171:

17:

252:

Membrane performance can suffer from fouling-induced mechanical degradation. This may result in unwanted pressure and flux gradients, both of the solute and the solvent. The mechanism of membrane failure may be the direct consequence of fouling by means of physical alterations to the membrane, or by

141:

Recent fundamental studies indicate that membrane fouling is influenced by numerous factors such as system hydrodynamics, operating conditions, membrane properties, and material properties (solute). At low pressure, low feed concentration, and high feed velocity, concentration polarisation effects

287:. This is a process whereby existing imperfections in the membrane (such as microcracks) can grow and propagate due to the complex stress state dynamics. These impacts are not unknown; A 2007 study simulated aging via cyclic backwash pulses, and reported similar embrittlement due to the effects.

282:

Beyond direct physical damage, fouling can also induce indirect effects on membrane mechanical properties due to the strategies used to combat it. Backwashing subjects not only the particulates, but the membrane to strong shear forces. Greater fouling frequency therefore exposes the membrane to

130:. Formation of a strong matrix of fouling layer with the solute during a continuous filtration process will result in reversible fouling being transformed into an irreversible fouling layer. Irreversible fouling is the strong attachment of particles which cannot be removed by physical cleaning.

261:

It is important to note that the majority of membranes used commercially are polymers such as polyvinylidene fluoride (PVDF), polyacrylonitrile (PAN), polyethersulfone (PES) and polyamide (PA), which are materials which offer desirable properties (elasticity and strength) to withstand constant

269:

material with a soft polymer membrane, weakening its structural integrity. Degradation of the mechanical structure makes the membranes more susceptible to mechanical damage, potentially reducing its overall lifespan. A 2006 study observed this degradation by uniaxially straining

208:

Additionally, researchers have investigated the impact different coatings have on resistance to wear. A 2018 study from the Global Aqua

Innovation Center in Japan reported improved surface roughness properties of PA membranes by coating them with multi-walled carbon nanotubes.

158:(TMP), Permeability, and Resistance are the best indicators of membrane fouling. Under constant flux operation, TMP increases to compensate for the fouling. On the other hand, under constant pressure operation, flux declines due to membrane fouling. In some technologies such as

290:

Additionally, repeated chemical treatment of fouling subjects membranes to excessive amounts of chlorine or other treatment chemicals which can cause degradation. This chemical degradation can lead to delamination of the membrane components, ultimately leading to failure.

422:

Tow, Emily W.; Warsinger, David M.; Trueworthy, Ali M.; Swaminathan, Jaichander; Thiel, Gregory P.; Zubair, Syed M.; Myerson, Allan S.; Lienhard V, John H. (2018). "Comparison of fouling propensity between reverse osmosis, forward osmosis, and membrane distillation".

586:

689:

Warsinger, David M.; Servi, Amelia; Connors, Grace B.; Mavukkandy, Musthafa O.; Arafat, Hassan A.; Gleason, Karen K.; Lienhard V, John H. (2017). "Reversing membrane wetting in membrane distillation: comparing dryout to backwashing with pressurized air".

212:

Another strategy to minimise membrane fouling is the use of the appropriate membrane for a specific operation. The nature of the feed water must first be known; then a membrane that is less prone to fouling with that solution is chosen. For aqueous

469:

142:

are minimal and flux is almost proportional to trans-membrane pressure difference. However, in the high pressure range, flux becomes almost independent of applied pressure. Deviation from linear flux-pressure relation is due to

571:

Choi, H., Zhang, K., Dionysiou, D.D.,Oerther, D.B.& Sorial, G.A. (2005) Effect of permeate flux and tangential flow on membrane fouling for wastewater treatment. J. Separation and

Purification Technology 45:

835:

Warsinger, David M.; Servi, Amelia; Van

Belleghem, Sarah; Gonzalez, Jocelyn; Swaminathan, Jaichander; Kharraz, Jehad; Chung, Hyung Won; Arafat, Hassan A.; Gleason, Karen K.; Lienhard V, John H. (2016).

325:

Meng, Fangang; Yang, Fenglin; Shi, Baoqiang; Zhang, Hanmin (February 2008). "A comprehensive study on membrane fouling in submerged membrane bioreactors operated under different aeration intensities".

126:

Fouling can be divided into reversible and irreversible fouling based on the attachment strength of particles to the membrane surface. Reversible fouling can be removed by a strong shear force or

800:

Goosen, M. F. A.; Sablani, S. S.; Al-Hinai, H.; Al-Obeidani, S.; Al-Belushi, R.; Jackson, D. (2005-01-02). "Fouling of

Reverse Osmosis and Ultrafiltration Membranes: A Critical Review".

265:

The accumulation of foulants can lead to the formation of cracks, surface roughening, and changes in pore size distribution. These physical changes are the result of impacts of

837:

735:

Ortiz-Medina, J.; Inukai, S.; Araki, T.; Morelos-Gomez, A.; Cruz-Silva, R.; Takeuchi, K.; Noguchi, T.; Kawaguchi, T.; Terrones, M.; Endo, M. (2018-02-09).

162:, fouling reduces membrane rejection, and thus permeate quality (e.g. as measured by electrical conductivity) is a primary measurement for fouling.

528:

Hong, Seungkwan; Elimelech, Menachem (1997). "Chemical and physical aspects of natural organic matter (NOM) fouling of nanofiltration membranes".

185:

Membranes can be cleaned physically, biologically or chemically. Physical cleaning includes gas scour, sponges, water jets or backflushing using

262:

osmotic pressures. The accumulation of foulants, however, degrades these properties through physical alterations to the membrane structure.

228:

Operating conditions during membrane filtration are also vital, as they may affect fouling conditions during filtration. For instance,

1036:"Chlorine-resistant membrane for reverse osmosis. I. Correlation between chemical structures and chlorine resistance of polyamides"

146:. At low feed flow rate or with high feed concentration, the limiting flux situation is observed even at relatively low pressures.

587:"Theoretical framework for predicting inorganic fouling in membrane distillation and experimental validation with calcium sulfate"

300:

352:

Warsinger, David M.; Tow, Emily W.; Maswadeh, Laith A.; Connors, Grace B.; Swaminathan, Jaichander; Lienhard V, John H. (2018).

244:). In some applications such as in many MBR applications, air scour is used to promote turbulence at the membrane surface.

127:

182:, it can be minimised by strategies such as cleaning, appropriate membrane selection and choice of operating conditions.

1081:

468:

Warsinger, David M.; Swaminathan, Jaichander; Guillen-Burrieza, Elena; Arafat, Hassan A.; Lienhard V, John H. (2015).

143:

1071:

155:

838:"Combining air recharging and membrane superhydrophobicity for fouling prevention in membrane distillation"

274:

that were both clean and fouled. The researchers reported the relative embrittlement of the fouled fibers.

20:

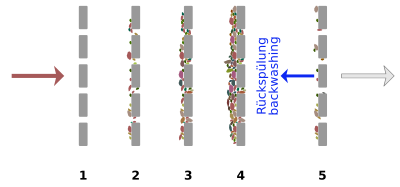

Fouling of a membrane in different steps 1–5. 1) virgin membrane 2) pore narrowing 3) pore blocking 4)

271:

222:

159:

56:

996:

939:

892:

240:

generated during the filtration entails a thinner deposit layer and therefore minimises fouling (e.g.

951:

904:

891:

Wang, Kui; Abdalla, Ahmed A.; Khaleel, Mohammad A.; Hilal, Nidal; Khraisheh, Marwan K. (2017-01-02).

748:

655:

484:

365:

241:

229:

71:

so that the membrane's performance is degraded. It is a major obstacle to the widespread use of this

32:

233:

179:

72:

44:

1035:

305:

284:

40:

1016:

977:

920:

870:

817:

782:

764:

737:"Robust water desalination membranes against degradation using high loads of carbon nanotubes"

717:

671:

636:

Ghosh, R., 2006, Principles of

Bioseparation Engineering, World Scientific Publishing Pvt Ltd.

619:

545:

510:

450:

401:

393:

1076:

1047:

1008:

967:

959:

912:

860:

852:

809:

772:

756:

707:

699:

663:

611:

601:

562:

Baker, R.W. (2004). Membrane

Technology and Applications, England: John Wiley & Sons Ltd

537:

500:

492:

440:

432:

383:

373:

334:

202:

120:

88:

112:

64:

60:

52:

48:

585:

Warsinger, David M.; Tow, Emily W.; Swaminathan, Jaichander; Lienhard V, John H. (2017).

83:

decline and affect the quality of the water produced. Severe fouling may require intense

955:

908:

752:

659:

488:

369:

777:

736:

194:

68:

646:

Liberman, Boris (2018). "Three methods of forward osmosis cleaning for RO membranes".

541:

470:"Scaling and fouling in membrane distillation for desalination applications: A review"

1065:

96:

1012:

856:

606:

436:

378:

353:

338:

997:"Statistical analysis of data from accelerated ageing tests of PES UF membranes"

963:

916:

893:"Mechanical properties of water desalination and wastewater treatment membranes"

667:

496:

21:

1051:

760:

253:

indirect means, in which the foulant removal processes yield membrane damage.

170:

237:

218:

214:

1020:

981:

924:

874:

821:

768:

721:

675:

623:

549:

514:

454:

397:

16:

786:

405:

354:"Inorganic fouling mitigation by salinity cycling in batch reverse osmosis"

87:

cleaning or membrane replacement. This increases the operating costs of a

865:

813:

712:

615:

505:

445:

388:

266:

186:

100:

84:

36:

940:"Fouling autopsy of hollow-fibre MF membranes in wastewater reclamation"

703:

190:

92:

76:

972:

198:

169:

116:

104:

995:

Zondervan, Edwin; Zwijnenburg, Arie; Roffel, Brian (2007-08-15).

178:

Even though membrane fouling is an inevitable phenomenon during

108:

80:

248:

Impact of

Fouling on the Mechanical Properties of Membranes

43:

surface or in membrane pores in a processes such as in a

692:

Environmental

Science: Water Research & Technology

1034:

Kawaguchi, Takeyuki; Tamura, Hiroki (November 1984).

174:

Sediment accumulated on the reverse osmosis membrane.

580:

578:

938:Nghiem, Long D.; Schäfer, Andrea I. (2006-02-05).

197:, whereas chemical cleaning involves the use of

189:or pressurized air. Biological cleaning uses

8:

946:. Integrated Concepts in Water Recycling.

971:

864:

776:

711:

605:

504:

444:

387:

377:

417:

415:

15:

317:

225:, a hydrophobic membrane is preferred.

91:. There are various types of foulants:

327:Separation and Purification Technology

138:Factors that affect membrane fouling:

886:

884:

7:

899:. 50th anniversary of Desalination.

24:layer formation 5) cleaned membrane

205:to remove foulants and impurities.

1040:Journal of Applied Polymer Science

14:

802:Separation Science and Technology

283:cyclic loading which can lead to

301:Vibratory shear-enhanced process

1:

542:10.1016/s0376-7388(97)00060-4

1013:10.1016/j.memsci.2007.05.015

857:10.1016/j.memsci.2016.01.018

607:10.1016/j.memsci.2017.01.031

437:10.1016/j.memsci.2018.03.065

379:10.1016/j.watres.2018.01.060

339:10.1016/j.seppur.2007.05.040

1001:Journal of Membrane Science

964:10.1016/j.desal.2005.04.108

917:10.1016/j.desal.2016.06.032

845:Journal of Membrane Science

668:10.1016/j.desal.2017.11.023

594:Journal of Membrane Science

530:Journal of Membrane Science

497:10.1016/j.desal.2014.06.031

425:Journal of Membrane Science

278:Indirect Impacts of Fouling

221:membrane is preferred. For

1098:

1052:10.1002/app.1984.070291113

761:10.1038/s41598-018-21192-5

144:concentration polarization

257:Direct Impacts of Fouling

123:(mineral precipitates).

31:is a process whereby a

232:is often preferred to

175:

156:transmembrane pressure

25:

223:membrane distillation

193:to remove all viable

173:

160:membrane distillation

57:membrane distillation

19:

814:10.1081/ss-120039343

242:tubular pinch effect

230:crossflow filtration

1082:Membrane technology

956:2006Desal.188..113N

909:2017Desal.401..190W

753:2018NatSR...8.2748O

660:2018Desal.431...22L

489:2015Desal.356..294W

370:2018WatRe.137..384W

234:dead end filtration

180:membrane filtration

134:Influential factors

45:membrane bioreactor

741:Scientific Reports

704:10.1039/c7ew00085e

306:Water purification

176:

39:is deposited on a

26:

1046:(11): 3359–3367.

808:(10): 2261–2297.

79:can cause severe

1089:

1072:Water technology

1056:

1055:

1031:

1025:

1024:

992:

986:

985:

975:

935:

929:

928:

888:

879:

878:

868:

842:

832:

826:

825:

797:

791:

790:

780:

732:

726:

725:

715:

686:

680:

679:

643:

637:

634:

628:

627:

609:

591:

582:

573:

569:

563:

560:

554:

553:

525:

519:

518:

508:

474:

465:

459:

458:

448:

419:

410:

409:

391:

381:

349:

343:

342:

322:

113:polyelectrolytes

29:Membrane fouling

1097:

1096:

1092:

1091:

1090:

1088:

1087:

1086:

1062:

1061:

1060:

1059:

1033:

1032:

1028:

994:

993:

989:

937:

936:

932:

890:

889:

882:

840:

834:

833:

829:

799:

798:

794:

734:

733:

729:

688:

687:

683:

645:

644:

640:

635:

631:

589:

584:

583:

576:

570:

566:

561:

557:

527:

526:

522:

472:

467:

466:

462:

421:

420:

413:

351:

350:

346:

324:

323:

319:

314:

297:

285:fatigue failure

280:

259:

250:

168:

166:Fouling control

152:

136:

99:), biological (

89:treatment plant

65:microfiltration

61:ultrafiltration

53:forward osmosis

49:reverse osmosis

12:

11:

5:

1095:

1093:

1085:

1084:

1079:

1074:

1064:

1063:

1058:

1057:

1026:

1007:(1): 111–116.

987:

950:(1): 113–121.

930:

880:

827:

792:

727:

698:(5): 930–939.

681:

638:

629:

574:

564:

555:

536:(2): 159–181.

520:

460:

411:

358:Water Research

344:

316:

315:

313:

310:

309:

308:

303:

296:

293:

279:

276:

258:

255:

249:

246:

195:microorganisms

167:

164:

151:

148:

135:

132:

69:nanofiltration

13:

10:

9:

6:

4:

3:

2:

1094:

1083:

1080:

1078:

1075:

1073:

1070:

1069:

1067:

1053:

1049:

1045:

1041:

1037:

1030:

1027:

1022:

1018:

1014:

1010:

1006:

1002:

998:

991:

988:

983:

979:

974:

969:

965:

961:

957:

953:

949:

945:

941:

934:

931:

926:

922:

918:

914:

910:

906:

902:

898:

894:

887:

885:

881:

876:

872:

867:

866:1721.1/105438

862:

858:

854:

850:

846:

839:

831:

828:

823:

819:

815:

811:

807:

803:

796:

793:

788:

784:

779:

774:

770:

766:

762:

758:

754:

750:

746:

742:

738:

731:

728:

723:

719:

714:

713:1721.1/118392

709:

705:

701:

697:

693:

685:

682:

677:

673:

669:

665:

661:

657:

653:

649:

642:

639:

633:

630:

625:

621:

617:

616:1721.1/107916

613:

608:

603:

599:

595:

588:

581:

579:

575:

568:

565:

559:

556:

551:

547:

543:

539:

535:

531:

524:

521:

516:

512:

507:

506:1721.1/102497

502:

498:

494:

490:

486:

482:

478:

471:

464:

461:

456:

452:

447:

446:1721.1/115270

442:

438:

434:

430:

426:

418:

416:

412:

407:

403:

399:

395:

390:

389:1721.1/114637

385:

380:

375:

371:

367:

363:

359:

355:

348:

345:

340:

336:

333:(1): 91–100.

332:

328:

321:

318:

311:

307:

304:

302:

299:

298:

294:

292:

288:

286:

277:

275:

273:

272:hollow fibers

268:

263:

256:

254:

247:

245:

243:

239:

235:

231:

226:

224:

220:

216:

210:

206:

204:

200:

196:

192:

188:

183:

181:

172:

165:

163:

161:

157:

149:

147:

145:

139:

133:

131:

129:

124:

122:

118:

114:

110:

106:

102:

98:

94:

90:

86:

82:

78:

74:

70:

66:

62:

58:

54:

50:

46:

42:

38:

34:

30:

23:

18:

1043:

1039:

1029:

1004:

1000:

990:

947:

944:Desalination

943:

933:

900:

897:Desalination

896:

848:

844:

830:

805:

801:

795:

744:

740:

730:

695:

691:

684:

651:

648:Desalination

647:

641:

632:

597:

593:

567:

558:

533:

529:

523:

480:

477:Desalination

476:

463:

428:

424:

361:

357:

347:

330:

326:

320:

289:

281:

264:

260:

251:

227:

211:

207:

184:

177:

153:

140:

137:

125:

107:), organic (

28:

27:

903:: 190–205.

851:: 241–252.

747:(1): 2748.

600:: 381–390.

483:: 294–313.

431:: 352–364.

364:: 384–394.

219:hydrophilic

150:Measurement

128:backwashing

75:. Membrane

1066:Categories

312:References

238:turbulence

236:, because

215:filtration

73:technology

1021:0376-7388

982:0011-9164

973:1842/4122

925:0011-9164

875:0376-7388

822:0149-6395

769:2045-2322

722:2053-1400

676:0011-9164

654:: 22–26.

624:0376-7388

550:0376-7388

515:0011-9164

455:0376-7388

398:0043-1354

93:colloidal

787:29426871

406:29573825

295:See also

191:biocides

187:permeate

101:bacteria

95:(clays,

85:chemical

41:membrane

37:particle

33:solution

1077:Fouling

952:Bibcode

905:Bibcode

778:5807517

749:Bibcode

656:Bibcode

485:Bibcode

366:Bibcode

121:scaling

77:fouling

1019:

980:

923:

873:

820:

785:

775:

767:

720:

674:

622:

572:68-78.

548:

513:

453:

404:

396:

154:Flux,

119:) and

117:humics

841:(PDF)

590:(PDF)

473:(PDF)

203:bases

199:acids

105:fungi

97:flocs

67:, or

35:or a

1017:ISSN

978:ISSN

921:ISSN

871:ISSN

818:ISSN

783:PMID

765:ISSN

718:ISSN

672:ISSN

620:ISSN

546:ISSN

511:ISSN

451:ISSN

402:PMID

394:ISSN

267:hard

217:, a

201:and

109:oils

81:flux

22:cake

1048:doi

1009:doi

1005:300

968:hdl

960:doi

948:188

913:doi

901:401

861:hdl

853:doi

849:505

810:doi

773:PMC

757:doi

708:hdl

700:doi

664:doi

652:431

612:hdl

602:doi

598:528

538:doi

534:132

501:hdl

493:doi

481:356

441:hdl

433:doi

429:556

384:hdl

374:doi

362:137

335:doi

1068::

1044:29

1042:.

1038:.

1015:.

1003:.

999:.

976:.

966:.

958:.

942:.

919:.

911:.

895:.

883:^

869:.

859:.

847:.

843:.

816:.

806:39

804:.

781:.

771:.

763:.

755:.

743:.

739:.

716:.

706:.

694:.

670:.

662:.

650:.

618:.

610:.

596:.

592:.

577:^

544:.

532:.

509:.

499:.

491:.

479:.

475:.

449:.

439:.

427:.

414:^

400:.

392:.

382:.

372:.

360:.

356:.

331:59

329:.

115:,

111:,

103:,

63:,

59:,

55:,

51:,

47:,

1054:.

1050::

1023:.

1011::

984:.

970::

962::

954::

927:.

915::

907::

877:.

863::

855::

824:.

812::

789:.

759::

751::

745:8

724:.

710::

702::

696:3

678:.

666::

658::

626:.

614::

604::

552:.

540::

517:.

503::

495::

487::

457:.

443::

435::

408:.

386::

376::

368::

341:.

337::

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.