72:, torque is applied to the input gear or ‘sun’ gear. A number of planet gears are arranged around and engaged with this sun gear, and therefore rotate. The outside casing of the multiplier is also engaged with the planet gear teeth, but is prevented from rotating by means of a reaction arm, causing the planet gears to orbit around the sun gear. The planet gears are held in a ‘planet carrier' which also holds the output drive shaft. As the planet gears orbit around the sun gear, the carrier and the output shaft rotate together. Without the reaction arm to prevent rotation of the outer casing, the output shaft cannot apply torque.

17:

61:". Extended handles use leverage instead of gear reduction to achieve torque. This torque is transmitted through the driving tool and could become dangerous in the case of a sudden catastrophic failure of the drive tool with the extended handle attached. Torque multipliers only have a fraction of the final torque pressure on the drive tool making them a safer choice.

96:

is unavailable due to remote locations without power, or where cost considerations require manually operated tools which do not require any power supply or power source of any kind. There are many instances where screws, bolts and other fasteners are secured so tightly that using a typical lug wrench

108:

A torque multiplier is generally used when there are space limitations that disallow the use of long handles. They are also used as a safer alternative to a cheater bar as lever length and operator effort are both reduced. Finally, torque multipliers allow for more accurate torque. By reducing the

75:

Along with the multiplication of torque, there is a decrease in rotational speed of the output shaft compared to the input shaft. This decrease in speed is inversely proportional to the increase in torque. For example, a torque multiplier with a rating of 3:1 will turn its output shaft with three

20:

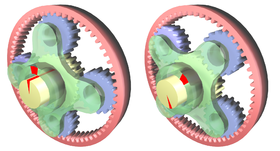

Epicyclic gearing can be used in a torque multiplier. The sun gear (yellow) is driven by an input torque. The planet gear carrier (green) provides the output torque, while the ring gear (red) is fixed. Note the red marks both before and after the input drive (yellow) is rotated 170°

105:, product assembly, construction projects, heavy equipment maintenance and other instances where high torque output is needed. A torque multiplier allows the user to generate high torque output without the use of an air compressor or impact gun.

109:

amount of effort needed to tighten, a torque multiplier allows for slow and smooth application, ensuring more accurate torque levels, and preventing damage to sensitive components.

484:

494:

187:

156:

459:

541:

49:

or other items designed to be actuated by application of torque, particularly where there are relatively high torque requirements.

265:

380:

499:

180:

225:

464:

454:

449:

325:

80:

and other inefficiencies in the mechanism, the output torque is slightly lower than the theoretical output.

489:

479:

469:

355:

509:

504:

430:

280:

173:

34:

474:

400:

315:

133:] of Norbar Torque Tools, and a popular product in the range is the Norbar Torque Multiplier."

146:", Maxpro Corp, 16 Dec 2015. "How does it work? Benefits and common uses for torque multipliers."

68:

gear train having one or more stages. Each stage of gearing multiplies the torque applied. In

531:

360:

285:

102:

69:

65:

425:

143:

126:

536:

410:

350:

89:

46:

16:

525:

405:

370:

305:

300:

230:

93:

345:

290:

255:

250:

76:

times the torque, but at one third the speed, of the input shaft. However, due to

435:

270:

240:

98:

58:

395:

375:

310:

196:

57:

Torque multipliers are often used instead of extended handles, often called "

420:

415:

390:

365:

335:

245:

212:

330:

295:

207:

77:

340:

320:

260:

235:

385:

129:", Worlifts, 8 March 2017. "Worlifts is a proud distributer [

38:

275:

42:

30:

169:

165:

101:is not sufficient to loosen them. These include

88:Torque multipliers are most often used when a

181:

8:

188:

174:

166:

15:

118:

64:Torque multipliers typically employ an

7:

14:

1:

144:What is a torque multiplier?

127:How torque multipliers work?

558:

444:

221:

203:

542:Mechanisms (engineering)

485:Machine and metalworking

495:Measuring and alignment

157:Handtorque™ multipliers

70:epicyclic gear systems

22:

356:Random orbital sander

19:

460:Cutting and abrasive

281:Electric motor brake

35:mechanical advantage

33:used to provide a

23:

519:

518:

361:Reciprocating saw

103:automotive repair

27:torque multiplier

549:

426:Thickness planer

190:

183:

176:

167:

160:

153:

147:

140:

134:

125:Andy Calloway, "

123:

557:

556:

552:

551:

550:

548:

547:

546:

522:

521:

520:

515:

514:

440:

336:Power miter saw

217:

199:

194:

164:

163:

154:

150:

141:

137:

124:

120:

115:

86:

55:

12:

11:

5:

555:

553:

545:

544:

539:

534:

524:

523:

517:

516:

513:

512:

507:

502:

497:

492:

487:

482:

477:

472:

467:

462:

457:

452:

450:Types of tools

446:

445:

442:

441:

439:

438:

433:

428:

423:

418:

413:

411:Soldering iron

408:

403:

398:

393:

388:

383:

378:

373:

368:

363:

358:

353:

351:Radial arm saw

348:

343:

338:

333:

328:

323:

318:

313:

308:

303:

298:

293:

288:

283:

278:

273:

268:

263:

258:

253:

248:

243:

238:

233:

228:

222:

219:

218:

216:

215:

210:

204:

201:

200:

195:

193:

192:

185:

178:

170:

162:

161:

148:

135:

117:

116:

114:

111:

90:compressed air

85:

82:

54:

51:

13:

10:

9:

6:

4:

3:

2:

554:

543:

540:

538:

535:

533:

530:

529:

527:

511:

508:

506:

503:

501:

498:

496:

493:

491:

488:

486:

483:

481:

478:

476:

473:

471:

468:

466:

463:

461:

458:

456:

453:

451:

448:

447:

443:

437:

434:

432:

429:

427:

424:

422:

419:

417:

414:

412:

409:

407:

406:Soldering gun

404:

402:

399:

397:

394:

392:

389:

387:

384:

382:

379:

377:

374:

372:

371:Rotary hammer

369:

367:

364:

362:

359:

357:

354:

352:

349:

347:

344:

342:

339:

337:

334:

332:

329:

327:

324:

322:

319:

317:

314:

312:

309:

307:

306:Impact wrench

304:

302:

301:Impact driver

299:

297:

294:

292:

289:

287:

284:

282:

279:

277:

274:

272:

269:

267:

266:Cutting torch

264:

262:

259:

257:

254:

252:

249:

247:

244:

242:

239:

237:

234:

232:

231:Angle grinder

229:

227:

224:

223:

220:

214:

211:

209:

206:

205:

202:

198:

191:

186:

184:

179:

177:

172:

171:

168:

158:

152:

149:

145:

139:

136:

132:

128:

122:

119:

112:

110:

106:

104:

100:

95:

94:impact wrench

91:

83:

81:

79:

73:

71:

67:

62:

60:

52:

50:

48:

44:

40:

36:

32:

28:

18:

381:Router table

346:Power trowel

291:Hammer drill

256:Concrete saw

251:Circular saw

151:

138:

130:

121:

107:

87:

84:Applications

74:

63:

59:cheater bars

56:

37:in applying

26:

24:

510:Woodworking

436:Wood shaper

431:Wood router

271:Die grinder

241:Belt sander

197:Power tools

99:cheater bar

53:Description

526:Categories

396:Scroll saw

376:Rotary saw

326:Multi-tool

311:Jackhammer

226:Air hammer

113:References

21:clockwise.

421:Table saw

416:Steam box

391:Screw gun

366:Rivet gun

246:Blowtorch

213:Workbench

155:Norbar, "

66:epicyclic

532:Wrenches

465:Forestry

455:Cleaning

331:Nail gun

296:Heat gun

286:Glue gun

208:Sawhorse

159:" (PDF).

92:powered

78:friction

41:to turn

490:Masonry

480:Kitchen

341:Nibbler

321:Jointer

261:Crusher

236:Bandsaw

97:with a

500:Mining

470:Garden

386:Sander

316:Jigsaw

39:torque

537:Gears

505:Power

401:Shear

276:Drill

43:bolts

29:is a

475:Hand

47:nuts

31:tool

131:sic

528::

45:,

25:A

189:e

182:t

175:v

142:"

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.