365:

1388:

31:

879:

394:

in the overhead stream, and therefore less steam is required. The multi-pressure configuration with split feed reduces the flow into the bottom section, which also reduces the equivalent work. Flashing feed requires less heat input because it uses the latent heat of water vapor to help strip some of

743:

capture systems. One major focus is on lowering the energy required for solvent regeneration, which has a major impact on process costs. However, there are trade-offs to consider. For example, the energy required for regeneration is typically related to the driving forces for achieving high capture

407:

The amine concentration in the absorbent aqueous solution is an important parameter in the design and operation of an amine gas treating process. Depending on which one of the following four amines the unit was designed to use and what gases it was designed to remove, these are some typical amine

384:

for specific solvents or operating conditions. Vacuum operation favors solvents with low heats of absorption while operation at normal pressure favors solvents with high heats of absorption. Solvents with high heats of absorption require less energy for stripping from temperature swing at fixed

96:

Processes within oil refineries or chemical processing plants that remove

Hydrogen Sulfide are referred to as "sweetening" processes because the odor of the processed products is improved by the absence of "sour" hydrogen sulfide. An alternative to the use of amines involves

340:

from the upflowing sour gas to produce a sweetened gas stream (i.e., a gas free of hydrogen sulfide and carbon dioxide) as a product and an amine solution rich in the absorbed acid gases. The resultant "rich" amine is then routed into the regenerator (a stripper with a

389:

at a higher pressure and does not have inefficiencies associated with multi-pressure stripper. Energy and costs are reduced since the reboiler duty cycle is slightly less than normal pressure stripper. An

Internal Exchange stripper has a smaller ratio of water vapor to

640:

production it is sometimes necessary to remove carbon dioxide from the biogas to make it comparable with natural gas. The removal of the sometimes high content of hydrogen sulfide is necessary to prevent corrosion of metallic parts after burning the bio gas.

462:

The choice of amine concentration in the circulating aqueous solution depends upon several factors and may be quite arbitrary. It is usually made simply on the basis of experience. The factors involved include whether the amine unit is treating raw

594:. In fact, the vast majority of the 64,000,000 metric tons of sulfur produced worldwide in 2005 was byproduct sulfur from refineries and other hydrocarbon processing plants. Another sulfur-removing process is the

300:

The resulting dissociated and ionized species being more soluble in solution are trapped, or scrubbed, by the amine solution and so easily removed from the gas phase. At the outlet of the amine scrubber, the

537:

in the selected amine. The choice of the type of amine will affect the required circulation rate of amine solution, the energy consumption for the regeneration and the ability to selectively remove either

1178:

191:

The chemistry involved in the amine treating of such gases varies somewhat with the particular amine being used. For one of the more common amines, monoethanolamine (MEA) denoted as

877:, Loren N. Miller & Thomas S. Zawacki, "Process for acid gas removal from gaseous mixtures", issued 21 Mar 1978, assigned to Institute of Gas Technology

744:

capacities. Thus, reducing the regeneration energy can lower the driving force and thereby increase the amount of solvent and size of absorber needed to capture a given amount of CO

399:

in the rich stream entering the stripper at the bottom of the column. The multi-pressure configuration is more attractive for solvents with a higher heats of absorption.

554:

MEA and DEA are primary and secondary amines. They are very reactive and can effectively remove a high volume of gas due to a high reaction rate. However, due to

380:

Alternative stripper configurations include matrix, internal exchange, flashing feed, and multi-pressure with split feed. Many of these configurations offer more

1250:

721:

into the liquid phase. Under low pressure, this transfer is hard to achieve without increasing the reboilers' heat duty, which will result in higher costs.

136:

The most commonly used amines in industrial plants are the alkanolamines DEA, MEA, and MDEA. These amines are also used in many oil refineries to remove

1186:, Polasek, J. (Bryan Research & Engineering) and Bullin, J.A. (Texas A&M University), Gas Processors Association Regional Meeting, Sept. 1994.

566:

during regeneration, which can be up to 70% of total operating costs. They are also more corrosive and chemically unstable compared to other amines.

1183:

1201:

328:

below) includes an absorber unit and a regenerator unit as well as accessory equipment. In the absorber, the downflowing amine solution absorbs

1304:

1159:

633:, amine treating is one of the commonly used processes for removing excess carbon dioxide in the final purification of the gaseous hydrogen.

101:. However, membrane separation is less attractive due to the relatively high capital and operating costs as well as other technical factors.

739:

Currently, a variety of amine mixtures are being synthesized and tested to achieve a more desirable set of overall properties for use in CO

1423:

615:

492:

1219:

858:

833:

797:

546:

alone if desired. For more information about selecting the amine concentration, the reader is referred to Kohl and

Nielsen's book.

1189:

371:

of a typical amine treating process used in petroleum refineries, natural gas processing plants and other industrial facilities.

1438:

992:

792:

526:, corrosion inhibitors are often used and that permits the use of higher concentrations of amine in the circulating solution.

602:. In some plants, more than one amine absorber unit may share a common regenerator unit. The current emphasis on removing CO

1392:

710:

Finding a suitable location (enhanced oil recovery, deep saline aquifers, basaltic rocks...) to dispose of the removed CO

920:

Oyenekan, Babatunde; Rochelle, Gary T. (2007). "Alternative

Stripper Configurations for CO2 Capture by Aqueous Amines".

468:

1428:

1243:

1236:

1418:

611:

653:

in various areas ranging from natural gas production to the food and beverage industry, and have been since 1930.

1433:

1413:

1344:

606:

from the flue gases emitted by fossil fuel power plants has led to much interest in using amines for removing CO

522:

on the surface of the steel that acts to protect the steel. When treating gases with a high percentage of CO

141:

1275:

988:

90:

1334:

1443:

1339:

1329:

1198:

656:

There are multiple classifications of amines, each of which has different characteristics relevant to CO

120:

874:

321:

1354:

1071:

762:

732:

from the inlet gas will cause degradation as well. The degraded amine is no longer able to capture CO

579:

368:

325:

1319:

1309:

98:

346:

345:) to produce regenerated or "lean" amine that is recycled for reuse in the absorber. The stripped

1314:

1259:

1103:

1040:

757:

676:

from the flue gas of a coal-fired plant, which is one of the most effective solvent to capture CO

484:

381:

199:

126:

1215:

1155:

1095:

1087:

1032:

954:

Capture

Performance of Aqueoues MEA and Mixed MEA/MDEA Solvents at the University of Regina CO

854:

829:

27:

Removal of impurities from gases by scrubbing them in aqueous solutions of various alkylamines

1079:

1024:

971:

929:

902:

62:

1324:

1205:

626:

529:

Another factor involved in choosing an amine concentration is the relative solubility of H

1075:

1015:

Abatzoglou, Nicolas; Boivin, Steve (2009). "A review of biogas purification processes".

1003:

108:

70:

1407:

1349:

1107:

772:

599:

587:

562:

per mole of amine. MEA and DEA also require a large amount of energy to strip the CO

555:

207:

86:

1044:

660:

capture. For example, monoethanolamine (MEA) reacts strongly with acid gases like CO

519:

507:

408:

concentrations, expressed as weight percent of pure amine in the aqueous solution:

114:

82:

78:

672:

concentrations. Typically, monoethanolamine (MEA) can capture 85% to 90% of the CO

1149:

1359:

893:

Baker, R. W. (2002). "Future

Directions of Membrane Gas Separation Technology".

767:

595:

464:

203:

185:

1364:

1091:

1036:

1270:

1083:

664:

and has a fast reaction time and an ability to remove high percentages of CO

1099:

364:

17:

724:

Primary and secondary amines, for example, MEA and DEA, will react with CO

1299:

782:

630:

488:

342:

180:

174:

137:

694:

Oxygen content of the gas can cause amine degradation and acid formation

30:

777:

622:

53:, refers to a group of processes that use aqueous solutions of various

975:

933:

906:

1228:

637:

591:

471:

by-product gases that contain relatively low concentrations of both H

1028:

578:

S, much of which often comes from a sulfur-removing process called

787:

479:

or whether the unit is treating gases with a high percentage of CO

363:

58:

54:

29:

1179:

Description of Gas

Sweetening Equipment and Operating Conditions

1288:

1232:

1124:

Folger, P. (2009). "Carbon

Capture: a Technology Assessment".

958:

Capture

Technology Development Plant and the Boundary Dam CO

483:

such as the offgas from the steam reforming process used in

439:

Methyldiethanolamine: About 30 to 55 % for removing H

736:, which decreases the overall carbon capture efficiency.

586:

S-rich stripped gas stream is then usually routed into a

717:

The partial pressure is the driving force to transfer CO

687:

Low pressure gas increases difficulty of transferring CO

1151:

Carbon

Dioxide Sequestration and Related Technologies

950:

Idem, Raphael (2006). "Pilot Plant Studies of the CO

621:

In the specific case of the industrial synthesis of

558:, the loading capacity is limited to 0.5 mol CO

1126:Congressional Research Service Report for Congress

683:Challenges of carbon capture using amine include:

598:which recovers sulfur in any form as concentrated

1143:

1141:

1139:

574:In oil refineries, that stripped gas is mostly H

429:Diethanolamine: About 20 to 25 % removing H

414:Monoethanolamine: About 20 % for removing H

385:capacity. The matrix stripper recovers 40% of CO

104:Many different amines are used in gas treating:

1199:Description of the classic book on gas treating

1058:Rochelle, G. T. (2009). "Amine Scrubbing for CO

1244:

701:degradation of primary (and secondary) amines

449:Diglycolamine: About 50 % for removing H

8:

210:to form a positively charged ammonium group

1154:. John Wiley & Sons. pp. 128–131.

851:Petroleum Refining Technology and Economics

629:process of hydrocarbons to produce gaseous

1285:

1251:

1237:

1229:

1148:Wu, Ying; Carroll, John J. (5 July 2011).

945:

943:

422:, and about 32 % for removing only CO

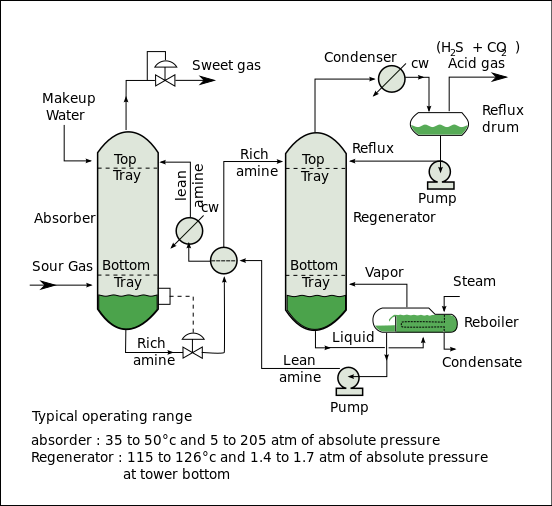

320:A typical amine gas treating process (the

1119:

1117:

1004:Discussion of recovered byproduct sulfur

510:. However, in an amine treating unit, CO

352:

331:

308:

234:

163:

155:

132:Aminoethoxyethanol (Diglycolamine) (DGA)

809:

819:

817:

815:

813:

506:are acid gases and hence corrosive to

148:Description of a typical amine treater

34:Amine gas plant at a natural gas field

1184:Selecting Amines for Sweetening Units

1017:Biofuels, Bioproducts and Biorefining

824:Arthur Kohl; Richard Nielson (1997).

748:, thus, increasing the capital cost.

349:from the regenerator is concentrated

7:

1387:

853:(2nd ed.). Marcel Dekker, Inc.

1214:(Fifth ed.). Gulf Publishing.

849:Gary, J.H.; Handwerk, G.E. (1984).

616:conventional coal-fired power plant

514:is the stronger acid of the two. H

25:

1194:Sulfur and Carbon Dioxide Removal

828:(5th ed.). Gulf Publishing.

798:Solid sorbents for carbon capture

140:from liquid hydrocarbons such as

1386:

728:and form degradation products. O

57:(commonly referred to simply as

993:United States Geological Survey

793:Ionic liquids in carbon capture

77:) from gases. It is a common

1210:Arthur Kohl; Richard Nielsen.

1190:Natural Gas Supply Association

962:Capture Demonstration Plant".

1:

590:to convert it into elemental

91:natural gas processing plants

649:Amines are used to remove CO

172:are commonly referred to as

1460:

1424:Carbon capture and storage

645:Carbon capture and storage

612:carbon capture and storage

1382:

1295:

1284:

1266:

1305:Atmospheric distillation

989:Sulfur production report

1084:10.1126/science.1176731

704:High energy consumption

691:from the gas into amine

188:processing industries.

142:liquified petroleum gas

1439:Natural gas technology

1276:List of oil refineries

372:

93:and other industries.

85:, and is also used in

35:

1340:Hydrodesulphurisation

707:Very large facilities

376:Alternative processes

367:

223:can be expressed as:

33:

1355:Solvent deasphalting

763:Hydrodesulfurization

668:, even at the low CO

580:hydrodesulfurization

369:Process flow diagram

305:is thus depleted in

121:Methyldiethanolamine

1320:Catalytic reforming

1310:Vacuum distillation

1076:2009Sci...325.1652R

1070:(5948): 1652–1654.

964:Ind. Eng. Chem. Res

895:Ind. Eng. Chem. Res

99:membrane technology

1429:Chemical processes

1370:Amine gas treating

1315:Catalytic cracking

1260:Petroleum refining

1204:2008-03-16 at the

758:Ammonia production

518:S forms a film of

485:ammonia production

469:petroleum refinery

373:

324:, as shown in the

200:acid-base reaction

127:Diisopropanolamine

39:Amine gas treating

36:

1419:Biogas technology

1401:

1400:

1378:

1377:

1161:978-0-470-93876-8

976:10.1021/ie050569e

934:10.1002/aic.11316

907:10.1021/ie0108088

382:energy efficiency

152:Gases containing

16:(Redirected from

1451:

1434:Gas technologies

1414:Acid gas control

1390:

1389:

1286:

1253:

1246:

1239:

1230:

1225:

1212:Gas Purification

1166:

1165:

1145:

1134:

1133:

1121:

1112:

1111:

1055:

1049:

1048:

1012:

1006:

1001:

995:

986:

980:

979:

970:(8): 2414–2420.

947:

938:

937:

928:(12): 3144–154.

917:

911:

910:

901:(6): 1393–1411.

890:

884:

883:

882:

878:

871:

865:

864:

846:

840:

839:

826:Gas Purification

821:

356:

335:

322:Girbotol process

312:

296:

295:

294:

284:

283:

275:

274:

273:

265:

264:

247:

246:

238:

220:

219:

167:

159:

115:Monoethanolamine

63:hydrogen sulfide

51:acid gas removal

41:, also known as

21:

1459:

1458:

1454:

1453:

1452:

1450:

1449:

1448:

1404:

1403:

1402:

1397:

1374:

1291:

1280:

1262:

1257:

1222:

1209:

1206:Wayback Machine

1192:Scroll down to

1175:

1170:

1169:

1162:

1147:

1146:

1137:

1123:

1122:

1115:

1061:

1057:

1056:

1052:

1029:10.1002/bbb.117

1014:

1013:

1009:

1002:

998:

987:

983:

961:

957:

953:

949:

948:

941:

919:

918:

914:

892:

891:

887:

880:

873:

872:

868:

861:

848:

847:

843:

836:

823:

822:

811:

806:

754:

747:

742:

735:

731:

727:

720:

713:

700:

690:

679:

675:

671:

667:

663:

659:

652:

647:

627:steam reforming

609:

605:

585:

577:

572:

565:

561:

552:

545:

541:

536:

532:

525:

517:

513:

505:

501:

482:

478:

474:

456:

452:

446:

442:

436:

432:

425:

421:

417:

405:

398:

393:

388:

378:

360:

354:

350:

339:

333:

329:

316:

310:

306:

293:

290:

289:

288:

286:

282:

279:

278:

277:

272:

269:

268:

267:

263:

260:

259:

258:

256:

254:

245:

242:

241:

240:

236:

232:

230:

218:

215:

214:

213:

196:

171:

165:

161:

157:

153:

150:

76:

68:

43:amine scrubbing

28:

23:

22:

15:

12:

11:

5:

1457:

1455:

1447:

1446:

1441:

1436:

1431:

1426:

1421:

1416:

1406:

1405:

1399:

1398:

1396:

1395:

1383:

1380:

1379:

1376:

1375:

1373:

1372:

1367:

1362:

1357:

1352:

1347:

1342:

1337:

1335:Polymerisation

1332:

1327:

1322:

1317:

1312:

1307:

1302:

1296:

1293:

1292:

1289:

1282:

1281:

1279:

1278:

1273:

1267:

1264:

1263:

1258:

1256:

1255:

1248:

1241:

1233:

1227:

1226:

1220:

1196:

1187:

1181:

1174:

1173:External links

1171:

1168:

1167:

1160:

1135:

1113:

1059:

1050:

1007:

996:

981:

959:

955:

951:

939:

912:

885:

866:

859:

841:

834:

808:

807:

805:

802:

801:

800:

795:

790:

785:

780:

775:

770:

765:

760:

753:

750:

745:

740:

733:

729:

725:

718:

715:

714:

711:

708:

705:

702:

698:

695:

692:

688:

677:

673:

669:

665:

661:

657:

650:

646:

643:

607:

603:

583:

575:

571:

568:

563:

559:

551:

548:

543:

539:

534:

530:

523:

515:

511:

503:

499:

480:

476:

472:

460:

459:

458:

457:

454:

450:

447:

444:

440:

437:

434:

430:

427:

423:

419:

415:

404:

401:

396:

391:

386:

377:

374:

358:

337:

314:

298:

297:

291:

280:

270:

261:

252:

249:

243:

228:

216:

202:involving the

194:

169:

149:

146:

134:

133:

130:

124:

118:

112:

109:Diethanolamine

74:

71:carbon dioxide

66:

47:gas sweetening

26:

24:

14:

13:

10:

9:

6:

4:

3:

2:

1456:

1445:

1442:

1440:

1437:

1435:

1432:

1430:

1427:

1425:

1422:

1420:

1417:

1415:

1412:

1411:

1409:

1394:

1385:

1384:

1381:

1371:

1368:

1366:

1363:

1361:

1358:

1356:

1353:

1351:

1350:Hydrocracking

1348:

1346:

1343:

1341:

1338:

1336:

1333:

1331:

1330:Isomerisation

1328:

1326:

1323:

1321:

1318:

1316:

1313:

1311:

1308:

1306:

1303:

1301:

1298:

1297:

1294:

1287:

1283:

1277:

1274:

1272:

1269:

1268:

1265:

1261:

1254:

1249:

1247:

1242:

1240:

1235:

1234:

1231:

1223:

1221:0-88415-220-0

1217:

1213:

1207:

1203:

1200:

1197:

1195:

1191:

1188:

1185:

1182:

1180:

1177:

1176:

1172:

1163:

1157:

1153:

1152:

1144:

1142:

1140:

1136:

1131:

1127:

1120:

1118:

1114:

1109:

1105:

1101:

1097:

1093:

1089:

1085:

1081:

1077:

1073:

1069:

1065:

1054:

1051:

1046:

1042:

1038:

1034:

1030:

1026:

1022:

1018:

1011:

1008:

1005:

1000:

997:

994:

990:

985:

982:

977:

973:

969:

965:

946:

944:

940:

935:

931:

927:

923:

922:AIChE Journal

916:

913:

908:

904:

900:

896:

889:

886:

876:

870:

867:

862:

860:0-8247-7150-8

856:

852:

845:

842:

837:

835:0-88415-220-0

831:

827:

820:

818:

816:

814:

810:

803:

799:

796:

794:

791:

789:

786:

784:

781:

779:

776:

774:

773:Claus process

771:

769:

766:

764:

761:

759:

756:

755:

751:

749:

737:

722:

709:

706:

703:

696:

693:

686:

685:

684:

681:

654:

644:

642:

639:

634:

632:

628:

624:

619:

617:

613:

601:

600:sulfuric acid

597:

593:

589:

588:Claus process

581:

569:

567:

557:

556:stoichiometry

549:

547:

542:S alone or CO

527:

521:

509:

496:

494:

490:

486:

470:

466:

448:

438:

428:

413:

412:

411:

410:

409:

402:

400:

383:

375:

370:

366:

362:

348:

344:

327:

323:

318:

304:

303:sweetened gas

250:

226:

225:

224:

222:

209:

208:electron pair

206:of the amine

205:

201:

197:

189:

187:

183:

182:

177:

176:

147:

145:

143:

139:

131:

128:

125:

122:

119:

116:

113:

110:

107:

106:

105:

102:

100:

94:

92:

88:

87:petrochemical

84:

80:

72:

64:

60:

56:

52:

48:

44:

40:

32:

19:

1444:Oil refining

1369:

1211:

1193:

1150:

1129:

1125:

1067:

1063:

1053:

1023:(1): 42–71.

1020:

1016:

1010:

999:

984:

967:

963:

925:

921:

915:

898:

894:

888:

869:

850:

844:

825:

738:

723:

716:

682:

655:

648:

635:

620:

573:

553:

528:

520:iron sulfide

508:carbon steel

497:

493:power plants

461:

406:

379:

347:overhead gas

326:flow diagram

319:

302:

299:

211:

192:

190:

179:

173:

151:

135:

103:

95:

79:unit process

61:) to remove

50:

46:

42:

38:

37:

1360:Visbreaking

768:WSA Process

610:(see also:

596:WSA Process

550:MEA and DEA

465:natural gas

204:protonation

186:hydrocarbon

55:alkylamines

18:Amine plant

1408:Categories

1345:Sweetening

1325:Alkylation

1062:Capture".

875:US 4080424

804:References

625:, for the

489:flue gases

181:acid gases

175:sour gases

138:sour gases

83:refineries

1300:Desalting

1290:Processes

1271:Petroleum

1108:206521374

1092:0036-8075

1037:1932-104X

582:. This H

1202:Archived

1132:: 26–44.

1100:19779188

1045:84907789

783:Rectisol

752:See also

631:hydrogen

533:S and CO

502:S and CO

475:S and CO

453:S and CO

443:S and CO

433:S and CO

418:S and CO

343:reboiler

160:or both

89:plants,

81:used in

1393:Commons

1072:Bibcode

1064:Science

991:by the

778:Selexol

636:In the

623:ammonia

487:or the

184:in the

144:(LPG).

69:S) and

1391:

1365:Coking

1218:

1158:

1106:

1098:

1090:

1043:

1035:

881:

857:

832:

638:biogas

592:sulfur

498:Both H

403:Amines

395:the CO

357:and CO

336:and CO

313:and CO

198:, the

168:and CO

129:(DIPA)

123:(MDEA)

59:amines

1104:S2CID

1041:S2CID

788:Amine

491:from

276:⇌ RNH

239:⇌ RNH

117:(MEA)

111:(DEA)

1216:ISBN

1156:ISBN

1096:PMID

1088:ISSN

1033:ISSN

855:ISBN

830:ISBN

614:and

570:Uses

248:+ HS

212:(RNH

49:and

1208:by

1080:doi

1068:325

1025:doi

972:doi

930:doi

903:doi

618:).

467:or

317:.

287:HCO

251:RNH

227:RNH

193:RNH

178:or

73:(CO

1410::

1138:^

1128:.

1116:^

1102:.

1094:.

1086:.

1078:.

1066:.

1039:.

1031:.

1019:.

968:45

966:.

942:^

926:53

924:.

899:41

897:.

812:^

697:CO

680:.

495:.

390:CO

361:.

285:+

266:CO

255:+

231:+

65:(H

45:,

1252:e

1245:t

1238:v

1224:.

1164:.

1130:5

1110:.

1082::

1074::

1060:2

1047:.

1027::

1021:3

978:.

974::

960:2

956:2

952:2

936:.

932::

909:.

905::

863:.

838:.

746:2

741:2

734:2

730:2

726:2

719:2

712:2

699:2

689:2

678:2

674:2

670:2

666:2

662:2

658:2

651:2

608:2

604:2

584:2

576:2

564:2

560:2

544:2

540:2

538:H

535:2

531:2

524:2

516:2

512:2

504:2

500:2

481:2

477:2

473:2

455:2

451:2

445:2

441:2

435:2

431:2

426:.

424:2

420:2

416:2

397:2

392:2

387:2

359:2

355:S

353:2

351:H

338:2

334:S

332:2

330:H

315:2

311:S

309:2

307:H

292:3

281:3

271:3

262:2

257:H

253:2

244:3

237:S

235:2

233:H

229:2

221:)

217:3

195:2

170:2

166:S

164:2

162:H

158:S

156:2

154:H

75:2

67:2

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.