184:

57:

31:. The ABEC scale is designed to provide bearing manufacturers dimensional specifications that meet the standards of precision bearings in a specified class. The scale is also used by manufacturers who produce equipment that require bearings must also know the dimensional tolerances to design parts that will accommodate a bearing.

150:

Outside the industrial uses mentioned, the scale may also works as a guide for consumers to make informed decisions about the type of bearing they desire. However, the ABEC scale itself does not inform anything about other critical factors related to materials, manufacturing, and performance.

198:

Often significant is also the maximum runout of the race on the inner ring, as this determines how far the axle may shift dynamically from its center position when rotating. For axle diameters between 1 and 18 mm, for the various ABEC classes, they are : ABEC1 : 10 um,

137:

The naming scheme is inverse with the tolerance, i.e. higher numbers means lower tolerance. The higher ABEC classes (lower tolerance) provide better precision, efficiency, and the possibility of greater speed capabilities, but do not necessarily allow the components to spin faster.

321:

hardness, degree of ball and raceway (cone) polishing, noise, vibration, and lubricant. Due to these factors, a high-quality ABEC 3 classified bearing could actually perform better than a lower-quality bearing which satisfies (the stricter) ABEC 7 requirement.

141:

Bearings which fulfill the least strict class (ABEC 1) can be referred to as "precision" (precise) bearings. Bearings not conforming to at least ABEC 1 cannot be classified as precision bearings because their tolerances are too loose.

154:

High ABEC-rated bearings are intended for precision applications such as aircraft instruments or surgical equipment. Lower graded bearings are intended for the vast majority of applications such as vehicles, mechanical hobbies,

208:

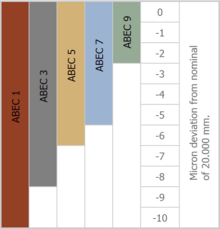

195:(μm) for a 20 mm inner diameter bearing. A 20 mm ABEC 7 bearing only has a 5 μm tolerance window, whereas an ABEC 1 has twice as wide a tolerance.

40:

104:

317:

The ABEC rating does not specify many critical factors, such as load handling capabilities, ball precision, materials, material

423:

82:

216:

78:

67:

338:

86:

71:

369:

ISO 492:2014 – Rolling bearings – Radial bearings – Geometrical product specifications (GPS) and tolerance values

24:

172:

351:

199:

ABEC3 : 7 um, ABEC5 : 4 um, ABEC7 : 2.5 um, ABEC9 : 1.5 um .

168:

187:

Illustration of bearing tolerances (in micrometers) for a bearing with a 20 mm inner diameter

183:

171:. High ABEC rated bearings allow optimal performance of critical applications requiring very high

393:

380:

318:

417:

156:

164:

28:

191:

For illustration, the figure shows the differences in tolerance per ABEC class in

56:

192:

160:

39:

It was developed by the

Annular Bearing Engineering Committee (ABEC) of the

368:

117:

There are five classes, which are named using the first five odd numbers:

182:

211:(ISO) equivalent standard is ISO 492. The German equivalent is

212:

50:

394:"General Bearing Technical Information - Technical Support"

383:. Minibearings.com.au. Retrieved on 2012-08-12.

209:International Organization for Standardization

371:. Iso.org (2014-09). Retrieved on 2017-10-11.

352:"Ball Bearings ABEC Standard Tolerances Data"

8:

85:. Unsourced material may be challenged and

41:American Bearing Manufacturers Association

105:Learn how and when to remove this message

23:is an industry accepted standard for the

221:

331:

16:Industrial scale for bearing tolerance

7:

339:differences between the ABEC classes

83:adding citations to reliable sources

179:Illustration of bearing tolerances

14:

215:620. The Japanese equivalent is

55:

313:Weaknesses of the specification

1:

381:Bearing Precision Comparison

203:Correspondence with ISO 492

440:

341:provided by GMN Bearings

188:

175:and smooth operation.

173:revolutions per minute

133:9 (tightest tolerance)

424:Bearings (mechanical)

186:

169:industrial machinery

121:1 (widest tolerance)

79:improve this section

358:. 31 December 2023.

189:

310:

309:

115:

114:

107:

47:Tolerance classes

431:

408:

407:

405:

404:

390:

384:

378:

372:

366:

360:

359:

348:

342:

336:

222:

110:

103:

99:

96:

90:

59:

51:

439:

438:

434:

433:

432:

430:

429:

428:

414:

413:

412:

411:

402:

400:

398:www.hambini.com

392:

391:

387:

379:

375:

367:

363:

350:

349:

345:

337:

333:

328:

315:

243:

205:

181:

148:

111:

100:

94:

91:

76:

60:

49:

37:

17:

12:

11:

5:

437:

435:

427:

426:

416:

415:

410:

409:

385:

373:

361:

356:Engineers EDGE

343:

330:

329:

327:

324:

314:

311:

308:

307:

304:

301:

298:

294:

293:

290:

287:

284:

280:

279:

276:

273:

270:

266:

265:

262:

259:

256:

252:

251:

248:

245:

240:

236:

235:

232:

229:

226:

204:

201:

180:

177:

147:

144:

135:

134:

131:

128:

125:

122:

113:

112:

63:

61:

54:

48:

45:

36:

33:

15:

13:

10:

9:

6:

4:

3:

2:

436:

425:

422:

421:

419:

399:

395:

389:

386:

382:

377:

374:

370:

365:

362:

357:

353:

347:

344:

340:

335:

332:

325:

323:

320:

312:

305:

302:

299:

296:

295:

291:

288:

285:

282:

281:

277:

274:

271:

268:

267:

263:

260:

257:

254:

253:

249:

246:

241:

238:

237:

233:

230:

227:

224:

223:

220:

218:

214:

210:

202:

200:

196:

194:

185:

178:

176:

174:

170:

166:

165:fishing reels

162:

158:

157:roller skates

152:

145:

143:

139:

132:

129:

126:

123:

120:

119:

118:

109:

106:

98:

88:

84:

80:

74:

73:

69:

64:This section

62:

58:

53:

52:

46:

44:

42:

34:

32:

30:

26:

22:

401:. Retrieved

397:

388:

376:

364:

355:

346:

334:

316:

206:

197:

190:

153:

149:

140:

136:

116:

101:

92:

77:Please help

65:

38:

29:ball bearing

20:

18:

193:micrometers

161:skateboards

95:August 2023

403:2019-11-19

326:References

234:JIS B1514

25:tolerances

21:ABEC scale

244:class 6X

66:does not

418:Category

319:Rockwell

306:Class 2

300:class 2

292:Class 4

286:class 4

278:Class 5

272:class 5

264:Class 6

258:class 6

250:Class 0

231:DIN 620

228:ISO 492

43:(ABMA).

219:B1514.

87:removed

72:sources

35:History

297:ABEC 9

283:ABEC 7

269:ABEC 5

255:ABEC 3

242:normal

239:ABEC 1

225:ABEC

27:of a

207:The

167:and

70:any

68:cite

19:The

303:P2

289:P4

275:P5

261:P6

247:P0

217:JIS

213:DIN

146:Use

81:by

420::

396:.

354:.

163:,

159:,

406:.

130:7

127:5

124:3

108:)

102:(

97:)

93:(

89:.

75:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.