322:

99:

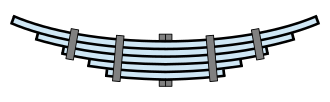

122:, while loops formed at either end provide for attaching to the vehicle chassis. For very heavy vehicles, a leaf spring can be made from several leaves stacked on top of each other in several layers, often with progressively shorter leaves. The longest leaf is also known as the main, master, or No. 1 leaf, with leaves numbered in descending order of length. The eyes at the end of the leaf spring are formed into the master leaf. In general, aside from the main leaf, the other leaves are tapered at each end. Sometimes auxiliary or rebound leaves are part of the main spring pack, in which case the auxiliary leaf closest to the main leaf is No. 1, the next closest is No. 2, etc. The leaves are attached to each other through the centre bolt, which is at or near the mid-point along the length of the leaf spring. To ensure that leaves remain aligned laterally, several methods can be used, including notches and grooves between leaves or external clips.

504:

307:

488:

275:

192:

291:

520:

243:

79:, it is one of the oldest forms of vehicle suspension. A leaf spring is one or more narrow, arc-shaped, thin plates that are attached to the axle and chassis in a way that allows the leaf spring to flex vertically in response to irregularities in the road surface. Lateral leaf springs are the most commonly used arrangement, running the length of the vehicle and mounted perpendicular to the wheel axle, but numerous examples of

414:

2329:

1869:

2319:

1859:

378:

673:

spring should not touch the machine member to which it is attached. The camber shown in the figure is known as positive camber. The central clamp is required to hold the leaves of the spring. Machine used for this operation is

Hydraulic press. Leaves are bent to required radius using a press. All the leaves are tested for required radius using cambering gauges.

333:. The intention of this design is to reduce inter-leaf friction, and therefore there is only contact between the leaves at the ends and at the centre, where the axle is connected. Spacers prevent contact at other points. Aside from weight-saving, the main advantage of parabolic springs is their greater flexibility, which translates into improved

680:

fire point of quenching oil is about 200°C and it is seen to that the oil temperature does not exceed 80°C. After quenching, the structure of the leaf spring becomes very hard and this property is not required. But this process is required to set the leaves to the correct radius after cambering. To remove hardness, tempering is done.

142:

33:

679:

Hot bent leaves kept in tray and quenched in oil bath to get martensite structure. Martensite is the hardest form of steel crystalline structure. Martensite is formed in carbon steels by rapid cooling that is quenching of austenite form of iron. The machine used is a conveyorised quench oil bath. The

672:

The top leaf is known as the master leaf. The eye is provided for attaching the spring with another machine member. The amount of bend that is given to the spring from the central line, passing through the eyes, is known as camber. The camber is provided so that even at the maximum load the deflected

665:

Any metal, or alloy which can be hard drawn, or rolled to fairly high strength and retains sufficient ductility to form, may be used for springs, or any alloy which can be heat treated to high strength and good ductility before, or after forming may be used. For special spring properties such as good

162:(seldom used now), to carry a swivelling member instead. One eye is usually fixed but allowed to pivot with the motion of the spring, whereas the other eye is fastened to a hinge mechanism that allows that end to pivot and undergo limited movement. A leaf spring can either be attached directly to the

166:

at both eyes or attached directly at one end, usually the front, with the other end attached through a shackle: a short swinging arm. The shackle takes up the tendency of the leaf spring to elongate when compressed and thus makes the suspension softer. The shackle provides some degree of flexibility

405:

Obadiah Elliot is credited with inventing the modern leaf spring with his 1804 patent on elliptical leaf springs, which brought him significant recognition and revenue, and engineers began studying leaf springs to develop improved designs and manufacturing processes. The mechanics and deflection of

686:

Tempering is a process of heat treating, which is used to increase the toughness. Quenched leaves are reheated to drop hardness to the required level. An electrically heated temperature furnace is used for this process. Hardness of the leaves is determined using

Brinell hardness testing, a process

385:

The earliest known leaf springs began appearing on carriages in France in the mid-17th century in the form of the two-part elbow spring (as the illustrated example from Lisbon), and later migrated to

England and Germany, appearing on the carriages of the wealthy in those countries around 1750. Dr.

344:

A further development by the

British GKN company and by Chevrolet, with the Corvette, among others, is the move to composite plastic leaf springs. Nevertheless, due to the lack of inter-leaf friction and other internal dampening effects, this type of spring requires more powerful dampers/shock

546:. This arrangement uses a straight leaf spring that is tightly secured to the chassis at the centre; the ends of the spring are bolted to the wheel suspension, allowing the spring to work independently on each wheel. This suspension is smaller, flatter and lighter than a traditional setup.

183:. However, because the leaf spring is also serving to hold the axle in position, soft springs—i.e. springs with low spring constant—are not suitable. The consequent stiffness, in addition to inter-leaf friction, makes this type of suspension not particularly comfortable for the riders.

666:

fatigue life, non-magnetic characteristics, resistance to corrosion, elevated temperatures and drift require special considerations. leaves are heated to critical temperature in an Oil-fired hardening furnace. Usually temperature maintained is between 850°C and 950°C.

410:(1861), and G.R. Henderson (1894). Improved steel rolling processes, process instruments, and spring steel alloys were developed during the latter half of the 19th century as well, making the manufacture of leaf springs more consistent and less expensive.

203:, referred to two circular arcs linked at their tips. This was joined to the frame at the top centre of the upper arc, the bottom centre was joined to the "live" suspension components, such as a solid front axle. Additional suspension components, such as

749:(known as soft-edge trampolines), which improves safety for users and reduces risk of concussion. The leaf springs are spaced around the frame as 'legs' that branch from the base frame to suspend the jumping mat, providing flexibility and resilience.

477:

rear suspension. A further advantage of a leaf spring over a helical spring is that the end of the leaf spring may be guided along a definite path. In many late 1990s and early 2000s trucks, the leaf spring is connected to a Hinkle Beam ball joint.

465:. For heavy vehicles, they have the advantage of spreading the load more widely over the vehicle's chassis, whereas coil springs transfer it to a single point. Unlike coil springs, leaf springs also locate the rear axle, eliminating the need for

259:

174:

The leaf spring acts as a linkage to hold the axle in position and thus separate linkages are not necessary. The result is a suspension that is simple and strong. Inter-leaf friction dampens the spring's motion and reduces rebound, which, until

348:

Typically when used in automobile suspension the leaf both supports an axle and locates/partially locates the axle. This can lead to handling issues (such as "axle tramp"), as the flexible nature of the spring makes precise control of the

321:

687:

that also relieves stresses. The temperature inside the machine is maintained between 540 and 680°C. The tempering process involves heating of leaves below their re-crystallization temperature then cooling them using water or air.

98:

129:, with typical thicknesses ranging between 0.203 to 0.375 in (5.2 to 9.5 mm) (6 to 3/8 or 00 gauge). The material and dimensions should be selected such that each leaf is capable of being hardened to have a fully

503:

145:

Each side of this rear axle is suspended by a leaf spring. The front eye of each leaf spring is secured to the frame; the rear eye is attached by a shackle that pivots to allow the spring to lengthen as it

214:"Quarter-elliptic" springs often had the thickest part of the stack of leaves stuck into the rear end of the side pieces of a short ladder frame, with the free end attached to the differential, as in the

86:

Leaf springs can serve multiple suspension functions: location, springing, and to some extent damping as well, through interleaf friction. However, this friction is not well controlled, resulting in

102:

Generic diagram of a leaf spring pack, without eyes; leaves are fastened together by the centre bolt, midway along the length of the spring, and lateral alignment is enforced by multiple clips

487:

233:

Elliot's invention revolutionized carriage design and construction, removing the need for a heavy perch and making transportation over rough roadways faster, easier, and less expensive.

361:) and radius arms to locate the axle and do not have this drawback. Such designs can use softer springs, resulting in a better ride. Examples include the various rear suspensions of

290:

258:

1905:

519:

199:

There are a variety of leaf springs, usually employing the word "elliptical". "Elliptical" or "full elliptical" leaf springs, patented in 1804 by the

British inventor

1189:

329:

A more modern implementation is the parabolic leaf spring. This design is characterized by fewer leaves whose thickness varies from centre to ends following a

2358:

306:

729:, where traditional blacksmiths still produce a large amount of the country's tools, leaf springs from scrapped cars are frequently used to make knives,

806:

1123:

125:

Spring steels were discovered to be most efficient at approximately 1% carbon content. Individual leaf thickness is specified by the Stubbs or

1898:

494:

150:

The two ends of a leaf spring usually are formed into round eyes or eyelets, through which a fastener connects each end of the spring to the

1472:

167:

to the leaf spring so that it does not fail when subjected to heavy loads. The axle is usually fastened to the middle of the spring by

2363:

2200:

1588:

1389:

36:

A traditional semi-elliptical

Hotchkiss leaf spring arrangement. On the left, the spring is connected to the frame through a shackle.

1182:

1891:

1598:

274:

1545:

985:

898:

2353:

1623:

2205:

1230:

1175:

2092:

1698:

973:

395:

337:, which approaches that of coil springs; the trade-off is reduced load carrying capability. They are widely used on

2155:

2145:

1984:

1535:

1384:

1366:

141:

2102:

1999:

1834:

1723:

1663:

1628:

1418:

914:

2150:

2127:

2107:

1613:

1465:

1270:

1245:

387:

133:

throughout the entire section. Suitable spring steel alloys include 55Si7, 60Si7, 65Si7, 50Cr4V2, and 60Cr4V2.

2180:

1583:

1555:

543:

531:

434:

1145:

2049:

2004:

1573:

1563:

1376:

80:

2024:

1413:

1225:

391:

422:

191:

538:

has a transverse leaf spring using composite materials for its rear suspension, similar in concept to

118:

cross-section. In the most common configuration, the centre of the arc provides the location for the

1936:

1668:

1603:

1255:

932:

791:

539:

442:

207:, would usually be needed for this design, but not for "semi-elliptical" leaf springs as used in the

49:

2195:

1969:

1693:

1673:

1458:

1396:

1210:

402:

showed that leaf springs were being marketed regularly by the late 18th century carriage industry.

90:

and irregular suspension motions. For this reason, some manufacturers have used mono-leaf springs.

2318:

1858:

701:

Because leaf springs are made of relatively high quality steel, they are a favourite material for

2235:

1839:

1744:

1052:

2064:

1633:

1520:

1502:

1433:

981:

894:

438:

1071:

242:

2284:

2044:

2019:

1708:

1515:

1401:

1280:

955:

462:

126:

832:

2294:

2220:

2215:

2122:

2117:

2069:

1914:

1728:

1658:

1295:

1285:

991:

801:

796:

230:), some manufacturers laid non-metallic sheets in between the metal leaves, such as wood.

208:

200:

163:

45:

17:

2299:

2210:

2160:

2112:

2034:

1829:

1643:

1638:

1529:

1525:

1329:

1319:

1314:

1215:

781:

510:

413:

407:

227:

176:

107:

1005:

1001:

2347:

2332:

2289:

2230:

2225:

2059:

1944:

1872:

1811:

1796:

1776:

1703:

1540:

1510:

1406:

1275:

1240:

873:

525:

Independent front suspension by semi-elliptical springs. Mercedes Benz 230 W153, 1938

362:

350:

155:

151:

733:, and other tools. They are also commonly used by amateur and hobbyist blacksmiths.

2269:

2240:

2175:

2097:

2054:

1979:

1964:

1781:

1718:

1688:

1683:

1428:

1350:

742:

466:

334:

222:

had multiple leaf springs over its differential that were curved in the shape of a

219:

204:

111:

1019:

2322:

2274:

2264:

2170:

2029:

1993:

1989:

1974:

1862:

1786:

1759:

1754:

1618:

1608:

1568:

1304:

1235:

786:

718:

702:

470:

449:

instead. Today leaf springs are still used in heavy commercial vehicles such as

446:

430:

358:

180:

2304:

2190:

2185:

2165:

2039:

1954:

1844:

1806:

1648:

1481:

1423:

746:

714:

535:

534:

uses a transverse leaf spring for its independent rear suspension. Similarly,

418:

354:

130:

1101:

2074:

2014:

1959:

1801:

1791:

1713:

1678:

1345:

1265:

1220:

995:

530:

The leaf spring also has seen modern applications in cars. For example, the

474:

115:

959:

377:

2084:

1883:

1593:

1250:

776:

726:

366:

330:

215:

87:

1056:

394:

in 1768 for demonstrating the superiority of sprung carriages. By 1796,

722:

56:

1167:

2279:

1764:

1578:

758:

730:

168:

2251:

2137:

1749:

1653:

771:

710:

706:

454:

412:

376:

338:

320:

190:

140:

97:

53:

32:

31:

2255:

1949:

1771:

1260:

893:. Tinley Park: The Goodheart-Willcox Company, Inc. p. 455.

889:

Stockel, Martin W.; Stockel, Martin T.; Johanson, Chris (1996).

875:

Leaf

Springs: Their Characteristics and Methods of Specification

223:

119:

1887:

1454:

1171:

1926:

1492:

458:

450:

218:

of the 1920s. As an example of non-elliptic leaf springs, the

1450:

946:

Terrier, Max (1986). "L'invention des ressorts de voiture".

493:

Leaf-spring front independent suspension. Front-wheel-drive

179:

were widely adopted, was a very significant advantage over

509:

Independent front suspension by transverse leaf spring.

833:"IS 1135(1995): Leaf Springs Assembly for Automobiles"

353:

of the axle difficult. Some suspension designs use a

158:. Some springs terminated in a concave end, called a

2249:

2136:

2083:

1935:

1822:

1737:

1554:

1501:

1375:

1359:

1338:

1328:

1294:

1203:

381:

17th-century coach spring in Lisbon

Carriage Museum

1082:. American Society of Mechanical Engineers: 92–105

195:Three-quarter-elliptic leaf spring on a carriage.

211:. That employed the lower arc, hence its name.

878:. Wilkesbarre, PA: Sheldon Axle Company. 1912.

1899:

1466:

1183:

473:, thereby saving cost and weight in a simple

406:leaf springs were developed by Clark (1855),

8:

1051:. Society of Automobile Engineers: 156–191.

915:"Springs – A simple study of car suspension"

741:Leaf springs have also replaced traditional

482:Leaf springs used in independent suspensions

980:(Reprint of both volumes). Astragal Press.

827:

825:

823:

1906:

1892:

1884:

1473:

1459:

1451:

1335:

1190:

1176:

1168:

106:A leaf spring takes the form of a slender

1072:"A Graphical Method of Designing Springs"

868:

866:

864:

862:

860:

858:

856:

854:

852:

850:

392:Society of English Arts and Manufacturers

554:Multi-leaf springs are made as follows.

325:Tapered or parabolic leaf spring diagram

819:

807:Transverse leaf spring front suspension

480:

235:

1043:Rowland, E.K. (1911). "Leaf Springs".

757:The "diaphragm" common in automotive

390:was awarded three gold medals by the

7:

2359:Automotive suspension technologies

2201:Electronic brakeforce distribution

1589:Continuously variable transmission

835:. Bureau of Indian Standards. 1995

25:

532:1963 Chevrolet Corvette Sting Ray

429:Leaf springs were very common on

67:, and sometimes referred to as a

2328:

2327:

2317:

1868:

1867:

1857:

1102:"Kamis, Khukuri makers of Nepal"

518:

502:

486:

305:

289:

273:

257:

241:

226:. As a substitute for dampers (

1146:"Trampolines WO 2012167300 A1"

634:Assembly and surface finishes:

612:Post-heat treatment processes:

1:

1624:Automated manual transmission

948:Revue d'Histoire des Sciences

445:designs were developed using

2206:Electronic stability control

1231:Electronic Stability Control

2093:Ackermann steering geometry

1699:Semi-automatic transmission

1124:"Joe Andon's leap of faith"

559:Pre-heat treatment process:

2380:

2156:Active rollover protection

1536:Internal combustion engine

921:: 936–937. 10 August 1912.

761:is a type of leaf spring.

94:Operation and basic design

27:Type of vehicle suspension

2364:Horse-drawn vehicle parts

2313:

1922:

1853:

1835:Hybrid vehicle drivetrain

1724:Transmission control unit

1664:Limited-slip differential

1629:Electrorheological clutch

1488:

1024:. Braunschweig: F. Vieweg

593:Heat treatment processes:

441:, and more sophisticated

425:and Lübecker Maschinenbau

18:Semi-elliptic leaf spring

2151:Anti-lock braking system

1945:Anti-roll bar (sway bar)

1614:Dual-clutch transmission

1070:Henderson, G.R. (1894).

1018:Reuleaux, Franz (1861).

578:scarfing and eye rolling

572:end cutting and pressing

435:automobile manufacturers

417:Leaf spring on a German

388:Richard Lovell Edgeworth

237:Examples of leaf springs

2181:Combined braking system

1584:Constant-velocity joint

1104:. Himalayan-imports.com

978:A Treatise on Carriages

933:"Carriages and Coaches"

705:. In countries such as

400:A Treatise on Carriages

81:transverse leaf springs

59:. Originally called a

2005:Independent suspension

1564:Automatic transmission

663:Heating for hardening:

426:

382:

341:for improved comfort.

326:

282:Three quarter-elliptic

196:

147:

103:

69:semi-elliptical spring

37:

2025:Multi-link suspension

960:10.3406/rhs.1986.4016

919:The Automotor Journal

597:heating for hardening

587:centre hole drilling.

550:Manufacturing process

437:shifted primarily to

433:until the 1970s when

416:

380:

324:

194:

144:

131:martensitic structure

101:

35:

2354:Springs (mechanical)

1669:Locking differential

1604:Direct-shift gearbox

792:Corvette leaf spring

650:marking and packing.

540:the front suspension

44:is a simple form of

2196:Electric park brake

1694:Preselector gearbox

1674:Manual transmission

1198:Automotive handling

2236:Regenerative brake

1840:Electric generator

1745:Wheel hub assembly

619:side bend removing

427:

383:

327:

197:

148:

110:-shaped length of

104:

48:commonly used for

38:

2341:

2340:

2146:Automatic braking

1881:

1880:

1634:Epicyclic gearing

1503:Automotive engine

1448:

1447:

1444:

1443:

1437:

1434:Semi-trailing arm

1410:

1393:

891:Auto Fundamentals

463:railway carriages

439:front-wheel drive

73:elliptical spring

16:(Redirected from

2371:

2331:

2330:

2321:

2285:Outline of tires

2020:MacPherson strut

1908:

1901:

1894:

1885:

1871:

1870:

1861:

1738:Wheels and tires

1709:Torque converter

1475:

1468:

1461:

1452:

1431:

1404:

1402:MacPherson strut

1387:

1360:Semi-independent

1336:

1281:Vehicle dynamics

1192:

1185:

1178:

1169:

1157:

1156:

1154:

1152:

1142:

1136:

1135:

1133:

1131:

1126:. The Australian

1120:

1114:

1113:

1111:

1109:

1098:

1092:

1091:

1089:

1087:

1067:

1061:

1060:

1040:

1034:

1033:

1031:

1029:

1021:Der Konstrukteur

1015:

1009:

999:

970:

964:

963:

943:

937:

936:

929:

923:

922:

911:

905:

904:

886:

880:

879:

870:

845:

844:

842:

840:

829:

677:Quenching :

522:

506:

490:

423:Orenstein-Koppel

316:

315:

309:

300:

299:

298:Quarter-elliptic

293:

284:

283:

277:

268:

267:

261:

252:

251:

245:

127:Birmingham gauge

21:

2379:

2378:

2374:

2373:

2372:

2370:

2369:

2368:

2344:

2343:

2342:

2337:

2309:

2258:

2254:

2245:

2221:Hydraulic fluid

2216:Hydraulic brake

2132:

2123:Torque steering

2118:Rack and pinion

2079:

2070:Wheel alignment

1985:Double wishbone

1931:

1918:

1912:

1882:

1877:

1849:

1818:

1733:

1729:Universal joint

1659:Hotchkiss drive

1550:

1497:

1484:

1479:

1449:

1440:

1385:Double wishbone

1371:

1355:

1324:

1290:

1286:Weight transfer

1199:

1196:

1166:

1161:

1160:

1150:

1148:

1144:

1143:

1139:

1129:

1127:

1122:

1121:

1117:

1107:

1105:

1100:

1099:

1095:

1085:

1083:

1069:

1068:

1064:

1042:

1041:

1037:

1027:

1025:

1017:

1016:

1012:

1006:Original Vol II

988:

974:Felton, William

972:

971:

967:

945:

944:

940:

931:

930:

926:

913:

912:

908:

901:

888:

887:

883:

872:

871:

848:

838:

836:

831:

830:

821:

816:

811:

802:Suspension lift

797:Spring (device)

767:

755:

739:

699:

694:

659:

628:clamp riveting.

552:

536:2016 Volvo XC90

526:

523:

514:

507:

498:

491:

375:

331:parabolic curve

317:

313:

312:

310:

301:

297:

296:

294:

285:

281:

280:

278:

269:

265:

264:

262:

253:

249:

248:

246:

228:shock absorbers

209:Hotchkiss drive

201:Obadiah Elliott

189:

181:helical springs

177:shock absorbers

139:

137:Characteristics

96:

83:exist as well.

65:carriage spring

28:

23:

22:

15:

12:

11:

5:

2377:

2375:

2367:

2366:

2361:

2356:

2346:

2345:

2339:

2338:

2336:

2335:

2325:

2314:

2311:

2310:

2308:

2307:

2302:

2300:Whitewall tire

2297:

2292:

2287:

2282:

2277:

2272:

2267:

2261:

2259:

2250:

2247:

2246:

2244:

2243:

2238:

2233:

2228:

2223:

2218:

2213:

2211:Engine braking

2208:

2203:

2198:

2193:

2188:

2183:

2178:

2173:

2168:

2163:

2161:Brake bleeding

2158:

2153:

2148:

2142:

2140:

2134:

2133:

2131:

2130:

2125:

2120:

2115:

2113:Power steering

2110:

2105:

2100:

2095:

2089:

2087:

2081:

2080:

2078:

2077:

2072:

2067:

2065:Watt's linkage

2062:

2057:

2052:

2047:

2042:

2037:

2035:Shock absorber

2032:

2027:

2022:

2017:

2012:

2007:

2002:

2000:Hydropneumatic

1997:

1987:

1982:

1977:

1972:

1967:

1962:

1957:

1952:

1947:

1941:

1939:

1933:

1932:

1923:

1920:

1919:

1917:control system

1913:

1911:

1910:

1903:

1896:

1888:

1879:

1878:

1876:

1875:

1865:

1854:

1851:

1850:

1848:

1847:

1842:

1837:

1832:

1830:Electric motor

1826:

1824:

1820:

1819:

1817:

1816:

1815:

1814:

1809:

1804:

1799:

1794:

1789:

1784:

1779:

1769:

1768:

1767:

1762:

1757:

1747:

1741:

1739:

1735:

1734:

1732:

1731:

1726:

1721:

1716:

1711:

1706:

1701:

1696:

1691:

1686:

1681:

1676:

1671:

1666:

1661:

1656:

1651:

1646:

1644:Friction drive

1641:

1639:Fluid coupling

1636:

1631:

1626:

1621:

1616:

1611:

1606:

1601:

1596:

1591:

1586:

1581:

1576:

1571:

1566:

1560:

1558:

1552:

1551:

1549:

1548:

1543:

1538:

1533:

1530:Plug-in hybrid

1523:

1518:

1513:

1507:

1505:

1499:

1498:

1489:

1486:

1485:

1480:

1478:

1477:

1470:

1463:

1455:

1446:

1445:

1442:

1441:

1439:

1438:

1426:

1421:

1419:Sliding pillar

1416:

1411:

1399:

1394:

1381:

1379:

1373:

1372:

1370:

1369:

1363:

1361:

1357:

1356:

1354:

1353:

1348:

1342:

1340:

1333:

1326:

1325:

1323:

1322:

1317:

1312:

1307:

1301:

1299:

1292:

1291:

1289:

1288:

1283:

1278:

1273:

1268:

1263:

1258:

1253:

1248:

1243:

1238:

1233:

1228:

1223:

1218:

1216:Center of mass

1213:

1207:

1205:

1201:

1200:

1197:

1195:

1194:

1187:

1180:

1172:

1165:

1164:External links

1162:

1159:

1158:

1137:

1115:

1093:

1062:

1035:

1010:

1002:Original Vol I

986:

965:

938:

935:. p. 205.

924:

906:

899:

881:

846:

818:

817:

815:

812:

810:

809:

804:

799:

794:

789:

784:

782:Car suspension

779:

774:

768:

766:

763:

754:

751:

738:

737:In trampolines

735:

698:

697:By blacksmiths

695:

693:

690:

689:

688:

681:

674:

667:

658:

657:Heat treatment

655:

654:

653:

652:

651:

648:

645:

642:

639:

631:

630:

629:

626:

623:

620:

617:

609:

608:

607:

604:

601:

598:

590:

589:

588:

585:

584:C’SKG punching

582:

579:

576:

575:second warping

573:

570:

567:

564:

551:

548:

528:

527:

524:

517:

515:

508:

501:

499:

492:

485:

483:

408:Franz Reuleaux

396:William Felton

374:

371:

319:

318:

311:

304:

302:

295:

288:

286:

279:

272:

270:

263:

256:

254:

247:

240:

238:

188:

185:

138:

135:

95:

92:

26:

24:

14:

13:

10:

9:

6:

4:

3:

2:

2376:

2365:

2362:

2360:

2357:

2355:

2352:

2351:

2349:

2334:

2326:

2324:

2320:

2316:

2315:

2312:

2306:

2303:

2301:

2298:

2296:

2293:

2291:

2290:Rostyle wheel

2288:

2286:

2283:

2281:

2278:

2276:

2273:

2271:

2268:

2266:

2263:

2262:

2260:

2257:

2256:Tires (Tyres)

2253:

2248:

2242:

2239:

2237:

2234:

2232:

2231:Parking brake

2229:

2227:

2226:Inboard brake

2224:

2222:

2219:

2217:

2214:

2212:

2209:

2207:

2204:

2202:

2199:

2197:

2194:

2192:

2189:

2187:

2184:

2182:

2179:

2177:

2174:

2172:

2169:

2167:

2164:

2162:

2159:

2157:

2154:

2152:

2149:

2147:

2144:

2143:

2141:

2139:

2135:

2129:

2126:

2124:

2121:

2119:

2116:

2114:

2111:

2109:

2106:

2104:

2101:

2099:

2096:

2094:

2091:

2090:

2088:

2086:

2082:

2076:

2073:

2071:

2068:

2066:

2063:

2061:

2060:Unsprung mass

2058:

2056:

2053:

2051:

2048:

2046:

2043:

2041:

2038:

2036:

2033:

2031:

2028:

2026:

2023:

2021:

2018:

2016:

2013:

2011:

2008:

2006:

2003:

2001:

1998:

1995:

1991:

1988:

1986:

1983:

1981:

1978:

1976:

1973:

1971:

1968:

1966:

1963:

1961:

1958:

1956:

1953:

1951:

1948:

1946:

1943:

1942:

1940:

1938:

1934:

1930:

1928:

1921:

1916:

1909:

1904:

1902:

1897:

1895:

1890:

1889:

1886:

1874:

1866:

1864:

1860:

1856:

1855:

1852:

1846:

1843:

1841:

1838:

1836:

1833:

1831:

1828:

1827:

1825:

1821:

1813:

1810:

1808:

1805:

1803:

1800:

1798:

1795:

1793:

1790:

1788:

1785:

1783:

1780:

1778:

1775:

1774:

1773:

1770:

1766:

1763:

1761:

1758:

1756:

1753:

1752:

1751:

1748:

1746:

1743:

1742:

1740:

1736:

1730:

1727:

1725:

1722:

1720:

1717:

1715:

1712:

1710:

1707:

1705:

1704:Shift-by-wire

1702:

1700:

1697:

1695:

1692:

1690:

1687:

1685:

1682:

1680:

1677:

1675:

1672:

1670:

1667:

1665:

1662:

1660:

1657:

1655:

1652:

1650:

1647:

1645:

1642:

1640:

1637:

1635:

1632:

1630:

1627:

1625:

1622:

1620:

1617:

1615:

1612:

1610:

1607:

1605:

1602:

1600:

1597:

1595:

1592:

1590:

1587:

1585:

1582:

1580:

1577:

1575:

1572:

1570:

1567:

1565:

1562:

1561:

1559:

1557:

1553:

1547:

1544:

1542:

1541:Petrol engine

1539:

1537:

1534:

1531:

1527:

1524:

1522:

1519:

1517:

1514:

1512:

1511:Diesel engine

1509:

1508:

1506:

1504:

1500:

1496:

1494:

1487:

1483:

1476:

1471:

1469:

1464:

1462:

1457:

1456:

1453:

1435:

1430:

1427:

1425:

1422:

1420:

1417:

1415:

1412:

1408:

1407:Chapman strut

1403:

1400:

1398:

1395:

1391:

1386:

1383:

1382:

1380:

1378:

1374:

1368:

1365:

1364:

1362:

1358:

1352:

1349:

1347:

1344:

1343:

1341:

1337:

1334:

1331:

1327:

1321:

1318:

1316:

1313:

1311:

1308:

1306:

1303:

1302:

1300:

1297:

1293:

1287:

1284:

1282:

1279:

1277:

1276:Unsprung mass

1274:

1272:

1269:

1267:

1264:

1262:

1259:

1257:

1254:

1252:

1249:

1247:

1244:

1242:

1241:Inboard brake

1239:

1237:

1234:

1232:

1229:

1227:

1224:

1222:

1219:

1217:

1214:

1212:

1209:

1208:

1206:

1202:

1193:

1188:

1186:

1181:

1179:

1174:

1173:

1170:

1163:

1147:

1141:

1138:

1125:

1119:

1116:

1103:

1097:

1094:

1081:

1077:

1073:

1066:

1063:

1058:

1054:

1050:

1046:

1039:

1036:

1023:

1022:

1014:

1011:

1007:

1003:

997:

993:

989:

983:

979:

975:

969:

966:

961:

957:

953:

949:

942:

939:

934:

928:

925:

920:

916:

910:

907:

902:

896:

892:

885:

882:

877:

876:

869:

867:

865:

863:

861:

859:

857:

855:

853:

851:

847:

834:

828:

826:

824:

820:

813:

808:

805:

803:

800:

798:

795:

793:

790:

788:

785:

783:

780:

778:

775:

773:

770:

769:

764:

762:

760:

752:

750:

748:

744:

736:

734:

732:

728:

724:

720:

716:

712:

708:

704:

696:

691:

685:

682:

678:

675:

671:

668:

664:

661:

660:

656:

649:

646:

643:

640:

637:

636:

635:

632:

627:

624:

621:

618:

616:rectification

615:

614:

613:

610:

605:

602:

599:

596:

595:

594:

591:

586:

583:

580:

577:

574:

571:

568:

566:taper rolling

565:

562:

561:

560:

557:

556:

555:

549:

547:

545:

544:1983 Corvette

541:

537:

533:

521:

516:

512:

505:

500:

496:

489:

484:

481:

479:

476:

472:

468:

467:trailing arms

464:

460:

456:

452:

448:

444:

440:

436:

432:

424:

420:

415:

411:

409:

403:

401:

397:

393:

389:

379:

372:

370:

368:

364:

363:Austin-Healey

360:

356:

352:

351:unsprung mass

346:

342:

340:

336:

332:

323:

308:

303:

292:

287:

276:

271:

266:Semi-elliptic

260:

255:

244:

239:

236:

234:

231:

229:

225:

221:

217:

212:

210:

206:

205:trailing arms

202:

193:

186:

184:

182:

178:

172:

170:

165:

161:

157:

153:

152:vehicle frame

143:

136:

134:

132:

128:

123:

121:

117:

113:

109:

100:

93:

91:

89:

84:

82:

78:

74:

70:

66:

62:

58:

55:

51:

47:

43:

34:

30:

19:

2270:Custom wheel

2241:Vacuum servo

2176:Brake lining

2098:Caster angle

2055:Trailing arm

2009:

1980:De Dion tube

1970:Car handling

1965:Camber angle

1925:Part of the

1924:

1782:Racing slick

1719:Transfer box

1689:Park-by-wire

1684:Parking pawl

1599:Differential

1574:Direct-drive

1556:Transmission

1546:Steam engine

1491:Part of the

1490:

1429:Trailing arm

1351:De Dion tube

1309:

1211:Car handling

1149:. Retrieved

1140:

1128:. Retrieved

1118:

1106:. Retrieved

1096:

1084:. Retrieved

1079:

1076:Transactions

1075:

1065:

1048:

1045:Transactions

1044:

1038:

1026:. Retrieved

1020:

1013:

977:

968:

954:(1): 17–30.

951:

947:

941:

927:

918:

909:

890:

884:

874:

837:. Retrieved

756:

743:coil springs

740:

700:

683:

676:

669:

662:

638:shot peening

633:

611:

592:

558:

553:

529:

447:coil springs

428:

404:

399:

384:

347:

343:

335:ride quality

328:

232:

220:Ford Model T

216:Austin Seven

213:

198:

173:

159:

149:

124:

112:spring steel

105:

85:

76:

72:

68:

64:

60:

41:

39:

29:

2305:Wire wheels

2275:Drive wheel

2265:Alloy wheel

2171:Brake fluid

2050:Torsion bar

2030:Panhard rod

2010:Leaf spring

1990:Hydrolastic

1975:Coil spring

1760:Alloy wheel

1619:Drive wheel

1609:Drive shaft

1569:Chain drive

1377:Independent

1261:Tire / Tyre

1236:Fishtailing

1204:Main topics

787:Coil spring

747:trampolines

719:Philippines

703:blacksmiths

471:Panhard rod

431:automobiles

359:Panhard rod

345:absorbers.

116:rectangular

77:cart spring

42:leaf spring

2348:Categories

2252:Roadwheels

2191:Drum brake

2186:Disc brake

2166:Brake fade

2128:Understeer

2040:Swing axle

1955:Axle track

1937:Suspension

1927:Automobile

1845:Alternator

1493:Automobile

1482:Powertrain

1424:Swing axle

1414:Multi-link

1390:Jaguar IRS

1367:Twist beam

1330:Suspension

1271:Understeer

1256:Suspension

1108:6 November

1086:13 October

1028:13 October

987:1879335700

900:1566371384

839:13 October

814:References

715:Bangladesh

692:Other uses

684:Tempering:

670:Cambering:

644:assembling

606:tempering.

443:suspension

419:locomotive

365:3000s and

355:Watts link

314:Transverse

50:suspension

2108:Oversteer

2075:Wheelbase

2045:Toe angle

2015:Live axle

1960:Beam axle

1714:Transaxle

1679:Manumatic

1649:Gearshift

1521:Fuel cell

1346:Beam axle

1339:Dependent

1315:Pneumatic

1266:Transaxle

1246:Oversteer

1221:Downforce

996:21753408M

976:(1996) .

647:scragging

603:quenching

600:cambering

475:live axle

421:built by

367:Fiat 128s

160:spoon end

61:laminated

2333:Category

2085:Steering

1994:Hydragas

1873:Category

1812:Tubeless

1797:Run-flat

1777:Off-road

1594:Coupling

1516:Electric

1397:Dubonnet

1251:Steering

1226:Drifting

1057:44579553

777:Carriage

765:See also

759:clutches

753:Clutches

745:in some

727:Pakistan

641:painting

569:trimming

563:thearing

250:Elliptic

88:stiction

57:vehicles

2295:Spinner

2103:Kingpin

1915:Chassis

1320:Torsion

723:Myanmar

625:reaming

622:bushing

581:nipping

542:of the

373:History

169:U-bolts

146:flexes.

54:wheeled

2323:Portal

2280:Hubcap

2138:Brakes

1929:series

1863:Portal

1823:Hybrid

1787:Radial

1765:Hubcap

1579:Clutch

1526:Hybrid

1495:series

1296:Spring

1151:4 July

1130:4 July

1055:

994:

984:

897:

731:kukris

513:, 1935

511:Humber

497:, 1928

469:and a

461:, and

455:trucks

357:(or a

75:, or

46:spring

1807:Spare

1750:Wheel

1654:Giubo

1332:types

1298:types

1053:JSTOR

772:Bogie

711:Nepal

707:India

495:Alvis

339:buses

187:Types

164:frame

114:of a

1950:Axle

1802:Snow

1792:Rain

1772:Tire

1310:Leaf

1305:Coil

1153:2013

1132:2013

1110:2011

1088:2022

1030:2022

982:ISBN

895:ISBN

841:2022

725:and

459:SUVs

453:and

451:vans

224:yoke

156:body

120:axle

1755:Rim

1080:XVI

956:doi

398:'s

154:or

108:arc

63:or

52:in

2350::

1078:.

1074:.

1047:.

1004:,

992:OL

990:.

952:39

950:.

917:.

849:^

822:^

721:,

717:,

713:,

709:,

457:,

369:.

171:.

71:,

40:A

1996:)

1992:(

1907:e

1900:t

1893:v

1532:)

1528:(

1474:e

1467:t

1460:v

1436:)

1432:(

1409:)

1405:(

1392:)

1388:(

1191:e

1184:t

1177:v

1155:.

1134:.

1112:.

1090:.

1059:.

1049:6

1032:.

1008:)

1000:(

998:.

962:.

958::

903:.

843:.

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.