118:

127:

106:

98:

33:

650:

When doing the hardness tests, the minimum distance between indentations and the distance from the indentation to the edge of the specimen must be taken into account to avoid interaction between the work-hardened regions and effects of the edge. These minimum distances are different for ISO 6507-1

161:

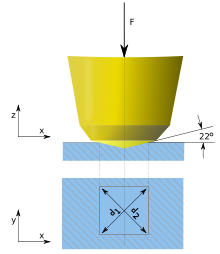

to the horizontal plane normal of 22° on each side. The angle was varied experimentally and it was found that the hardness value obtained on a homogeneous piece of material remained constant, irrespective of load. Accordingly, loads of various magnitudes are applied to a flat surface, depending on

56:

of materials. The

Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of hardness. The basic principle, as with all common measures of hardness, is to

522:

is in millimeters. A common error is that the above formula to calculate the HV number does not result in a number with the unit newton per square millimeter (N/mm), but results directly in the

Vickers hardness number (usually given without units), which is in fact one

1159:

843:

709:

Vickers values are generally independent of the test force: they will come out the same for 500 gf and 50 kgf, as long as the force is at least 200 gf. However, lower load indents often display a dependence of hardness on indent depth known as the

134:

It was decided that the indenter shape should be capable of producing geometrically similar impressions, irrespective of size; the impression should have well-defined points of measurement; and the indenter should have high resistance to self-deformation. A

1216:

the pins were later found to have been replaced with sub-standard parts, leading to rapid wear and finally loss of the aircraft. On examination, accident investigators found that the sub-standard pins had a hardness value of only some 200–230HV5.

955:

1083:, and ideally can be directly compared with other hardness tests also defined using projected area. Care must be used when comparing other hardness tests due to various size scale factors which can impact the measured hardness.

1075:

1187:

is a constant determined by yield strength, Poisson's ratio, work-hardening exponent and geometrical factors – usually ranging between 2 and 4. In other words, if HV is expressed in N/mm (i.e. in MPa) then the

397:

121:

An indentation left in case-hardened steel after a

Vickers hardness test. The difference in length of both diagonals and the illumination gradient, are both classic indications of an out-of-level sample. This is not a good

509:

717:

For thin samples indentation depth can be an issue due to substrate effects. As a rule of thumb the sample thickness should be kept greater than 2.5 times the indent diameter. Alternatively indent depth,

254:

1088:

303:

744:

89:, which uses the same units. The hardness number is determined by the load over the surface area of the indentation and not the area normal to the force, and is therefore not pressure.

1289:

893:

986:

886:

1525:

736:

1287:

R.L. Smith & G.E. Sandland, "An

Accurate Method of Determining the Hardness of Metals, with Particular Reference to Those of a High Degree of Hardness,"

993:

426:

in mm, giving HV in the SI unit of MPa. To calculate

Vickers hardness number (VHN) using SI units one needs to convert the force applied from newtons to

318:

157:/8 long intersect at 136°, it was decided to use this as the included angle between plane faces of the indenter tip. This gives an angle from each face

959:

Vickers hardness can also be converted to an SI hardness based on the projected area of the indent rather than the surface area. The projected area,

1344:

1560:

440:

1208:

airliner were specified by the aircraft manufacturer to be hardened to a

Vickers Hardness specification of 390HV5, the '5' meaning five

1423:

184:

1447:

418:

The corresponding unit of HV is then the kilogram-force per square millimeter (kgf/mm) or HV number. In the above equation,

1154:{\displaystyle {\text{projected area hardness (GPa)}}={\frac {g_{0}}{1000}}{\frac {2}{1.854}}HV\approx {\frac {HV}{94.5}}}

838:{\displaystyle t={\frac {d_{\rm {avg}}}{2{\sqrt {2}}\tan {\frac {\theta }{2}}}}\approx {\frac {d_{\rm {avg}}}{7.0006}},}

265:

139:

in the form of a square-based pyramid satisfied these conditions. It had been established that the ideal size of a

1232:

1531:

ISO 6507-2: Metallic materials – Vickers hardness test – Part 2: Verification and calibration of testing machines

117:

65:

and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the

1492:

Report on the

Convair 340/580 LN-PAA aircraft accident North of Hirtshals, Denmark on September 8, 1989 | aibn

1576:

711:

126:

1341:

1205:

140:

950:{\displaystyle {\text{surface area hardness (GPa)}}={\frac {g_{0}}{1000}}HV={\frac {9.80665}{1000}}HV}

1519:

E92: Standard method for

Vickers hardness of metallic materials (withdrawn and replaced by E384-10e2)

1378:

1227:

1192:(in MPa) ≈ HV/3. This empirical law depends variably on the work-hardening behavior of the material.

1247:

1242:

1237:

1213:

1201:

1080:

58:

1267:

962:

1534:

ISO 6507-3: Metallic materials – Vickers hardness test – Part 3: Calibration of reference blocks

888:, to get the hardness in MPa (N/mm) and furthermore divided by 1000 to get the hardness in GPa.

1429:

1419:

1396:

158:

1474:

1386:

1189:

1169:

858:

431:

864:

162:

the hardness of the material to be measured. The HV number is then determined by the ratio

1537:

ISO 6507-4: Metallic materials – Vickers hardness test – Part 4: Tables of hardness values

1348:

854:

594:

1367:"Indentation size effects in crystalline materials: A law for strain gradient plasticity"

1168:

If HV is first expressed in N/mm (MPa), or otherwise by converting from kgf/mm, then the

1382:

1257:

1209:

721:

524:

427:

408:

1555:

1391:

1366:

105:

17:

1570:

82:

49:

1070:{\displaystyle A_{\rm {p}}={\frac {d_{\rm {avg}}^{2}}{2}}={\frac {1.854}{2}}{A_{s}}}

1262:

714:(ISE). Small indent sizes will also have microstructure-dependent hardness values.

604:

1491:

1465:

Zhang, P. (September 2011). "General relationship between strength and hardness".

542:

if duration of force differs from 10 s to 15 s, e.g. 440HV30/20, where:

392:{\displaystyle \mathrm {HV} ={\frac {F}{A}}\approx {\frac {1.8544F}{d^{2}}}\quad }

312:

is the average length of the diagonal left by the indenter in millimeters. Hence,

45:

1478:

1550:

1252:

624:

1433:

1400:

153:

of the ball diameter. As two tangents to the circle at the ends of a chord 3

97:

32:

1522:

ASTM E384: Standard Test Method for Knoop and

Vickers Hardness of Materials

1302:

853:

To convert the

Vickers hardness number to SI units the hardness number in

178:

is the surface area of the resulting indentation in square millimeters.

86:

53:

1528:

6507-1: Metallic materials – Vickers hardness test – Part 1: Test method

663:

Distance from the center of the indentation to the edge of the specimen

1352:

634:

136:

110:

504:{\displaystyle \mathrm {HV} \approx {0.1891}{\frac {F}{d^{2}}}\quad ,}

567:

indicates the loading time if it differs from 10 s to 15 s

1079:

This hardness is sometimes referred to as the mean contact area or

44:

was developed in 1921 by Robert L. Smith and George E. Sandland at

125:

116:

104:

96:

62:

31:

1516:

614:

988:, is defined as the following for a Vickers indenter geometry:

259:

which can be approximated by evaluating the sine term to give,

61:

from a standard source. The Vickers test can be used for all

1540:

ISO 18265: Metallic materials – Conversion of Hardness Values

857:

per square millimeter (kgf/mm) has to be multiplied with the

174:

is the force applied to the diamond in kilograms-force and

686:

for steel and copper alloys and > 3·d for light metals

249:{\displaystyle A={\frac {d^{2}}{2\sin(136^{\circ }/2)}},}

1418:(2nd ed.). New York: Springer. pp. 212–213.

1290:

Proceedings of the Institution of Mechanical Engineers

81:). The hardness number can be converted into units of

1091:

996:

965:

896:

867:

747:

724:

443:

321:

268:

187:

1332:

Smithells Metals Reference Book, 8th Edition, ch. 22

1153:

1069:

980:

949:

880:

837:

730:

503:

391:

297:

248:

298:{\displaystyle A\approx {\frac {d^{2}}{1.8544}},}

1305:. UKcalibrations.co.uk. Retrieved on 2016-06-03.

1172:(in MPa) of the material can be approximated as

1371:Journal of the Mechanics and Physics of Solids

1365:Nix, William D.; Gao, Huajian (1 March 1998).

8:

572:Examples of HV values for various materials

1508:Meyers and Chawla (1999). "Section 3.8".

1390:

1136:

1117:

1106:

1100:

1092:

1090:

1060:

1055:

1045:

1031:

1019:

1018:

1012:

1002:

1001:

995:

971:

970:

964:

931:

911:

905:

897:

895:

872:

866:

814:

813:

807:

791:

778:

761:

760:

754:

746:

723:

530:Vickers hardness numbers are reported as

489:

483:

482:

469:

460:

455:

444:

442:

434:). This leads to the following equation:

380:

374:

373:

360:

346:

333:

322:

320:

281:

275:

267:

229:

223:

200:

194:

186:

653:

570:

1563:– Vickers, Brinell, and Rockwell scales

1280:

675:for steel and copper alloys and > 6·

527:per square millimeter (1 kgf/mm).

57:observe a material's ability to resist

113:indenter of a Vickers hardness tester

7:

1303:The Vickers Hardness Testing Machine

1494:. Aibn.no. Retrieved on 2016-06-03.

1467:Materials Science and Engineering A

1414:Fischer-Cripps, Anthony C. (2007).

1204:attachment pins and sleeves in the

555:names the hardness scale (Vickers),

1551:Video on the Vickers hardness test

1263:Vickers toughness test of ceramics

1212:. However, on the aircraft flying

1026:

1023:

1020:

1003:

972:

821:

818:

815:

768:

765:

762:

738:, can be calculated according to:

448:

445:

326:

323:

85:, but should not be confused with

25:

1416:Introduction to contact mechanics

1510:Mechanical Behavior of Materials

561:indicates the load used in kgf.

477:

368:

495:

478:

386:

369:

237:

216:

1:

1392:10.1016/S0022-5096(97)00086-0

1094:projected area hardness (GPa)

660:Distance between indentations

1164:Estimating tensile strength

981:{\displaystyle A_{\rm {p}}}

899:surface area hardness (GPa)

130:This is a good indentation.

1593:

1479:10.1016/j.msea.2011.08.061

1293:, Vol. I, 1922, p 623–641.

1233:Leeb Rebound Hardness Test

651:and ASTM E384 standards.

430:by dividing by 9.806 65 (

48:as an alternative to the

36:A Vickers hardness tester

75:Diamond Pyramid Hardness

1347:21 October 2014 at the

712:indentation size effect

549:is the hardness number,

1155:

1071:

982:

951:

882:

849:Conversion to SI units

839:

732:

505:

393:

299:

250:

131:

123:

114:

102:

67:Vickers Pyramid Number

52:method to measure the

37:

18:Vickers hardness scale

1556:Vickers hardness test

1512:. Prentice Hall, Inc.

1156:

1072:

983:

952:

883:

881:{\displaystyle g_{0}}

840:

733:

506:

394:

300:

251:

129:

120:

108:

100:

42:Vickers hardness test

35:

1228:Indentation hardness

1089:

994:

963:

894:

865:

745:

722:

585:316L stainless steel

441:

319:

266:

185:

1383:1998JMPSo..46..411N

1248:Meyer hardness test

1243:Knoop hardness test

1238:Hardness comparison

1214:Partnair Flight 394

1036:

573:

415:is in millimeters.

101:Vickers test scheme

59:plastic deformation

1323:ISO 6507-1:2005(E)

1268:Superhard material

1151:

1067:

1014:

978:

947:

878:

835:

728:

571:

501:

422:could be in N and

389:

295:

246:

132:

124:

115:

103:

38:

1149:

1125:

1115:

1095:

1053:

1040:

939:

920:

900:

830:

802:

799:

783:

731:{\displaystyle t}

707:

706:

643:

642:

486:

475:

377:

366:

341:

290:

241:

16:(Redirected from

1584:

1561:Conversion table

1513:

1495:

1489:

1483:

1482:

1462:

1456:

1455:

1444:

1438:

1437:

1411:

1405:

1404:

1394:

1362:

1356:

1339:

1333:

1330:

1324:

1321:

1315:

1312:

1306:

1300:

1294:

1285:

1190:tensile strength

1186:

1182:

1178:

1170:tensile strength

1160:

1158:

1157:

1152:

1150:

1145:

1137:

1126:

1118:

1116:

1111:

1110:

1101:

1096:

1093:

1076:

1074:

1073:

1068:

1066:

1065:

1064:

1054:

1046:

1041:

1035:

1030:

1029:

1013:

1008:

1007:

1006:

987:

985:

984:

979:

977:

976:

975:

956:

954:

953:

948:

940:

932:

921:

916:

915:

906:

901:

898:

887:

885:

884:

879:

877:

876:

859:standard gravity

844:

842:

841:

836:

831:

826:

825:

824:

808:

803:

801:

800:

792:

784:

779:

773:

772:

771:

755:

737:

735:

734:

729:

679:for light metals

654:

574:

510:

508:

507:

502:

494:

493:

488:

487:

484:

476:

474:

473:

461:

459:

451:

432:standard gravity

398:

396:

395:

390:

385:

384:

379:

378:

375:

367:

365:

364:

355:

347:

342:

334:

329:

304:

302:

301:

296:

291:

286:

285:

276:

255:

253:

252:

247:

242:

240:

233:

228:

227:

205:

204:

195:

152:

151:

147:

21:

1592:

1591:

1587:

1586:

1585:

1583:

1582:

1581:

1567:

1566:

1547:

1507:

1504:

1502:Further reading

1499:

1498:

1490:

1486:

1464:

1463:

1459:

1446:

1445:

1441:

1426:

1413:

1412:

1408:

1364:

1363:

1359:

1349:Wayback Machine

1340:

1336:

1331:

1327:

1322:

1318:

1313:

1309:

1301:

1297:

1286:

1282:

1277:

1272:

1223:

1198:

1184:

1180:

1177:

1173:

1166:

1138:

1102:

1087:

1086:

1056:

997:

992:

991:

966:

961:

960:

907:

892:

891:

868:

863:

862:

855:kilograms-force

851:

809:

774:

756:

743:

742:

720:

719:

648:

595:stainless steel

481:

465:

439:

438:

372:

356:

348:

317:

316:

277:

264:

263:

219:

206:

196:

183:

182:

149:

145:

144:

143:impression was

95:

28:

23:

22:

15:

12:

11:

5:

1590:

1588:

1580:

1579:

1577:Hardness tests

1569:

1568:

1565:

1564:

1558:

1553:

1546:

1545:External links

1543:

1542:

1541:

1538:

1535:

1532:

1529:

1523:

1520:

1514:

1503:

1500:

1497:

1496:

1484:

1457:

1439:

1424:

1406:

1377:(3): 411–425.

1357:

1334:

1325:

1316:

1314:ASTM E384-10e2

1307:

1295:

1279:

1278:

1276:

1273:

1271:

1270:

1265:

1260:

1258:Rockwell scale

1255:

1250:

1245:

1240:

1235:

1230:

1224:

1222:

1219:

1197:

1194:

1175:

1165:

1162:

1148:

1144:

1141:

1135:

1132:

1129:

1124:

1121:

1114:

1109:

1105:

1099:

1081:Meyer hardness

1063:

1059:

1052:

1049:

1044:

1039:

1034:

1028:

1025:

1022:

1017:

1011:

1005:

1000:

974:

969:

946:

943:

938:

935:

930:

927:

924:

919:

914:

910:

904:

875:

871:

850:

847:

846:

845:

834:

829:

823:

820:

817:

812:

806:

798:

795:

790:

787:

782:

777:

770:

767:

764:

759:

753:

750:

727:

705:

704:

698:

692:

688:

687:

680:

669:

665:

664:

661:

658:

647:

644:

641:

640:

637:

631:

630:

627:

621:

620:

617:

611:

610:

607:

601:

600:

597:

590:

589:

586:

582:

581:

578:

569:

568:

562:

556:

550:

525:kilogram-force

512:

511:

500:

497:

492:

480:

472:

468:

464:

458:

454:

450:

447:

428:kilogram-force

401:

400:

388:

383:

371:

363:

359:

354:

351:

345:

340:

337:

332:

328:

325:

306:

305:

294:

289:

284:

280:

274:

271:

257:

256:

245:

239:

236:

232:

226:

222:

218:

215:

212:

209:

203:

199:

193:

190:

109:The pyramidal

94:

93:Implementation

91:

26:

24:

14:

13:

10:

9:

6:

4:

3:

2:

1589:

1578:

1575:

1574:

1572:

1562:

1559:

1557:

1554:

1552:

1549:

1548:

1544:

1539:

1536:

1533:

1530:

1527:

1524:

1521:

1518:

1515:

1511:

1506:

1505:

1501:

1493:

1488:

1485:

1480:

1476:

1472:

1468:

1461:

1458:

1453:

1452:matter.org.uk

1449:

1443:

1440:

1435:

1431:

1427:

1425:9780387681887

1421:

1417:

1410:

1407:

1402:

1398:

1393:

1388:

1384:

1380:

1376:

1372:

1368:

1361:

1358:

1354:

1350:

1346:

1343:

1338:

1335:

1329:

1326:

1320:

1317:

1311:

1308:

1304:

1299:

1296:

1292:

1291:

1284:

1281:

1274:

1269:

1266:

1264:

1261:

1259:

1256:

1254:

1251:

1249:

1246:

1244:

1241:

1239:

1236:

1234:

1231:

1229:

1226:

1225:

1220:

1218:

1215:

1211:

1207:

1203:

1195:

1193:

1191:

1171:

1163:

1161:

1146:

1142:

1139:

1133:

1130:

1127:

1122:

1119:

1112:

1107:

1103:

1097:

1084:

1082:

1077:

1061:

1057:

1050:

1047:

1042:

1037:

1032:

1015:

1009:

998:

989:

967:

957:

944:

941:

936:

933:

928:

925:

922:

917:

912:

908:

902:

889:

873:

869:

860:

856:

848:

832:

827:

810:

804:

796:

793:

788:

785:

780:

775:

757:

751:

748:

741:

740:

739:

725:

715:

713:

703:

699:

697:

693:

690:

689:

685:

681:

678:

674:

670:

667:

666:

662:

659:

656:

655:

652:

645:

638:

636:

633:

632:

628:

626:

623:

622:

618:

616:

613:

612:

608:

606:

603:

602:

598:

596:

592:

591:

587:

584:

583:

579:

576:

575:

566:

563:

560:

557:

554:

551:

548:

545:

544:

543:

541:

537:

533:

528:

526:

521:

517:

498:

490:

470:

466:

462:

456:

452:

437:

436:

435:

433:

429:

425:

421:

416:

414:

410:

406:

381:

361:

357:

352:

349:

343:

338:

335:

330:

315:

314:

313:

311:

292:

287:

282:

278:

272:

269:

262:

261:

260:

243:

234:

230:

224:

220:

213:

210:

207:

201:

197:

191:

188:

181:

180:

179:

177:

173:

169:

165:

160:

156:

142:

138:

128:

119:

112:

107:

99:

92:

90:

88:

84:

80:

76:

72:

68:

64:

60:

55:

51:

47:

43:

34:

30:

27:Hardness test

19:

1509:

1487:

1470:

1466:

1460:

1451:

1442:

1415:

1409:

1374:

1370:

1360:

1342:Vickers Test

1337:

1328:

1319:

1310:

1298:

1288:

1283:

1199:

1167:

1085:

1078:

990:

958:

890:

852:

716:

708:

701:

695:

683:

676:

672:

649:

605:Carbon steel

564:

558:

552:

546:

539:

535:

531:

529:

519:

518:is in N and

515:

513:

423:

419:

417:

412:

404:

402:

309:

307:

258:

175:

171:

167:

163:

154:

133:

122:indentation.

78:

74:

70:

66:

41:

39:

29:

1206:Convair 580

1196:Application

646:Precautions

46:Vickers Ltd

1448:"Hardness"

1275:References

1253:Mohs scale

668:ISO 6507-1

625:Martensite

609:55–120HV5

540:xxxHVyy/zz

1434:187014877

1401:0022-5096

1210:kiloponds

1134:≈

805:≈

794:θ

789:

691:ASTM E384

619:30–80HV5

453:≈

344:≈

273:≈

225:∘

214:

1571:Category

1355:website.

1345:Archived

1221:See also

1183:, where

657:Standard

639:10000HV

599:180HV30

588:140HV30

577:Material

170:, where

87:pressure

54:hardness

1379:Bibcode

1353:Instron

934:9.80665

671:> 3·

635:Diamond

629:1000HV

536:440HV30

534:, e.g.

532:xxxHVyy

148:⁄

141:Brinell

137:diamond

111:diamond

83:pascals

50:Brinell

1473:: 62.

1432:

1422:

1399:

828:7.0006

580:Value

514:where

457:0.1891

407:is in

403:where

376:kgf/mm

350:1.8544

308:where

288:1.8544

159:normal

63:metals

1179:≈ HV/

1123:1.854

1048:1.854

593:347L

538:, or

73:) or

1517:ASTM

1430:OCLC

1420:ISBN

1397:ISSN

1200:The

1147:94.5

1113:1000

937:1000

918:1000

700:2.5·

694:2.5·

682:2.5·

615:Iron

485:N/mm

411:and

40:The

1526:ISO

1475:doi

1471:529

1387:doi

1202:fin

786:tan

547:440

409:kgf

221:136

211:sin

79:DPH

1573::

1469:.

1450:.

1428:.

1395:.

1385:.

1375:46

1373:.

1369:.

1351:.

861:,

565:20

559:30

553:HV

71:HV

1481:.

1477::

1454:.

1436:.

1403:.

1389::

1381::

1185:c

1181:c

1176:u

1174:σ

1143:V

1140:H

1131:V

1128:H

1120:2

1108:0

1104:g

1098:=

1062:s

1058:A

1051:2

1043:=

1038:2

1033:2

1027:g

1024:v

1021:a

1016:d

1010:=

1004:p

999:A

973:p

968:A

945:V

942:H

929:=

926:V

923:H

913:0

909:g

903:=

874:0

870:g

833:,

822:g

819:v

816:a

811:d

797:2

781:2

776:2

769:g

766:v

763:a

758:d

752:=

749:t

726:t

702:d

696:d

684:d

677:d

673:d

520:d

516:F

499:,

496:]

491:2

479:[

471:2

467:d

463:F

449:V

446:H

424:d

420:F

413:d

405:F

399:,

387:]

382:2

370:[

362:2

358:d

353:F

339:A

336:F

331:=

327:V

324:H

310:d

293:,

283:2

279:d

270:A

244:,

238:)

235:2

231:/

217:(

208:2

202:2

198:d

192:=

189:A

176:A

172:F

168:A

166:/

164:F

155:d

150:8

146:3

77:(

69:(

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.