119:

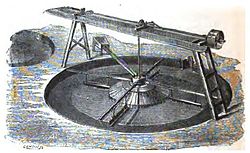

small diameter, and then to re-treat the concentrates thus produced in one of a larger diameter. The sides of the buddle pit are formed of stone or brick, set in mortar, and the floor, which has an inclination outwards of 1 in 30, is made either of smooth planed boards or cement run upon a layer of concrete. The centre head is from 6 ft. to 10 ft. in diameter, and may even be less. A revolving head is fixed to the shaft, and this carries four arms. The revolving head receives the slime waters from the trough, and distributes them on an even layer over the fixed head ; the liquid stream, which should be in a uniform thin film, falls over the edge of the fixed head, and distributes itself outwards over the sloping floor of the buddle towards the circumference, depositing in its passage the rich ore it contains, according to its specific gravity, the richest first, close to the fixed head, and the poorest at the circumference. To each of the four arms a board is attached, carrying a cloth or a series of brushes, which sweep round and smooth out each successive layer of mineral as soon as it is formed. In some cases sprays of fresh water are used instead of the cloths or brushes, the number of revolutions in either case being 3 or 4 per minute.

125:

the full thickness of the deposit equal to the height of the cone is reached. At this point the machine is stopped, a groove is cut from the cone to the circumference, and samples of the ore are taken and washed on a vanning shovel. By this means an idea is formed as to where the divisions should be made ; for at the head the concentrates are rich in galena, and then follow the mixed ores, either of galena, blende, and gangue, if blende is present, or of galena and gangue, if it is absent. Two qualities of the mixed ores are formed. Rings are formed around the deposit on the buddle to indicate the division lines. The rich heads are taken out and reworked once in another buddle, when they will be rich enough to be sent to the dolly tub. The middles are likewise re-treated, the ores of approximately the same percentage being treated in the same machine until all the mineral is abstracted, and the waste contains not more than ½ per cent. of lead, and 1 to 1½ per cent. of zinc. By successive re-treatment the minerals may thus be enriched up to 50 to 60 per cent. Pb., and when blende is present, to about 42 per cent. Zn. These concentrates may either be sold as they are, or further enriched in a dolly tub.

28:

20:

48:

36:

124:

The outflow of the waste waters takes place through the small sluice gate shown in the circumference of the huddle. In the door of this sluice is a vertical line of holes, and, as the layer of mineral thickens on the floor, a plug is placed in the lowest hole, and so successively up the series, until

130:

The great drawbacks to the round buddle are the facts that no clean products can be made straight away. The mineral must be handled several times, always a costly proceeding, and the machine must be stopped when full, and lie idle until emptied. A large number of buddles are always required to cope

118:

The buddle itself consists of a shallow circular pit formed in the ground from 14 ft. to 22 ft. diameter, and from 1 ft. to 1½ ft. deep. The poorer the slimes the greater the diameter, and as the product from the buddle always requires re-treatment, it is usual to concentrate first in a machine of

113:

The concentrating machine for slimes, which has hitherto been a great favourite, is the round buddle, and this was perhaps due to the great simplicity of its construction, which permitted its being made out of the odds and ends of machinery usually to be found on a mine. The fixed and revolving

94:

which rotated in the water in order to agitate the mixture. The result of which was that the heavier and denser material - i.e. the ore - tended to collect at the centre of the pit, from where it could be retrieved. The

102:

Usually a set of buddle pits were used to further refine the ore, where the processed ore was put in another buddle until the achieved concentration of the desired mineral was met.

23:

A large buddle pit at

Mulreesh, one of the historic lead mining areas of Islay. A buddle pit was used to concentrate the heavier plumbiferous ores from the lighter rocks by washing.

242:

27:

176:

712:

235:

131:

with the slimes from even a small mill, while in large mills, especially when blende is present, from sixteen to twenty would be needed.

263:

90:

The pit, often constructed from stone, cement, or brick and mortar, contained water and used a set of brushes often powered by a

212:

Mining and mining machinery: explaining the methods of obtaining minerals, precious stones, &c., in all parts of the world

342:

337:

228:

19:

616:

785:

626:

157:

114:

cast-iron heads, shafting, bevel wheels, and driving pulleys, are usually procured from a firm of machinery makers.

871:

866:

87:

and are often circularly shaped. There was also a variation called the concave buddle, which had a concave bottom.

188:

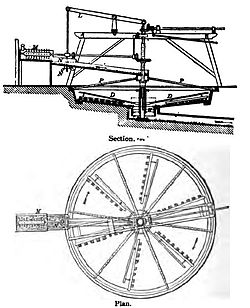

Machinery for

Metalliferous Mines: A practical treatise for mining engineers, metallurgists and managers of mines

107:

Machinery for

Metalliferous Mines: A practical treatise for mining engineers, metallurgists and managers of mines

511:

679:

647:

598:

251:

152:

67:

is an ore processing technique that separates heavier minerals from lighter minerals when the crushed

464:

732:

621:

507:

454:

260:

142:

562:

502:

459:

271:

759:

497:

290:

71:

is washed in water. This technique was used in the mining industry to extract metals such as

31:

Remain of Buddle pit in Cwm Bychan. Another buddle pit nearby still retains the central cone.

840:

745:

717:

305:

295:

830:

790:

666:

482:

474:

411:

399:

394:

389:

780:

611:

577:

541:

449:

332:

320:

860:

835:

740:

722:

707:

702:

697:

692:

572:

567:

84:

772:

492:

487:

444:

147:

642:

606:

434:

366:

91:

845:

795:

588:

517:

374:

315:

687:

652:

522:

406:

349:

47:

35:

815:

582:

554:

379:

220:

439:

416:

384:

310:

16:

A pit for separating heavier minerals from lighter minerals using water

820:

327:

96:

354:

46:

34:

26:

18:

825:

80:

76:

224:

300:

72:

68:

109:, by E. Henry Davies, C. Lockwood and son, 1902 :

808:

771:

758:

731:

678:

665:

635:

597:

553:

540:

473:

427:

365:

283:

270:

190:, by E. Henry Davies, C. Lockwood and son, 1902

111:

236:

8:

51:A diagram of a working concave buddle, from

768:

675:

550:

280:

243:

229:

221:

200:Undiscovered Wales: Fifteen Circular Walks

105:The following detailed extract comes from

39:A diagram of a working round buddle, from

202:, by Kevin Walker, Francis Lincoln, 2010

83:. Many buddles seen today date from the

177:Sine Project - Term Definitions: BUDDLE

169:

158:Adelong Falls Gold Workings (Australia)

99:was then drained off and disposed of.

7:

14:

264:Non-ferrous extractive metallurgy

53:Machinery for Metalliferous Mines

41:Machinery for Metalliferous Mines

214:, by Sydney Ferris Walker, 1913

1:

617:Bottom-blown oxygen converter

888:

55:, by E. Henry Davies, 1902

43:, by E. Henry Davies, 1902

258:

343:Underground in soft rock

338:Underground in hard rock

143:Buddle pits in Dartmoor

134:

56:

44:

32:

24:

671:(by aqueous solution)

503:Gravity Concentration

252:Extractive metallurgy

153:Metal mining in Wales

50:

38:

30:

22:

786:Hall–Héroult process

465:Mechanical screening

508:Magnetic separation

455:Cyclonic separation

276:(by physical means)

261:Metallurgical assay

589:Refractory linings

460:Gyratory equipment

272:Mineral processing

57:

45:

33:

25:

872:History of mining

867:Mining techniques

854:

853:

804:

803:

765:

760:Electrometallurgy

754:

753:

713:Gold chlorination

672:

661:

660:

547:

536:

535:

498:Jig concentrators

296:Natural resources

291:Geological survey

277:

879:

769:

764:(by electricity)

763:

746:Pan amalgamation

718:Gold cyanidation

708:In situ leaching

676:

670:

551:

545:

306:Economic geology

281:

275:

245:

238:

231:

222:

215:

209:

203:

197:

191:

185:

179:

174:

887:

886:

882:

881:

880:

878:

877:

876:

857:

856:

855:

850:

800:

791:Castner process

762:

750:

727:

669:

667:Hydrometallurgy

657:

631:

627:IsaKidd process

593:

544:

532:

483:Froth flotation

469:

423:

361:

274:

266:

254:

249:

219:

218:

210:

206:

198:

194:

186:

182:

175:

171:

166:

139:

17:

12:

11:

5:

885:

883:

875:

874:

869:

859:

858:

852:

851:

849:

848:

843:

838:

833:

828:

823:

818:

812:

810:

806:

805:

802:

801:

799:

798:

793:

788:

783:

781:Electrowinning

777:

775:

766:

756:

755:

752:

751:

749:

748:

743:

737:

735:

729:

728:

726:

725:

720:

715:

710:

705:

700:

695:

690:

684:

682:

673:

663:

662:

659:

658:

656:

655:

650:

645:

639:

637:

633:

632:

630:

629:

624:

619:

614:

612:Parkes process

609:

603:

601:

595:

594:

592:

591:

586:

580:

578:Flash smelting

575:

570:

565:

559:

557:

548:

542:Pyrometallurgy

538:

537:

534:

533:

531:

530:

525:

520:

515:

505:

500:

495:

490:

485:

479:

477:

471:

470:

468:

467:

462:

457:

452:

447:

442:

437:

431:

429:

425:

424:

422:

421:

420:

419:

414:

404:

403:

402:

397:

392:

382:

377:

371:

369:

363:

362:

360:

359:

358:

357:

347:

346:

345:

340:

335:

325:

324:

323:

321:Precious metal

318:

313:

308:

298:

293:

287:

285:

278:

268:

267:

259:

256:

255:

250:

248:

247:

240:

233:

225:

217:

216:

204:

192:

180:

168:

167:

165:

162:

161:

160:

155:

150:

145:

138:

135:

15:

13:

10:

9:

6:

4:

3:

2:

884:

873:

870:

868:

865:

864:

862:

847:

844:

842:

839:

837:

834:

832:

829:

827:

824:

822:

819:

817:

814:

813:

811:

807:

797:

794:

792:

789:

787:

784:

782:

779:

778:

776:

774:

770:

767:

761:

757:

747:

744:

742:

741:Patio process

739:

738:

736:

734:

730:

724:

723:Bayer process

721:

719:

716:

714:

711:

709:

706:

704:

703:Tank leaching

701:

699:

698:Dump leaching

696:

694:

693:Heap leaching

691:

689:

686:

685:

683:

681:

677:

674:

668:

664:

654:

651:

649:

646:

644:

641:

640:

638:

634:

628:

625:

623:

620:

618:

615:

613:

610:

608:

605:

604:

602:

600:

596:

590:

587:

584:

581:

579:

576:

574:

573:Zinc smelting

571:

569:

568:Lead smelting

566:

564:

563:Iron smelting

561:

560:

558:

556:

552:

549:

543:

539:

529:

526:

524:

521:

519:

516:

513:

509:

506:

504:

501:

499:

496:

494:

491:

489:

486:

484:

481:

480:

478:

476:

475:Concentration

472:

466:

463:

461:

458:

456:

453:

451:

448:

446:

443:

441:

438:

436:

433:

432:

430:

426:

418:

415:

413:

410:

409:

408:

405:

401:

398:

396:

393:

391:

388:

387:

386:

383:

381:

378:

376:

373:

372:

370:

368:

364:

356:

353:

352:

351:

348:

344:

341:

339:

336:

334:

331:

330:

329:

326:

322:

319:

317:

314:

312:

309:

307:

304:

303:

302:

299:

297:

294:

292:

289:

288:

286:

282:

279:

273:

269:

265:

262:

257:

253:

246:

241:

239:

234:

232:

227:

226:

223:

213:

208:

205:

201:

196:

193:

189:

184:

181:

178:

173:

170:

163:

159:

156:

154:

151:

149:

146:

144:

141:

140:

136:

133:

132:

127:

126:

121:

120:

115:

110:

108:

103:

100:

98:

93:

88:

86:

85:Victorian era

82:

78:

74:

70:

66:

62:

54:

49:

42:

37:

29:

21:

773:Electrolysis

733:Amalgamation

527:

488:Jameson cell

445:Hydrocyclone

211:

207:

199:

195:

187:

183:

172:

148:Metal mining

129:

128:

123:

122:

117:

116:

112:

106:

104:

101:

89:

64:

60:

58:

52:

40:

809:Co-products

643:Calcination

607:Cupellation

523:Dry washing

512:Magnetation

435:Ore sorting

400:Pebble mill

367:Comminution

92:water wheel

65:buddle pond

861:Categories

846:Stamp sand

796:Downs cell

528:Buddle pit

518:Rocker box

375:Stamp mill

316:Base metal

284:Extraction

164:References

61:buddle pit

688:Lixiviant

653:Liquation

546:(by heat)

407:Ball mill

350:Recycling

97:byproduct

816:Tailings

680:Leaching

648:Roasting

599:Refining

583:ISASMELT

555:Smelting

412:Rod mill

395:SAG mill

380:Arrastra

137:See also

841:Red mud

831:Clinker

585:furnace

493:Panning

450:Trommel

440:Vanning

417:IsaMill

390:AG mill

385:Crusher

333:Surface

311:Mineral

821:Gangue

622:Poling

428:Sizing

328:Mining

636:Other

355:Scrap

836:Chat

826:Slag

81:zinc

79:and

77:lead

301:Ore

73:tin

69:ore

63:or

863::

75:,

59:A

514:)

510:(

244:e

237:t

230:v

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.