399:. In the middle of a terminal strip of a breadboard, one typically finds a notch running in parallel to the long side. The notch is to mark the centerline of the terminal strip and provides limited airflow (cooling) to DIP ICs straddling the centerline. The clips on the right and left of the notch are each connected in a radial way; typically five clips (i.e., beneath five holes) in a row on each side of the notch are electrically connected. The five columns on the left of the notch are often marked as A, B, C, D, and E, while the ones on the right are marked F, G, H, I and J. When a "skinny" dual in-line pin package (DIP) integrated circuit (such as a typical DIP-14 or DIP-16, which have a 0.3-inch (7.6 mm) separation between the pin rows) is plugged into a breadboard, the pins of one side of the chip are supposed to go into column E while the pins of the other side go into column F on the other side of the notch. The rows are identified by numbers from 1 to as many the breadboard design goes. A full-size terminal breadboard strip typically consists of around 56 to 65 rows of connectors. Together with bus strips on each side this makes up a typical 784 to 910 tie point solderless breadboard. Most breadboards are designed to accommodate 17, 30 or 64 rows in the mini, half, and full configurations respectively.

605:

380:

117:

431:

736:

441:(also called jumper wires) for solderless breadboarding can be obtained in ready-to-use jump wire sets or can be manually manufactured. The latter can become tedious work for larger circuits. Ready-to-use jump wires come in different qualities, some even with tiny plugs attached to the wire ends. Jump wire material for ready-made or homemade wires should usually be 22

46:

32:

588:

assembly methodology to exploit full-speed operation. A single small SoC often provides most of these electrical interface options in a form factor barely larger than a large postage stamp, available in the

American hobby market (and elsewhere) for a few dollars, allowing fairly sophisticated breadboard projects to be created at modest expense.

660:

prototype systems with thousands of connecting points, but great care must be taken in careful assembly, and such a system becomes unreliable as contact resistance develops over time. At some point, very complex systems must be implemented in a more reliable interconnection technology, to have a likelihood of working over a usable time period.

310:

597:

411:(inductively coupled noise) on the power supply bus. Often the groups in a bus strip are indicated by gaps in the color marking. Bus strips typically run down one or both sides of a terminal strip or between terminal strips. On large breadboards additional bus strips can often be found on the top and bottom of terminal strips.

480:

discipline are often adhered to for consistency. However, the number of available colors is typically far fewer than the number of signal types or paths. Typically, a few wire colors are reserved for the supply voltages and ground (e.g., red, blue, black), some are reserved for main signals, and the

406:

are used. A bus strip usually contains two columns: one for ground and one for a supply voltage. However, some breadboards only provide a single-column power distribution bus strip on each long side. Typically the row intended for a supply voltage is marked in red, while the row for ground is marked

387:

Solderless breadboards connect pin to pin by metal strips inside the breadboard. The layout of a typical solderless breadboard is made up from two types of areas, called strips. Strips consist of interconnected electrical terminals. Often breadboard strips or blocks of one brand have male and female

139:

Breadboards have evolved over time with the term now being used for all kinds of prototype electronic devices. For example, US Patent 3,145,483, was filed in 1961 and describes a wooden plate breadboard with mounted springs and other facilities. US Patent 3,496,419, was filed in 1967 and refers to

659:

Very complex circuits can become unmanageable on a solderless breadboard due to the large amount of wiring required. The very convenience of easy plugging and unplugging of connections also makes it too easy to accidentally disturb a connection, and the system becomes unreliable. It is possible to

655:

or dual in-line layout, for insertion into a solderless breadboard. Larger components are usually plugged into a socket on the adapter, while smaller components (e.g., SMD resistors) are usually soldered directly onto the adapter. The adapter is then plugged into the breadboard via the 0.1 in

587:

is then developed for the MCU to test, debug, and interact with the circuit prototype. High frequency operation is then largely confined to the SoC's PCB. In the case of high speed interconnects such as SPI and I²C, these can be debugged at a lower speed and later rewired using a different circuit

415:

516:

For high-frequency development, a metal breadboard affords a desirable solderable ground plane, often an unetched piece of printed circuit board; integrated circuits are sometimes stuck upside down to the breadboard and soldered to directly, a technique sometimes called

715:

designs are a more extreme version of the same process: since producing prototype silicon is costly, extensive software simulations are performed before fabricating the first prototypes. However, prototyping techniques are still used for some applications such as

723:

It is also possible to use a square grid of pairs of holes where one hole per pair connects to its row and the other connects to its column. This same shape can be in a circle with rows and columns each spiraling opposite clockwise/counterclockwise.

636:, depending on the nature of the circuit. The relatively high contact resistance can already be a problem for some DC and very low frequency circuits. Solderless breadboards are further limited by their voltage and current ratings.

465: in (4.8 to 7.9 mm). Shorter stripped wires might result in bad contact with the board's spring clips (insulation being caught in the springs). Longer stripped wires increase the likelihood of short-circuits on the board.

407:

in blue or black. Some manufacturers connect all terminals in a column. Others just connect groups of, for example, 25 consecutive terminals in a column. The latter design provides a circuit designer with some more control over

159:

patented a solderless breadboard connecting rows of holes together with spring metal. In 1971, Ronald

Portugal of E&L Instruments patented a similar concept with holes in 0.1 inches (2.54 mm) spacings, the same as

496:

Some manufacturers provide high-end versions of solderless breadboards. These are typically high-quality breadboard modules mounted on a flat casing. The casing contains additional equipment for breadboarding, such as a

108:, relatively high resistance, and less reliable connections, which are subject to jostle and physical degradation. Signaling is limited to about 10 MHz, and not everything works properly even well below that frequency.

359:) can be inserted into the remaining free holes to complete the circuit. Where ICs are not used, discrete components and connecting wires may use any of the holes. Typically the spring clips are rated for 1

643:

devices (SMD) or components with grid spacing other than 0.1 inches (2.54 mm). Further, they cannot accommodate components with multiple rows of connectors if these connectors do not match the

651:

adapters called "breakout adapters" can be used to fit the component to the board. Such adapters carry one or more components and have 0.1 inches (2.54 mm) spaced male connector pins in a

1095:

Dead-bug breadboards with ground plane, and other prototyping techniques, illustrated in

Figures F1 to F24, from p. AN47-98. There is information on breadboarding on pp. AN47-26 to AN47-29.

481:

rest are simply used where convenient. Some ready-to-use jump wire sets use the color to indicate the length of the wires, but these sets do not allow a meaningful color-coding schema.

521:" construction because of its appearance. Examples of dead bug with ground plane construction are illustrated in a Linear Technologies application note.

656:(2.54 mm) connectors. However, the need to solder the components onto the adapter negates some of the advantage of using a solderless breadboard.

545:(IO) pins in a header suitable to plug into a breadboard, and then to prototype a circuit which exploits one or more of the MCU's peripherals, such as

132:

was first glued to the board as a guide to placing terminals, then components and wires were installed over their symbols on the schematic. Using

489:

In a more robust variant, one or more breadboard strips are mounted on a sheet of metal. Typically, that backing sheet also holds a number of

94:

or destruction of tracks and are hence reusable. For this reason, breadboards are also popular with students and in technological education.

445:(0.33 mm) solid copper, tin-plated wire - assuming no tiny plugs are to be attached to the wire ends. The wire ends should be stripped

1160:

1135:

422:

Some manufacturers provide separate bus and terminal strips. Others just provide breadboard blocks which contain both in one block.

347:(DIPs) can be inserted to straddle the centerline of the block. Interconnecting wires and the leads of discrete components (such as

493:. These posts provide a clean way to connect an external power supply. This type of breadboard may be slightly easier to handle.

1165:

1155:

124:

In the early days of radio, amateurs nailed bare copper wires or terminal strips to a wooden board (often literally a bread

97:

A variety of electronic systems may be prototyped by using breadboards, from small analog and digital circuits to complete

704:

796:

1110:

546:

669:

574:

562:

558:

518:

20:

692:, do not lend themselves to prototyping using breadboards, as their complex designs can be difficult to lay out and

1150:

1061:

236:

156:

847: : "Device for facilitating construction of electrical apparatus", filed 7 Jul 1960, retrieved 14 Jan 2017.

640:

98:

632:, solderless breadboards are limited to operation at relatively low frequencies, usually less than 10

652:

609:

566:

37:

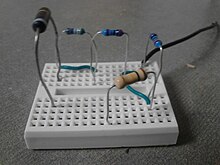

400 point solderless breadboard with 0.1 inches (2.54 mm) hole-to-hole spacing, top and bottom views

708:

648:

629:

621:

538:

141:

105:

52:

680:, and boards like the stripboard. Complicated systems, such as modern computers comprising millions of

164:

IC packages, which became the basis of the modern solderless breadboard that is commonly used today.

886: : "Primary electrical training test board apparatus", filed 10 Apr 1943, retrieved 14 July 2017.

644:

613:

344:

161:

75:

442:

946: : "Mounting assemblage for electrical circuits", filed 14 Nov 1958, retrieved 14 July 2017.

934: : "Quick attaching and detaching circuit system", filed 8 Sep 1958, retrieved 14 July 2017.

741:

712:

466:

340:

79:

910: : "Board for demonstrating electric circuits", filed 10 Apr 1945, retrieved 14 July 2017.

862:: "Breadboard for electronic components or the like", filed 1 Dec 1971, retrieved 14 July 2017.

604:

379:

1077:

700:

647:

layout—it is impossible to provide the correct electrical connectivity. Sometimes small

624:

compared to a properly laid out PCB (approx 2 pF between adjacent contact columns), high

317:

A modern solderless breadboard socket consists of a perforated block of plastic with numerous

129:

769:

759:

570:

530:

506:

502:

268:

116:

1065:

800:

764:

717:

534:

321:

211:

16:

Board with embedded spring clips that allows for electronics to be wired without soldering

817: : "Test board for electronic circuits", filed 4 May 1961, retrieved 14 July 2017.

389:

1144:

774:

677:

325:

125:

1026:

414:

104:

Compared to more permanent circuit connection methods, modern breadboards have high

542:

498:

490:

339:

The spacing between the clips (lead pitch) is typically 0.1 inches (2.54 mm).

895:

859:

430:

336:. The number of tie points is often given in the specification of the breadboard.

832: : "Printed circuit breadboard", filed 25 Apr 1967, retrieved 14 July 2017.

510:

1038:

1003:

991:

979:

967:

955:

943:

931:

919:

907:

883:

844:

829:

814:

735:

1106:

970: : "Electrical experiment kit", filed 5 Nov 1964, retrieved 14 July 2017.

871:

793:

749:

731:

681:

625:

477:

473:

are helpful when inserting or removing wires, particularly on crowded boards.

87:

1006:: "Miniature tandem spring clips", filed 23 Jun 1971, retrieved 14 Jan 2017.

720:

circuits, or where software models of components are inexact or incomplete.

673:

633:

628:

of some connections and a relatively high and not very reproducible contact

438:

408:

348:

149:

133:

91:

83:

958: : "Circuit assembly board", filed 21 Nov 1960, retrieved 14 Jan 2017.

922:: "Modular circuit fabrication", filed 4 Apr 1955, retrieved 14 July 2017.

45:

994:: "Educational training aids", filed 11 Oct 1968, retrieved 14 July 2017.

754:

689:

584:

470:

356:

352:

898:"Electrical instruction board", filed 4 Oct 1944, retrieved 23 Oct 2022.

1136:

Large parallel processing design prototyped on 50 connected breadboards

1058:

318:

31:

874:"Electrical switch board", filed 31 Aug 1880, retrieved 4 August 2019.

395:

The main areas, to hold most of the electronic components, are called

392:

notches so boards can be clipped together to form a large breadboard.

328:

alloy spring clips under the perforations. The clips are often called

309:

982:: "Electronic building set", filed 5 May 1966, retrieved 14 Jan 2017.

360:

175:

148:. Both examples refer to and describe other types of breadboards as

578:

596:

55:(PCB) is electrically equivalent to the above solderless breadboard

1081:

693:

685:

608:

Prototype microphone preamp built with SMD components soldered to

603:

595:

554:

429:

413:

378:

308:

299:", E&L Instruments. This is the modern solderless breadboard.

115:

550:

368:

364:

128:) and soldered electronic components to them. Sometimes a paper

1015:

313:

Breadboard consisting of only terminal strips but no bus strips

1027:

E&L Instruments in Open

Database Of The Corporate World.

233:

Device for facilitating construction of electrical apparatus

383:

Solderless breadboard with dual bus strips on both sides

699:

Modern circuit designs are generally developed using a

19:

This article is about electronics. For other uses, see

1082:"Application Note 47: High Speed Amplifier Techniques"

74:

is a construction base used to build semi-permanent

1016:

707:before the first prototype circuits are built on a

1107:"EEVblog #568 - Solderless Breadboard Capacitance"

855:

853:

840:

838:

825:

823:

810:

808:

672:(reminiscent of the original wooden breadboards),

639:Solderless breadboards usually cannot accommodate

136:or small nails as mounting posts was also common.

297:Breadboard for electronic components or the like

187:Primary electrical training test board apparatus

402:To provide power to the electronic components,

668:Alternative methods to create prototypes are

600:Complex circuit built around a microprocessor

8:

219:Quick attaching and detaching circuit system

226:Mounting assemblage for electrical circuits

434:Stranded 22AWG jump wires with solid tips

201:Board for demonstrating electric circuits

786:

418:Inside of a solderless breadboard strip

120:Educational circuits on blocks of wood

703:and simulation system, and tested in

7:

1113:from the original on 21 January 2014

295:US Patent D228136, filed in 1971, "

288:US Patent 3733574, filed in 1971, "

281:US Patent 3540135, filed in 1968, "

274:US Patent 3496419, filed in 1967, "

263:US Patent 3447249, filed in 1966, "

256:US Patent 3277589, filed in 1964, "

249:US Patent 3145483, filed in 1961, "

242:US Patent 3078596, filed in 1960, "

231:US Patent 3085177, filed in 1960, "

224:US Patent 2983892, filed in 1958, "

217:US Patent 3062991, filed in 1958, "

206:US Patent 2885602, filed in 1955, "

199:US Patent 2568535, filed in 1945, "

192:US Patent 2592552, filed in 1944, "

185:US Patent 2477653, filed in 1943, "

794:Description of the term breadboard

509:, LED display or LCD modules, and

251:Test board for electronic circuits

14:

367:and 0.333 amperes at 15 volts (5

734:

541:(PCB) which exposes an array of

44:

30:

476:Differently colored wires and

1:

290:Miniature tandem spring clips

155:In 1960, Orville Thompson of

90:, breadboards do not require

547:general-purpose input/output

212:National Cash Register (NCR)

194:Electrical instruction board

670:point-to-point construction

575:Serial Peripheral Interface

563:digital-to-analog converter

559:analog-to-digital converter

208:Modular circuit fabrication

21:Breadboard (disambiguation)

1182:

533:(SoC) era is to obtain an

276:Printed circuit breadboard

146:Printed Circuit Breadboard

18:

1161:Electronic test equipment

537:(MCU) on a pre-assembled

283:Educational training aids

258:Electrical experiment kit

237:DeVry Technical Institute

157:DeVry Technical Institute

641:surface-mount technology

620:Due to relatively large

178:231708, filed in 1880, "

99:central processing units

375:Bus and terminal strips

265:Electronic building set

180:Electrical switch board

1166:Electronics work tools

1156:Electronics substrates

617:

601:

567:pulse-width modulation

435:

419:

384:

314:

292:", Vector Electronics.

244:Circuit assembly board

121:

709:printed circuit board

622:parasitic capacitance

607:

599:

557:serial transceivers,

539:printed circuit board

433:

417:

382:

345:dual in-line packages

312:

142:printed circuit board

119:

106:parasitic capacitance

68:solderless breadboard

53:printed circuit board

1004:U.S. Patent 3733574.

992:U.S. Patent 3540135.

980:U.S. Patent 3447249.

968:U.S. Patent 3277589.

956:U.S. Patent 3078596.

944:U.S. Patent 2983892.

932:U.S. Patent 3062991.

920:U.S. Patent 2885602.

908:U.S. Patent 2568535.

896:U.S. Patent 2592552.

884:U.S. Patent 2477653.

860:U.S. Patent D228136.

845:U.S. Patent 3085177.

830:U.S. Patent 3496419.

815:U.S. Patent 3145483.

529:A common use in the

872:U.S. Patent 231708.

705:software simulation

341:Integrated circuits

80:electronic circuits

1064:2011-10-09 at the

1059:Powered breadboard

799:2007-09-27 at the

742:Electronics portal

713:Integrated circuit

618:

602:

467:Needle-nose pliers

436:

420:

385:

315:

271:blocks / dominoes.

122:

1151:Electronic design

1078:Linear Technology

701:schematic capture

696:on a breadboard.

507:serial interfaces

503:signal generators

130:schematic diagram

1173:

1123:

1122:

1120:

1118:

1102:

1096:

1094:

1092:

1091:

1086:

1074:

1068:

1056:

1050:

1049:

1047:

1045:

1035:

1029:

1024:

1018:

1013:

1007:

1001:

995:

989:

983:

977:

971:

965:

959:

953:

947:

941:

935:

929:

923:

917:

911:

905:

899:

893:

887:

881:

875:

869:

863:

857:

848:

842:

833:

827:

818:

812:

803:

791:

770:Iterative design

760:Expansion spring

744:

739:

738:

531:system on a chip

485:Advanced designs

464:

463:

459:

454:

453:

449:

48:

34:

1181:

1180:

1176:

1175:

1174:

1172:

1171:

1170:

1141:

1140:

1132:

1127:

1126:

1116:

1114:

1104:

1103:

1099:

1089:

1087:

1084:

1080:(August 1991).

1076:

1075:

1071:

1066:Wayback Machine

1057:

1053:

1043:

1041:

1039:"wire stripper"

1037:

1036:

1032:

1025:

1021:

1014:

1010:

1002:

998:

990:

986:

978:

974:

966:

962:

954:

950:

942:

938:

930:

926:

918:

914:

906:

902:

894:

890:

882:

878:

870:

866:

858:

851:

843:

836:

828:

821:

813:

806:

801:Wayback Machine

792:

788:

783:

765:Fahnestock clip

740:

733:

730:

666:

594:

535:microcontroller

527:

487:

461:

457:

456:

451:

447:

446:

428:

397:terminal strips

377:

322:phosphor bronze

307:

302:

170:

114:

60:

59:

58:

57:

56:

49:

40:

39:

38:

35:

24:

17:

12:

11:

5:

1179:

1177:

1169:

1168:

1163:

1158:

1153:

1143:

1142:

1139:

1138:

1131:

1130:External links

1128:

1125:

1124:

1105:Jones, David.

1097:

1069:

1051:

1030:

1019:

1008:

996:

984:

972:

960:

948:

936:

924:

912:

900:

888:

876:

864:

849:

834:

819:

804:

785:

784:

782:

779:

778:

777:

772:

767:

762:

757:

752:

746:

745:

729:

726:

665:

662:

653:single in-line

616:adapter boards

593:

590:

569:(PWM; used in

526:

523:

501:, one or more

486:

483:

427:

424:

376:

373:

334:contact points

306:

303:

301:

300:

293:

286:

279:

272:

261:

254:

247:

240:

229:

222:

215:

204:

197:

190:

183:

171:

169:

166:

113:

110:

50:

43:

42:

41:

36:

29:

28:

27:

26:

25:

15:

13:

10:

9:

6:

4:

3:

2:

1178:

1167:

1164:

1162:

1159:

1157:

1154:

1152:

1149:

1148:

1146:

1137:

1134:

1133:

1129:

1112:

1108:

1101:

1098:

1083:

1079:

1073:

1070:

1067:

1063:

1060:

1055:

1052:

1040:

1034:

1031:

1028:

1023:

1020:

1017:

1012:

1009:

1005:

1000:

997:

993:

988:

985:

981:

976:

973:

969:

964:

961:

957:

952:

949:

945:

940:

937:

933:

928:

925:

921:

916:

913:

909:

904:

901:

897:

892:

889:

885:

880:

877:

873:

868:

865:

861:

856:

854:

850:

846:

841:

839:

835:

831:

826:

824:

820:

816:

811:

809:

805:

802:

798:

795:

790:

787:

780:

776:

775:Optical table

773:

771:

768:

766:

763:

761:

758:

756:

753:

751:

748:

747:

743:

737:

732:

727:

725:

721:

719:

714:

710:

706:

702:

697:

695:

691:

687:

683:

679:

678:wiring pencil

675:

671:

663:

661:

657:

654:

650:

646:

642:

637:

635:

631:

627:

623:

615:

611:

606:

598:

591:

589:

586:

582:

580:

576:

572:

571:motor control

568:

564:

560:

556:

552:

548:

544:

540:

536:

532:

524:

522:

520:

514:

512:

508:

504:

500:

494:

492:

491:binding posts

484:

482:

479:

474:

472:

468:

444:

440:

432:

425:

423:

416:

412:

410:

405:

400:

398:

393:

391:

381:

374:

372:

370:

366:

362:

358:

354:

350:

346:

342:

337:

335:

331:

327:

326:nickel silver

323:

320:

311:

304:

298:

294:

291:

287:

284:

280:

277:

273:

270:

266:

262:

259:

255:

252:

248:

245:

241:

238:

234:

230:

227:

223:

220:

216:

213:

209:

205:

202:

198:

195:

191:

188:

184:

181:

177:

173:

172:

167:

165:

163:

158:

153:

151:

147:

143:

140:a particular

137:

135:

131:

127:

126:cutting board

118:

111:

109:

107:

102:

100:

95:

93:

89:

85:

81:

77:

73:

69:

65:

54:

47:

33:

22:

1115:. Retrieved

1100:

1088:. Retrieved

1072:

1054:

1042:. Retrieved

1033:

1022:

1011:

999:

987:

975:

963:

951:

939:

927:

915:

903:

891:

879:

867:

789:

722:

698:

667:

664:Alternatives

658:

645:dual in-line

638:

619:

583:

543:input/output

528:

515:

511:logic probes

499:power supply

495:

488:

478:color-coding

475:

437:

421:

403:

401:

396:

394:

386:

338:

333:

329:

316:

296:

289:

282:

275:

264:

257:

250:

243:

232:

225:

218:

207:

200:

193:

186:

179:

154:

145:

144:layout as a

138:

123:

103:

96:

71:

67:

63:

61:

1109:. EEVblog.

682:transistors

592:Limitations

82:. Unlike a

1145:Categories

1117:15 January

1090:2016-02-14

781:References

750:Brassboard

630:resistance

626:inductance

577:(SPI), or

439:Jump wires

426:Jump wires

404:bus strips

349:capacitors

330:tie points

319:tin plated

134:thumbtacks

88:stripboard

76:prototypes

72:protoboard

64:breadboard

51:400 point

690:resistors

674:wire wrap

409:crosstalk

357:inductors

353:resistors

343:(ICs) in

168:Prior art

150:prior art

92:soldering

84:perfboard

1111:Archived

1062:Archived

1044:14 April

797:Archived

755:DIN rail

728:See also

585:Firmware

549:(GPIO),

519:dead bug

471:tweezers

390:dovetail

267:". See

101:(CPUs).

565:(DAC),

561:(ADC),

460:⁄

450:⁄

269:Lectron

112:History

688:, and

686:diodes

361:ampere

355:, and

305:Design

176:Patent

1085:(pdf)

694:debug

612:- or

555:USART

369:watts

365:volts

363:at 5

70:, or

1119:2014

1046:2023

551:UART

525:Uses

469:and

649:PCB

634:MHz

614:DIL

610:SIP

581:.

579:I²C

573:),

455:to

443:AWG

371:).

332:or

324:or

235:",

210:",

174:US

162:DIP

152:.

86:or

78:of

1147::

852:^

837:^

822:^

807:^

718:RF

711:.

684:,

676:,

513:.

505:,

462:16

452:16

351:,

285:".

278:".

260:".

253:".

246:".

228:".

221:".

203:".

196:".

189:".

182:".

66:,

62:A

1121:.

1093:.

1048:.

553:/

517:"

458:5

448:3

239:.

214:.

23:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.