1166:

27:

531:

865:

characterized by a decrease in resistance as the heater temperature increases and thus have a higher power at higher temperatures for a given input voltage. PTC heaters behave in an opposite manner with an increase of resistance and decreasing heater power at elevated temperatures. This characteristic of PTC heaters makes them self-regulating, as their power stabilizes at fixed temperatures. On the other hand, NTC-type heaters generally require a thermostat or a

824:

714:

398:

832:

uniformity, quick thermal response due to low thermal mass, high energy density, and wide range of voltage compatibility. Typically, thick-film heaters are printed on flat substrates, as well as on tubes in different heater patterns. These heaters can attain power densities of as high as 100 W/cm depending on the heat transfer conditions. The thick-film heater patterns are highly customizable based on the

137:

670:

727:

552:

437:. Compared to wire, ribbon can be bent with a tighter radius and can produce heat faster and at a lower cost due to its higher surface area to volume ratio. On the other hand, ribbon life is often shorter than wire life and the price per unit mass of ribbon is generally higher. In many applications, resistance ribbon is wound around a mica card or on one of its sides.

989:, are described by an ASTM standard. Manufacturers may opt to use this class of alloys as opposed to Ni-Cr(Fe) alloys to avoid the typically relatively higher cost of nickel as a raw material compared to aluminum. The tradeoff is that Fe-Cr-Al alloys are more brittle and less ductile than Ni-Cr(Fe) ones, making them more delicate and prone to failure.

1097:. New generation hot surface igniter for gas furnace and diesel engine glow plug are made of silicon nitride material. Such heating element or glow plug reach a maximum temperature of 1400 °C and are quick to ignite gasoline or kerosene. The material is also used in diesel and spark ignited engines for other combustion components and wear parts.

861:

heater design helps to control the heating power and modulate the local temperatures across the heater substrate. In cases where there is a requirement of two or more heating zones with different power densities over a relatively small area, a thick-film heater can be designed to achieve a zonal heating pattern on a single substrate.

685:

increases exponentially with increasing temperature. Such a heater will produce high power when it is cold, and rapidly heat itself to a constant temperature. Due to the exponentially increasing resistivity, the heater can never heat itself to warmer than this temperature. Above this temperature, the

860:

For most applications, the thermal performance and temperature distribution are the two key design parameters. In order to maintain a uniform temperature distribution across a substrate, the circuit design can be optimized by changing the localized power density of the resistor circuit. An optimized

922:

While the majority of atoms in these alloys correspond to the ones listed in their name, they also consist of trace elements. Trace elements play an important role in resistance alloys, as they have a substantial influence on mechanical properties such as work-ability, form stability, and oxidation

831:

Thick-film heaters are a type of resistive heater that can be printed on a thin substrate. Thick-film heaters exhibit various advantages over the conventional metal-sheathed resistance elements. In general, thick-film elements are characterized by their low-profile form factor, improved temperature

493:

Heating element terminals serve to isolate the active resistance material from the leads. Terminals are designed to have a lower resistance than the active material by having with a lower resistivity and/or a larger diameter. They may also have a lower oxidation resistance than the active material.

931:

are used to classify trace elements. Contaminates typically have undesirable effects such as decreased life and limited temperature range. Enhancements are intentionally added by the manufacturer and may provide improvements such as increased oxide layer adhesion, greater ability to hold shape, or

660:

Etched foil elements are generally made from the same alloys as resistance wire elements, but are produced with a subtractive photo-etching process that starts with a continuous sheet of metal foil and ends with a complex resistance pattern. These elements are commonly found in precision heating

992:

On the other hand, the aluminum oxide layer that forms on the surface of Fe-Cr-Al alloys is more thermodynamically stable than the chromium oxide layer that tends to form on Ni-Cr(Fe), making Fe-Cr-Al better at resisting corrosion. However, humidity may be more detrimental to the wire life of

651:

Removable ceramic core elements use a coiled resistance heating alloy wire threaded through one or more cylindrical ceramic segments to make a required length (related to output), with or without a center rod. Inserted into a metal sheath or tube sealed at one end, this type of element allows

864:

Thick-film heaters can largely be characterized under two subcategories – negative-temperature-coefficient (NTC) and positive-temperature-coefficient (PTC) materials – based on the effect of temperature changes on the element's resistance. NTC-type heaters are

432:

heating elements are made by flattening round resistance wire, giving them a rectangular cross-section with rounded corners. Generally ribbon widths are between 0.3 and 4 mm. If a ribbon is wider than that, it is cut out from a broader strip and may instead be called resistance

852:

There are several conventional applications of thick-film heaters. They can be used in griddles, waffle irons, stove-top electric heating, humidifiers, tea kettles, heat sealing devices, water heaters, clothes irons and steamers, hair straighteners, boilers, heated beds of

905:

Materials used in heating elements are selected for a variety of mechanical, thermal, and electrical properties. Due to the wide range of operating temperatures that these elements withstand, temperature dependencies of material properties are a common consideration.

75:

839:

These heaters can be printed on a variety of substrates including metal, ceramic, glass, and polymer using metal- or alloy-loaded thick-film pastes. The most common substrates used to print thick-film heaters are aluminum 6061-T6, stainless steel, and

1223:

The life of a heating element specifies how long it is expected to last in an application. Generally heating elements in a domestic appliance will be rated for between 500 and 5000 hours of use, depending on the type of product and how it is used.

1057:) an inter-metallic compound, a silicide of molybdenum, is a refractory ceramic primarily used in heating elements. It has moderate density, melting point 2030 °C (3686 °F) and is electrically conductive. At high temperatures it forms a

514:

In a suspended design, a resistance heater is attached at two or more points to normally either a ceramic or mica insulator. Suspended resistance heaters can transfer heat via convection and radiation, but not conduction as they are surrounded by

559:

Tubular or sheathed elements (also referred to by their brand name, Calrods®) normally comprise a fine coil of resistance wire surrounded by an electrical insulator and a metallic tube-shaped sheath or casing. Insulation is typically a

80:

448:

is a resistance wire that has a coiled shape. Coils are wound very tightly and then relax to up to 10 times their original length in use. Coils are classified by their diameter and the pitch, or number of coils per unit length.

857:, thermal print heads, glue guns, laboratory heating equipment, clothes dryers, baseboard heaters, warming trays, heat exchangers, deicing and defogging devices for car windshields, side mirrors, refrigerator defrosting, etc.

635:

film is deposited on the inside that reduces the visible light and allows most of the short and medium wave infrared through. Mainly for heating people. A number of manufacturers now manufacture these lamps and they improve

104:. Heating elements are used in household appliances, industrial equipment, and scientific instruments enabling them to perform tasks such as cooking, warming, or maintaining specific temperatures higher than the ambient.

869:

in order to control the heater runaway. These heaters are used in applications which require a quick ramp-up of heater temperature to a predetermined set-point as they are usually faster-acting than PTC-type heaters.

297:(Ω/m) of a heating element material is defined in ASTM and DIN standards. In ASTM, wires greater than 0.127 mm in diameter are specified to be held within a tolerance of ±5% Ω/m and for thinner wires ±8% Ω/m.

848:

mica sheets. The applications and operational characteristics of these heaters vary widely based on the chosen substrate materials. This is primarily attributed to the thermal characteristics of the substrates.

918:

are metals that can be used for electrical heating purposes above 600 °C in air. They can be distinguished from resistance alloys which are used primarily for resistors operating below 600 °C.

461:

serve to electrically and thermally insulate the resistance heater from the environment and foreign objects. Generally for elements that operate higher than 600 °C, ceramic insulators are used.

1119:

composites) have a highly nonlinear thermal response, so that above a composition-dependent threshold temperature their resistance increases rapidly. This behavior causes the material to act as a

521:

Supported heating elements are a combination of the suspended and embedded frameworks. In these assemblies, the resistance heater can transfer heat via conduction, convection, or radiation.

1735:

190:

1258:. The standard specifies limits for parameters such as insulation strength, creepage distance, and leakage current. It also provides tolerances on the rating of a heating element.

686:

rubber acts as an electrical insulator. The temperature can be chosen during the production of the rubber. Typical temperatures are between 0 and 80 °C (32 and 176 °F).

923:

life. Some of these trace elements may be present in the basic raw materials, while others may be added deliberately to improve the performance of the material. The terms

347:

518:

In an embedded heating element, the resistance heater is encased in the insulator. In this framework the heater can only transfer heat via conduction to the insulator.

2074:

2037:

1508:

1494:

1405:

1365:

1234:. Accelerated life tests for Ni-Cr(Fe) alloys and Fe-Cr-Al alloys intended for electrical heating are used to measure the cyclic oxidation resistance of materials.

257:

235:

283:

213:

1202:

In industries, heating elements are integral to processes such as metal smelting, plastic molding, and chemical reactions that require controlled temperatures.

1971:

Jang, Joohee; Parmar, Narendra S.; Choi, Won-Kook; Choi, Ji-Won (2020). "Rapid

Defrost Transparent Thin-Film Heater with Flexibility and Chemical Stability".

1789:

639:

Ruby-coated – Same function as the gold-coated lamps, but at a fraction of the cost. The visible glare is much higher than the gold variant.

1643:

627:

reflector-lamp form. The reflector lamp style is often tinted red to minimize the visible light produced; the tubular form comes in different formats:

1255:

603:-insulated metal (generally steel) plates have found widespread application as elements in kettles and other domestic appliances since the mid-1990s.

882:

uses electricity flowing through streams of water to create steam. Operating voltages are typically between 240 and 600 volts, single or three-phase

92:

is a device used for conversion of electric energy into heat, consisting of a heating resistor and accessories. Heat is generated by the passage of

973:

Nichrome 80/20 is one of the most commonly used resistance heating alloys because it has relatively high resistance and forms an adherent layer of

145:

1107:

materials are named for their positive thermal coefficient of resistance (i.e., resistance increases upon heating). While most ceramics have a

1905:

1719:

1570:

568:

insulator, the ends are equipped with beads of insulating material such as ceramic or silicone rubber, or a combination of both. The tube is

149:

305:

Heating element performance is often quantified by characterizing the power density of the element. Power density is defined as the output

1669:

977:

when it is heated for the first time. Material beneath this layer will not oxidize, preventing the wire from breaking or burning out.

370:

Heating elements with low power density tend to be more expensive but have longer life than heating elements with high power density.

373:

In the United States, power density is often referred to as 'watt density.' It is also sometimes referred to as 'wire surface load.'

1762:"New raster-scanned CO2 laser heater for pulsed laser deposition applications: design and modeling for homogenous substrate heating"

810:

1282:

1101:

744:

1214:

Heating elements are utilized in vehicles for applications like heated seats, rear window defrosters, and engine block heaters.

481:

Electrical leads serve to connect a heating element to a power source. They generally are made of conductive materials such as

473:

are compounds commonly used in ceramic heating element insulators. For lower temperatures a wider range of materials are used.

159:

791:

748:

763:

701:

means that every point of the heater independently keeps a constant temperature without the need of regulating electronics.

1246:. Generally the thinner the wire, the smaller the spool. In some cases pail packs or rings may be used instead of spools.

1702:

Radosavljević, Goran; Smetana, Walter (2012). "Printed heater elements". In

Prudenziati, Maria; Hormadaly, Jacob (eds.).

770:

1208:

Laboratories use heating elements in various equipment, including incubators, furnaces, and analytical instruments.

959:

that should be present in an alloy. In ASTM three alloys that are specified contain, amongst other trace elements:

1761:

1165:

737:

1344:

Specification for Drawn or Rolled Nickel-Chromium and Nickel-Chromium-Iron Alloys for

Electrical Heating Elements

1315:

777:

1000:

at room temperature after being heated in the temperature range of 400 to 575 °C for an extended duration.

705:

means that the heater can never exceed a certain temperature in any point and requires no overheat protection.

286:

26:

1806:

1316:"IEC 60050 - International Electrotechnical Vocabulary - Details for IEV number 841-23-14: "heating element""

1087:, which are heating elements designed for igniting flammable gas, are common in gas ovens and clothes dryers.

1058:

759:

44:

2016:

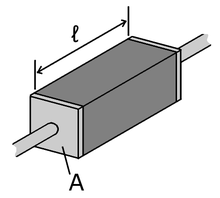

Test Method for

Accelerated Life of Nickel-Chromium and Nickel-Chromium-Iron Alloys for Electrical Heating

1120:

690:

1736:"Electrode and Electric Resistance Steam Generators and Hot Water Heaters for low carbon process heating"

1639:

1293:

1074:

1050:

1029:

652:

replacement or repair without breaking into the process involved, usually fluid heating under pressure.

2088:

1131:, in automotive rear-window defrost heaters, and honeycomb-shaped elements are used in more expensive

564:

powder and the sheath is normally constructed of a copper or steel alloy. To keep moisture out of the

2068:

2031:

1773:

1399:

1359:

1227:

A thinner wire or ribbon will always have a shorter life than a thicker one at the same temperature.

1143:. Such heating elements can reach temperatures of 950–1000 °C and can reach equilibrium quickly.

694:

1173:

Heating elements find application in a wide range of domestic, commercial, and industrial settings:

951:, are described by both ASTM and DIN standards. These standards specify the relative percentages of

1025:

883:

530:

418:

1996:

1953:

1615:

1254:

General safety requirements for heating elements used in household appliances are defined by the

1231:

1017:

108:

1930:

1591:

1423:

DIN 17470:1984-10, Heizleiterlegierungen; Technische

Lieferbedingungen für Rund- und Flachdrähte

823:

1470:

1445:

1384:

Specification for Drawn or Rolled Iron-Chromium-Aluminum Alloys for

Electrical Heating Elements

318:

1988:

1911:

1887:

1879:

1852:

1715:

1675:

1665:

1566:

1488:

1061:

layer of silicon dioxide, protecting it from further oxidation. The application area includes

612:

66:

784:

2106:

2056:

2019:

1980:

1945:

1844:

1781:

1707:

1426:

1387:

1347:

879:

833:

93:

242:

220:

1149:

1146:

1112:

1094:

1090:

1080:

986:

620:

596:

572:

to compress the powder and maximize heat transmission. These can be a straight rod (as in

561:

470:

466:

462:

392:

306:

485:

that do not have as high of a resistance to oxidation as the active resistance material.

1777:

2053:

Test Method of

Accelerated Life of Iron-Chromium-Aluminum Alloys for Electrical Heating

1704:

Printed Films: Materials

Science and Applications in Sensors, Electronics and Photonics

1662:

Printed films: materials science and applications in sensors, electronics and photonics

1277:

1267:

1062:

1037:

974:

713:

577:

397:

268:

198:

120:

74:

1383:

2100:

2052:

2015:

2000:

1957:

1189:

1181:

1136:

1116:

1070:

1066:

997:

631:

Gold-coated – Made famous by the patented

Phillips Helen lamp. A gold

101:

59:

136:

119:. They are different than devices that generate heat from electrical energy via the

1690:

1343:

1287:

1193:

1153:

1140:

866:

669:

585:

573:

569:

310:

1871:

1685:

1560:

417:, the diameter of resistance wire is often measured with a gauge system, such as

1711:

1272:

1010:

854:

726:

682:

565:

1832:

413:

s are very long and slender resistors that have a circular cross-section. Like

148:, which is a measure of the material's ability to resist electric current. The

1132:

1033:

845:

678:

356:

112:

1949:

1931:"A review of flexible electric heating element and electric heating garments"

1915:

1891:

1883:

1856:

1785:

1679:

1196:

rely on heating elements to generate the necessary heat for their functions.

1124:

841:

352:

116:

1992:

1984:

1741:. New Zealand: EECA Energy Efficiency and Conservation Authority. July 2019

1230:

Standardized life tests for resistance heating materials are described by

642:

Clear – No coating and mainly used in production processes.

1128:

1021:

956:

944:

632:

616:

97:

32:

2060:

2023:

1391:

897:

heaters are heating elements used for achieving very high temperatures.

1848:

1185:

1104:

1084:

948:

751: in this section. Unsourced material may be challenged and removed.

600:

403:

1422:

551:

502:

Heating elements are generally classified in one of three frameworks:

79:

1430:

1351:

1243:

1123:, since current passes when it is cool, and does not when it is hot.

952:

482:

260:

140:

A piece of resistive material with electrical contacts on both ends

1164:

915:

894:

822:

712:

668:

550:

529:

396:

215:

is the electrical resistance of a uniform specimen of the material

135:

123:, and have no dependence on the direction of electrical current.

581:

414:

364:

360:

1242:

Resistance wire and ribbon are most often shipped wound around

720:

576:) or bent to a shape to span an area to be heated (such as in

1907:

How to

Specify a PTC Heater for an Oven or Similar Appliance2

152:

that some amount of element material will have is defined by

355:(denoted Φ) and is most often expressed in watts per square

1929:

Fang, Shu; Wang, Rui; Ni, Haisu; Liu, Hao; Liu, Li (2022).

1446:"Understanding Watt Density When Choosing Flanged Elements"

623:

and food warmers, taking either a long, tubular form or an

313:, A, of the element. In mathematical terms it is given as:

144:

Materials used in heating elements have a relatively high

1562:

Integrating Electrical Heating Elements in Product Design

935:

The most common alloys used in heating elements include:

611:

Radiative heating elements (heat lamps) are high-powered

996:

Fe-Cr-Al alloys, like stainless steels, tend to undergo

1616:"Electric Stoves, Calrods and Cooking with Electricity"

615:

that run at less than maximum power to radiate mostly

1872:"Silicon Nitride (Si₃N₄) Properties and Applications"

661:

applications like medical diagnostics and aerospace.

619:

instead of visible light. These are usually found in

321:

271:

245:

223:

201:

162:

2089:

Household and similar electrical appliances - Safety

943:Ni-Cr(Fe) resistance heating alloys, also known as

65:

50:

40:

1831:Nichol, T. J.; Datta, A.; Aggen, G. (April 1980).

985:Fe-Cr-Al resistance heating alloys, also known as

341:

309:, P, from a heating element divided by the heated

277:

251:

229:

207:

184:

107:Heating elements may be used to transfer heat via

1706:. Oxford: Woodhead Publishing. pp. 429–468.

1256:International Electrotechnical Commission (IEC)

827:Thick-film heaters printed on a metal substrate

673:A flexible PTC heater made of conductive rubber

1020:are often made of exotic materials, including

1660:Prudenziati, Maria; Hormadaly, Jacob (2012).

8:

1833:"Embrittlement of ferritic stainless steels"

677:Resistive heaters can be made of conducting

19:

2073:: CS1 maint: numeric names: authors list (

2036:: CS1 maint: numeric names: authors list (

1807:"Why Your Toaster Will Eventually Fail You"

1760:Rashidian Vaziri, M R; et al. (2012).

1493:: CS1 maint: numeric names: authors list (

1404:: CS1 maint: numeric names: authors list (

1364:: CS1 maint: numeric names: authors list (

717:A thick-film heater printed on a mica sheet

402:A coiled heating element from an electric

25:

16:Device that converts electricity into heat

811:Learn how and when to remove this message

331:

320:

270:

244:

222:

200:

185:{\displaystyle R=\rho {\frac {\ell }{A}}}

172:

161:

31:A folded tubular heating element from an

939:Ni-Cr(Fe) alloys (AKA nichrome, Chromel)

1307:

2066:

2029:

1973:ACS Applied Materials & Interfaces

1811:Wirecutter: Reviews for the Real World

1664:. Cambridge, UK: Woodhead Publishing.

1486:

1397:

1357:

1016:Heating elements for high-temperature

18:

1801:

1799:

1655:

1653:

1554:

1552:

1550:

1548:

1169:Toaster with red hot heating elements

1127:of this material are used in heating

1095:silicon nitride § automotive industry

7:

1586:

1584:

1582:

1546:

1544:

1542:

1540:

1538:

1536:

1534:

1532:

1530:

1528:

1417:

1415:

1377:

1375:

1337:

1335:

1180:Common household appliances such as

1111:coefficient, these materials (often

932:longer life at higher temperatures.

749:adding citations to reliable sources

1013:): Used for low temperature heating

599:metal–ceramic tracks deposited on

322:

237:is the resistivity of the material

14:

1910:. Process Heating. 26 May 2005.

1792:from the original on 2016-10-10.

1283:Positive temperature coefficient

725:

78:

73:

836:of the printed resistor paste.

736:needs additional citations for

647:Removable ceramic core elements

2055:(Report). ASTM International.

2018:(Report). ASTM International.

1938:Journal of Industrial Textiles

1469:iqsupport91hn7l (2014-11-03).

1386:(Report). ASTM International.

1346:(Report). ASTM International.

981:Fe-Cr-Al alloys (AKA Kanthal®)

351:Power density is a measure of

1:

1870:Sorrell, Chris (2001-02-06).

1596:TUTCO HEATING SOLUTIONS GROUP

1444:Toledano, Ilan (2022-10-04).

1425:(Report). Beuth Verlag GmbH.

1045:Ceramics & semiconductors

1837:Metallurgical Transactions A

1471:"Watt Density | What is it?"

665:Polymer PTC heating elements

555:Tubular oven heating element

132:Resistance & resistivity

1712:10.1533/9780857096210.2.429

1559:Hegbom, Thor (2017-12-19).

100:through a process known as

2123:

1509:"Resistance Wire Overview"

538:Resistance heating element

390:

295:resistance per wire length

1152:are also used to provide

1083:, is used in hot surface

993:Fe-Cr-Al than Ni-Cr(Fe).

534:Tubular electric heater.

419:American Wire Gauge (AWG)

342:{\displaystyle \Phi =P/A}

72:

24:

1950:10.1177/1528083720968278

1876:AZo Journal of Materials

1786:10.1117/1.OE.51.4.044301

1640:US patent 6,734,250

1206:Scientific Instruments:

1067:heat treatment furnaces

592:Screen-printed elements

127:Principles of operation

1985:10.1021/acsami.0c10852

1772:(4): 044301–044301–9.

1170:

1121:self-regulating heater

1100:PTC ceramic elements:

828:

718:

674:

556:

548:

407:

343:

279:

253:

231:

209:

186:

146:electrical resistivity

141:

1294:Thermoelectric effect

1200:Industrial Processes:

1168:

1065:, ceramic sintering,

1051:Molybdenum disilicide

1030:molybdenum disilicide

826:

716:

672:

621:radiant space heaters

554:

533:

400:

344:

280:

254:

252:{\displaystyle \ell }

232:

230:{\displaystyle \rho }

210:

187:

150:electrical resistance

139:

1320:www.electropedia.org

1212:Automotive Industry:

745:improve this article

695:self-limiting heater

681:materials where the

656:Etched foil elements

541:Electrical insulator

504:suspended, embedded,

319:

287:cross-sectional area

269:

243:

221:

199:

160:

2061:10.1520/b0078-90r19

2024:10.1520/b0076-90r18

1979:(34): 38406–38414.

1778:2012OptEn..51d4301R

1766:Optical Engineering

1513:temcoindustrial.com

1392:10.1520/b0603-07r18

1188:, electric stoves,

1026:tungsten disilicide

914:Resistance heating

689:It is a point-wise

570:drawn through a die

21:

2087:IEC 60335-1:2020,

1849:10.1007/BF02670694

1620:Edison Tech Center

1592:"Heating Elements"

1232:ASTM International

1171:

829:

719:

709:Thick-film heaters

675:

613:incandescent lamps

607:Radiative elements

557:

549:

408:

339:

275:

249:

227:

205:

182:

142:

1944:(15): 1015–136S.

1721:978-1-84569-988-8

1572:978-1-4822-9220-6

821:

820:

813:

795:

760:"Heating element"

430:Resistance ribbon

382:Resistance heater

278:{\displaystyle A}

208:{\displaystyle R}

180:

86:

85:

67:Electronic symbol

52:Working principle

2114:

2091:

2085:

2079:

2078:

2072:

2064:

2048:

2042:

2041:

2035:

2027:

2011:

2005:

2004:

1968:

1962:

1961:

1935:

1926:

1920:

1919:

1902:

1896:

1895:

1867:

1861:

1860:

1828:

1822:

1821:

1819:

1818:

1803:

1794:

1793:

1757:

1751:

1750:

1748:

1746:

1740:

1732:

1726:

1725:

1699:

1693:

1683:

1657:

1648:

1647:

1646:

1642:

1636:

1630:

1629:

1627:

1626:

1612:

1606:

1605:

1603:

1602:

1588:

1577:

1576:

1556:

1523:

1522:

1520:

1519:

1505:

1499:

1498:

1492:

1484:

1482:

1481:

1466:

1460:

1459:

1457:

1456:

1441:

1435:

1434:

1431:10.31030/1164343

1419:

1410:

1409:

1403:

1395:

1379:

1370:

1369:

1363:

1355:

1352:10.1520/b0344-20

1339:

1330:

1329:

1327:

1326:

1312:

1178:Home Appliances:

1150:infrared heaters

1139:and most modern

880:electrode boiler

834:sheet resistance

816:

809:

805:

802:

796:

794:

753:

729:

721:

526:Tubes (Calrods®)

457:Heating element

348:

346:

345:

340:

335:

284:

282:

281:

276:

258:

256:

255:

250:

236:

234:

233:

228:

214:

212:

211:

206:

191:

189:

188:

183:

181:

173:

94:electric current

82:

77:

56:

55:

29:

22:

2122:

2121:

2117:

2116:

2115:

2113:

2112:

2111:

2097:

2096:

2095:

2094:

2086:

2082:

2065:

2051:B02 Committee.

2050:

2049:

2045:

2028:

2014:B02 Committee.

2013:

2012:

2008:

1970:

1969:

1965:

1933:

1928:

1927:

1923:

1904:

1903:

1899:

1869:

1868:

1864:

1830:

1829:

1825:

1816:

1814:

1805:

1804:

1797:

1759:

1758:

1754:

1744:

1742:

1738:

1734:

1733:

1729:

1722:

1701:

1700:

1696:

1672:

1659:

1658:

1651:

1644:

1638:

1637:

1633:

1624:

1622:

1614:

1613:

1609:

1600:

1598:

1590:

1589:

1580:

1573:

1558:

1557:

1526:

1517:

1515:

1507:

1506:

1502:

1485:

1479:

1477:

1468:

1467:

1463:

1454:

1452:

1443:

1442:

1438:

1421:

1420:

1413:

1396:

1382:B02 Committee.

1381:

1380:

1373:

1356:

1342:B02 Committee.

1341:

1340:

1333:

1324:

1322:

1314:

1313:

1309:

1304:

1264:

1252:

1240:

1221:

1163:

1154:radiant heating

1113:barium titanate

1091:Silicon nitride

1081:Silicon carbide

1056:

1047:

1038:vacuum furnaces

1006:

983:

941:

912:

903:

892:

876:

817:

806:

800:

797:

754:

752:

742:

730:

711:

699:Self-regulating

691:self-regulating

667:

658:

649:

609:

594:

578:electric stoves

562:magnesium oxide

547:

528:

500:

491:

479:

471:magnesium oxide

467:silicon dioxide

455:

446:Resistance coil

443:

427:

415:conductive wire

411:Resistance wire

395:

393:Resistance wire

389:

384:

379:

317:

316:

303:

289:of the specimen

267:

266:

263:of the specimen

241:

240:

219:

218:

197:

196:

158:

157:

134:

129:

90:heating element

53:

51:

36:

20:Heating element

17:

12:

11:

5:

2120:

2118:

2110:

2109:

2099:

2098:

2093:

2092:

2080:

2043:

2006:

1963:

1921:

1897:

1862:

1843:(4): 573–585.

1823:

1795:

1752:

1727:

1720:

1694:

1671:978-0857096210

1670:

1649:

1631:

1607:

1578:

1571:

1524:

1500:

1461:

1436:

1411:

1371:

1331:

1306:

1305:

1303:

1300:

1299:

1298:

1296:

1291:

1288:Resistive load

1285:

1280:

1278:Heating mantle

1275:

1270:

1268:Ceramic heater

1263:

1260:

1251:

1248:

1239:

1236:

1220:

1217:

1216:

1215:

1209:

1203:

1197:

1162:

1159:

1158:

1157:

1147:Quartz halogen

1144:

1098:

1088:

1078:

1063:glass industry

1054:

1046:

1043:

1042:

1041:

1014:

1009:Cu-Ni alloys (

1005:

1002:

982:

979:

975:chromium oxide

971:

970:

969:35% Ni, 20% Cr

967:

966:60% Ni, 16% Cr

964:

963:80% Ni, 20% Cr

940:

937:

911:

908:

902:

899:

891:

888:

875:

872:

819:

818:

733:

731:

724:

710:

707:

666:

663:

657:

654:

648:

645:

644:

643:

640:

637:

608:

605:

597:Screen-printed

593:

590:

546:

545:

542:

539:

535:

527:

524:

523:

522:

519:

516:

499:

496:

490:

487:

478:

475:

463:Aluminum oxide

454:

451:

442:

439:

426:

423:

391:Main article:

388:

385:

383:

380:

378:

375:

338:

334:

330:

327:

324:

302:

299:

291:

290:

274:

264:

248:

238:

226:

216:

204:

179:

176:

171:

168:

165:

154:Pouillet's law

133:

130:

128:

125:

121:Peltier effect

84:

83:

70:

69:

63:

62:

57:

48:

47:

42:

38:

37:

30:

15:

13:

10:

9:

6:

4:

3:

2:

2119:

2108:

2105:

2104:

2102:

2090:

2084:

2081:

2076:

2070:

2062:

2058:

2054:

2047:

2044:

2039:

2033:

2025:

2021:

2017:

2010:

2007:

2002:

1998:

1994:

1990:

1986:

1982:

1978:

1974:

1967:

1964:

1959:

1955:

1951:

1947:

1943:

1939:

1932:

1925:

1922:

1917:

1913:

1909:

1908:

1901:

1898:

1893:

1889:

1885:

1881:

1877:

1873:

1866:

1863:

1858:

1854:

1850:

1846:

1842:

1838:

1834:

1827:

1824:

1812:

1808:

1802:

1800:

1796:

1791:

1787:

1783:

1779:

1775:

1771:

1767:

1763:

1756:

1753:

1737:

1731:

1728:

1723:

1717:

1713:

1709:

1705:

1698:

1695:

1692:

1688:

1687:

1681:

1677:

1673:

1667:

1663:

1656:

1654:

1650:

1641:

1635:

1632:

1621:

1617:

1611:

1608:

1597:

1593:

1587:

1585:

1583:

1579:

1574:

1568:

1565:. CRC Press.

1564:

1563:

1555:

1553:

1551:

1549:

1547:

1545:

1543:

1541:

1539:

1537:

1535:

1533:

1531:

1529:

1525:

1514:

1510:

1504:

1501:

1496:

1490:

1476:

1472:

1465:

1462:

1451:

1447:

1440:

1437:

1432:

1428:

1424:

1418:

1416:

1412:

1407:

1401:

1393:

1389:

1385:

1378:

1376:

1372:

1367:

1361:

1353:

1349:

1345:

1338:

1336:

1332:

1321:

1317:

1311:

1308:

1301:

1297:

1295:

1292:

1289:

1286:

1284:

1281:

1279:

1276:

1274:

1271:

1269:

1266:

1265:

1261:

1259:

1257:

1249:

1247:

1245:

1237:

1235:

1233:

1228:

1225:

1218:

1213:

1210:

1207:

1204:

1201:

1198:

1195:

1194:space heaters

1191:

1190:water heaters

1187:

1183:

1179:

1176:

1175:

1174:

1167:

1160:

1155:

1151:

1148:

1145:

1142:

1141:pellet stoves

1138:

1137:space heaters

1134:

1130:

1126:

1122:

1118:

1117:lead titanate

1114:

1110:

1106:

1103:

1099:

1096:

1092:

1089:

1086:

1082:

1079:

1076:

1072:

1071:semiconductor

1068:

1064:

1060:

1052:

1049:

1048:

1044:

1039:

1035:

1031:

1027:

1023:

1019:

1015:

1012:

1008:

1007:

1003:

1001:

999:

998:embrittlement

994:

990:

988:

980:

978:

976:

968:

965:

962:

961:

960:

958:

954:

950:

946:

938:

936:

933:

930:

926:

920:

917:

909:

907:

900:

898:

896:

890:Laser heaters

889:

887:

885:

881:

873:

871:

868:

862:

858:

856:

850:

847:

843:

837:

835:

825:

815:

812:

804:

793:

790:

786:

783:

779:

776:

772:

769:

765:

762: –

761:

757:

756:Find sources:

750:

746:

740:

739:

734:This section

732:

728:

723:

722:

715:

708:

706:

704:

703:Self-limiting

700:

696:

692:

687:

684:

680:

671:

664:

662:

655:

653:

646:

641:

638:

634:

630:

629:

628:

626:

622:

618:

614:

606:

604:

602:

598:

591:

589:

587:

586:coffee makers

583:

579:

575:

574:toaster ovens

571:

567:

563:

553:

543:

540:

537:

536:

532:

525:

520:

517:

513:

512:

511:

509:

505:

497:

495:

488:

486:

484:

476:

474:

472:

468:

464:

460:

452:

450:

447:

440:

438:

436:

431:

424:

422:

420:

416:

412:

406:

405:

399:

394:

386:

381:

376:

374:

371:

368:

366:

362:

358:

354:

349:

336:

332:

328:

325:

314:

312:

308:

301:Power density

300:

298:

296:

288:

272:

265:

262:

246:

239:

224:

217:

202:

195:

194:

193:

177:

174:

169:

166:

163:

155:

151:

147:

138:

131:

126:

124:

122:

118:

114:

110:

105:

103:

102:Joule Heating

99:

95:

91:

81:

76:

71:

68:

64:

61:

60:Joule heating

58:

49:

46:

43:

39:

34:

28:

23:

2083:

2046:

2009:

1976:

1972:

1966:

1941:

1937:

1924:

1906:

1900:

1875:

1865:

1840:

1836:

1826:

1815:. Retrieved

1813:. 2021-09-27

1810:

1769:

1765:

1755:

1743:. Retrieved

1730:

1703:

1697:

1691:Google Books

1684:

1661:

1634:

1623:. Retrieved

1619:

1610:

1599:. Retrieved

1595:

1561:

1516:. Retrieved

1512:

1503:

1478:. Retrieved

1474:

1464:

1453:. Retrieved

1449:

1439:

1323:. Retrieved

1319:

1310:

1253:

1241:

1229:

1226:

1222:

1211:

1205:

1199:

1177:

1172:

1161:Applications

1108:

1004:Other alloys

995:

991:

984:

972:

942:

934:

929:enhancements

928:

925:contaminates

924:

921:

913:

910:Metal alloys

904:

893:

877:

867:thermocouple

863:

859:

851:

838:

830:

807:

798:

788:

781:

774:

767:

755:

743:Please help

738:verification

735:

702:

698:

688:

676:

659:

650:

624:

610:

595:

558:

544:Metal casing

507:

503:

501:

492:

480:

458:

456:

445:

444:

434:

429:

428:

410:

409:

401:

372:

369:

350:

315:

311:surface area

304:

294:

292:

153:

143:

106:

89:

87:

2069:cite report

2032:cite report

1400:cite report

1360:cite report

1273:Heated hose

1133:hair dryers

1059:passivation

1011:cupronickel

855:3D printers

683:resistivity

636:constantly.

566:hygroscopic

363:per square

1817:2023-12-29

1625:2024-01-28

1601:2024-01-11

1518:2024-01-08

1480:2023-12-27

1455:2023-12-27

1325:2023-12-27

1302:References

1219:Life cycle

1125:Thin films

1073:diffusion

1034:molybdenum

846:phlogopite

771:newspapers

679:PTC rubber

459:insulators

377:Components

357:millimeter

113:convection

109:conduction

96:through a

2001:220717357

1958:228936246

1916:1077-5870

1892:939116350

1884:1833-122X

1857:0360-2133

1745:2 October

1680:823040859

1238:Packaging

901:Materials

842:muscovite

801:June 2023

508:supported

489:Terminals

453:Insulator

353:heat flux

323:Φ

247:ℓ

225:ρ

175:ℓ

170:ρ

117:radiation

2101:Category

1993:32698575

1790:Archived

1489:cite web

1262:See also

1186:toasters

1129:garments

1109:negative

1085:igniters

1075:furnaces

1022:platinum

1018:furnaces

987:Kanthal®

957:chromium

945:nichrome

633:dichroic

617:infrared

98:resistor

33:espresso

2107:Heating

1774:Bibcode

1686:Preview

1475:Indeeco

1105:ceramic

949:Chromel

785:scholar

601:ceramic

404:toaster

285:is the

259:is the

54:

45:Passive

35:machine

1999:

1991:

1956:

1914:

1890:

1882:

1855:

1718:

1678:

1668:

1645:

1569:

1450:Wattco

1250:Safety

1244:spools

1192:, and

1093:, see

1032:, and

953:nickel

916:alloys

874:Liquid

787:

780:

773:

766:

758:

584:, and

483:copper

469:, and

425:Ribbon

261:length

192:where

1997:S2CID

1954:S2CID

1934:(PDF)

1739:(PDF)

1182:ovens

1053:(MoSi

895:Laser

792:JSTOR

778:books

582:ovens

498:Types

477:Leads

435:strip

361:watts

307:power

115:, or

2075:link

2038:link

1989:PMID

1912:ISSN

1888:OCLC

1880:ISSN

1853:ISSN

1747:2023

1716:ISBN

1676:OCLC

1666:ISBN

1567:ISBN

1495:link

1406:link

1366:link

1115:and

1069:and

955:and

927:and

764:news

693:and

515:air.

441:Coil

387:Wire

365:inch

293:The

41:Type

2057:doi

2020:doi

1981:doi

1946:doi

1845:doi

1782:doi

1708:doi

1689:at

1427:doi

1388:doi

1348:doi

1102:PTC

947:or

878:An

844:or

747:by

625:R40

588:).

506:or

359:or

156:as

2103::

2071:}}

2067:{{

2034:}}

2030:{{

1995:.

1987:.

1977:12

1975:.

1952:.

1942:51

1940:.

1936:.

1886:.

1878:.

1874:.

1851:.

1841:11

1839:.

1835:.

1809:.

1798:^

1788:.

1780:.

1770:51

1768:.

1764:.

1714:.

1674:.

1652:^

1618:.

1594:.

1581:^

1527:^

1511:.

1491:}}

1487:{{

1473:.

1448:.

1414:^

1402:}}

1398:{{

1374:^

1362:}}

1358:{{

1334:^

1318:.

1184:,

1135:,

1040:).

1024:,

886:.

884:AC

697:.

580:,

510:.

465:,

421:.

367:.

111:,

88:A

2077:)

2063:.

2059::

2040:)

2026:.

2022::

2003:.

1983::

1960:.

1948::

1918:.

1894:.

1859:.

1847::

1820:.

1784::

1776::

1749:.

1724:.

1710::

1682:.

1628:.

1604:.

1575:.

1521:.

1497:)

1483:.

1458:.

1433:.

1429::

1408:)

1394:.

1390::

1368:)

1354:.

1350::

1328:.

1290:s

1156:.

1077:.

1055:2

1036:(

1028:/

814:)

808:(

803:)

799:(

789:·

782:·

775:·

768:·

741:.

337:A

333:/

329:P

326:=

273:A

203:R

178:A

167:=

164:R

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.