1653:

tallow for the work that they caused a shortage in their own countries—I, Sennacherib, leader of all princes, knowledgeable in all kinds of work, took much advice and deep thought over doing that work. Great pillars of bronze, colossal striding lions, such as no previous king had ever constructed before me, with the technical skill that

Ninushki brought to perfection in me, and at the prompting of my intelligence and the desire of my heart I invented a technique for bronze and made it skillfully. I created clay moulds as if by divine intelligence....twelve fierce lion-colossi together with twelve mighty bull-colossi which were perfect castings... I poured copper into them over and over again; I made the castings as skillfully as if they had only weighed half a shekel each

534:, which is a non-expanding clay. Most foundries do not have the very expensive equipment to remove the burned out clay and substitute new clay, so instead, those that pour iron typically work with silica sand that is inexpensive compared to the other sands. As the clay is burned out, newly mixed sand is added and some of the old sand is discarded or recycled into other uses. Silica is the least desirable of the sands, since metamorphic grains of silica sand have a tendency to explode to form sub-micron sized particles when thermally shocked during pouring of the molds. These particles enter the air of the work area and can lead to

669:

sheet of plastic is placed over the top of the sand in the flask and a vacuum is drawn through the special flask; this hardens and strengthens the unbonded sand. The vacuum is then released on the pattern and the cope is removed. The drag is made in the same way (without the sprue and pouring cup). Any cores are set in place and the mold is closed. The molten metal is poured while the cope and drag are still under a vacuum, because the plastic vaporizes but the vacuum keeps the shape of the sand while the metal solidifies. When the metal has solidified, the vacuum is turned off and the sand runs out freely, releasing the casting.

774:) invented a flask-less molding process by using vertically parted and poured molds. The first line could produce up to 240 complete sand molds per hour. Today molding lines can achieve a molding rate of 550 sand molds per hour and requires only one monitoring operator. Maximum mismatch of two mold halves is 0.1 mm (0.0039 in). Although very fast, vertically parted molds are not typically used by jobbing foundries due to the specialized tooling needed to run on these machines. Cores need to be set with a core mask as opposed to by hand and must hang in the mold as opposed to being set on parting surface.

227:

the mold may be parted and the pattern with its sprue and vent patterns removed. Additional sizing may be added and any defects introduced by the removal of the pattern are corrected. The box is closed again. This forms a "green" mold which must be dried to receive the hot metal. If the mold is not sufficiently dried a steam explosion can occur that can throw molten metal about. In some cases, the sand may be oiled instead of moistened, which makes casting possible without waiting for the sand to dry. Sand may also be bonded by chemical binders, such as furane resins or amine-hardened resins.

677:. Other advantages include no moisture related defects, no cost for binders, excellent sand permeability, and no toxic fumes from burning the binders. Finally, the pattern does not wear out because the sand does not touch it. The main disadvantage is that the process is slower than traditional sand casting so it is only suitable for low to medium production volumes; approximately 10 to 15,000 pieces a year. However, this makes it perfect for prototype work, because the pattern can be easily modified as it is made from plastic.

604:. The sand mixture is tamped down as it is added around the pattern, and the final mold assembly is sometimes vibrated to compact the sand and fill any unwanted voids in the mold. Then the pattern is removed along with the channel plug, leaving the mold cavity. The casting liquid (typically molten metal) is then poured into the mold cavity. After the metal has solidified and cooled, the casting is separated from the sand mold. There is typically no mold release agent, and the mold is generally destroyed in the removal process.

608:

of pockets in the pattern. Air-set molds can produce castings with smoother surfaces than coarse green sand but this method is primarily chosen when deep narrow pockets in the pattern are necessary, due to the expense of the plastic used in the process. Air-set castings can typically be easily identified by the burnt color on the surface. The castings are typically shot blasted to remove that burnt color. Surfaces can also be later ground and polished, for example when making a large

373:, must be used on surfaces perpendicular to the parting line, in order to be able to remove the pattern from the mold. This requirement also applies to cores, as they must be removed from the core box in which they are formed. The sprue and risers must be arranged to allow a proper flow of metal and gasses within the mold in order to avoid an incomplete casting. Should a piece of core or mold become dislodged it may be embedded in the final casting, forming a

798:

series so typical for the jobbing foundries. Modern matchplate molding machine is capable of high molding quality, less casting shift due to machine-mold mismatch (in some cases less than 0.15 mm (0.0059 in)), consistently stable molds for less grinding and improved parting line definition. In addition, the machines are enclosed for a cleaner, quieter working environment with reduced operator exposure to safety risks or service-related problems.

340:

222:, the top and bottom halves of which are known respectively as the cope and drag) is prepared to receive the pattern. Molding boxes are made in segments that may be latched to each other and to end closures. For a simple object—flat on one side—the lower portion of the box, closed at the bottom, will be filled with a molding sand. The sand is packed in through a vibratory process called ramming, and in this case, periodically

47:

31:

332:. After being filled with liquid metal the box is set aside until the metal is sufficiently cool to be strong. The sand is then removed, revealing a rough casting that, in the case of iron or steel, may still be glowing red. In the case of metals that are significantly heavier than the casting sand, such as iron or lead, the casting flask is often covered with a heavy plate to prevent a problem known as

206:

233:(AM) can be used in the sand mold preparation, so that instead of the sand mold being formed via packing sand around a pattern, it is 3D-printed. This can reduce lead times for casting by obviating patternmaking. Besides replacing older methods, additive can also complement them in hybrid models, such as making a variety of AM-printed cores for a cavity derived from a traditional pattern.

943:— This refers to the sand's ability to withstand the temperature of the liquid metal being cast without breaking down. For example, some sands only need to withstand 650 °C (1,202 °F) if casting aluminum alloys, whereas steel needs a sand that will withstand 1,500 °C (2,730 °F). Sand with too low refractoriness will melt and fuse to the casting.

758:

1053:

377:, which may render the casting unusable. Gas pockets can cause internal voids. These may be immediately visible or may only be revealed after extensive machining has been performed. For critical applications, or where the cost of wasted effort is a factor, non-destructive testing methods may be applied before further work is performed.

146:

360:—that adds resistance to tensile cracking and smooths the rough surface. And when high precision is required, various machining operations (such as milling or boring) are made to finish critical areas of the casting. Examples of this would include the boring of cylinders and milling of the deck on a cast engine block.

781:

1011:— This is the ability of the sand to be easily stripped off the casting after it has solidified. Sands with poor collapsibility will adhere strongly to the casting. When casting metals that contract a lot during cooling or with long freezing temperature ranges a sand with poor collapsibility will cause cracking and

1201:) above 1,100 °C (2,010 °F). Its fusion point is 1,750 °C (3,180 °F) and has low thermal expansion. It is the second cheapest sand, however it is still twice as expensive as silica. Its disadvantages are very coarse grains, which result in a poor surface finish, and it is limited to

1167:) and one-third silica. It has the highest fusion point of all the base sands at 2,600 °C (4,710 °F), a very low thermal expansion, and a high thermal conductivity. Because of these good properties it is commonly used when casting alloy steels and other expensive alloys. It is also used as a

672:

The V-process is known for not requiring a draft because the plastic film has a certain degree of lubricity and it expands slightly when the vacuum is drawn in the flask. The process has high dimensional accuracy, with a tolerance of ±0.010 in for the first inch and ±0.002 in/in thereafter.

624:

Cold box uses organic and inorganic binders that strengthen the mold by chemically adhering to the sand. This type of mold gets its name from not being baked in an oven like other sand mold types. This type of mold is more accurate dimensionally than green-sand molds but is more expensive. Thus it is

615:

During casting, some of the components of the sand mixture are lost in the thermal casting process. Green sand can be reused after adjusting its composition to replenish the lost moisture and additives. The pattern itself can be reused indefinitely to produce new sand molds. The sand molding process

1652:

Whereas in former times the kings my forefathers had created bronze statues imitating real-life forms to put on display inside their temples, but in their method of work they had exhausted all the craftsmen, for lack of skill and failure to understand the principles they needed so much oil, wax and

668:

is draped over the pattern and a vacuum is drawn (200 to 400 mmHg (27 to 53 kPa)). A special vacuum forming flask is placed over the plastic pattern and is filled with a free-flowing sand. The sand is vibrated to compact the sand and a sprue and pouring cup are formed in the cope. Another

637:

and catalyst. Rather than being rammed, the molding sand is poured into the flask and held until the resin solidifies, which occurs at room temperature. This type of molding also produces a better surface finish than other types of sand molds. Because no heat is involved it is called a cold-setting

607:

The accuracy of the casting is limited by the type of sand and the molding process. Sand castings made from coarse green sand impart a rough texture to the surface, and this makes them easy to identify. Castings made from fine green sand can shine as cast but are limited by the depth to width ratio

226:

level. The surface of the sand may then be stabilized with a sizing compound. The pattern is placed on the sand and another molding box segment is added. Additional sand is rammed over and around the pattern. Finally a cover is placed on the box and it is turned and unlatched, so that the halves of

1125:. Its main advantage is that it is free from silica, therefore it can be used with basic metals, such as manganese steels. Other advantages include a low thermal expansion, high thermal conductivity, and high fusion point. Finally, it is safer to use than silica, therefore it is popular in Europe.

409:

These castings are made using sand molds formed from "wet" sand which contains water and organic bonding compounds, typically referred to as clay. The name "green sand" comes from the fact that the sand mold is not "set", it is still in the "green" or uncured state even when the metal is poured in

797:

The method alike to the DISA's (DISAMATIC) vertical molding is flaskless, however horizontal. The matchplate molding technology is today used widely. Its great advantage is inexpensive pattern tooling, easiness of changing the molding tooling, thus suitability for manufacturing castings in short

88:

Molds made of sand are relatively cheap, and sufficiently refractory even for steel foundry use. In addition to the sand, a suitable bonding agent (usually clay) is mixed or occurs with the sand. The mixture is moistened, typically with water, but sometimes with other substances, to develop the

793:

The principle of the matchplate, meaning pattern plates with two patterns on each side of the same plate, was developed and patented in 1910, fostering the perspectives for future sand molding improvements. However, first in the early sixties the

American company Hunter Automated Machinery

750:

Today there are many manufacturers of the automatic horizontal flask molding lines. The major disadvantages of these systems is high spare parts consumption due to multitude of movable parts, need of storing, transporting and maintaining the flasks and productivity limited to approximately

1592:

powder can be used to prevent mold cracking and metal penetration, essentially improving refractoriness. Silica flour (fine silica) and zircon flour also improve refractoriness, especially in ferrous castings. The disadvantages to these additives is that they greatly reduce permeability.

701:

and/or jolt-squeeze devices that compacted the sand in the flasks. Subsequent mold handling was mechanical using cranes, hoists and straps. After core setting the copes and drags were coupled using guide pins and clamped for closer accuracy. The molds were manually pushed off on a roller

1585:, can be used to increase dry strength (the strength of the mold after curing) and improve surface finish. Cereal binders also improve collapsibility and reduce shakeout time because they burn off when the metal is poured. The disadvantage to cereal binders is that they are expensive.

1753:. In 1940, thermal sand reclamation was applied for molding and core sands. In 1952, the "D-process" was developed for making shell molds with fine, pre-coated sand. In 1953, the hotbox core sand process in which the cores are thermally cured was invented. In 1954, a new core binder—

589:. When these are used, they are collectively called "air set" sand castings to distinguish them from "green sand" castings. Two types of molding sand are natural bonded (bank sand) and synthetic (lake sand); the latter is generally preferred due to its more consistent composition.

689:. The basic process stages of the mechanical molding and casting process are similar to those described under the manual sand casting process. The technical and mental development however was so rapid and profound that the character of the sand casting process changed radically.

1021:— The availability and cost of the sand is very important because for every ton of metal poured, three to six tons of sand is required. Although sand can be screened and reused, the particles eventually become too fine and require periodic replacement with fresh sand.

368:

The part to be made and its pattern must be designed to accommodate each stage of the process, as it must be possible to remove the pattern without disturbing the molding sand and to have proper locations to receive and position the cores. A slight taper, known as

1078:

of pure silica is 1,760 °C (3,200 °F), however the sands used have a lower melting point due to impurities. For high melting point casting, such as steels, a minimum of 98% pure silica sand must be used; however for lower melting point metals, such as

1280:

instead of a heat to cure the binder. Resin binders are quite popular because different properties can be achieved by mixing with various additives. Other advantages include good collapsibility, low gassing, and they leave a good surface finish on the casting.

1601:

To get the pattern out of the mold, prior to casting, a parting compound is applied to the pattern to ease removal. They can be a liquid or a fine powder (particle diameters between 75 and 150 micrometres (0.0030 and 0.0059 in)). Common powders include

1558:

casting defects when casting high temperature metals. These materials are beneficial because burn-off when the metal is poured creates tiny voids in the mold, allowing the sand particles to expand. They also increase collapsibility and reduce shakeout time.

1684:

set a record by producing 1 million cars, in the process consuming one-third of the total casting production in the U.S. As the automobile industry grew the need for increased casting efficiency grew. The increasing demand for castings in the growing

1256:, used to be used as a binder, however due to their increasing cost, they have been mostly phased out. The oil also required careful baking at 100 to 200 °C (212 to 392 °F) to cure (if overheated, the oil becomes brittle, wasting the mold).

1024:

In large castings it is economical to use two different sands, because the majority of the sand will not be in contact with the casting, so it does not need any special properties. The sand that is in contact with the casting is called

989:— The size and shape of the sand particles defines the best surface finish achievable, with finer particles producing a better finish. However, as the particles become finer (and surface finish improves) the permeability becomes worse.

179:. Different scaled rules are used for different metals, because each metal and alloy contracts by an amount distinct from all others. Patterns also have core prints that create registers within the molds into which are placed sand

596:, forming a mold cavity. If necessary, a temporary plug is placed in the sand and touching the pattern in order to later form a channel into which the casting fluid can be poured. Air-set molds are often formed with the help of a

355:

may be applied to relieve stresses from the initial cooling and to add hardness—in the case of steel or iron, by quenching in water or oil. The casting may be further strengthened by surface compression treatment—like

802:

503:, which is present at a ratio of less than 5%, partially combusts in the presence of the molten metal, leading to offgassing of organic vapors. Green sand casting for non-ferrous metals does not use coal additives, since the

273:

Cores are apparatus used to generate hollow cavities or internal features which cannot be formed using pattern alone in moulding, cores are usually made using sand, but some processes also use permanent cores made of metal.

1144:. Its advantages are a low percentage of silica, a very high fusion point (1,850 °C (3,360 °F)), and a very high thermal conductivity. Its disadvantage is its costliness, therefore it is only used with expensive

289:. Usually sand-molded, cores are inserted into the casting box after removal of the pattern. Whenever possible, designs are made that avoid the use of cores, due to the additional set-up time, mass and thus greater cost.

183:. Such cores, sometimes reinforced by wires, are used to create under-cut profiles and cavities which cannot be molded with the cope and drag, such as the interior passages of valves or cooling passages in engine blocks.

1479:

174:

into shape. The metal to be cast will contract during solidification, and this may be non-uniform due to uneven cooling. Therefore, the pattern must be slightly larger than the finished product, a difference known as

876:

There is no machine-specific standard for sand-mold manufacturing equipment. The ANSI B11 family of standards includes some generic machine-tool standards that could be applied to this type of machinery, including:

1519:, may be added to the molding material to prevent wetting (prevention of liquid metal sticking to sand particles, thus leaving them on the casting surface), improve surface finish, decrease metal penetration, and

1732:

clay instead of simple fire clay as the bonding additive to the molding sand. This increased tremendously the green and dry strength of the molds. In 1918, the first fully automated foundry for fabricating hand

893:

Functional Safety for

Equipment (Electrical/Fluid Power Control Systems) General Principles for the Design of Safety Control Systems Using ISO 13849-1, ANSI B11.26. American National Standards Institute (ANSI).

1523:. These additives achieve this by creating gases at the surface of the mold cavity, which prevent the liquid metal from adhering to the sand. Reducing agents are not used with steel casting, because they can

714:

Increasing quality requirements made it necessary to increase the mold stability by applying steadily higher squeeze pressure and modern compaction methods for the sand in the flasks. In early fifties the

1029:, and is designed for the casting on hand. This sand will be built up around the pattern to a thickness of 30 to 100 mm (1.2 to 3.9 in). The sand that fills in around the facing sand is called

1484:

The advantage to this binder is that it can be used at room temperature and is fast. The disadvantage is that its high strength leads to shakeout difficulties and possibly hot tears (probably due to

190:, various feeders which maintain a good metal 'feed', and in-gates which attach the runner system to the casting cavity. Gas and steam generated during casting exit through the permeable sand or via

557:

that causes rapid expansion of the grains. Olivine and chromite also offer greater density, which cools the metal faster, thereby producing finer grain structures in the metal. Since they are not

538:

in the workers. Iron foundries expend considerable effort on aggressive dust collection to capture this fine silica. Various types of respiratory-protective equipment are also used in foundries.

545:

from alpha quartz to beta quartz at 680 °C (1250 °F). Often, combustible additives such as wood flour are added to create spaces for the grains to expand without deforming the mold.

868:

for functional safety. Additional type C standards may also be necessary for conveyors, robotics or other equipment that may be needed to support the operation of the mold-making equipment.

747:

drop over the pre-compacted sand mold was developed (sand-impulse and gas-impact). The general working principle for most of the horizontal flask line systems is shown on the sketch below.

247:, in the mold. The associated rapid local cooling will form a finer-grained structure and may form a somewhat harder metal at these locations. In ferrous castings, the effect is similar to

526:

The choice of sand has a lot to do with the temperature at which the metal is poured. At the temperatures that copper and iron are poured, the clay is inactivated by the heat, in that the

836:

343:

Left: Corebox, with resulting (wire reinforced) cores directly below. Right:- Pattern (used with the core) and the resulting casting below (the wires are from the remains of the core)

739:

powered pistons or multi-piston systems were used for the sand compaction in the flasks. This method produced much more stable and accurate molds than it was possible manually or

612:. After molding, the casting is covered with a residue of oxides, silicates and other compounds. This residue can be removed by various means, such as grinding, or shot blasting.

828:

719:

molding was developed and applied in mechanical and later automatic flask lines. The first lines were using jolting and vibrations to pre-compact the sand in the flasks and

937:, are defined by eight characteristics: refractoriness, chemical inertness, permeability, surface finish, cohesiveness, flowability, collapsibility, and availability/cost.

2559:

491:

There are many recipes for the proportion of clay, but they all strike different balances between moldability, surface finish, and ability of the hot molten metal to

884:

Performance

Requirements for Risk Reduction Measures: Safeguarding and other Means of Reducing Risk, ANSI B11.19. American National Standards Institute (ANSI). 2019.

1090:

Silica sand is the most commonly used sand because of its great abundance, and, thus, low cost (therein being its greatest advantage). Its disadvantages are high

735:. The subsequent mold handling including turn-over, assembling, pushing-out on a conveyor were accomplished either manually or automatically. In the late fifties

2521:

861:

857:

847:

661:. The pattern is specially vented so that a vacuum can be pulled through it. A heat-softened thin sheet (0.003 to 0.008 in (0.076 to 0.203 mm)) of

292:

With a completed mold at the appropriate moisture content, the box containing the sand mold is then positioned for filling with molten metal—typically

983:, such as blow holes and gas holes, occur in the casting. Note that for each cubic centimeter (cc) of water added to the mold 1600 cc of steam is produced.

1044:

is the type used to make the mold or core without any binder. Because it does not have a binder it will not bond together and is not usable in this state.

616:

has been used for many centuries to produce castings manually. Since 1950, partially automated casting processes have been developed for production lines.

731:

In the first automatic horizontal flask lines the sand was shot or slung down on the pattern in a flask and squeezed with hydraulic pressure of up to 140

1915:

848:

Safety requirements for foundry moulding and coremaking machinery and plant associated equipment, EN 710. European

Committee for Standardization (CEN).

1102:

metals because it will chemically interact with the metal, forming surface defects. Finally, it releases silica particulates during the pour, risking

853:

865:

1648:(704–681 BC) cast massive bronzes of up to 30 tonnes, and claims to have been the first to have used clay molds rather than the "lost-wax" method:

1314:

2552:

1980:

77:

material. The term "sand casting" can also refer to an object produced via the sand casting process. Sand castings are produced in specialized

2473:

2352:

2286:

89:

strength and plasticity of the clay and to make the aggregate suitable for molding. The sand is typically contained in a system of frames or

963:— This refers to the sand's ability to exhaust gases. This is important because during the pouring process many gases are produced, such as

825:

Canada does not have a machine-specific voluntary technical standard for sand-mold making machinery. This type of machinery is covered by:

657:) is a variation of the sand casting process for most ferrous and non-ferrous metals, in which unbonded sand is held in the flask with a

336:

Floating the mold occurs when the pressure of the metal pushes the sand above the mold cavity out of shape, causing the casting to fail.

1500:

Additives are added to the molding components to improve: surface finish, dry strength, refractoriness, and "cushioning properties".

2545:

2514:

2454:

2433:

1895:

887:

Safety

Requirements for the Integration of Machinery into a System, ANSI B11.20. American National Standards Institute (ANSI). 2017.

638:

process. Common flask materials that are used are wood, metal, and plastic. Common metals cast into no-bake molds are brass, iron (

2384:

673:

Cross-sections as small as 0.090 in (2.3 mm) are possible. The surface finish is very good, usually between 150 and 125

2824:

2582:

259:

of the casting. In controlling the way a casting freezes, it is possible to prevent internal voids or porosity inside castings.

1701:

1276:(PF) resins. PF resins have a higher heat resistance than UF resins and cost less. There are also cold-set resins, which use a

1205:. Mold washes are used to overcome the surface finish problems. This sand is usually used when casting large steel workpieces.

255:

work. The inner diameter of an engine cylinder is made hard by a chilling core. In other metals, chills may be used to promote

2741:

2407:

The Book of

Knowledge of Ingenious Mechanical Devices (Kitab fi Ma'rifat al-Hiyal al-Handasiyya) by ibn al-Razzaz al-Jazari

410:

the mould. Green sand is not green in color, but "green" in the sense that it is used in a wet state (akin to green wood).

2067:

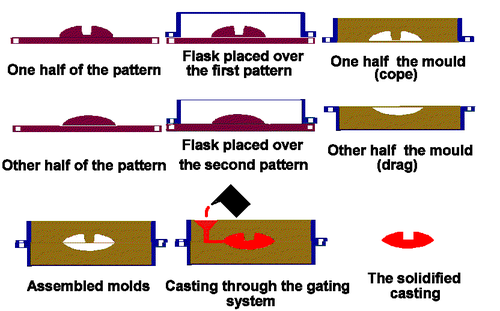

1704:

to faster casting production but rather several. Improvements were made in molding speed, molding sand preparation, sand

1171:(a coating applied to the molding cavity) to improve surface finish. However, it is expensive and not readily available.

170:

of the object to be produced, using wood, metal, or a plastic such as expanded polystyrene. Sand can be ground, swept or

2507:

1705:

685:

With the fast development of the car and machine building industry the casting consuming areas called for steady higher

633:

No-bake molds are expendable sand molds, similar to typical sand molds, except they also contain a quick-setting liquid

1296:) is a high strength binder used with silica molding sand both for cores and molds. To cure a mixture of finely ground

949:— The sand must not react with the metal being cast. This is especially important with highly reactive metals, such as

2597:

1005:– The ability for the sand to flow into intricate details and tight corners without special processes or equipment.

890:

Safety

Requirements for Transfer Machines, ANSI B11.24. American National Standards Institute (ANSI). 2002 (R2020).

278:

256:

1216:

are added to a base sand to bond the sand particles together (i.e. it is the glue that holds the mold together).

794:

Corporation launched its first automatic flaskless, horizontal molding line applying the matchplate technology.

2634:

897:

Sound Level

Measurement Guidelines, ANSI B11.TR5. American National Standards Institute (ANSI). 2006 (R2017).

2798:

2490:

Sand

Molding at Hopewell Furnace (18th-19th century techniques) - U.S. National Park Service (YouTube video)

1742:

1614:

and water-based silicon solutions. The latter are more commonly used with metal and large wooden patterns.

1070:) sand is the sand found on a beach and is also the most commonly used sand. It is either made by crushing

2619:

1689:

and machine building industry during and after World War I and World War II, stimulated new inventions in

1662:

209:

Sand molding tools and books used in Auckland and Nelson, New Zealand, between approximately 1946 and 1960

102:

98:

2700:

2680:

1887:

1674:

1284:

MDI (methylene diphenyl diisocyanate) is also a commonly used binder resin in the foundry core process.

348:

347:

After casting, the cores are broken up by rods or shot and removed from the casting. The metal from the

2027:

2675:

2639:

2624:

1792:

1786:

1709:

1095:

586:

558:

268:

180:

74:

2405:

1520:

2721:

2369:

1273:

186:

Paths for the entrance of metal into the mold cavity constitute the runner system and include the

2614:

2587:

1724:

company Beardsley & Piper. In 1912, the first sand mixer with individually mounted revolving

1681:

814:

1845:

from the casting. In US practice, a riser is another term for a feeder to the top of a casting.

1308:) gas is used. The mixture is exposed to the gas at ambient temperature reacting as following:

1168:

1033:. This sand is simply silica sand with only a small amount of binder and no special additives.

2773:

2768:

2690:

2607:

2602:

2469:

2450:

2429:

2381:

2348:

2292:

2282:

1962:

1891:

1269:

1091:

609:

126:

106:

1771:; instead of the sand mold being formed via packing sand around a pattern, it is 3D-printed.

2340:

1952:

1769:

additive manufacturing began to be applied to sand mold preparation in commercial production

1658:

1485:

1099:

674:

554:

241:

To control the solidification structure of the metal, it is possible to place metal plates,

1945:

Tanaffos Journal of Respiratory Diseases, Thoracic Surgery, Intensive Care and Tuberculosis

813:

With automated mold manufacturing came additional workplace safety requirements. Different

339:

2695:

2665:

2388:

1808:

1293:

1160:

999:) — This is the ability of the sand to retain a given shape after the pattern is removed.

980:

527:

504:

243:

191:

187:

94:

385:

In general, we can distinguish between two methods of sand casting; the first one using

46:

2716:

1957:

1940:

1758:

1717:

1301:

1228:

and water is the most commonly used binder. There are two types of clay commonly used:

1137:

972:

720:

492:

352:

42:(top and bottom halves, respectively) of a sand mold, with cores in place on the drag.

30:

2818:

2670:

2644:

2568:

2494:

1721:

1690:

1623:

1508:

1249:

1118:

716:

601:

597:

282:

219:

62:

881:

Safety of Machinery, ANSI B11.0. American National Standards Institute (ANSI). 2020.

817:

apply depending on the geopolitical jurisdiction where the machinery is to be used.

2685:

2649:

2530:

1746:

1670:

1634:

1555:

1075:

968:

964:

744:

698:

686:

562:

404:

387:

357:

202:

In addition to patterns, the sand molder could also use tools to create the holes.

205:

171:

2444:

2355:. Translation by the author, reproduced by permission of Oxford University Press.

1783: – Manufacturing process in which a liquid is poured into a mold to solidify

1728:

was marketed by the Simpson Company. In 1915, the first experiments started with

2592:

2401:

2377:

2364:

1826:

1803:

1754:

1645:

1611:

1265:

1245:

1145:

1084:

581:

method uses dry sand bonded with materials other than clay, using a fast curing

541:

The sand also has the dimensional instability associated with the conversion of

370:

230:

110:

2076:

1074:

or taken from natural occurring locations, such as beaches and river beds. The

2793:

2788:

2489:

2003:

1797:

1741:

went into production. In the 1930s the first high-frequency coreless electric

1694:

1589:

1253:

740:

736:

732:

512:

484:

454:

1488:) in the casting. The mixed sodium silicate and sand may also be heated by a

2783:

2778:

2345:

The Mystery of the Hanging Garden of Babylon: An Elusive World Wonder Traced

2296:

1750:

1738:

1729:

1524:

1233:

1229:

1186:

1183:

1103:

1080:

1071:

1057:

950:

771:

535:

464:

415:

317:

313:

309:

2177:

1966:

1474:{\displaystyle {\ce {{Na2O(SiO2)}+ CO2 <=> {Na2CO3}+ {2SiO2}+ Heat}}}

507:

created does not prevent oxidation. Green sand for aluminum typically uses

277:

To produce cavities within the casting—such as for liquid cooling in

1094:, which can cause casting defects with high melting point metals, and low

829:

Safeguarding of machinery, CSA Z432. Canadian Standards Association. 2016.

569:, and subsequently they do not form hazardous sub-micron sized particles.

85:. In 2003, over 60% of all metal castings were produced via sand casting.

2276:

2111:

1818:

1607:

1582:

1575:

1551:

1547:

1516:

1512:

1489:

1300:(e.g. by using a sand muller) and 3 to 4% of sodium silicate the binder,

1277:

1179:

1133:

1098:, which can lead to unsound casting. It also cannot be used with certain

1015:

in the casting. Special additives can be used to improve collapsibility.

1012:

954:

846:

The primary standard for sand-mold manufacturing equipment in the EU is:

703:

582:

550:

516:

500:

458:

430:

411:

17:

1052:

145:

132:

Incorporate the pattern and sand in a gating system. Remove the pattern.

2803:

2763:

2731:

1941:"Respiratory Health and Cross-Shift Changes of Foundry Workers in Iran"

1916:"Foundry Says Robotic Sand Printing a "Game Changer" for Metal Casting"

1822:

1812:

1780:

1734:

1713:

1641:

1567:

1531:

1114:

757:

662:

639:

546:

508:

496:

450:

194:, which are added either in the pattern itself, or as separate pieces.

82:

78:

1939:

Mayam Saraei; Habibbolah Masoudi; Omid Aminian; Nazanin Izadi (2018).

1571:

1156:

1141:

1122:

1063:

658:

566:

542:

531:

520:

478:

442:

422:

301:

248:

223:

50:

Two sets of castings (bronze and aluminium) from the above sand mold.

801:

1841:'Riser' (UK) is a term for an up-runner, in which the poured metal

1087:

metals, a lower purity sand can be used (between 94 and 98% pure).

2736:

2726:

1543:

976:

634:

305:

297:

252:

204:

45:

29:

2746:

1789: – Metallurgical casting defect, common sand casting defect

1725:

1603:

1539:

1535:

1297:

1225:

833:

In addition, the electrical safety requirements are covered by:

665:

468:

329:

321:

293:

66:

2541:

2503:

2499:

906:

There are four main components for making a sand casting mold:

780:

2374:

1686:

1578:

743:. In the late sixties mold compaction by fast air pressure or

414:, "green sand" is not a type of sand on its own (that is, not

325:

800:

144:

1981:"Respirator Use and Practices in Primary Metal Operations"

1264:

Resin binders are natural or synthetic high melting point

2424:

Degarmo, E. Paul; Black, J T.; Kohser, Ronald A. (2003),

1768:

1460:

1438:

1425:

1371:

1350:

1330:

837:

Industrial Electrical Machinery, CSA C22.2 No. 301. 2016.

105:

are created by compacting the sand around models called

2029:

Metal Casting Techniques - Vacuum ("V") Process Molding

1530:

Up to 3% of "cushioning material", such as wood flour,

592:

With both methods, the sand mixture is packed around a

2367:, "Mechanical Engineering in the Medieval Near East",

1909:

1907:

1395:

2443:

Todd, Robert H.; Allen, Dell K.; Alting, Leo (1994),

1317:

553:, etc. are therefore used because they do not have a

27:

Metal casting process using sand as the mold material

2281:. A. Kumar, Narendra B. Dahotre. Amsterdam: Boston.

1749:

was invented by adding magnesium to the widely used

418:

in the geologic sense), but is rather a mixture of:

2709:

2658:

2575:

1800: – Tool used in injection molding and printing

162:From the design, provided by a designer, a skilled

2143:

2099:

2051:

1473:

351:and risers is cut from the rough casting. Various

1403:

1402:

1385:

1384:

1720:. In 1912, the sand slinger was invented by the

1622:Clay molds were used in ancient China since the

852:EN 710 will need to be used in conjunction with

697:The first mechanized molding lines consisted of

141:Break away the sand mold and remove the casting.

2014:

1159:sand is a compound of approximately two-thirds

625:used only in applications that necessitate it.

2410:. D. Reidel Publishing Company. pp. xiii.

2278:Materials processing and manufacturing science

1673:. Sand casting molding method was recorded by

1666:

90:

2553:

2515:

2047:

2045:

449:), 75 to 85%, sometimes with a proportion of

8:

1712:manufacturing processes, and the slow metal

109:, by carving directly into the sand, or via

2062:

2060:

770:In 1962, Dansk Industri Syndikat A/S (DISA-

2560:

2546:

2538:

2522:

2508:

2500:

2495:Different Types of Metal Casting Processes

1637:(c. 1300 BC) was made using clay molding.

710:Automatic high pressure sand molding lines

285:—negative forms are used to produce

1956:

1815:), est. 1881, specialized in sand casting

1610:, and dry silica; common liquids include

1459:

1454:

1449:

1445:

1437:

1432:

1424:

1419:

1414:

1404:

1397:

1396:

1394:

1386:

1379:

1377:

1376:

1374:

1370:

1365:

1349:

1344:

1336:

1329:

1324:

1319:

1318:

1316:

1236:, with the former being the most common.

600:having a top and bottom part, termed the

2426:Materials and Processes in Manufacturing

2312:

2310:

2308:

2306:

2251:

2249:

2247:

2210:

2208:

2206:

2204:

2202:

2178:"Beneficial Reuse Of Spent Foundry Sand"

2160:

2158:

2156:

2154:

2152:

2127:

2125:

2123:

2121:

2119:

1697:of the sand casting process technology.

1051:

585:. The latter may also be referred to as

338:

2446:Manufacturing Processes Reference Guide

1862:

1834:

1378:

1121:of iron and magnesium from the mineral

135:Fill the mold cavity with molten metal.

2466:Metal Casting: Principles and Practice

979:, which must leave the mold otherwise

723:powered pistons to compact the molds.

121:There are five steps in this process:

2270:

2268:

2266:

2264:

1202:

218:A multi-part molding box (known as a

7:

2328:

2316:

2255:

2238:

2226:

2214:

2193:

2164:

2131:

1869:

1745:was installed in the U.S. In 1943,

1677:in his book published around 1540.

2347:, Oxford University Press (2013).

412:Contrary to what the name suggests

25:

1985:Foundry Management and Technology

1757:(sodium silicate), hardened with

495:. Coal, typically referred to in

2144:Degarmo, Black & Kohser 2003

2100:Degarmo, Black & Kohser 2003

2052:Degarmo, Black & Kohser 2003

2004:Sand Casting Process Description

1268:. The two common types used are

779:

756:

511:sand (a mixture of the minerals

1914:Donaldson, Brent (2017-11-01),

766:Vertical sand flaskless molding

65:process characterized by using

2742:Semi-finished casting products

1811: – Finnish bell foundry (

1492:to achieve better rigideness.

1405:

1380:

1353:

1337:

405:Molding sand § Green sand

1:

2015:Todd, Allen & Alting 1994

1627:

815:voluntary technical standards

727:Horizontal sand flask molding

751:90–120 molds per hour.

519:, which is made by crushing

320:alloys, which often include

1764:from ambient air, came out

1148:casting and to make cores.

856:for electrical safety, and

2841:

1527:the metal during casting.

681:Fast mold making processes

402:

266:

257:directional solidification

2759:

2537:

2468:, New Age International,

2449:, Industrial Press Inc.,

1546:, can be added to reduce

706:for casting and cooling.

391:and the second being the

214:Molding box and materials

129:in sand to create a mold.

2387:25 December 2007 at the

1633:to 1046 BC). The famous

642:), and aluminum alloys.

138:Allow the metal to cool.

2825:Casting (manufacturing)

2428:(9th ed.), Wiley,

1882:Campbell, John (1993).

1507:, such as coal powder,

789:Matchplate sand molding

693:Mechanized sand molding

561:, they do not have the

2402:Hill, Donald Routledge

2382:Mechanical Engineering

2373:, May 1991, pp. 64-9 (

1920:Additive Manufacturing

1655:

1475:

1060:

805:

344:

231:Additive manufacturing

210:

149:

51:

43:

2799:Tools and terminology

2615:Investment (Lost wax)

1888:Butterworth-Heinemann

1675:Vannoccio Biringuccio

1650:

1476:

1055:

804:

403:Further information:

342:

208:

177:contraction allowance

148:

49:

33:

2275:Asthana, R. (2006).

1793:Foundry sand testing

1787:Veining (metallurgy)

1665:of metals in closed

1661:first described the

1315:

1106:in foundry workers.

1096:thermal conductivity

587:no bake mold casting

559:metamorphic minerals

269:Core (manufacturing)

2598:Evaporative-pattern

2464:Rao, T. V. (2003),

2370:Scientific American

2017:, pp. 256–257.

1462:

1440:

1427:

1391:

1373:

1352:

1332:

1274:phenol formaldehyde

1037:Types of base sands

364:Design requirements

316:alloys, or various

59:sand molded casting

1700:There was not one

1682:Ford Motor Company

1471:

1450:

1428:

1415:

1410:

1361:

1340:

1320:

1061:

947:Chemical inertness

806:

345:

334:floating the mold.

211:

150:

52:

44:

2812:

2811:

2755:

2754:

2475:978-81-224-0843-0

2353:978-0-19-966226-5

2288:978-0-08-046488-6

1597:Parting compounds

1469:

1453:

1431:

1418:

1412:

1364:

1343:

1335:

1323:

1270:urea formaldehyde

1092:thermal expansion

1019:Availability/cost

16:(Redirected from

2832:

2635:Semi-solid metal

2562:

2555:

2548:

2539:

2524:

2517:

2510:

2501:

2479:

2460:

2439:

2412:

2411:

2398:

2392:

2362:

2356:

2341:Stephanie Dalley

2338:

2332:

2326:

2320:

2314:

2301:

2300:

2272:

2259:

2253:

2242:

2236:

2230:

2224:

2218:

2212:

2197:

2191:

2185:

2184:

2182:

2174:

2168:

2162:

2147:

2141:

2135:

2129:

2114:

2109:

2103:

2097:

2091:

2090:

2088:

2087:

2081:

2075:, archived from

2074:

2064:

2055:

2049:

2040:

2039:

2037:

2036:

2024:

2018:

2012:

2006:

2001:

1995:

1994:

1992:

1991:

1977:

1971:

1970:

1960:

1936:

1930:

1929:

1927:

1926:

1911:

1902:

1901:

1879:

1873:

1867:

1846:

1839:

1659:Ismail al-Jazari

1632:

1629:

1486:quartz inversion

1480:

1478:

1477:

1472:

1470:

1467:

1463:

1461:

1458:

1451:

1441:

1439:

1436:

1429:

1426:

1423:

1416:

1413:

1411:

1409:

1408:

1401:

1393:

1392:

1390:

1383:

1375:

1372:

1369:

1362:

1357:

1356:

1351:

1348:

1341:

1333:

1331:

1328:

1321:

1203:dry sand molding

1117:is a mixture of

933:, also known as

920:parting compound

809:Safety standards

783:

760:

573:"Air set" method

555:phase transition

530:is converted to

57:, also known as

21:

2840:

2839:

2835:

2834:

2833:

2831:

2830:

2829:

2815:

2814:

2813:

2808:

2751:

2717:Casting defects

2705:

2654:

2571:

2566:

2533:

2528:

2486:

2476:

2463:

2457:

2442:

2436:

2423:

2420:

2415:

2400:

2399:

2395:

2389:Wayback Machine

2363:

2359:

2339:

2335:

2327:

2323:

2315:

2304:

2289:

2274:

2273:

2262:

2254:

2245:

2237:

2233:

2225:

2221:

2213:

2200:

2192:

2188:

2180:

2176:

2175:

2171:

2163:

2150:

2142:

2138:

2130:

2117:

2110:

2106:

2098:

2094:

2085:

2083:

2079:

2072:

2066:

2065:

2058:

2050:

2043:

2034:

2032:

2026:

2025:

2021:

2013:

2009:

2002:

1998:

1989:

1987:

1979:

1978:

1974:

1938:

1937:

1933:

1924:

1922:

1913:

1912:

1905:

1898:

1881:

1880:

1876:

1868:

1864:

1860:

1855:

1850:

1849:

1840:

1836:

1809:Juutila Foundry

1777:

1762:

1718:cupola furnaces

1630:

1620:

1599:

1521:burn-on defects

1505:reducing agents

1498:

1313:

1312:

1307:

1294:sodium silicate

1290:

1288:Sodium silicate

1262:

1242:

1222:

1211:

1200:

1196:

1192:

1177:

1166:

1161:zirconium oxide

1154:

1131:

1112:

1069:

1056:Silica sand at

1050:

1039:

981:casting defects

928:

904:

874:

844:

823:

811:

791:

786:

785:

784:

768:

763:

762:

761:

729:

712:

695:

683:

648:

631:

622:

575:

528:montmorillonite

448:

440:

436:

428:

407:

401:

383:

366:

353:heat treatments

271:

265:

239:

216:

200:

160:

155:

119:

28:

23:

22:

15:

12:

11:

5:

2838:

2836:

2828:

2827:

2817:

2816:

2810:

2809:

2807:

2806:

2801:

2796:

2791:

2786:

2781:

2776:

2771:

2766:

2760:

2757:

2756:

2753:

2752:

2750:

2749:

2744:

2739:

2734:

2729:

2724:

2719:

2713:

2711:

2707:

2706:

2704:

2703:

2698:

2693:

2688:

2683:

2678:

2673:

2668:

2662:

2660:

2656:

2655:

2653:

2652:

2647:

2642:

2637:

2632:

2627:

2622:

2620:Permanent mold

2617:

2612:

2611:

2610:

2605:

2595:

2590:

2585:

2579:

2577:

2573:

2572:

2567:

2565:

2564:

2557:

2550:

2542:

2535:

2534:

2529:

2527:

2526:

2519:

2512:

2504:

2498:

2497:

2492:

2485:

2484:External links

2482:

2481:

2480:

2474:

2461:

2455:

2440:

2434:

2419:

2416:

2414:

2413:

2393:

2357:

2333:

2321:

2302:

2287:

2260:

2243:

2231:

2219:

2198:

2186:

2169:

2148:

2146:, p. 300.

2136:

2115:

2104:

2102:, p. 311.

2092:

2056:

2054:, p. 310.

2041:

2019:

2007:

1996:

1972:

1951:(4): 285–290.

1931:

1903:

1896:

1890:. p. 49.

1874:

1861:

1859:

1856:

1854:

1851:

1848:

1847:

1833:

1832:

1831:

1830:

1816:

1806:

1801:

1795:

1790:

1784:

1776:

1773:

1767:In the 2010s,

1760:

1619:

1616:

1598:

1595:

1564:cereal binders

1497:

1494:

1482:

1481:

1466:

1457:

1448:

1444:

1435:

1422:

1407:

1400:

1389:

1382:

1368:

1360:

1355:

1347:

1339:

1327:

1305:

1302:carbon dioxide

1292:Water glass (

1289:

1286:

1261:

1258:

1250:vegetable oils

1244:Oils, such as

1241:

1238:

1221:

1220:Clay and water

1218:

1210:

1207:

1198:

1194:

1190:

1176:

1173:

1164:

1153:

1150:

1138:solid solution

1130:

1127:

1119:orthosilicates

1111:

1108:

1067:

1049:

1046:

1038:

1035:

1009:Collapsibility

987:Surface finish

973:carbon dioxide

941:Refractoriness

927:

924:

903:

902:Mold materials

900:

899:

898:

895:

891:

888:

885:

882:

873:

870:

862:EN ISO 13849-2

858:EN ISO 13849-1

843:

842:European Union

840:

822:

819:

810:

807:

790:

787:

778:

777:

776:

767:

764:

755:

754:

753:

728:

725:

721:compressed air

711:

708:

694:

691:

682:

679:

651:Vacuum molding

647:

646:Vacuum molding

644:

630:

627:

621:

618:

574:

571:

489:

488:

482:

475:

474:water, 2 to 4%

472:

462:

446:

438:

434:

426:

400:

397:

382:

379:

365:

362:

283:cylinder heads

267:Main article:

264:

261:

238:

235:

215:

212:

199:

196:

159:

156:

154:

151:

143:

142:

139:

136:

133:

130:

118:

115:

26:

24:

14:

13:

10:

9:

6:

4:

3:

2:

2837:

2826:

2823:

2822:

2820:

2805:

2802:

2800:

2797:

2795:

2792:

2790:

2787:

2785:

2782:

2780:

2777:

2775:

2772:

2770:

2767:

2765:

2762:

2761:

2758:

2748:

2745:

2743:

2740:

2738:

2735:

2733:

2730:

2728:

2725:

2723:

2720:

2718:

2715:

2714:

2712:

2708:

2702:

2699:

2697:

2694:

2692:

2689:

2687:

2684:

2682:

2679:

2677:

2674:

2672:

2671:Cope and drag

2669:

2667:

2664:

2663:

2661:

2657:

2651:

2648:

2646:

2645:Shell molding

2643:

2641:

2638:

2636:

2633:

2631:

2628:

2626:

2623:

2621:

2618:

2616:

2613:

2609:

2606:

2604:

2601:

2600:

2599:

2596:

2594:

2591:

2589:

2586:

2584:

2581:

2580:

2578:

2574:

2570:

2563:

2558:

2556:

2551:

2549:

2544:

2543:

2540:

2536:

2532:

2525:

2520:

2518:

2513:

2511:

2506:

2505:

2502:

2496:

2493:

2491:

2488:

2487:

2483:

2477:

2471:

2467:

2462:

2458:

2456:0-8311-3049-0

2452:

2448:

2447:

2441:

2437:

2435:0-471-65653-4

2431:

2427:

2422:

2421:

2417:

2409:

2408:

2403:

2397:

2394:

2390:

2386:

2383:

2379:

2376:

2372:

2371:

2366:

2361:

2358:

2354:

2350:

2346:

2342:

2337:

2334:

2331:, p. 26.

2330:

2325:

2322:

2319:, p. 25.

2318:

2313:

2311:

2309:

2307:

2303:

2298:

2294:

2290:

2284:

2280:

2279:

2271:

2269:

2267:

2265:

2261:

2258:, p. 24.

2257:

2252:

2250:

2248:

2244:

2241:, p. 23.

2240:

2235:

2232:

2229:, p. 21.

2228:

2223:

2220:

2217:, p. 20.

2216:

2211:

2209:

2207:

2205:

2203:

2199:

2196:, p. 22.

2195:

2190:

2187:

2179:

2173:

2170:

2167:, p. 19.

2166:

2161:

2159:

2157:

2155:

2153:

2149:

2145:

2140:

2137:

2134:, p. 18.

2133:

2128:

2126:

2124:

2122:

2120:

2116:

2113:

2112:B11 Standards

2108:

2105:

2101:

2096:

2093:

2082:on 2012-03-01

2078:

2071:

2070:

2069:The V-Process

2063:

2061:

2057:

2053:

2048:

2046:

2042:

2031:

2030:

2023:

2020:

2016:

2011:

2008:

2005:

2000:

1997:

1986:

1982:

1976:

1973:

1968:

1964:

1959:

1954:

1950:

1946:

1942:

1935:

1932:

1921:

1917:

1910:

1908:

1904:

1899:

1897:0-7506-1696-2

1893:

1889:

1885:

1878:

1875:

1872:, p. 15.

1871:

1866:

1863:

1857:

1852:

1844:

1838:

1835:

1828:

1824:

1820:

1817:

1814:

1810:

1807:

1805:

1802:

1799:

1796:

1794:

1791:

1788:

1785:

1782:

1779:

1778:

1774:

1772:

1770:

1765:

1763:

1756:

1752:

1748:

1744:

1740:

1736:

1731:

1727:

1723:

1719:

1715:

1711:

1707:

1703:

1698:

1696:

1692:

1691:mechanization

1688:

1683:

1680:In 1924, the

1678:

1676:

1672:

1668:

1664:

1660:

1654:

1649:

1647:

1643:

1638:

1636:

1625:

1624:Shang dynasty

1617:

1615:

1613:

1609:

1605:

1596:

1594:

1591:

1586:

1584:

1580:

1577:

1573:

1569:

1565:

1560:

1557:

1553:

1549:

1545:

1541:

1537:

1533:

1528:

1526:

1522:

1518:

1514:

1510:

1506:

1501:

1495:

1493:

1491:

1487:

1464:

1455:

1446:

1442:

1433:

1420:

1398:

1387:

1366:

1358:

1345:

1325:

1311:

1310:

1309:

1303:

1299:

1295:

1287:

1285:

1282:

1279:

1275:

1271:

1267:

1259:

1257:

1255:

1251:

1247:

1239:

1237:

1235:

1231:

1227:

1224:A mixture of

1219:

1217:

1215:

1208:

1206:

1204:

1188:

1185:

1181:

1175:Chamotte sand

1174:

1172:

1170:

1162:

1158:

1151:

1149:

1147:

1143:

1139:

1135:

1129:Chromite sand

1128:

1126:

1124:

1120:

1116:

1109:

1107:

1105:

1101:

1097:

1093:

1088:

1086:

1082:

1077:

1073:

1065:

1059:

1054:

1047:

1045:

1043:

1036:

1034:

1032:

1028:

1022:

1020:

1016:

1014:

1010:

1006:

1004:

1000:

998:

994:

990:

988:

984:

982:

978:

974:

970:

966:

962:

958:

956:

952:

948:

944:

942:

938:

936:

935:foundry sands

932:

931:Molding sands

926:Molding sands

925:

923:

921:

917:

913:

909:

901:

896:

892:

889:

886:

883:

880:

879:

878:

872:United States

871:

869:

867:

863:

859:

855:

850:

849:

841:

839:

838:

834:

831:

830:

826:

820:

818:

816:

808:

803:

799:

795:

788:

782:

775:

773:

765:

759:

752:

748:

746:

742:

741:pneumatically

738:

737:hydraulically

734:

726:

724:

722:

718:

717:high pressure

709:

707:

705:

700:

699:sand slingers

692:

690:

688:

680:

678:

676:

670:

667:

664:

660:

656:

652:

645:

643:

641:

636:

629:No-bake molds

628:

626:

619:

617:

613:

611:

605:

603:

602:cope and drag

599:

598:casting flask

595:

590:

588:

584:

580:

572:

570:

568:

564:

560:

556:

552:

548:

544:

539:

537:

533:

529:

524:

522:

518:

514:

510:

506:

502:

498:

494:

486:

483:

480:

476:

473:

470:

466:

463:

460:

456:

452:

444:

432:

424:

421:

420:

419:

417:

413:

406:

398:

396:

394:

390:

389:

380:

378:

376:

372:

363:

361:

359:

354:

350:

341:

337:

335:

331:

327:

323:

319:

315:

311:

307:

303:

299:

295:

290:

288:

284:

280:

275:

270:

262:

260:

258:

254:

250:

246:

245:

236:

234:

232:

228:

225:

221:

220:casting flask

213:

207:

203:

197:

195:

193:

189:

184:

182:

178:

173:

169:

165:

164:pattern maker

157:

152:

147:

140:

137:

134:

131:

128:

124:

123:

122:

117:Basic process

116:

114:

112:

108:

104:

100:

99:mold cavities

96:

92:

86:

84:

80:

76:

72:

68:

64:

63:metal casting

60:

56:

48:

41:

37:

32:

19:

2686:Molding sand

2640:Shaw process

2629:

2625:Plaster mold

2531:Metalworking

2465:

2445:

2425:

2418:Bibliography

2406:

2396:

2368:

2360:

2344:

2336:

2324:

2277:

2234:

2222:

2189:

2172:

2139:

2107:

2095:

2084:, retrieved

2077:the original

2068:

2033:, retrieved

2028:

2022:

2010:

1999:

1988:. Retrieved

1984:

1975:

1948:

1944:

1934:

1923:, retrieved

1919:

1883:

1877:

1865:

1842:

1837:

1766:

1747:ductile iron

1699:

1679:

1656:

1651:

1639:

1635:Houmuwu ding

1621:

1600:

1588:Up to 2% of

1587:

1563:

1562:Up to 2% of

1561:

1529:

1504:

1503:Up to 5% of

1502:

1499:

1483:

1291:

1283:

1263:

1243:

1223:

1213:

1212:

1178:

1155:

1132:

1113:

1110:Olivine sand

1089:

1076:fusion point

1062:

1041:

1040:

1031:backing sand

1030:

1026:

1023:

1018:

1017:

1008:

1007:

1002:

1001:

996:

993:Cohesiveness

992:

991:

986:

985:

961:Permeability

960:

959:

946:

945:

940:

939:

934:

930:

929:

919:

915:

911:

907:

905:

875:

851:

845:

835:

832:

827:

824:

812:

796:

792:

769:

749:

745:gas pressure

730:

713:

696:

687:productivity

684:

671:

654:

650:

649:

632:

623:

614:

606:

593:

591:

578:

576:

563:polycrystals

540:

525:

490:

408:

392:

386:

384:

374:

367:

358:shot peening

346:

333:

291:

286:

276:

272:

242:

240:

229:

217:

201:

185:

176:

167:

163:

161:

120:

87:

71:casting sand

70:

58:

55:Sand casting

54:

53:

39:

35:

2769:Fabrication

2710:Terminology

2583:Centrifugal

2378:Donald Hill

2365:Donald Hill

1827:3D printing

1804:Sand rammer

1755:water glass

1646:Sennacherib

1631: 1600

1612:mineral oil

1534:, powdered

1254:marine oils

1246:linseed oil

1182:is made by

1152:Zircon sand

1146:alloy steel

1085:non-ferrous

1048:Silica sand

1027:facing sand

1003:Flowability

471:), 5 to 11%

445:sand (ZrSiO

281:blocks and

111:3D printing

103:gate system

93:known as a

2789:Metallurgy

2659:Components

2588:Continuous

2086:2009-11-09

2035:2009-11-09

1990:2021-04-05

1925:2017-11-14

1853:References

1798:Hand mould

1702:bottleneck

1695:automation

1693:and later

1667:mold boxes

1590:iron oxide

1566:, such as

1136:sand is a

854:EN 60204-1

513:forsterite

485:anthracite

455:staurolite

433:sand (FeCr

399:Green sand

388:green sand

251:metals in

153:Components

91:mold boxes

69:—known as

2784:Machining

2779:Jewellery

2608:Lost foam

2603:Full mold

2576:Processes

1751:grey iron

1739:U.S. Army

1730:bentonite

1657:In 1206,

1556:hot crack

1525:carburize

1496:Additives

1406:⇀

1399:−

1388:−

1381:↽

1272:(UF) and

1234:kaolinite

1230:bentonite

1187:fire clay

1184:calcining

1169:mold wash

1104:silicosis

1081:cast iron

1072:sandstone

1058:Panavally

1042:Base sand

1013:hot tears

951:magnesium

916:additives

908:base sand

772:DISAMATIC

655:V-process

565:found in

536:silicosis

497:foundries

487:(0 to 1%)

465:bentonite

425:sand (SiO

416:greensand

381:Processes

318:pot metal

314:magnesium

310:aluminium

249:quenching

172:strickled

166:builds a

83:foundries

79:factories

18:Sand cast

2819:Category

2794:Smithing

2404:(1974).

2385:Archived

2329:Rao 2003

2317:Rao 2003

2297:85814321

2256:Rao 2003

2239:Rao 2003

2227:Rao 2003

2215:Rao 2003

2194:Rao 2003

2165:Rao 2003

2132:Rao 2003

1967:31143220

1884:Castings

1870:Rao 2003

1819:voxeljet

1775:See also

1737:for the

1735:grenades

1722:American

1716:rate in

1642:Assyrian

1608:graphite

1583:molasses

1576:sulphite

1552:hot tear

1548:scabbing

1517:fuel oil

1513:creosote

1490:heat gun

1278:catalyst

1248:, other

1180:Chamotte

1134:Chromite

969:nitrogen

965:hydrogen

955:titanium

918:, and a

866:EN 62061

704:conveyor

620:Cold box

583:adhesive

551:chromite

517:fayalite

501:sea-coal

459:graphite

431:chromite

395:method.

375:sand pit

224:screeded

158:Patterns

125:Place a

107:patterns

73:—as the

2804:Welding

2774:Forming

2764:Casting

2732:Foundry

2691:Pattern

2569:Casting

2183:. 1996.

1958:6534795

1823:Germany

1813:Finland

1781:Casting

1743:furnace

1714:melting

1663:casting

1618:History

1568:dextrin

1532:sawdust

1214:Binders

1209:Binders

1142:spinels

1115:Olivine

663:plastic

640:ferrous

594:pattern

579:air set

547:Olivine

523:rock).

509:olivine

481:3 to 5%

451:olivine

393:air set

168:pattern

127:pattern

81:called

61:, is a

2472:

2453:

2432:

2351:

2295:

2285:

1965:

1955:

1894:

1706:mixing

1581:, and

1572:starch

1554:, and

1542:, and

1515:, and

1157:Zircon

1123:dunite

1064:Silica

975:, and

912:binder

821:Canada

659:vacuum

567:silica

543:quartz

532:illite

521:dunite

479:sludge

477:inert

443:zircon

441:), or

423:silica

328:, and

302:bronze

279:engine

244:chills

237:Chills

192:risers

97:. The

2737:Ingot

2727:Dross

2722:Draft

2701:Sprue

2696:Riser

2681:Flask

2666:Chill

2181:(PDF)

2080:(PDF)

2073:(PDF)

1858:Notes

1843:rises

1726:plows

1669:with

1644:king

1544:straw

1536:husks

1509:pitch

1260:Resin

1100:basic

977:steam

894:2018.

635:resin

493:degas

457:, or

371:draft

349:sprue

306:brass

298:steel

287:cores

263:Cores

253:forge

198:Tools

188:sprue

181:cores

95:flask

2747:Slag

2676:Core

2650:Spin

2630:Sand

2470:ISBN

2451:ISBN

2430:ISBN

2349:ISBN

2293:OCLC

2283:ISBN

1963:PMID

1892:ISBN

1710:core

1671:sand

1640:The

1604:talc

1540:peat

1468:Heat

1298:sand

1266:gums

1252:and

1232:and

1226:clay

1197:-SiO

1163:(ZrO

1083:and

1066:(SiO

997:bond

995:(or

953:and

910:, a

860:and

733:bars

666:film

610:bell

577:The

515:and

469:clay

330:zinc

322:lead

294:iron

101:and

75:mold

67:sand

40:drag

38:and

36:cope

34:The

2593:Die

2375:cf.

1953:PMC

1825:),

1687:car

1579:lye

1452:SiO

1342:SiO

1304:(CO

1240:Oil

1189:(Al

1140:of

864:or

675:rms

499:as

429:),

326:tin

2821::

2380:,

2343:,

2305:^

2291:.

2263:^

2246:^

2201:^

2151:^

2118:^

2059:^

2044:^

1983:.

1961:.

1949:17

1947:.

1943:.

1918:,

1906:^

1886:.

1759:CO

1708:,

1628:c.

1606:,

1574:,

1570:,

1550:,

1538:,

1511:,

1430:CO

1417:Na

1363:CO

1322:Na

971:,

967:,

957:.

922:.

914:,

549:,

505:CO

453:,

324:,

312:,

308:,

304:,

300:,

296:,

113:.

2561:e

2554:t

2547:v

2523:e

2516:t

2509:v

2478:.

2459:.

2438:.

2391:)

2299:.

2089:.

2038:.

1993:.

1969:.

1928:.

1900:.

1829:,

1821:(

1761:2

1626:(

1465:+

1456:2

1447:2

1443:+

1434:3

1421:2

1367:2

1359:+

1354:)

1346:2

1338:(

1334:O

1326:2

1306:2

1199:2

1195:3

1193:O

1191:2

1165:2

1068:2

653:(

467:(

461:.

447:4

439:4

437:O

435:2

427:2

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.