480:) under the biorefinery concept is a promissory alternative since is possible to obtain biogas and other co-products including ethanol, xylitol, syngas, and electricity; this process also provides high profitability for high production scales. The economic assessment of the integration of organic waste anaerobic digestion with other mixed culture anaerobic fermentation technologies was studied; the highest profit is obtained by dark fermentation of food waste with separation and purification of acetic and butyric acids (47 USD/t of food waste). The technical feasibility, profitability and extent of investment risk to produce sugar syrups from food and beverage waste was analyzed; the

448:

energy contents; the economics of biorefineries depend on the cost-effective processes to transform lignin into value-added fuels and chemicals. The conversion of an existing

Swedish kraft pulp mill to the production of dissolving pulp, electricity, lignin, and hemicellulose has been studied; self-sufficiency in terms of steam and the production of excess steam was a key factor for the integration of a lignin separation plant; in this case; the digester has to be upgraded for preserving the same production level and represents 70% of the total investment cost of conversion. The potential of using the

416:/biodiesel industry, the conversion of this residue into ethanol, heat and power, and cattle feed were evaluated according to techno-economic principles, the scenarios under study shown reduced economic benefits, although their implementation represented a reduction in the environmental impact (climate change and fossil fuel depletion) compared to the traditional biodiesel production. The economic feasibility for bio-oil production from EFB via fast pyrolysis using the fluidized-bed was studied, crude bio-oil can potentially be produced from EFB at a product value of 0.47 $ /kg with a

122:

396:

saccharification and co-fermentation shows a minimum selling price between 50.38 and 62.72 US cents/L which is comparable with the market price. The production of xylitol, citric acid and glutamic acid from sugarcane lignocellulose (bagasse and harvesting residues), each in combination with electricity have been evaluated; the three biorefinery systems were simulated to be annexed to an existing sugar mill in South Africa. The production of xylitol and glutamic acid has shown economic feasibility with an

146:(biomass) into multiple intermediates (carbohydrates, proteins, triglycerides) that can be further converted into value-added products. Each refining phase is also referred to as a "cascading phase". The use of biomass as feedstock can provide a benefit by reducing the impacts on the environment, as lower pollutants emissions and reduction in the emissions of hazard products. In addition, biorefineries are intended to achieve the following goals:

510:

followed by lignocellulosic crops; and finally by first-generation arable crops, although the environmental impacts are sensitive to factors such as crop management practices, harvesting systems, and crop yields. The production of chemicals from biomass feedstock has shown environmental benefits; bulk chemicals from biomass-derived feedstocks have been studied showing savings on non renewable energy use and greenhouse gas emissions.

3653:

730:

532:

US Department of Energy; the LCA of eight food waste valorization routes for the production of HMF shows that the most environmentally favorable option uses less polluting catalyst (AlCl3) and co-solvent (acetone), and provides the highest yield of HMF (27.9 Cmol%), metal depletion and toxicity impacts (marine ecotoxicity, freshwater toxicity, and human toxicity) were the categories with the highest values.

744:

25:

178:

370:

506:(LCA) is a methodology to evaluate the environmental load of a process, from the extraction of raw materials to the end use. LCA can be used to investigate the potential benefits of biorefinery systems; multiple LCA studies has been developed to analyse whether biorefineries are more environmentally friendly compared to conventional alternatives.

517:

shows that these two biorefinery systems are able to mitigate climate change impacts in comparison to gasoline, but higher climate change benefits are achieved with 2G ethanol production (up to 80% reduction). The conversion of palm empty fruit bunches into valuable products (ethanol, heat and power,

531:

The majority of the LCA studies for the valorization of food waste have been focused on the environmental impacts on biogas or energy production, with only few on the synthesis of high value-added chemicals; hydroxymethylfurfural (HMF) has been listed as one of the top 10 bio-based chemicals by the

434:

as a viable route for the production of biofuels and biochemicals has been analyzed in the United Arab

Emirates (UAE) context. Three scenarios were examined; in all of them, biodiesel and glycerol is produced; in the first scenario biogas and organic fertilizer is produced by anaerobic fermentation

488:

syrup (9.4%), HFS42 (22.8%) and glucose-rich syrup (58.9%); the sugar syrups also have high cost competitiveness with relatively low net production costs and minimum selling prices. The valorization of municipal solid waste through integrated mechanical biological chemical treatment (MBCT) systems

447:

In regard to the pulp and paper industry; lignin is a natural polymer co-generated and is generally used as boiler fuel to generate heat or steam to cover the energy demand in the process. Since lignin accounts for 10–30 wt% of the available lignocellulosic biomass and is equivalent to ~40% of its

461:

has been investigated; in the process, cellulose is separated by and an alkaline pretreatment and then is hydrolyzed and fermented to produce ethanol, while the resulting liquor containing dissolved lignin is gasified and refined to dimethyl ether; the process demonstrate to be self-sufficient in

145:

Bioenergy Task 42 defined biorefining as "the sustainable processing of biomass into a spectrum of bio-based products (food, feed, chemicals, materials) and bioenergy (biofuels, power and/or heat)". As refineries, biorefineries can provide multiple chemicals by fractioning an initial raw material

443:

and microalgae to produce biodiesel and the production of animal feed, biogas and organic fertilizer; the third scenario involves the production of lipids from microalgae for the production of biodiesel as well as hydrogen and animal feed as final product; only the first scenario was profitable.

540:

The pulp and paper industry is considered as the first industrialized biorefinery system; in this industrial process other co-products are produced including tall oil, rosin, vanillin, and lignosulfonates. Apart from these co-products; the system includes energy generation (in for of steam and

509:

Feedstock is one of the main sources of environmental impacts in the biofuel production, the source of this impacts are related to the field operation to grow, handle and transport the biomass to the biorefinery gate. Agricultural residues are the feedstock with the lowest environmental impact

497:

One of the main goals of biorefineries is to contribute to a more sustainable industry by the conservation of resources and by reducing greenhouse gas emissions and other pollutants. Nevertheless, other environmental impacts may be associated to the production of biobased products; as land use

407:

As for biodiesel production, this industry also has the potential to integrate biorefinery systems to convert residual biomasses and wastes into biofuel, heat, electricity and bio-based green products. Glycerol is the main co-product in biodiesel production and can be transformed into valuable

466:

from lignin was performed to determine its feasibility; the results showed that the total capital investment was 4.9 M$ based on the plant capacity of 2,544 kg/d of feedstock; besides, the catechol price was estimated to be 1,100 $ /t and the valorization ratio was found to be 3.02.

395:

is a feasible feedstock to produce fuels and chemicals; lignocellulosic bioethanol (2G) is produced in Brazil in two plants with capacities of 40 and 84 Ml/y (about 0.4% of the production capacity in Brazil). TEA of ethanol production using mild liquefaction of bagasse plus simultaneous

1474:

Giwa, Adewale; Adeyemi, Idowu; Dindi, Abdallah; Lopez, Celia García-Baños; Lopresto, Catia

Giovanna; Curcio, Stefano; Chakraborty, Sudip (May 2018). "Techno-economic assessment of the sustainability of an integrated biorefinery from microalgae and Jatropha: A review and case study".

1312:

De Corato, Ugo; De Bari, Isabella; Viola, Egidio; Pugliese, Massimo (May 2018). "Assessing the main opportunities of integrated biorefining from agro-bioenergy co/by-products and agroindustrial residues into high-value added products associated to some emerging markets: A review".

1226:Özüdoğru, H.M. Raoul; Nieder-Heitmann, M.; Haigh, K.F.; Görgens, J.F. (March 2019). "Techno-economic analysis of product biorefineries utilizing sugarcane lignocelluloses: Xylitol, citric acid and glutamic acid scenarios annexed to sugar mills with electricity co-production".

412:, allyl alcohol, propanediols, and glycerol carbonate has been evaluated; all glycerol valorization routes shown to be profitable, being the most attractive the manufacture of glycerol carbonate. Palm empty fruit bunches (EFB) are an abundant lignocellulosic residues from the

400:(IRR) of 12.3% and 31.5%, exceeding the IRR of the base case (10.3%). Likewise, the production of ethanol, lactic acid or methanol and ethanol-lactic acid from sugarcane bagasse have been studied; lactic acid demonstrated to be economically attractive by showing the greatest

1133:

Lopes, Mario Lucio; de Lima

Paulillo, Silene Cristina; Godoy, Alexander; Cherubin, Rudimar Antonio; Lorenzi, Marcel Salmeron; Carvalho Giometti, Fernando Henrique; Domingos Bernardino, Claudemir; de Amorim Neto, Henrique Berbert; de Amorim, Henrique Vianna (December 2016).

1700:

Martínez-Ruano, Jimmy

Anderson; Caballero-Galván, Ashley Sthefanía; Restrepo-Serna, Daissy Lorena; Cardona, Carlos Ariel (2018-04-07). "Techno-economic and environmental assessment of biogas production from banana peel (Musa paradisiaca) in a biorefinery concept".

404:(M$ 476–1278); in the same way; the production of ethanol and lactic acid as co-product was found to be a favorable scenario (net present value between M$ 165 and M$ 718) since this acid has applications in the pharmaceutical, cosmetic, chemical and food industry.

2788:

522:

produced by fermentation of glycerol leads to significant reduction of GHG emissions compared to fossil fuel alternatives; however the energy input is double and the contribution to eutrophication is significantly higher The LCA for the integration of

652:, and then products for healthcare, cosmetics, and fine chemicals industries. The side streams will be used for the production of fertilizer and biogas. Other seaweed biorefinery projects include MacroAlgaeBiorefinery (MAB4), SeaRefinery and SEAFARM.

462:

terms of hot utility (fresh steam) demand but with a deficit of electricity; the process can be feasible, economically speaking, but is highly dependent on the development of biofuel prices. The exergetic and economic evaluation for the production of

380:(TEA) is a methodology to evaluate whether a technology or process is economically attractive. TEA research has been developed to provide information about the performance of the biorefinery concept in diverse production systems as sugarcane mills,

489:

for the production of levulinic acid has been studied, the revenue from resource recovery and product generation (without the inclusion of gate fees) is more than enough to out- weigh the waste collection fees, annual capital and operating costs.

373:(a) Counts of operational, planned and under-construction cellulosic biorefineries with biochemical conversion technology, (b) global distribution of plants and (c) shares of corn, wheat, rice, barley and sugarcane residues as feedstock as of 2015

456:

in a repurposed or co-located kraft mill has been studied, a sugar recovery higher than 60% enables the process to be competitive for the production of ethanol from softwood. The repurposing of a kraft pulp mill to produce both ethanol and

674:

into various products. Lignin for example can be transformed into phenolic components which can be used to make glue, plastics and agricultural products (e.g. crop protection). Cellulose can be transformed into clothes and packaging.

2634:

Garcia, Edgar Suarez; Olivieri, Giuseppe; Sijtsma, Lolke; Vermuë, Marian H.; Barbosa, Maria; Reith, J. Hans; van den Berg, Corjan; Eppink, Michel H. M.; Wijffels, René H. (2019), Hallmann, Armin; Rampelotto, Pabulo H. (eds.),

2131:

Levasseur, Annie; Bahn, Olivier; Beloin-Saint-Pierre, Didier; Marinova, Mariya; Vaillancourt, Kathleen (July 2017). "Assessing butanol from integrated forest biorefinery: A combined techno-economic and life cycle approach".

3082:

Patsalou, Maria; Menikea, Kristia

Karolina; Makri, Eftychia; Vasquez, Marlen I.; Drouza, Chryssoula; Koutinas, Michalis (2017). "Development of a citrus peel-based biorefinery strategy for the production of succinic acid".

1580:

Lundberg, Valeria; Bood, Jon; Nilsson, Linus; Axelsson, Erik; Berntsson, Thore; Svensson, Elin (2014-03-25). "Converting a kraft pulp mill into a multi-product biorefinery: techno-economic analysis of a case mill".

527:

from prehydrolysate in a

Canadian Kraft dissolving pulp mill shows that the carbon footprint of this butanol may be 5% lower compare to gasoline; but is not as low as corn butanol (23% lower than that of gasoline).

1793:

Kwan, Tsz Him; Ong, Khai Lun; Haque, Md Ariful; Kulkarni, Sandeep; Lin, Carol Sze Ki (January 2019). "Biorefinery of food and beverage waste valorisation for sugar syrups production: Techno-economic assessment".

2284:

Mongkhonsiri, Ghochapon; Gani, Rafiqul; Malakul, Pomthong; Assabumrungrat, Suttichai (2018). "Integration of the biorefinery concept for the development of sustainable processes for pulp and paper industry".

276:

Products: Biorefineries can be grouped in two main categories according to the conversion of biomass in an energetic or non-energetic product. In this classification the main market must be identified:

2037:

Junqueira, Tassia L.; Chagas, Mateus F.; Gouveia, Vera L. R.; Rezende, Mylene C. A. F.; Watanabe, Marcos D. B.; Jesus, Charles D. F.; Cavalett, Otavio; Milanez, Artur Y.; Bonomi, Antonio (2017-03-14).

548:. Other important features of this industry are a well-established logistic for biomass production, avoiding competition with food production for fertile land, and presenting higher biomass yields.

1269:

Mandegari, Mohsen; Farzad, Somayeh; Görgens, Johann F. (June 2018). "A new insight into sugarcane biorefineries with fossil fuel co-combustion: Techno-economic analysis and life cycle assessment".

1049:

Cherubini, Francesco; Jungmeier, Gerfried; Wellisch, Maria; Willke, Thomas; Skiadas, Ioannis; Van Ree, René; de Jong, Ed (2009). "Toward a common classification approach for biorefinery systems".

678:

In South Africa, Numbitrax LLC bought a Blume

Biorefinery system for producing bioethanol as well as additional high-return offtake products from local and readily available resources such as the

518:

and cattle feed) reduces the impact for climate change and fossil fuel depletion compared to the traditional biodiesel production; but the benefits for toxicity and eutrophication are limited.

1839:"Novel integrated mechanical biological chemical treatment (MBCT) systems for the production of levulinic acid from fraction of municipal solid waste: A comprehensive techno-economic analysis"

2958:

1358:

D’Angelo, Sebastiano C.; Dall’Ara, Agostino; Mondelli, Cecilia; Pérez-Ramírez, Javier; Papadokonstantakis, Stavros (2018-10-26). "Techno-Economic

Analysis of a Glycerol Biorefinery".

544:

This industry has consolidated as the highest consumer of biomass; and uses not only wood as feedstock, it is capable of processing agricultural waste as bagasse, rice straw and

1647:

Fornell, Rickard; Berntsson, Thore; Åsblad, Anders (January 2013). "Techno-economic analysis of a kraft pulp-mill-based biorefinery producing both ethanol and dimethyl ether".

2251:

2363:

Moshkelani, Maryam; Marinova, Mariya; Perrier, Michel; Paris, Jean (2013). "The forest biorefinery and its implementation in the pulp and paper industry: Energy overview".

689:

on waste from the agricultural and food industry (i.e. fruit and vegetable surplus, remaining waste from fruit juice and jam production). These larvae are used to produce

1404:

Vaskan, Pavel; Pachón, Elia Ruiz; Gnansounou, Edgard (2018). "Techno-economic and life-cycle assessments of biorefineries based on palm empty fruit bunches in Brazil".

298:

Mechanical/physical: The chemical structure of the biomass components is preserved. This operation includes pressing, milling, separation, distillation, among others

3530:

897:

874:

304:

Chemical processes: The substrate suffer change by the action of an external chemical (e.g., hydrolysis, transesterification, hydrogenation, oxidation, pulping)

615:

Novamont has converted old petrochemical factories into biorefineries, producing protein, plastics, animal feed, lubricants, herbicides and elastomers from

1187:"Techno-economic analysis of ethanol production from sugarcane bagasse using a Liquefaction plus Simultaneous Saccharification and co-Fermentation process"

1967:

The BREW Project: Medium and long-term opportunities and risks of the biotechnological production of bulk chemicals from renewable resources; Final Report

3535:

1439:

Do, Truong Xuan; Lim, Young-il; Yeo, Heejung (February 2014). "Techno-economic analysis of biooil production process from palm empty fruit bunches".

2096:

Ekman, Anna; Börjesson, Pål (July 2011). "Environmental assessment of propionic acid produced in an agricultural biomass-based biorefinery system".

2398:

1625:

2586:

2508:

3692:

2482:

666:

The BIOCON platform is researching the processing of wood into various products. More precisely, their researchers are looking at transforming

2966:

2320:

Anderson, Nathaniel; Mitchell, Dana (2016). "Forest

Operations and Woody Biomass Logistics to Improve Efficiency, Value, and Sustainability".

2656:

2458:

3603:

3190:

474:

several biorefinery routes has been proposed to upgrade waste streams in valuable products. The production of biogas from banana peel (

1895:

Uihlein, Andreas; Schebek, Liselotte (2009). "Environmental impacts of a lignocellulose feedstock biorefinery system: An assessment".

848:

391:

Bioethanol plants and sugarcane mills are well-established processes where the biorefinery concept can be implemented since sugarcane

2450:

Blue economy 3.0 : the marriage of science, innovation and entrepreneurship creates a new business model that transforms society

502:

of water, the pollution of the environment with pesticides, or higher energy and material demand that lead to environmental burdens.

292:, oil-based crops, grasses, marine biomass); and residues (oil-based residues, lignocellulosic residues, organic residues and others)

3687:

2260:

2235:

1950:

1033:

1008:

108:

655:

FUMI Ingredients produces foaming agents, heat-set gels and emulsifiers from micro-algae with the help of micro-organisms such as

911:

Cherubini, Francesco (July 2017). "The biorefinery concept: Using biomass instead of oil for producing energy and chemicals".

2556:

1626:"Techno-economic analysis of the optimum softwood lignin content for the production of bioethanol in a repurposed Kraft mill"

1510:

Lora, Jairo H (April 2002). "Recent Industrial Applications of Lignin: A Sustainable Alternative to Nonrenewable Materials".

46:

39:

307:

Thermochemical: Severe conditions are apply to the feedstock (high pressure and high temperature, with or without catalyst).

3008:

514:

89:

712:

Biteback Insect makes insect cooking oil, insect butter, fatty alcohols, insect frass protein and chitin from superworm (

3677:

3287:

2886:

Verheyen, Geert R.; Ooms, Tom; Vogels, Liesbeth; Vreysen, Steven; Bovy, Ann; Van Miert, Sabine; Meersman, Filip (2018).

2874:

1185:

Gubicza, Krisztina; Nieves, Ismael U.; William J., Sagues; Barta, Zsolt; Shanmugam, K.T.; Ingram, Lonnie O. (May 2016).

61:

3550:

3633:

3623:

3141:

1933:

Dufossé, K.; Ben Aoun, W.; Gabrielle, B. (2017), "Life-Cycle Assessment of Agricultural Feedstock for Biorefineries",

189:

Platforms: Refers to key intermediates between raw material and final products. The most important intermediates are:

142:

1676:"Techno-Economic Evaluation for Feasibility of Lignin Valorization Process for the Production of Bio-Based Chemicals"

541:

electricity) to cover its internal energy demand; and it has the potential to feed heat and electricity to the grid.

2039:"Techno-economic analysis and climate change impacts of sugarcane biorefineries considering different time horizons"

121:

589:

377:

151:

68:

3070:

323:

Label the refinery system according by citing the number of platforms, products, feedstock, and processes involved

3608:

3486:

950:

3020:

Kehili, M.; Schmidt, L. M.; Reynolds, W.; Zammel, A.; Zetzl, C.; Smirnova, I.; Allouche, N.; Sayadi, S. (2016).

1545:

Maity, Sunil K. (March 2015). "Opportunities, recent trends and challenges of integrated biorefinery: Part II".

3582:

3555:

208:

3158:

408:

products through chemocatalytic technologies; the valorization of glycerol for the production of lactic acid,

75:

3682:

3183:

2643:, Grand Challenges in Biology and Biotechnology, Cham: Springer International Publishing, pp. 293–317,

832:

735:

397:

313:

The aforementioned features are used to classified biorefineries systems according to the following method:

35:

2986:

2218:

de Jong, Ed; Jungmeier, Gerfried (2015), "Biorefinery Concepts in Comparison to Petrochemical Refineries",

1982:"Producing Bio-Based Bulk Chemicals Using Industrial Biotechnology Saves Energy and Combats Climate Change"

280:

Energy-driven biorefinery systems: The main product is a second energy carrier as biofuels, power and heat.

3540:

3147:

780:: can be made into tomato flesh (food), tomato seeds (containing fatty acids) and tomato peel (containing

289:

1838:

767:

503:

481:

385:

57:

3022:"Biorefinery cascade processing for creating added value on tomato industrial by-products from Tunisia"

2812:

Ciriminna, Rosaria; Delisi, Riccardo; Albanese, Lorenzo; Meneguzzo, Francesco; Pagliaro, Mario (2017).

476:

317:

Identify the feedstock, the main technologies included in the process, platform, and the final products

357:

3316:

1993:

421:

3638:

787:

2755:

2731:

3656:

3457:

3282:

3270:

3176:

2662:

2345:

2302:

1877:

1819:

1734:

1606:

1527:

1383:

1294:

1251:

1066:

694:

626:

557:

216:

162:

2610:

470:

The high generation of waste biomass is an attractive source for conversion to valuable products

156:

Supply new building blocks for the production of novel materials with disruptive characteristics

709:

for shower gel), replacing other vegetable oils such as palm oil, or it can be used in fodder.

342:

3577:

3469:

3053:

2907:

2899:

2833:

2652:

2464:

2454:

2399:"Chemrec granted $ 70 million to build biorefinery at Swedish pulp mill | Biomassmagazine.com"

2380:

2337:

2231:

2200:

2149:

2113:

2078:

2060:

2019:

2011:

1946:

1912:

1869:

1861:

1811:

1775:

1726:

1718:

1598:

1562:

1492:

1456:

1421:

1375:

1340:

1286:

1243:

1208:

1167:

1115:

1107:

1029:

1004:

928:

891:

843:

822:

795:: GM tobacco could provide industrial enzymes for biofuel production. Tobacco can also supply

686:

656:

401:

2997:

2813:

3509:

3420:

3260:

3164:

Top Value Added Chemicals from Biomass: list of chemicals that can be extracted from biomass

3092:

3043:

3033:

2825:

2644:

2372:

2329:

2294:

2223:

2190:

2180:

2141:

2105:

2068:

2050:

2001:

1938:

1904:

1853:

1803:

1765:

1710:

1656:

1590:

1554:

1519:

1484:

1448:

1413:

1367:

1330:

1322:

1278:

1235:

1198:

1157:

1147:

1097:

1086:"Production of bioethanol, methane and heat from sugarcane bagasse in a biorefinery concept"

1058:

920:

660:

3121:

2685:

2422:

3618:

3480:

3430:

3342:

622:

609:

301:

Biochemical: Processes under low temperature and pressure, using microorganism or enzymes.

212:

2376:

567:

is located in Alberta. The biorefinery utilizes Source Separated Organics from the metro

82:

3163:

1997:

326:

Elaborate a table with the features identified, and the source of internal energy demand

3136:

3048:

3021:

2998:

Canadian Startup is Turning Food Waste into Biodegradable, Plastic 3D Printing Filament

2789:"Bume Distillation Sells First South African-Based Biorefinery Plant to Numbitrax, LLC"

2636:

2227:

2073:

2038:

1942:

1162:

1135:

853:

714:

597:

519:

499:

458:

417:

2298:

563:

Canada's first Integrated Biorefinery, developed on anaerobic digestion technology by

3671:

3628:

3294:

2666:

1823:

1610:

1531:

1387:

1298:

1255:

814:

806:

749:

605:

564:

449:

268:

230:

2349:

2306:

1881:

1070:

439:

fruit cake and seedcake; the second scenario includes the production of lipids from

3570:

3440:

3277:

3235:

3215:

2145:

1908:

1857:

1738:

1452:

1282:

1203:

1186:

1102:

1085:

924:

838:

585:

582:

524:

409:

3096:

2564:

2185:

2168:

2109:

1417:

1371:

1239:

2167:

Lam, Chor-Man; Yu, Iris K.M.; Hsu, Shu-Chien; Tsang, Daniel C.W. (October 2018).

1660:

3613:

3565:

3560:

3353:

3331:

3304:

3265:

3250:

3225:

2648:

1674:

Mabrouk, Aicha; Erdocia, Xabier; González Alriols, Maria; Labidi, Jalel (2017).

729:

593:

545:

24:

2851:

1807:

1558:

1488:

1326:

3504:

3474:

3410:

3255:

3220:

3153:

3038:

2468:

2333:

2055:

1714:

1594:

1523:

1152:

771:

763:

725:

706:

630:

425:

352:

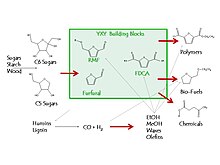

C6 and C5 sugar and syngas platform biorefinery for bioethanol, FT-diesel and

335:

177:

2903:

2837:

2384:

2341:

2204:

2153:

2117:

2064:

2015:

1916:

1865:

1815:

1779:

1722:

1602:

1566:

1496:

1460:

1425:

1379:

1344:

1290:

1247:

1111:

932:

3598:

3514:

3415:

3240:

3199:

818:

743:

702:

671:

601:

381:

243:

3057:

2911:

2888:"Insects as an Alternative Source for the Production of Fats for Cosmetics"

2887:

2829:

2082:

2023:

1873:

1730:

1212:

1171:

1119:

1084:

Rabelo, S.C.; Carrere, H.; Maciel Filho, R.; Costa, A.C. (September 2011).

560:

company has multiple biorefineries located in Odessa, WA and Missoula, MT.

283:

Material-driven biorefinery systems: The main product is a biobased product

2169:"Life-cycle assessment on food waste valorisation to value-added products"

875:"Bio-based Chemicals: Value Added Products from Biorefineries | Bioenergy"

3498:

3463:

3388:

3378:

3321:

1754:"Increasing Profits in Food Waste Biorefinery—A Techno-Economic Analysis"

1675:

796:

781:

634:

568:

485:

463:

453:

430:

413:

353:

295:

Processes: Conversion process to transform biomass into a final product:

235:

222:

204:

134:

2195:

1335:

369:

320:

Draw the scheme of the refinery using the features identified in step 1.

16:

Refinery that converts biomass to energy and other beneficial byproducts

3405:

3399:

3348:

3230:

3207:

2709:

2509:"Synthetic palm oil being brewed like beer gets Bill Gates' investment"

1770:

1753:

975:

828:

792:

690:

679:

645:

616:

578:

392:

226:

138:

2987:

Greener straws? Bacteria help turn food waste into compostable plastic

2448:

2006:

1981:

384:

production, pulp and paper mills, and the treatment of industrial and

3451:

3383:

3299:

3245:

1624:

Wu, Shufang; Chang, Houmin; Jameel, Hasan; Phillips, Richard (2014).

1136:"Ethanol production in Brazil: a bridge between science and industry"

810:

802:

777:

698:

667:

649:

572:

346:

261:

239:

198:

192:

1062:

2814:"Opuntia ficus‐indica seed oil: Biorefinery and bioeconomy aspects"

1026:

Biorefineries. Integrated Biochemical Processes for Liquid Biofuels

141:

to energy and other beneficial byproducts (such as chemicals). The

3425:

3368:

3358:

3311:

1837:

Sadhukhan, Jhuma; Ng, Kok Siew; Martinez-Hernandez, Elias (2016).

758:

638:

368:

258:), from hydrolysis of hemicellulose and food and feed side streams

176:

120:

2934:

2532:

3393:

3363:

3172:

3373:

18:

1752:

Bastidas-Oyanedel, Juan-Rodrigo; Schmidt, Jens (2018-06-13).

185:

Biorefineries can be classified based in four main features:

3168:

3126:

1965:

Patel, Martin; Hermann, Barbara; Dornburg, Veronika (2006).

805:: can be made into juice (food) and citrus peel (containing

288:

Feedstock: Dedicated feedstocks (Sugar crops, starch crops,

3131:

3071:

Tobacco plants may boost biofuel and biorefining industries

2483:"Bill Gates-Led Fund Invests in Synthetic Palm Oil Startup"

424:

of 3.2 years and 21.9%, respectively. The integration of

1980:

Hermann, B. G.; Blok, K.; Patel, M. K. (November 2007).

2852:"How to make biodegradable 'plastic' from cactus juice"

701:. The grease is usable in the pharmaceutical industry (

685:

Circular Organics (part of Kempen Insect Valley) grows

2686:"Innovative Bio-refinery platform, BIOCON, wins award"

1024:

Qureshi, Nasib; Hodge, David; Vertès, Alain (2014).

3591:

3523:

3439:

3330:

3206:

168:

Achieve the ultimate goal of reducing GHG emissions

2220:Industrial Biorefineries & White Biotechnology

3009:Bioplastic Feedstock 1st, 2nd and 3rd Generations

2637:"Integrated Biorefineries for Algal Biomolecules"

2587:"FUMI produces proteins for growing vegan market"

873:International Energy Agency - Bioenergy Task 42.

181:Chemical diagram of the activity of a biorefinery

2818:European Journal of Lipid Science and Technology

3531:Bioconversion of biomass to mixed alcohol fuels

3109:Kijk magazine, 10, 2019, page 51: Peelpioneers]

2959:"From Pest to Pot: Can Insects Feed the World?"

484:shown to be satisfactory for the production of

264:from the processing of lignocellulosic biomass.

3184:

8:

3148:Wisconsin Biorefining Development Initiative

1703:Environmental Science and Pollution Research

951:"Seaweed biorefinery: much work, high hopes"

2611:"FUMI Ingredients - World Food Innovations"

1969:. Utrecht, Netherlands: Utrecht University.

1796:Process Safety and Environmental Protection

1583:Clean Technologies and Environmental Policy

1360:ACS Sustainable Chemistry & Engineering

896:: CS1 maint: numeric names: authors list (

493:Environmental impact of biorefinery systems

165:(agricultural, urban, and industrial waste)

159:Creation of new jobs, including rural areas

3191:

3177:

3169:

1001:Biorefinery in the Pulp and Paper Industry

536:Biorefinery in the pulp and paper industry

3536:Bioenergy with carbon capture and storage

3047:

3037:

2194:

2184:

2072:

2054:

2005:

1769:

1334:

1202:

1161:

1151:

1101:

365:Economic viability of biorefinery systems

109:Learn how and when to remove this message

1547:Renewable and Sustainable Energy Reviews

1477:Renewable and Sustainable Energy Reviews

1315:Renewable and Sustainable Energy Reviews

944:

942:

513:The environmental assessment for 1G and

2641:Grand Challenges in Algae Biotechnology

1512:Journal of Polymers and the Environment

949:Hoeven, Diederik van der (2018-01-17).

865:

788:Biomaterials use in sustainable textile

125:The Alpena biorefinery plant in the USA

2447:Pauli, Gunter A. (11 September 2017).

1986:Environmental Science & Technology

1935:Life-Cycle Assessment of Biorefineries

889:

330:Some examples of classifications are:

150:Supply the current fuels and chemical

45:Please improve this article by adding

1928:

1926:

1399:

1397:

173:Classification of biorefinery systems

7:

3604:Cellulosic ethanol commercialization

2377:10.1016/j.applthermaleng.2011.12.038

2287:Computers & Chemical Engineering

2250:International Energy Agency (2017).

2253:Tracking Clean Energy Progress 2017

629:from carbon-containing waste (i.e.

2228:10.1016/b978-0-444-63453-5.00001-x

1943:10.1016/b978-0-444-63585-3.00003-6

849:Renewable energy commercialization

338:and animal feed from starch crops.

334:C6 sugar platform biorefinery for

14:

2585:Jongeling, Coretta (2019-07-08).

2299:10.1016/j.compchemeng.2018.07.019

1683:Chemical Engineering Transactions

1140:Brazilian Journal of Microbiology

770:(thus a 2nd generation feedstock

3652:

3651:

1441:Energy Conversion and Management

1271:Energy Conversion and Management

913:Energy Conversion and Management

742:

728:

341:Syngas platform biorefinery for

23:

2427:Bio-based Industries Consortium

2507:Campbell, Maeve (2020-03-26).

2146:10.1016/j.apenergy.2017.04.040

1909:10.1016/j.biombioe.2008.12.001

1858:10.1016/j.biortech.2016.04.030

1453:10.1016/j.enconman.2014.01.024

1283:10.1016/j.enconman.2018.03.057

1204:10.1016/j.biortech.2016.01.093

1103:10.1016/j.biortech.2011.05.081

925:10.1016/j.enconman.2010.01.015

452:for producing bioethanol from

1:

3693:Bright green environmentalism

3159:Active Biorefinery Facilities

3097:10.1016/j.jclepro.2017.08.039

3085:Journal of Cleaner Production

2186:10.1016/j.jclepro.2018.07.199

2173:Journal of Cleaner Production

2110:10.1016/j.jclepro.2011.03.008

2098:Journal of Cleaner Production

1418:10.1016/j.jclepro.2017.07.218

1406:Journal of Cleaner Production

1372:10.1021/acssuschemeng.8b03770

1240:10.1016/j.indcrop.2019.03.015

1228:Industrial Crops and Products

575:, and food processing waste.

47:secondary or tertiary sources

2965:. 2016-08-15. Archived from

2615:www.worldfoodinnovations.com

2259:. p. 42. Archived from

1937:, Elsevier, pp. 77–96,

1661:10.1016/j.energy.2012.11.041

799:(i.e. as used in e-liquids).

644:MacroCascade aims to refine

612:waste product as feedstock.

3634:Issues relating to biofuels

3624:Energy return on investment

2924:EOS magazine, February 2020

2892:Journal of Cosmetic Science

2778:EOS magazine, December 2019

2649:10.1007/978-3-030-25233-5_8

2365:Applied Thermal Engineering

2222:, Elsevier, pp. 3–33,

143:International Energy Agency

3709:

3026:Biotechnology for Biofuels

2043:Biotechnology for Biofuels

1808:10.1016/j.psep.2018.10.018

1559:10.1016/j.rser.2014.08.075

1489:10.1016/j.rser.2018.02.032

1327:10.1016/j.rser.2018.02.041

919:(7). Elsevier: 1412–1421.

600:is integrated with a host

590:second-generation biofuels

378:Techno-economic assessment

3647:

3609:Energy content of biofuel

3039:10.1186/s13068-016-0676-x

2793:www.blumedistillation.com

2334:10.1007/s12155-016-9735-1

2056:10.1186/s13068-017-0722-3

1715:10.1007/s11356-018-1848-y

1595:10.1007/s10098-014-0741-8

1153:10.1016/j.bjm.2016.10.003

571:region, open pen feedlot

3688:Sustainable technologies

3583:Thermal depolymerization

3556:Industrial biotechnology

3137:Biorefinery from biomass

1028:. Elsevier. p. 59.

1003:. Elsevier. p. 99.

999:Bajpai, Pratima (2013).

687:black soldier fly larvae

229:, starch, cellulose and

209:water-gas shift reaction

195:from anaerobic digestion

3551:Fischer–Tropsch process

3541:Biomass heating systems

3142:Aqueous-Phase Reforming

1524:10.1023/A:1021070006895

736:Renewable energy portal

398:Internal Rate of Return

267:Liquid from pyrolysis (

2830:10.1002/ejlt.201700013

2732:"Sander Van den Bosch"

1846:Bioresource Technology

1191:Bioresource Technology

1090:Bioresource Technology

821:; also just usable as

556:The fully operational

374:

182:

126:

34:relies excessively on

1897:Biomass and Bioenergy

1051:Modeling and Analysis

604:and utilizes a major

504:Life cycle assessment

482:returns on investment

386:municipal solid waste

372:

290:lignocellulosic crops

180:

163:Valorization of waste

124:

3122:Tactical Biorefinery

2875:Kempen Insect Valley

2533:"AlgeCenter Danmark"

422:return on investment

3678:Biofuels technology

3639:Sustainable biofuel

2403:biomassmagazine.com

1998:2007EnST...41.7915H

1709:(36): 35971–35980.

1366:(12): 16563–16572.

766:: can be made into

680:prickly pear cactus

225:from hydrolysis of

2537:AlgeCenter Danmark

2322:BioEnergy Research

1771:10.3390/en11061551

1146:(Suppl 1): 64–76.

627:synthetic palm oil

588:and production of

558:Blue Marble Energy

477:Musa x paradisiaca

375:

217:water electrolysis

183:

127:

3665:

3664:

3578:Sabatier reaction

2969:on April 10, 2021

2760:scholar.google.fr

2756:"Joost Van Aelst"

2736:scholar.google.be

2710:"Research/BIOCON"

2658:978-3-030-25232-8

2557:"Our Ingredients"

2460:978-1-5245-2107-3

2104:(11): 1257–1265.

2007:10.1021/es062559q

1992:(22): 7915–7921.

1096:(17): 7887–7895.

844:Carbon neutrality

402:net present value

358:saw mill residues

201:from gasification

119:

118:

111:

93:

3700:

3655:

3654:

3499:Pongamia pinnata

3193:

3186:

3179:

3170:

3154:Biorefinery Film

3127:Saccharification

3110:

3107:

3101:

3100:

3079:

3073:

3068:

3062:

3061:

3051:

3041:

3017:

3011:

3006:

3000:

2995:

2989:

2984:

2978:

2977:

2975:

2974:

2955:

2949:

2948:

2946:

2945:

2931:

2925:

2922:

2916:

2915:

2883:

2877:

2872:

2866:

2865:

2863:

2862:

2848:

2842:

2841:

2809:

2803:

2802:

2800:

2799:

2785:

2779:

2776:

2770:

2769:

2767:

2766:

2752:

2746:

2745:

2743:

2742:

2728:

2722:

2721:

2719:

2717:

2706:

2700:

2699:

2697:

2696:

2682:

2676:

2675:

2674:

2673:

2631:

2625:

2624:

2622:

2621:

2607:

2601:

2600:

2598:

2597:

2582:

2576:

2575:

2573:

2572:

2563:. Archived from

2561:FUMI Ingredients

2553:

2547:

2546:

2544:

2543:

2529:

2523:

2522:

2520:

2519:

2504:

2498:

2497:

2495:

2494:

2479:

2473:

2472:

2444:

2438:

2437:

2435:

2434:

2419:

2413:

2412:

2410:

2409:

2395:

2389:

2388:

2371:(2): 1427–1436.

2360:

2354:

2353:

2317:

2311:

2310:

2281:

2275:

2274:

2272:

2271:

2265:

2258:

2247:

2241:

2240:

2215:

2209:

2208:

2198:

2188:

2164:

2158:

2157:

2128:

2122:

2121:

2093:

2087:

2086:

2076:

2058:

2034:

2028:

2027:

2009:

1977:

1971:

1970:

1962:

1956:

1955:

1930:

1921:

1920:

1892:

1886:

1885:

1843:

1834:

1828:

1827:

1790:

1784:

1783:

1773:

1749:

1743:

1742:

1697:

1691:

1690:

1680:

1671:

1665:

1664:

1644:

1638:

1637:

1621:

1615:

1614:

1589:(7): 1411–1422.

1577:

1571:

1570:

1542:

1536:

1535:

1507:

1501:

1500:

1471:

1465:

1464:

1436:

1430:

1429:

1401:

1392:

1391:

1355:

1349:

1348:

1338:

1309:

1303:

1302:

1266:

1260:

1259:

1223:

1217:

1216:

1206:

1182:

1176:

1175:

1165:

1155:

1130:

1124:

1123:

1105:

1081:

1075:

1074:

1046:

1040:

1039:

1021:

1015:

1014:

996:

990:

989:

987:

986:

974:Cascade, Macro.

971:

965:

964:

962:

961:

946:

937:

936:

908:

902:

901:

895:

887:

885:

884:

879:

870:

831:(can be used in

752:

747:

746:

738:

733:

732:

219:and fermentation

114:

107:

103:

100:

94:

92:

51:

27:

19:

3708:

3707:

3703:

3702:

3701:

3699:

3698:

3697:

3668:

3667:

3666:

3661:

3643:

3619:Energy forestry

3587:

3519:

3481:Jatropha curcas

3442:

3435:

3343:Camelina sativa

3333:

3326:

3202:

3197:

3118:

3113:

3108:

3104:

3081:

3080:

3076:

3069:

3065:

3019:

3018:

3014:

3007:

3003:

2996:

2992:

2985:

2981:

2972:

2970:

2957:

2956:

2952:

2943:

2941:

2933:

2932:

2928:

2923:

2919:

2885:

2884:

2880:

2873:

2869:

2860:

2858:

2850:

2849:

2845:

2811:

2810:

2806:

2797:

2795:

2787:

2786:

2782:

2777:

2773:

2764:

2762:

2754:

2753:

2749:

2740:

2738:

2730:

2729:

2725:

2715:

2713:

2708:

2707:

2703:

2694:

2692:

2690:www.kuleuven.be

2684:

2683:

2679:

2671:

2669:

2659:

2633:

2632:

2628:

2619:

2617:

2609:

2608:

2604:

2595:

2593:

2591:Resource online

2584:

2583:

2579:

2570:

2568:

2555:

2554:

2550:

2541:

2539:

2531:

2530:

2526:

2517:

2515:

2506:

2505:

2501:

2492:

2490:

2481:

2480:

2476:

2461:

2446:

2445:

2441:

2432:

2430:

2421:

2420:

2416:

2407:

2405:

2397:

2396:

2392:

2362:

2361:

2357:

2319:

2318:

2314:

2283:

2282:

2278:

2269:

2267:

2263:

2256:

2249:

2248:

2244:

2238:

2217:

2216:

2212:

2166:

2165:

2161:

2130:

2129:

2125:

2095:

2094:

2090:

2036:

2035:

2031:

1979:

1978:

1974:

1964:

1963:

1959:

1953:

1932:

1931:

1924:

1894:

1893:

1889:

1841:

1836:

1835:

1831:

1792:

1791:

1787:

1751:

1750:

1746:

1699:

1698:

1694:

1678:

1673:

1672:

1668:

1646:

1645:

1641:

1623:

1622:

1618:

1579:

1578:

1574:

1544:

1543:

1539:

1509:

1508:

1504:

1473:

1472:

1468:

1438:

1437:

1433:

1403:

1402:

1395:

1357:

1356:

1352:

1311:

1310:

1306:

1268:

1267:

1263:

1225:

1224:

1220:

1184:

1183:

1179:

1132:

1131:

1127:

1083:

1082:

1078:

1063:10.1002/bbb.172

1048:

1047:

1043:

1036:

1023:

1022:

1018:

1011:

998:

997:

993:

984:

982:

973:

972:

968:

959:

957:

955:Bio Based Press

948:

947:

940:

910:

909:

905:

888:

882:

880:

877:

872:

871:

867:

863:

858:

748:

741:

734:

727:

724:

623:C16 Biosciences

610:sulfite process

581:technology for

554:

538:

495:

367:

257:

253:

249:

213:steam reforming

175:

152:building blocks

115:

104:

98:

95:

52:

50:

44:

40:primary sources

28:

17:

12:

11:

5:

3706:

3704:

3696:

3695:

3690:

3685:

3683:Oil refineries

3680:

3670:

3669:

3663:

3662:

3660:

3659:

3648:

3645:

3644:

3642:

3641:

3636:

3631:

3626:

3621:

3616:

3611:

3606:

3601:

3595:

3593:

3589:

3588:

3586:

3585:

3580:

3575:

3574:

3573:

3568:

3558:

3553:

3548:

3543:

3538:

3533:

3527:

3525:

3521:

3520:

3518:

3517:

3512:

3507:

3502:

3495:

3484:

3477:

3472:

3470:Chinese tallow

3467:

3460:

3455:

3447:

3445:

3437:

3436:

3434:

3433:

3428:

3423:

3418:

3413:

3408:

3403:

3396:

3391:

3386:

3381:

3376:

3371:

3366:

3361:

3356:

3351:

3346:

3338:

3336:

3328:

3327:

3325:

3324:

3319:

3317:Water hyacinth

3314:

3309:

3308:

3307:

3297:

3292:

3291:

3290:

3285:

3275:

3274:

3273:

3263:

3258:

3253:

3248:

3243:

3238:

3233:

3228:

3223:

3218:

3212:

3210:

3204:

3203:

3198:

3196:

3195:

3188:

3181:

3173:

3167:

3166:

3161:

3156:

3151:

3145:

3139:

3134:

3129:

3124:

3117:

3116:External links

3114:

3112:

3111:

3102:

3074:

3063:

3012:

3001:

2990:

2979:

2950:

2926:

2917:

2898:(3): 187–202.

2878:

2867:

2843:

2824:(8): 1700013.

2804:

2780:

2771:

2747:

2723:

2701:

2677:

2657:

2626:

2602:

2577:

2548:

2524:

2499:

2474:

2459:

2439:

2414:

2390:

2355:

2328:(2): 518–533.

2312:

2276:

2242:

2236:

2210:

2159:

2134:Applied Energy

2123:

2088:

2029:

1972:

1957:

1951:

1922:

1903:(5): 793–802.

1887:

1829:

1785:

1744:

1692:

1666:

1639:

1616:

1572:

1537:

1502:

1466:

1431:

1393:

1350:

1304:

1261:

1218:

1177:

1125:

1076:

1057:(5): 534–546.

1041:

1034:

1016:

1009:

991:

966:

938:

903:

864:

862:

859:

857:

856:

854:Maggot farming

851:

846:

841:

836:

826:

800:

790:

785:

775:

761:

755:

754:

753:

739:

723:

720:

715:Zophobas morio

657:brewer's yeast

648:into food and

637:) by means of

553:

550:

537:

534:

520:Propionic acid

500:eutrophication

494:

491:

459:dimethyl ether

418:payback period

366:

363:

362:

361:

350:

339:

328:

327:

324:

321:

318:

311:

310:

309:

308:

305:

302:

299:

293:

286:

285:

284:

281:

274:

273:

272:

265:

259:

255:

251:

247:

233:

220:

202:

196:

174:

171:

170:

169:

166:

160:

157:

154:

137:that converts

117:

116:

31:

29:

22:

15:

13:

10:

9:

6:

4:

3:

2:

3705:

3694:

3691:

3689:

3686:

3684:

3681:

3679:

3676:

3675:

3673:

3658:

3650:

3649:

3646:

3640:

3637:

3635:

3632:

3630:

3629:Food vs. fuel

3627:

3625:

3622:

3620:

3617:

3615:

3612:

3610:

3607:

3605:

3602:

3600:

3597:

3596:

3594:

3590:

3584:

3581:

3579:

3576:

3572:

3569:

3567:

3564:

3563:

3562:

3559:

3557:

3554:

3552:

3549:

3547:

3544:

3542:

3539:

3537:

3534:

3532:

3529:

3528:

3526:

3522:

3516:

3513:

3511:

3508:

3506:

3503:

3501:

3500:

3496:

3494:

3493:

3489:

3485:

3483:

3482:

3478:

3476:

3473:

3471:

3468:

3466:

3465:

3461:

3459:

3456:

3454:

3453:

3449:

3448:

3446:

3444:

3438:

3432:

3429:

3427:

3424:

3422:

3419:

3417:

3414:

3412:

3409:

3407:

3404:

3402:

3401:

3397:

3395:

3392:

3390:

3387:

3385:

3382:

3380:

3377:

3375:

3372:

3370:

3367:

3365:

3362:

3360:

3357:

3355:

3352:

3350:

3347:

3345:

3344:

3340:

3339:

3337:

3335:

3329:

3323:

3320:

3318:

3315:

3313:

3310:

3306:

3303:

3302:

3301:

3298:

3296:

3293:

3289:

3286:

3284:

3281:

3280:

3279:

3276:

3272:

3271:vegetable oil

3269:

3268:

3267:

3264:

3262:

3259:

3257:

3254:

3252:

3249:

3247:

3244:

3242:

3239:

3237:

3234:

3232:

3229:

3227:

3224:

3222:

3219:

3217:

3214:

3213:

3211:

3209:

3205:

3201:

3194:

3189:

3187:

3182:

3180:

3175:

3174:

3171:

3165:

3162:

3160:

3157:

3155:

3152:

3149:

3146:

3143:

3140:

3138:

3135:

3133:

3130:

3128:

3125:

3123:

3120:

3119:

3115:

3106:

3103:

3098:

3094:

3090:

3086:

3078:

3075:

3072:

3067:

3064:

3059:

3055:

3050:

3045:

3040:

3035:

3031:

3027:

3023:

3016:

3013:

3010:

3005:

3002:

2999:

2994:

2991:

2988:

2983:

2980:

2968:

2964:

2960:

2954:

2951:

2940:

2936:

2930:

2927:

2921:

2918:

2913:

2909:

2905:

2901:

2897:

2893:

2889:

2882:

2879:

2876:

2871:

2868:

2857:

2853:

2847:

2844:

2839:

2835:

2831:

2827:

2823:

2819:

2815:

2808:

2805:

2794:

2790:

2784:

2781:

2775:

2772:

2761:

2757:

2751:

2748:

2737:

2733:

2727:

2724:

2711:

2705:

2702:

2691:

2687:

2681:

2678:

2668:

2664:

2660:

2654:

2650:

2646:

2642:

2638:

2630:

2627:

2616:

2612:

2606:

2603:

2592:

2588:

2581:

2578:

2567:on 2020-11-30

2566:

2562:

2558:

2552:

2549:

2538:

2534:

2528:

2525:

2514:

2510:

2503:

2500:

2488:

2487:Bloomberg.com

2484:

2478:

2475:

2470:

2466:

2462:

2456:

2452:

2451:

2443:

2440:

2428:

2424:

2418:

2415:

2404:

2400:

2394:

2391:

2386:

2382:

2378:

2374:

2370:

2366:

2359:

2356:

2351:

2347:

2343:

2339:

2335:

2331:

2327:

2323:

2316:

2313:

2308:

2304:

2300:

2296:

2292:

2288:

2280:

2277:

2266:on 2018-05-07

2262:

2255:

2254:

2246:

2243:

2239:

2237:9780444634535

2233:

2229:

2225:

2221:

2214:

2211:

2206:

2202:

2197:

2192:

2187:

2182:

2178:

2174:

2170:

2163:

2160:

2155:

2151:

2147:

2143:

2139:

2135:

2127:

2124:

2119:

2115:

2111:

2107:

2103:

2099:

2092:

2089:

2084:

2080:

2075:

2070:

2066:

2062:

2057:

2052:

2048:

2044:

2040:

2033:

2030:

2025:

2021:

2017:

2013:

2008:

2003:

1999:

1995:

1991:

1987:

1983:

1976:

1973:

1968:

1961:

1958:

1954:

1952:9780444635853

1948:

1944:

1940:

1936:

1929:

1927:

1923:

1918:

1914:

1910:

1906:

1902:

1898:

1891:

1888:

1883:

1879:

1875:

1871:

1867:

1863:

1859:

1855:

1851:

1847:

1840:

1833:

1830:

1825:

1821:

1817:

1813:

1809:

1805:

1801:

1797:

1789:

1786:

1781:

1777:

1772:

1767:

1763:

1759:

1755:

1748:

1745:

1740:

1736:

1732:

1728:

1724:

1720:

1716:

1712:

1708:

1704:

1696:

1693:

1688:

1684:

1677:

1670:

1667:

1662:

1658:

1654:

1650:

1643:

1640:

1635:

1631:

1627:

1620:

1617:

1612:

1608:

1604:

1600:

1596:

1592:

1588:

1584:

1576:

1573:

1568:

1564:

1560:

1556:

1553:: 1446–1466.

1552:

1548:

1541:

1538:

1533:

1529:

1525:

1521:

1517:

1513:

1506:

1503:

1498:

1494:

1490:

1486:

1482:

1478:

1470:

1467:

1462:

1458:

1454:

1450:

1446:

1442:

1435:

1432:

1427:

1423:

1419:

1415:

1412:: 3655–3668.

1411:

1407:

1400:

1398:

1394:

1389:

1385:

1381:

1377:

1373:

1369:

1365:

1361:

1354:

1351:

1346:

1342:

1337:

1332:

1328:

1324:

1320:

1316:

1308:

1305:

1300:

1296:

1292:

1288:

1284:

1280:

1276:

1272:

1265:

1262:

1257:

1253:

1249:

1245:

1241:

1237:

1233:

1229:

1222:

1219:

1214:

1210:

1205:

1200:

1196:

1192:

1188:

1181:

1178:

1173:

1169:

1164:

1159:

1154:

1149:

1145:

1141:

1137:

1129:

1126:

1121:

1117:

1113:

1109:

1104:

1099:

1095:

1091:

1087:

1080:

1077:

1072:

1068:

1064:

1060:

1056:

1052:

1045:

1042:

1037:

1035:9780444594983

1031:

1027:

1020:

1017:

1012:

1010:9780124095083

1006:

1002:

995:

992:

981:

980:Macro Cascade

977:

970:

967:

956:

952:

945:

943:

939:

934:

930:

926:

922:

918:

914:

907:

904:

899:

893:

876:

869:

866:

860:

855:

852:

850:

847:

845:

842:

840:

837:

834:

830:

827:

824:

820:

816:

815:essential oil

812:

808:

807:succinic acid

804:

801:

798:

794:

791:

789:

786:

783:

779:

776:

773:

769:

765:

762:

760:

757:

756:

751:

750:Energy portal

745:

740:

737:

731:

726:

721:

719:

717:

716:

710:

708:

704:

700:

696:

692:

688:

683:

681:

676:

673:

669:

664:

662:

661:baker's yeast

658:

653:

651:

647:

642:

640:

636:

632:

628:

624:

620:

618:

613:

611:

607:

603:

599:

595:

591:

587:

584:

580:

576:

574:

570:

566:

565:Himark BioGas

561:

559:

551:

549:

547:

542:

535:

533:

529:

526:

521:

516:

511:

507:

505:

501:

492:

490:

487:

483:

479:

478:

473:

468:

465:

460:

455:

451:

450:kraft process

445:

442:

438:

433:

432:

427:

423:

419:

415:

411:

405:

403:

399:

394:

389:

387:

383:

379:

371:

364:

359:

355:

351:

348:

344:

340:

337:

333:

332:

331:

325:

322:

319:

316:

315:

314:

306:

303:

300:

297:

296:

294:

291:

287:

282:

279:

278:

275:

270:

269:pyrolysis oil

266:

263:

260:

245:

241:

237:

234:

232:

231:hemicellulose

228:

224:

221:

218:

214:

210:

206:

203:

200:

197:

194:

191:

190:

188:

187:

186:

179:

172:

167:

164:

161:

158:

155:

153:

149:

148:

147:

144:

140:

136:

132:

123:

113:

110:

102:

91:

88:

84:

81:

77:

74:

70:

67:

63:

60: –

59:

58:"Biorefinery"

55:

54:Find sources:

48:

42:

41:

37:

32:This article

30:

26:

21:

20:

3545:

3497:

3491:

3487:

3479:

3462:

3458:Big bluestem

3450:

3443:energy crops

3398:

3341:

3105:

3088:

3084:

3077:

3066:

3029:

3025:

3015:

3004:

2993:

2982:

2971:. Retrieved

2967:the original

2962:

2953:

2942:. Retrieved

2938:

2929:

2920:

2895:

2891:

2881:

2870:

2859:. Retrieved

2855:

2846:

2821:

2817:

2807:

2796:. Retrieved

2792:

2783:

2774:

2763:. Retrieved

2759:

2750:

2739:. Retrieved

2735:

2726:

2714:. Retrieved

2704:

2693:. Retrieved

2689:

2680:

2670:, retrieved

2640:

2629:

2618:. Retrieved

2614:

2605:

2594:. Retrieved

2590:

2580:

2569:. Retrieved

2565:the original

2560:

2551:

2540:. Retrieved

2536:

2527:

2516:. Retrieved

2512:

2502:

2491:. Retrieved

2489:. 2020-03-02

2486:

2477:

2449:

2442:

2431:. Retrieved

2429:. 2014-12-11

2426:

2417:

2406:. Retrieved

2402:

2393:

2368:

2364:

2358:

2325:

2321:

2315:

2290:

2286:

2279:

2268:. Retrieved

2261:the original

2252:

2245:

2219:

2213:

2196:10397/101206

2176:

2172:

2162:

2137:

2133:

2126:

2101:

2097:

2091:

2046:

2042:

2032:

1989:

1985:

1975:

1966:

1960:

1934:

1900:

1896:

1890:

1849:

1845:

1832:

1799:

1795:

1788:

1761:

1757:

1747:

1706:

1702:

1695:

1686:

1682:

1669:

1652:

1648:

1642:

1636:: 6817–6830.

1633:

1630:BioResources

1629:

1619:

1586:

1582:

1575:

1550:

1546:

1540:

1515:

1511:

1505:

1480:

1476:

1469:

1444:

1440:

1434:

1409:

1405:

1363:

1359:

1353:

1336:2318/1664231

1318:

1314:

1307:

1274:

1270:

1264:

1231:

1227:

1221:

1194:

1190:

1180:

1143:

1139:

1128:

1093:

1089:

1079:

1054:

1050:

1044:

1025:

1019:

1000:

994:

983:. Retrieved

979:

969:

958:. Retrieved

954:

916:

912:

906:

881:. Retrieved

868:

839:Gasification

713:

711:

684:

677:

665:

654:

643:

621:

614:

586:gasification

583:black liquor

577:

562:

555:

543:

539:

530:

512:

508:

496:

475:

471:

469:

446:

440:

436:

429:

410:acrylic acid

406:

390:

376:

329:

312:

184:

130:

128:

105:

96:

86:

79:

72:

65:

53:

33:

3614:Energy crop

3561:Pellet fuel

3546:Biorefinery

3510:Switchgrass

3354:Coconut oil

3332:Energy from

3266:Cooking oil

3251:Biogasoline

3226:Babassu oil

3091:: 706–716.

2453:. Xlibris.

2179:: 840–848.

2140:: 440–452.

1852:: 131–143.

1802:: 194–208.

1764:(6): 1551.

1483:: 239–257.

1447:: 525–534.

1321:: 326–346.

1234:: 259–268.

833:CHP systems

707:surfactants

594:biomethanol

546:corn stover

131:biorefinery

3672:Categories

3524:Technology

3505:Salicornia

3488:Miscanthus

3411:Sugar beet

3283:cellulosic

3256:Bioliquids

3236:Biobutanol

3132:Biosynergy

2973:2022-08-03

2944:2022-08-03

2935:"BITEBACK"

2861:2022-08-03

2798:2022-08-03

2765:2022-08-03

2741:2022-08-03

2695:2022-08-02

2672:2022-08-02

2620:2022-08-02

2596:2022-08-02

2571:2022-08-02

2542:2022-08-02

2518:2022-08-02

2493:2022-08-02

2469:1021287775

2433:2022-08-02

2423:"Novamont"

2408:2022-08-02

2270:2019-03-04

1689:: 427–432.

985:2022-08-02

976:"Products"

960:2022-08-02

883:2019-02-11

861:References

772:bioplastic

764:Food waste

759:Microalgae

631:food waste

515:2G ethanol

426:microalgae

349:from straw

336:bioethanol

69:newspapers

36:references

3599:Agflation

3492:giganteus

3421:Sunflower

3416:Sugarcane

3334:foodstock

3241:Biodiesel

3200:Bioenergy

2904:1525-7886

2838:1438-7697

2667:213905222

2385:1359-4311

2342:1939-1234

2293:: 70–84.

2205:0959-6526

2154:0306-2619

2118:0959-6526

2065:1754-6834

2049:(1): 50.

2016:0013-936X

1917:0961-9534

1866:0960-8524

1824:105125791

1816:0957-5820

1780:1996-1073

1723:0944-1344

1655:: 83–92.

1611:111152226

1603:1618-954X

1567:1364-0321

1532:136857454

1518:: 39–48.

1497:1364-0321

1461:0196-8904

1426:0959-6526

1388:105754039

1380:2168-0485

1345:1364-0321

1299:102815519

1291:0196-8904

1277:: 76–91.

1256:108653056

1248:0926-6690

1197:: 42–48.

1112:0960-8524

933:0196-8904

819:cellulose

703:cosmetics

672:cellulose

625:produces

602:pulp mill

579:Chemrec's

454:softwoods

382:biodiesel

343:FT-diesel

244:arabinose

236:C5 sugars

223:C6 sugars

99:June 2019

3657:Category

3592:Concepts

3475:Duckweed

3464:Camelina

3441:Non-food

3389:Rapeseed

3379:Palm oil

3322:Wood gas

3295:Methanol

3288:mixtures

3208:Biofuels

3058:27980671

2939:BITEBACK

2912:30052193

2856:BBC News

2716:3 August

2513:euronews

2350:14901394

2307:53791073

2083:28293288

2024:18075108

1882:20163159

1874:27085988

1758:Energies

1731:29626328

1213:26918837

1172:27818090

1120:21689929

1071:84298986

892:cite web

797:nicotine

782:lycopene

722:See also

635:glycerol

592:such as

569:Edmonton

552:Examples

498:change,

486:fructose

464:catechol

441:Jatropha

437:Jatropha

431:Jatropha

414:palm oil

354:furfural

205:Hydrogen

135:refinery

3406:Soybean

3400:Sorghum

3349:Cassava

3278:Ethanol

3261:Biomass

3231:Bagasse

3216:Alcohol

3049:5133755

3032:: 261.

2963:Culture

2074:5348788

1994:Bibcode

1739:4653627

1163:5156502

829:Biomass

793:Tobacco

691:protein

646:seaweed

617:cardoon

606:sulfate

525:butanol

393:bagasse

347:phenols

238:(e.g.,

227:sucrose

139:biomass

83:scholar

3452:Arundo

3384:Potato

3300:Stover

3246:Biogas

3056:

3046:

2910:

2902:

2836:

2712:. 2017

2665:

2655:

2467:

2457:

2383:

2348:

2340:

2305:

2234:

2203:

2152:

2116:

2081:

2071:

2063:

2022:

2014:

1949:

1915:

1880:

1872:

1864:

1822:

1814:

1778:

1737:

1729:

1721:

1649:Energy

1609:

1601:

1565:

1530:

1495:

1459:

1424:

1386:

1378:

1343:

1297:

1289:

1254:

1246:

1211:

1170:

1160:

1118:

1110:

1069:

1032:

1007:

931:

811:pectin

803:Citrus

778:Tomato

699:chitin

697:, and

695:grease

668:lignin

650:fodder

596:or Bio

573:manure

262:Lignin

240:xylose

199:Syngas

193:Biogas

85:

78:

71:

64:

56:

3571:stove

3426:Wheat

3369:Maize

3359:Grape

3312:Straw

3221:Algae

2663:S2CID

2346:S2CID

2303:S2CID

2264:(PDF)

2257:(PDF)

1878:S2CID

1842:(PDF)

1820:S2CID

1735:S2CID

1679:(PDF)

1607:S2CID

1528:S2CID

1384:S2CID

1295:S2CID

1252:S2CID

1067:S2CID

878:(PDF)

639:yeast

356:from

207:from

133:is a

90:JSTOR

76:books

3566:mill

3515:Wood

3394:Rice

3364:Hemp

3305:corn

3054:PMID

2908:PMID

2900:ISSN

2834:ISSN

2718:2022

2653:ISBN

2465:OCLC

2455:ISBN

2381:ISSN

2338:ISSN

2232:ISBN

2201:ISSN

2150:ISSN

2114:ISSN

2079:PMID

2061:ISSN

2020:PMID

2012:ISSN

1947:ISBN

1913:ISSN

1870:PMID

1862:ISSN

1812:ISSN

1776:ISSN

1727:PMID

1719:ISSN

1599:ISSN

1563:ISSN

1493:ISSN

1457:ISSN

1422:ISSN

1376:ISSN

1341:ISSN

1287:ISSN

1244:ISSN

1209:PMID

1168:PMID

1116:PMID

1108:ISSN

1030:ISBN

1005:ISBN

929:ISSN

898:link

823:zest

670:and

659:and

428:and

420:and

345:and

62:news

3431:Yam

3374:Oat

3093:doi

3089:166

3044:PMC

3034:doi

2826:doi

2822:119

2645:doi

2373:doi

2330:doi

2295:doi

2291:119

2224:doi

2191:hdl

2181:doi

2177:199

2142:doi

2138:198

2106:doi

2069:PMC

2051:doi

2002:doi

1939:doi

1905:doi

1854:doi

1850:215

1804:doi

1800:121

1766:doi

1711:doi

1657:doi

1591:doi

1555:doi

1520:doi

1485:doi

1449:doi

1414:doi

1410:172

1368:doi

1331:hdl

1323:doi

1279:doi

1275:165

1236:doi

1232:133

1199:doi

1195:208

1158:PMC

1148:doi

1098:doi

1094:102

1059:doi

921:doi

768:PHA

718:).

608:or

598:DME

435:of

246:: C

38:to

3674::

3490:×

3087:.

3052:.

3042:.

3028:.

3024:.

2961:.

2937:.

2906:.

2896:69

2894:.

2890:.

2854:.

2832:.

2820:.

2816:.

2791:.

2758:.

2734:.

2688:.

2661:,

2651:,

2639:,

2613:.

2589:.

2559:.

2535:.

2511:.

2485:.

2463:.

2425:.

2401:.

2379:.

2369:50

2367:.

2344:.

2336:.

2324:.

2301:.

2289:.

2230:,

2199:.

2189:.

2175:.

2171:.

2148:.

2136:.

2112:.

2102:19

2100:.

2077:.

2067:.

2059:.

2047:10

2045:.

2041:.

2018:.

2010:.

2000:.

1990:41

1988:.

1984:.

1945:,

1925:^

1911:.

1901:33

1899:.

1876:.

1868:.

1860:.

1848:.

1844:.

1818:.

1810:.

1798:.

1774:.

1762:11

1760:.

1756:.

1733:.

1725:.

1717:.

1707:25

1705:.

1687:61

1685:.

1681:.

1653:50

1651:.

1632:.

1628:.

1605:.

1597:.

1587:16

1585:.

1561:.

1551:43

1549:.

1526:.

1516:10

1514:.

1491:.

1481:88

1479:.

1455:.

1445:80

1443:.

1420:.

1408:.

1396:^

1382:.

1374:.

1362:.

1339:.

1329:.

1319:88

1317:.

1293:.

1285:.

1273:.

1250:.

1242:.

1230:.

1207:.

1193:.

1189:.

1166:.

1156:.

1144:47

1142:.

1138:.

1114:.

1106:.

1092:.

1088:.

1065:.

1053:.

978:.

953:.

941:^

927:.

917:15

915:.

894:}}

890:{{

817:,

813:,

809:,

705:,