

1261:

1256:

1251:

1249:Daniel Adamson

1245:

1243:

1239:

1238:

1231:

1229:

1227:

1226:

1221:

1219:Stott and Sons

1216:

1211:

1206:

1201:

1196:

1190:

1188:

1184:

1183:

1175:

1173:

1172:

1165:

1158:

1150:

1141:

1140:

1138:

1137:

1132:

1127:

1125:Throstle frame

1122:

1117:

1115:Spinning jenny

1112:

1110:Spinning frame

1107:

1102:

1097:

1092:

1087:

1082:

1077:

1071:

1069:

1065:

1064:

1062:

1061:

1056:

1054:Spinning wheel

1051:

1046:

1041:

1036:

1031:

1025:

1023:

1019:

1018:

1016:

1015:

1013:Twist per inch

1010:

1005:

1000:

995:

990:

985:

979:

977:

973:

972:

965:

963:

961:

960:

955:

950:

945:

940:

935:

930:

925:

920:

914:

912:

908:

907:

902:

900:

899:

892:

885:

877:

871:

870:

865:

859:

851:

850:External links

848:

847:

846:

840:

827:

809:

791:

785:

767:

764:

762:

761:

749:

728:

713:

704:|journal=

671:

660:

648:

636:

624:

596:

574:

553:

538:

523:

510:

508:

505:

504:

503:

498:

493:

488:

486:Spinning wheel

483:

478:

473:

468:

463:

458:

453:

446:

443:

335:

332:

331:

330:

322:Czechoslovakia

315:

298:

295:

258:

255:

182:

179:

145:

142:

141:

140:

125:

121:throstle frame

117:

97:

94:spinning wheel

80:

79:Early machines

77:

75:

72:

26:

24:

14:

13:

10:

9:

6:

4:

3:

2:

2086:

2075:

2072:

2070:

2067:

2065:

2062:

2060:

2057:

2056:

2054:

2039:

2036:

2034:

2031:

2029:

2026:

2024:

2021:

2019:

2016:

2014:

2011:

2009:

2006:

2004:

2001:

2000:

1998:

1994:

1988:

1985:

1983:

1980:

1978:

1975:

1973:

1970:

1968:

1967:Bancroft Shed

1965:

1964:

1962:

1958:

1952:

1949:

1947:

1944:

1942:

1939:

1937:

1934:

1932:

1929:

1927:

1924:

1922:

1919:

1917:

1914:

1912:

1909:

1907:

1904:

1902:

1899:

1897:

1894:

1892:

1889:

1887:

1884:

1882:

1879:

1878:

1876:

1872:

1866:

1863:

1861:

1858:

1856:

1853:

1851:

1848:

1847:

1845:

1841:

1835:

1832:

1830:

1827:

1825:

1822:

1820:

1817:

1815:

1812:

1810:

1807:

1805:

1802:

1800:

1797:

1795:

1792:

1790:

1787:

1785:

1782:

1780:

1777:

1775:

1772:

1771:

1769:

1765:

1759:

1756:

1754:

1751:

1749:

1746:

1744:

1741:

1739:

1738:Northrop Loom

1736:

1734:

1731:

1729:

1726:

1724:

1721:

1719:

1716:

1714:

1711:

1709:

1708:Spinning mule

1706:

1704:

1701:

1699:

1696:

1694:

1693:Ring spinning

1691:

1689:

1686:

1684:

1681:

1679:

1676:

1674:

1671:

1669:

1666:

1665:

1663:

1659:

1653:

1650:

1648:

1645:

1643:

1640:

1638:

1635:

1633:

1630:

1628:

1625:

1623:

1620:

1618:

1615:

1614:

1612:

1608:

1602:

1599:

1597:

1594:

1592:

1589:

1587:

1584:

1582:

1579:

1577:

1574:

1572:

1569:

1567:

1564:

1562:

1559:

1557:

1554:

1552:

1549:

1547:

1544:

1542:

1539:

1537:

1534:

1532:

1529:

1527:

1524:

1522:

1519:

1517:

1514:

1512:

1509:

1507:

1504:

1502:

1499:

1497:

1494:

1493:

1491:

1487:

1481:

1478:

1476:

1473:

1471:

1468:

1466:

1463:

1461:

1458:

1456:

1453:

1451:

1448:

1446:

1443:

1441:

1438:

1436:

1433:

1431:

1428:

1426:

1423:

1421:

1418:

1416:

1413:

1411:

1408:

1406:

1403:

1401:

1398:

1396:

1393:

1391:

1388:

1386:

1383:

1382:

1380:

1376:

1370:

1367:

1365:

1362:

1360:

1357:

1355:

1352:

1350:

1347:

1345:

1342:

1340:

1337:

1335:

1332:

1330:

1327:

1325:

1322:

1320:

1317:

1315:

1312:

1310:

1307:

1305:

1302:

1300:

1297:

1295:

1292:

1290:

1287:

1285:

1284:Carels Frères

1282:

1280:

1277:

1275:

1272:

1270:

1267:

1265:

1262:

1260:

1257:

1255:

1252:

1250:

1247:

1246:

1244:

1242:Engine makers

1240:

1235:

1225:

1222:

1220:

1217:

1215:

1212:

1210:

1207:

1205:

1202:

1200:

1197:

1195:

1192:

1191:

1189:

1185:

1181:

1178:

1171:

1166:

1164:

1159:

1157:

1152:

1151:

1148:

1136:

1133:

1131:

1128:

1126:

1123:

1121:

1120:Spinning mule

1118:

1116:

1113:

1111:

1108:

1106:

1103:

1101:

1098:

1096:

1093:

1091:

1088:

1086:

1083:

1081:

1080:Ring spinning

1078:

1076:

1073:

1072:

1070:

1066:

1060:

1057:

1055:

1052:

1050:

1047:

1045:

1042:

1040:

1037:

1035:

1032:

1030:

1029:Hand spinning

1027:

1026:

1024:

1020:

1014:

1011:

1009:

1006:

1004:

1001:

999:

996:

994:

991:

989:

986:

984:

981:

980:

978:

974:

969:

959:

956:

954:

951:

949:

946:

944:

941:

939:

936:

934:

931:

929:

926:

924:

921:

919:

916:

915:

913:

909:

905:

898:

893:

891:

886:

884:

879:

878:

875:

869:

866:

863:

862:Ring Spinning

860:

857:

854:

853:

849:

843:

841:0-948789-89-1

837:

833:

828:

817:

816:

810:

799:

798:

792:

788:

786:1-4021-4558-6

782:

778:

774:

770:

769:

765:

759:, p. 302

758:

753:

750:

738:

732:

729:

724:

717:

714:

709:

696:

685:

678:

676:

672:

669:

664:

661:

658:, p. 307

657:

652:

649:

646:, p. 308

645:

640:

637:

634:, p. 300

633:

628:

625:

614:on 2009-08-07

613:

609:

603:

601:

597:

585:

578:

575:

563:

557:

554:

551:, p. 298

550:

545:

543:

539:

535:

530:

528:

524:

521:, p. 297

520:

515:

512:

506:

502:

499:

497:

494:

492:

489:

487:

484:

482:

479:

477:

474:

472:

469:

467:

464:

462:

459:

457:

454:

452:

449:

448:

444:

442:

440:

436:

431:

427:

425:

421:

417:

412:

408:

403:

401:

397:

392:

388:

383:

379:

375:

371:

367:

344:

340:

333:

328:

323:

319:

316:

313:

309:

305:

301:

300:

296:

294:

292:

287:

282:

278:

274:

272:

268:

264:

256:

254:

252:

248:

243:

240:

236:

232:

226:

223:

219:

218:Samuel Brooks

210:

206:

204:

200:

196:

192:

188:

180:

178:

174:

171:

165:

161:

157:

155:

151:

143:

138:

134:

130:

126:

122:

118:

115:

111:

110:River Derwent

107:

102:

98:

95:

91:

90:

85:

78:

73:

71:

68:

64:

63:mule spinning

60:

56:

52:

48:

44:

40:

39:Ring spinning

32:

19:

2023:Thomas Highs

1767:Associations

1743:Air-jet loom

1728:Roberts Loom

1692:

1596:John Rylands

1566:John Kennedy

1541:William Gray

1536:John Fielden

1521:James Burton

1339:George Saxon

1254:Ashton Frost

1209:Edward Potts

1079:

831:

820:. Retrieved

814:

802:. Retrieved

796:

776:

766:Bibliography

757:Marsden 1884

752:

740:. Retrieved

731:

722:

716:

695:cite journal

663:

656:Marsden 1884

651:

644:Marsden 1884

639:

632:Marsden 1884

627:

616:. Retrieved

612:the original

588:. Retrieved

577:

566:. Retrieved

556:

549:Marsden 1884

519:Marsden 1884

514:

429:

428:

419:

415:

410:

406:

404:

399:

395:

391:thread guide

390:

386:

377:

373:

369:

365:

363:

356:6 Traveller

342:

334:How it works

283:

279:

275:

260:

244:

227:

215:

184:

175:

166:

162:

158:

147:

129:Rhode Island

38:

37:

2038:Robert Owen

1748:Rapier loom

1723:Water frame

1591:Robert Peel

1551:Samuel Greg

1546:Hannah Greg

1506:Hugh Birley

1489:Mill owners

1130:Water frame

1039:Niddy noddy

742:23 November

536:, p. 8

456:Cotton mill

411:the spindle

199:New England

101:water frame

59:water frame

2053:Categories

1911:Manchester

1906:Lancashire

1901:Derbyshire

1850:More looms

1753:Dandy loom

1642:Courtaulds

1581:Hugh Mason

1187:Architects

1177:Lancashire

1044:Nostepinne

1008:Short draw

976:Techniques

822:2009-04-26

804:2009-04-26

618:2009-04-30

590:2009-04-30

568:2009-04-30

507:References

366:ring frame

251:young boys

235:Accrington

195:antebellum

191:Manchester

114:Derbyshire

1951:Yorkshire

1936:Stockport

1881:LCC mills

1299:Fairbairn

1003:Scutching

998:Long draw

911:Materials

416:ring rail

407:traveller

348:2 Spindle

55:Arkwright

18:Ring spun

2069:Spinning

1996:Pioneers

1941:Tameside

1926:Rochdale

1896:Cheshire

1718:Steaming

1435:Asa Lees

993:Heckling

904:Spinning

775:(1895).

481:Spinning

445:See also

374:spindles

203:spinners

124:success.

47:spinning

1960:Museums

1931:Salford

1921:Preston

1713:Carding

1049:Spindle

1034:Distaff

988:Combing

983:Carding

958:Worsted

451:Carding

430:Doffing

358:7 Rings

286:Milnrow

247:doffers

74:History

43:spindle

1886:Bolton

1180:cotton

953:Woolen

938:Staple

933:Sliver

928:Roving

838:

783:

439:Toyota

435:Rieter

271:Oldham

239:Mellor

135:, who

67:roving

1946:Wigan

1214:Stott

923:Rolag

687:(PDF)

382:creel

41:is a

1891:Bury

918:Noil

836:ISBN

781:ISBN

744:2010

708:help

409:and

405:The

400:ring

370:side

265:and

119:The

99:The

51:yarn

948:Tow

943:Top

424:cop

233:of

220:of

216:Mr

112:in

57:'s

2055::

699::

697:}}

693:{{

674:^

599:^

541:^

526:^

364:A

1169:e

1162:t

1155:v

896:e

889:t

882:v

844:.

825:.

807:.

789:.

746:.

725:.

710:)

706:(

621:.

593:.

571:.

396:D

329:.

314:.

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.