597:-shaped) configuration, sometimes called a star winding, connects all of the windings to a central point, and power is applied to the remaining end of each winding. A motor with windings in delta configuration gives low torque at low speed but can give higher top speed. Wye configuration gives high torque at low speed, but not as high top speed. The wye winding is normally more efficient. Delta-connected windings can allow high-frequency parasitic electrical currents to circulate entirely within the motor. A Wye-connected winding does not contain a closed loop in which parasitic currents can flow, preventing such losses. Aside from the higher impedance of the wye configuration, from a controller standpoint, the two winding configurations can be treated exactly the same.

54:

33:

350:, but the motors have important differences due to differences in implementation and operation. While stepper motors are frequently stopped with the rotor in a defined angular position, a brushless motor is usually intended to produce continuous rotation. Both motor types may have a rotor position sensor for internal feedback. Both a stepper motor and a well-designed brushless motor can hold finite torque at zero RPM.

221:, press against the commutator, making sliding electrical contact with successive segments as the rotor turns. The brushes selectively provide electric current to the windings. As the rotor rotates, the commutator selects different windings and the directional current is applied to a given winding such that the rotor's magnetic field remains misaligned with the stator and creates a torque in one direction.

508:

198:, providing the power that runs the motor. The misalignment generates a torque that tries to realign the fields. As the rotor moves, and the fields come into alignment, it is necessary to move either the rotor's or stator's field to maintain the misalignment and continue to generate torque and movement. The device that moves the fields based on the position of the rotor is called a

835:

728:. The most significant reason to switch to a brushless motor is a reduction in power required to operate them versus a typical AC motor. In addition to the brushless motor's higher efficiency, HVAC systems, especially those featuring variable-speed or load modulation, use brushless motors to give the built-in microprocessor continuous control over cooling and airflow.

305:, eliminating problems associated with connecting current to the moving armature. An electronic controller replaces the commutator assembly of the brushed DC motor, which continually switches the phase to the windings to keep the motor turning. The controller performs similar timed power distribution by using a solid-state circuit rather than the commutator system.

569:

316:(EMI). With no windings on the rotor, they are not subjected to centrifugal forces, and because the windings are supported by the housing, they can be cooled by conduction, requiring no airflow inside the motor for cooling. This in turn means that the motor's internals can be entirely enclosed and protected from dirt or other foreign matter.

927:

606:

821:

or belts, that would be necessary for rotary motors. Transmission systems are known to introduce less responsiveness and reduced accuracy. Direct drive, brushless DC linear motors consist of a slotted stator with magnetic teeth and a moving actuator, which has permanent magnets and coil windings. To

617:

Brushless motors fulfill many functions originally performed by brushed DC motors, but cost and control complexity prevents brushless motors from replacing brushed motors completely in the lowest-cost areas. Nevertheless, brushless motors have come to dominate many applications, particularly devices

584:

configuration, the radial relationship between the coils and magnets is reversed; the stator coils form the center (core) of the motor, while the permanent magnets spin within an overhanging rotor that surrounds the core. Outrunners typically have more poles, set up in triplets to maintain the three

338:

When converting electricity into mechanical power, brushless motors are more efficient than brushed motors primarily due to the absence of brushes, which reduces mechanical energy loss due to friction. The enhanced efficiency is greatest in the no-load and low-load regions of the motor's performance

151:

are high power-to-weight ratio, high speed, nearly instantaneous control of speed (rpm) and torque, high efficiency, and low maintenance. Brushless motors find applications in such places as computer peripherals (disk drives, printers), hand-held power tools, and vehicles ranging from model aircraft

785:

and a rotor position feedback sensor. Brushless DC motors are widely used as servomotors for machine tool servo drives. Servomotors are used for mechanical displacement, positioning or precision motion control. DC stepper motors can also be used as servomotors; however, since they are operated with

289:

that switch current through the windings, either reversing the direction of the current or, in some motors turning it off, at the correct angle so the electromagnets create torque in one direction. The elimination of the sliding contact allows brushless motors to have less friction and longer life;

862:

and wide range of available sizes have revolutionized the market for electric-powered model flight, displacing virtually all brushed electric motors, except for low powered inexpensive often toy grade aircraft. They have also encouraged growth of simple, lightweight electric model aircraft, rather

297:

Brushed DC motors develop a maximum torque when stationary, linearly decreasing as velocity increases. Some limitations of brushed motors can be overcome by brushless motors; they include higher efficiency and lower susceptibility to mechanical wear. These benefits come at the cost of potentially

210:

In brushed motors this is done with a rotary switch on the motor's shaft called a commutator. It consists of a rotating cylinder or disc divided into multiple metal contact segments on the rotor. The segments are connected to conductor windings on the rotor. Two or more stationary contacts called

378:

Controllers that sense rotor position based on back-EMF have extra challenges in initiating motion because no back-EMF is produced when the rotor is stationary. This is usually accomplished by beginning rotation from an arbitrary phase, and then skipping to the correct phase if it is found to be

776:

Brushless motors are commonly used as pump, fan and spindle drives in adjustable or variable speed applications as they are capable of developing high torque with good speed response. In addition, they can be easily automated for remote control. Due to their construction, they have good thermal

622:

and CD/DVD players. Small cooling fans in electronic equipment are powered exclusively by brushless motors. They can be found in cordless power tools where the increased efficiency of the motor leads to longer periods of use before the battery needs to be charged. Low speed, low power brushless

914:

peak at around 46,800 r/min and 2.2 kilowatts (3.0 hp), while a smaller brushless motor can reach 50,000 r/min and 3.7 kilowatts (5.0 hp). Larger brushless RC motors can reach upwards of 10 kilowatts (13 hp) and 28,000 r/min to power one-fifth-scale models.

748:

design. Brushless motors are ideally suited for manufacturing applications because of their high power density, good speed-torque characteristics, high efficiency, wide speed ranges and low maintenance. The most common uses of brushless DC motors in industrial engineering are

358:

Because the controller implements the traditional brushes' functionality, it needs to know the rotor's orientation relative to the stator coils. This is automatic in a brushed motor due to the fixed geometry of the rotor shaft and brushes. Some designs use

342:

Environments and requirements in which manufacturers use brushless-type DC motors include maintenance-free operation, high speeds, and operation where sparking is hazardous (i.e. explosive environments) or could affect electronically sensitive equipment.

379:

wrong. This can cause the motor to run backwards briefly, adding even more complexity to the startup sequence. Other sensorless controllers are capable of measuring winding saturation caused by the position of the magnets to infer the rotor position.

40:

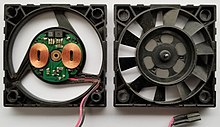

drive. The coils, arranged radially, are made from copper wire coated with blue insulation. The rotor (upper right) has been removed and turned upside-down. The grey ring inside its cup is a permanent magnet. This particular motor is an

323:, or may alternatively be implemented using analog or digital circuits. Commutation with electronics instead of brushes allows for greater flexibility and capabilities not available with brushed DC motors, including speed limiting,

867:

powering larger and heavier models. The increased power-to-weight ratio of modern batteries and brushless motors allows models to ascend vertically, rather than climb gradually. The low noise and lack of mass compared to small

327:

operation for slow and fine motion control, and a holding torque when stationary. Controller software can be customized to the specific motor being used in the application, resulting in greater commutation efficiency.

386:

working from the orientation sensors to determine when the output phase should be advanced. More advanced controllers employ a microcontroller to manage acceleration, control motor speed and fine-tune efficiency.

667:

use brushless motors that are sometimes built into the wheel hub itself, with the stator fixed solidly to the axle and the magnets attached to and rotating with the wheel. The same principle is applied in

592:

There are two common electrical winding configurations; the delta configuration connects three windings to each other in a triangle-like circuit, and power is applied at each of the connections. The wye

235:

The soft brush material wears down due to friction, creating dust, and eventually the brushes must be replaced. This makes commutated motors unsuitable for low particulate or sealed applications like

97:

producing magnetic fields that effectively rotate in space and which the permanent magnet rotor follows. The controller adjusts the phase and amplitude of the current pulses that control the

708:. The weight and efficiency advantages of brushless over brushed motors are more important to handheld, battery-powered tools than to large, stationary tools plugged into an AC outlet.

1254:

312:, increased reliability, reduced noise, longer lifetime by eliminating brush and commutator erosion, elimination of ionizing sparks from the commutator, and an overall reduction of

492:

1424:

1402:

445:

418:

273:. Today, brushed motors are used only in low-power applications or where only DC is available, but the above drawbacks limit their use even in these applications.

1760:

1008:

822:

obtain linear motion, a motor controller excites the coil windings in the actuator causing an interaction of the magnetic fields resulting in linear motion.

529:

2060:

1804:

281:

In brushless DC motors, an electronic controller replaces the brush commutator contacts. An electronic sensor detects the angle of the rotor and controls

717:

589:, used where there are space or shape constraints, stator and rotor plates are mounted face to face. In all brushless motors, the coils are stationary.

308:

Brushless motors offer several advantages over brushed DC motors, including high torque to weight ratio, increased efficiency producing more torque per

1750:

1319:

1592:

As far as THE fastest RC car available for sale is concerned, it is the

Traxxas XO-1 Supercar. The XO-1 hits 100mph, with proper LiPos batteries.

152:

to automobiles. In modern washing machines, brushless DC motors have allowed replacement of rubber belts and gearboxes by a direct-drive design.

910:

Brushless motors are capable of producing more torque and have a faster peak rotational speed compared to nitro- or gasoline-powered engines.

1559:

1532:

1505:

1478:

1451:

1220:

1165:

793:

Brushless motors are used in industrial positioning and actuation applications. For assembly robots, Brushless technogy may be used to build

1181:

371:

in the undriven coils to infer the rotor position, eliminating the need for separate Hall effect sensors. These are therefore often called

899:(ROAR) since 2006. These motors provide a great amount of power to RC racers and, if paired with appropriate gearing and high-discharge

883:

for almost all model engines being available over the most recent decades—have also supported the shift to high-power electric systems.

1128:

1138:

1070:

113:

1725:

1690:

1670:

1650:

555:

302:

1060:

2458:

2240:

572:

Schematic for delta and wye winding styles. (This image does not illustrate the motor's inductive and generator-like properties)

1797:

1700:

232:

of the brushes sliding along the rotating commutator segments causes power losses that can be significant in a low power motor.

2189:

1406:

1104:

904:

875:

Legal restrictions for the use of combustion engine driven model aircraft in some countries, most often due to potential for

533:

580:

configuration, the permanent magnets are part of the rotor. Three stator windings surround the rotor. In the external-rotor

1576:

781:. To obtain a variable speed response, brushless motors operate in an electromechanical system that includes an electronic

1974:

1761:

Animation of BLDC Motor in different commutation (Block, Star, Sinus (sine) & Sensorless) – compared to stepper motors

1740:

253:

of the windings causes sparks at the commutator contacts, which is a fire hazard in explosive atmospheres and a source of

1094:

382:

A typical controller contains three polarity-reversible outputs controlled by a logic circuit. Simple controllers employ

2322:

313:

258:

2332:

2045:

368:

1362:

518:

163:

were invented in the 19th century and are still common. Brushless DC motors were made possible by the development of

224:

The brush commutator has disadvantages that has led to a decline in use of brushed motors. These disadvantages are:

2342:

2337:

1790:

896:

537:

522:

2417:

2035:

2013:

1042:

T.G. Wilson, P.H. Trickey, "D.C. Machine. With Solid State

Commutation", AIEE paper I. CP62-1372, October 7, 1962

741:

117:

609:

The four poles on the stator of a two-windings single-phase brushless motor. This is part of a computer cooling

2453:

2286:

2140:

1776:

798:

2387:

1009:

Control differences between ac induction motor and brushless dc motor? – Electrical

Engineering Stack Exchange

636:

1241:

265:

During the last hundred years, high-power DC brushed motors, once the mainstay of industry, were replaced by

2327:

1878:

900:

855:

164:

1779:– Video explanation how Brushless DC Motor works, plus how to control one with an Arduino micro-controller.

450:

331:

The maximum power that can be applied to a brushless motor is limited almost exclusively by heat; too much

61:. The two coils on the printed circuit board interact with six round permanent magnets in the fan assembly.

2150:

2055:

1984:

737:

673:

669:

624:

1323:

242:

The electrical resistance of the sliding brush contact causes a voltage drop in the motor circuit called

2281:

2145:

1883:

1863:

1843:

859:

745:

199:

106:

53:

966:

576:

Brushless motors can be constructed in several different physical configurations. In the conventional

2276:

2169:

1918:

1893:

978:

892:

823:

787:

778:

656:

291:

187:

94:

2382:

2085:

2080:

1825:

1274:

945:

940:

632:

266:

32:

2448:

2407:

2301:

2256:

2194:

2164:

2118:

1941:

1928:

762:

360:

1441:

907:(LiFePO4) batteries, these cars can achieve speeds over 160 kilometres per hour (99 mph).

797:. The advantage of linear motors is that they can produce linear motion without the need of a

2367:

2317:

2271:

2199:

1991:

1979:

1969:

1721:

1686:

1666:

1646:

1555:

1528:

1522:

1501:

1495:

1474:

1468:

1447:

1216:

1161:

1155:

1134:

1100:

1066:

697:

660:

628:

332:

270:

125:

78:

1549:

2422:

2412:

2357:

2352:

2296:

2266:

2214:

2110:

2100:

2090:

2040:

1903:

1873:

1813:

1420:

1208:

986:

851:

782:

664:

648:

610:

586:

254:

213:

175:

160:

141:

423:

396:

2397:

2347:

2209:

2030:

2008:

1996:

1964:

1868:

1764:

1754:

1744:

1428:

895:

area. Brushless motors have been legal in North

American RC car racing in accordance with

876:

814:

810:

754:

391:

320:

121:

2372:

1611:

1212:

1597:

982:

838:

A microprocessor-controlled BLDC motor powering a micro radio-controlled airplane. This

17:

2392:

2291:

2261:

2123:

2075:

2023:

1951:

1888:

1831:

847:

750:

685:

652:

364:

195:

191:

90:

82:

834:

2442:

2402:

2070:

932:

721:

705:

347:

324:

282:

183:

148:

1706:

2427:

2362:

2050:

911:

864:

794:

693:

1715:

1680:

1660:

1640:

990:

2204:

2135:

1202:

770:

689:

507:

37:

2095:

2065:

1936:

1898:

1770:

922:

802:

758:

383:

286:

250:

58:

2377:

2130:

1908:

1295:

1021:

869:

806:

619:

581:

236:

182:(the fixed part of the machine) misaligned. One or both sets of magnets are

129:

301:

A typical brushless motor has permanent magnets that rotate around a fixed

2159:

2003:

1959:

766:

725:

684:

Brushless motors are found in many modern cordless tools, including some

577:

229:

218:

137:

86:

1204:

The Rotor

Position Study of Brushless DC Motors Without Position Sensors

2235:

2230:

1612:"Brushed vs. Brushless Motors: What's the Difference, and What's Best?"

1551:

Industrial

Control Technology: A Handbook for Engineers and Researchers

880:

112:

The construction of a brushless motor system is typically similar to a

1011:. electronics.stackexchange.com (2019-12-20). Retrieved on 2019-12-26.

965:

Widmer, James D.; Martin, Richard; Kimiabeigi, Mohammed (April 2015),

585:

groups of windings, and have a higher torque at low RPMs. In the flat

568:

1913:

1837:

631:. Brushless motors can also be found in marine applications, such as

239:

motors, and for applications that require maintenance-free operation.

179:

171:

133:

102:

46:

1782:

872:

internal combustion engines is another reason for their popularity.

926:

826:

are another form of linear motor design operated in a similar way.

319:

Brushless motor commutation can be implemented in software using a

298:

less rugged, more complex, and more expensive control electronics.

833:

701:

604:

567:

98:

52:

31:

1099:. London: Institution of Electrical Engineers. pp. 165–166.

1376:"Reliance Electric GV3000 Drive 30V4160 | Automation Industrial"

818:

605:

309:

1786:

724:

industries to use brushless motors instead of various types of

501:

390:

Two key performance parameters of brushless DC motors are the

27:

Synchronous electric motor powered by an electronic controller

967:"Electric vehicle traction motors without rare earth magnets"

367:

to directly measure the rotor's position. Others measure the

1345:

290:

their working life is limited only by the lifetime of their

1717:

Brushless Motors: Magnetic Design, Performance, and

Control

1595:

The maker's product specifications indicate the usage of a

1375:

842:

motor weighs 5 g and consumes approximately 11 W.

1741:

How Motors Work (brushed and brushless RC airplane motors)

1642:

Permanent magnet motor technology: design and applications

1771:

Electric Drives – Brushless DC / AC and

Reluctance Motors

249:

The repeated abrupt switching of the current through the

846:

Brushless motors have become a popular motor choice for

635:. Drones also utilize brushless motors to elevate their

1682:

Energy-efficient electric motors and their applications

1244:. Learningrc.com (2015-07-29). Retrieved on 2019-12-26.

1130:

Permanent Magnet

Brushless DC Motor Drives and Controls

676:

use brushless motors because of their high efficiency.

1527:. Springer Science & Business Media. p. 174.

1403:"Brushless DC Motors Used in Industrial Applications"

453:

426:

399:

109:(brushes) used in many conventional electric motors.

105:

of the motor. It is an improvement on the mechanical

2061:

Dual-rotor permanent magnet induction motor (DRPMIM)

1702:

An

Evaluation of Electric Motors for Ship Propulsion

1662:

Permanent Magnet Synchronous and Brushless DC Motors

1521:

Shimon Y. Nof; Wilbert Wilhelm; H. Warnecke (1997).

1182:"Brushless DC Motor vs. AC Motor vs. Brushed Motor?"

2310:

2249:

2223:

2178:

2109:

1950:

1927:

1852:

1397:

1395:

486:

439:

412:

346:The construction of a brushless motor resembles a

447:(back-EMF constant, also known as speed constant

1470:Permanent Magnet Materials and Their Application

839:

736:The application of brushless DC motors within

144:(the rotor and stator are flat and parallel).

1798:

1577:"Top 4 Fastest RC Cars for Sale in the World"

194:running through the wire winding creates the

8:

1405:. Ohio Electric Motors. 2012. Archived from

1022:"What is a BLDC Motor in a Washing Machine?"

790:, they typically exhibit torque pulsations.

140:(the rotor is surrounded by the stator), or

1751:BLDC Motor Fan Advantages And Disadvantages

1705:, Naval Postgraduate School, archived from

1500:. Tata McGraw-Hill Education. p. 159.

1473:. Cambridge University Press. p. 172.

1160:. Tata McGraw-Hill Education. p. 165.

1062:Modeling and Control of Engineering Systems

536:. Unsourced material may be challenged and

178:(the rotating part of the machine) and the

1805:

1791:

1783:

1446:. McGraw Hill Professional. pp. 5–6.

718:heating, ventilation, and air conditioning

1365:. Thomasnet.com. Retrieved on 2019-12-26.

1320:"Custom axial flux permanent magnet BLDC"

1088:

1086:

1084:

1082:

1054:

1052:

1050:

1048:

556:Learn how and when to remove this message

476:

467:

458:

452:

431:

425:

404:

398:

147:The advantages of a brushless motor over

1639:Jacek F. Gieras; Mitchell Wing (2002),

1133:. John Wiley and Sons. pp. 18–19.

957:

891:Their popularity has also risen in the

1497:Control Systems: Principles and Design

1157:Control Systems: Principles and Design

971:Sustainable Materials and Technologies

335:and damages the windings' insulation.

174:by keeping the magnetic fields of the

1242:Brushless Motor Kv Constant Explained

1122:

1120:

1118:

1116:

487:{\displaystyle K_{V}={1 \over K_{e}}}

7:

1213:10.1109/ICNC-FSKD59587.2023.10280801

534:adding citations to reliable sources

89:power supply. It uses an electronic

1598:"Traxxas Big Block brushless motor"

1575:Bobby Bernstein (15 January 2015).

261:in nearby microelectronic circuits.

217:, made of a soft conductor such as

190:of wire wound around an iron core.

93:to switch DC currents to the motor

1275:"Vinyl Turntable Drive Techniques"

672:wheels. Most electrically powered

114:permanent magnet synchronous motor

25:

769:drive motors and feed drives for

1777:How Brushless Motor and ESC Work

1767: (archived 2020-02-05) Flash

1554:. Elsevier Science. p. 91.

1255:"Delta vs Wye phase connections"

1201:Cui, Guohua; Jiao, Jiye (2023).

925:

506:

1065:. CRC Press. pp. 632–633.

75:electronically commutated motor

2190:Timeline of the electric motor

647:Brushless motors are found in

122:induction (asynchronous) motor

1:

1975:Dahlander pole changing motor

1610:Maning, Jayric (2022-08-20).

1322:. Turncircles. Archived from

1059:Clarence W. de Silva (2009).

613:; the rotor has been removed.

136:is surrounded by the rotor),

36:The motor from a 3.5 in

1423:Ohio Electric Motors. 2011.

991:10.1016/j.susmat.2015.02.001

879:—even with purpose-designed

314:electromagnetic interference

259:electromagnetic interference

2019:Brushless DC electric motor

865:internal combustion engines

170:An electric motor develops

67:brushless DC electric motor

2475:

1757: (archived 2022-01-17)

1747: (archived 2013-10-02)

897:Radio Operated Auto Racing

498:Variations in construction

354:Controller implementations

116:(PMSM), but can also be a

2036:Switched reluctance (SRM)

2014:Brushed DC electric motor

1820:

1699:Bobby A. Bassham (2003),

1679:Howard E. Jordan (1994),

1427:January 26, 2012, at the

893:radio-controlled (RC) car

777:characteristics and high

742:manufacturing engineering

118:switched reluctance motor

2224:Experimental, futuristic

2141:Variable-frequency drive

1714:Duane Hanselman (2012),

1127:Chang-liang Xia (2012).

716:There is a trend in the

333:heat weakens the magnets

246:, which consumes energy.

18:Brushless electric motor

2459:20th-century inventions

2241:Superconducting machine

1879:Coil winding technology

1467:Peter Campbell (1996).

1440:Sabrie Soloman (1999).

1093:Helmut Moczala (1998).

765:for industrial robots,

712:Heating and ventilation

674:radio-controlled models

625:direct-drive turntables

165:solid state electronics

1659:Krishnan Ramu (2009),

1419:Ohio Electric Motors.

905:lithium iron phosphate

860:power-to-weight ratios

843:

738:industrial engineering

732:Industrial engineering

670:self-balancing scooter

614:

573:

488:

441:

420:(torque constant) and

414:

62:

50:

2282:Power-to-weight ratio

2146:Direct torque control

1363:ECMs and HVAC Systems

1296:"What is a Thruster?"

1096:Small Electric Motors

887:Radio-controlled cars

837:

824:Tubular linear motors

746:industrial automation

740:primarily focuses on

657:personal transporters

608:

571:

489:

442:

440:{\displaystyle K_{e}}

415:

413:{\displaystyle K_{T}}

56:

35:

2277:Open-loop controller

2170:Ward Leonard control

1894:DC injection braking

1773:with useful diagrams

1421:DC Motor Protection.

1409:on November 4, 2012.

633:underwater thrusters

530:improve this section

451:

424:

397:

124:. They may also use

73:), also known as an

2180:History, education,

1826:Alternating current

1548:Peng Zhang (2013).

1524:Industrial Assembly

1326:on 24 November 2020

983:2015SusMT...3....7W

946:Squirrel-cage rotor

941:Piezoelectric motor

623:motors are used in

361:Hall effect sensors

267:alternating current

2343:Dolivo-Dobrovolsky

2302:Voltage controller

2257:Blocked-rotor test

2195:Ball bearing motor

2165:Motor soft starter

2119:AC-to-AC converter

1980:Wound-rotor (WRIM)

1942:Electric generator

863:than the previous

858:. Their favorable

844:

629:gramophone records

615:

574:

484:

437:

410:

277:Brushless solution

271:synchronous motors

257:, which can cause

63:

51:

2436:

2435:

2272:Open-circuit test

2111:Motor controllers

1992:Synchronous motor

1814:Electric machines

1561:978-0-08-094752-5

1534:978-0-412-55770-5

1507:978-0-07-048289-0

1494:M. Gopal (2002).

1480:978-0-521-56688-9

1453:978-0-07-059630-6

1277:. 2 November 2019

1222:979-8-3503-0439-8

1167:978-0-07-048289-0

1154:M. Gopal (2002).

1024:. Dumb Little Man

788:open loop control

779:energy efficiency

665:electric bicycles

661:electric aircraft

649:electric vehicles

618:such as computer

566:

565:

558:

482:

285:switches such as

161:Brushed DC motors

126:neodymium magnets

79:synchronous motor

49:inside the rotor.

16:(Redirected from

2466:

2287:Two-phase system

2267:Electromagnetism

2215:Mouse mill motor

2182:recreational use

2056:Permanent magnet

1985:Linear induction

1838:Permanent magnet

1807:

1800:

1793:

1784:

1730:

1710:

1709:on April 8, 2013

1695:

1675:

1655:

1626:

1625:

1623:

1622:

1607:

1601:

1594:

1589:

1587:

1572:

1566:

1565:

1545:

1539:

1538:

1518:

1512:

1511:

1491:

1485:

1484:

1464:

1458:

1457:

1443:Sensors Handbook

1437:

1431:

1417:

1411:

1410:

1399:

1390:

1389:

1387:

1386:

1372:

1366:

1360:

1354:

1353:

1342:

1336:

1335:

1333:

1331:

1316:

1310:

1309:

1307:

1306:

1292:

1286:

1285:

1283:

1282:

1271:

1265:

1264:

1262:

1261:

1251:

1245:

1239:

1233:

1232:

1230:

1229:

1207:. pp. 1–6.

1198:

1192:

1191:

1189:

1188:

1178:

1172:

1171:

1151:

1145:

1144:

1124:

1111:

1110:

1090:

1077:

1076:

1056:

1043:

1040:

1034:

1033:

1031:

1029:

1018:

1012:

1006:

1000:

999:

998:

997:

962:

935:

930:

929:

801:system, such as

783:motor controller

755:linear actuators

561:

554:

550:

547:

541:

510:

502:

493:

491:

490:

485:

483:

481:

480:

468:

463:

462:

446:

444:

443:

438:

436:

435:

419:

417:

416:

411:

409:

408:

255:electronic noise

206:Brush commutator

21:

2474:

2473:

2469:

2468:

2467:

2465:

2464:

2463:

2454:Electric motors

2439:

2438:

2437:

2432:

2306:

2245:

2219:

2210:Mendocino motor

2183:

2181:

2174:

2105:

1965:Induction motor

1946:

1923:

1869:Braking chopper

1857:

1855:

1848:

1816:

1811:

1765:Wayback Machine

1755:Wayback Machine

1745:Wayback Machine

1737:

1728:

1720:, E-Man Press,

1713:

1698:

1693:

1678:

1673:

1658:

1653:

1638:

1635:

1633:Further reading

1630:

1629:

1620:

1618:

1609:

1608:

1604:

1585:

1583:

1574:

1573:

1569:

1562:

1547:

1546:

1542:

1535:

1520:

1519:

1515:

1508:

1493:

1492:

1488:

1481:

1466:

1465:

1461:

1454:

1439:

1438:

1434:

1429:Wayback Machine

1418:

1414:

1401:

1400:

1393:

1384:

1382:

1374:

1373:

1369:

1361:

1357:

1344:

1343:

1339:

1329:

1327:

1318:

1317:

1313:

1304:

1302:

1294:

1293:

1289:

1280:

1278:

1273:

1272:

1268:

1259:

1257:

1253:

1252:

1248:

1240:

1236:

1227:

1225:

1223:

1200:

1199:

1195:

1186:

1184:

1180:

1179:

1175:

1168:

1153:

1152:

1148:

1141:

1126:

1125:

1114:

1107:

1092:

1091:

1080:

1073:

1058:

1057:

1046:

1041:

1037:

1027:

1025:

1020:

1019:

1015:

1007:

1003:

995:

993:

964:

963:

959:

954:

931:

924:

921:

901:lithium polymer

889:

877:noise pollution

832:

811:rack-and-pinion

734:

714:

686:string trimmers

682:

653:hybrid vehicles

645:

603:

587:axial flux type

562:

551:

545:

542:

527:

511:

500:

472:

454:

449:

448:

427:

422:

421:

400:

395:

394:

392:motor constants

356:

321:microcontroller

279:

208:

158:

28:

23:

22:

15:

12:

11:

5:

2472:

2470:

2462:

2461:

2456:

2451:

2441:

2440:

2434:

2433:

2431:

2430:

2425:

2420:

2415:

2410:

2405:

2400:

2395:

2390:

2385:

2380:

2375:

2370:

2365:

2360:

2355:

2350:

2345:

2340:

2335:

2330:

2325:

2320:

2314:

2312:

2308:

2307:

2305:

2304:

2299:

2294:

2292:Inchworm motor

2289:

2284:

2279:

2274:

2269:

2264:

2262:Circle diagram

2259:

2253:

2251:

2250:Related topics

2247:

2246:

2244:

2243:

2238:

2233:

2227:

2225:

2221:

2220:

2218:

2217:

2212:

2207:

2202:

2200:Barlow's wheel

2197:

2192:

2186:

2184:

2179:

2176:

2175:

2173:

2172:

2167:

2162:

2157:

2156:

2155:

2154:

2153:

2151:Vector control

2148:

2133:

2128:

2127:

2126:

2124:Cycloconverter

2115:

2113:

2107:

2106:

2104:

2103:

2098:

2093:

2088:

2083:

2078:

2073:

2068:

2063:

2058:

2053:

2048:

2043:

2038:

2033:

2028:

2027:

2026:

2021:

2016:

2011:

2001:

2000:

1999:

1994:

1989:

1988:

1987:

1982:

1977:

1972:

1956:

1954:

1948:

1947:

1945:

1944:

1939:

1933:

1931:

1925:

1924:

1922:

1921:

1916:

1911:

1906:

1901:

1896:

1891:

1889:Damper winding

1886:

1881:

1876:

1871:

1866:

1860:

1858:

1854:Components and

1853:

1850:

1849:

1847:

1846:

1840:

1834:

1832:Direct current

1828:

1821:

1818:

1817:

1812:

1810:

1809:

1802:

1795:

1787:

1781:

1780:

1774:

1768:

1758:

1748:

1736:

1735:External links

1733:

1732:

1731:

1726:

1711:

1696:

1691:

1676:

1671:

1656:

1651:

1634:

1631:

1628:

1627:

1602:

1567:

1560:

1540:

1533:

1513:

1506:

1486:

1479:

1459:

1452:

1432:

1412:

1391:

1367:

1355:

1337:

1311:

1287:

1266:

1246:

1234:

1221:

1193:

1173:

1166:

1146:

1140:978-1118188361

1139:

1112:

1105:

1078:

1072:978-1420076875

1071:

1044:

1035:

1013:

1001:

956:

955:

953:

950:

949:

948:

943:

937:

936:

920:

917:

888:

885:

848:model aircraft

840:external rotor

831:

828:

751:motion control

733:

730:

713:

710:

681:

680:Cordless tools

678:

644:

641:

602:

599:

564:

563:

514:

512:

505:

499:

496:

479:

475:

471:

466:

461:

457:

434:

430:

407:

403:

365:rotary encoder

355:

352:

278:

275:

263:

262:

247:

245:

240:

233:

207:

204:

196:magnetic field

184:electromagnets

167:in the 1960s.

157:

154:

149:brushed motors

83:direct current

26:

24:

14:

13:

10:

9:

6:

4:

3:

2:

2471:

2460:

2457:

2455:

2452:

2450:

2447:

2446:

2444:

2429:

2426:

2424:

2421:

2419:

2416:

2414:

2411:

2409:

2406:

2404:

2401:

2399:

2396:

2394:

2391:

2389:

2386:

2384:

2381:

2379:

2376:

2374:

2371:

2369:

2366:

2364:

2361:

2359:

2356:

2354:

2351:

2349:

2346:

2344:

2341:

2339:

2336:

2334:

2331:

2329:

2326:

2324:

2321:

2319:

2316:

2315:

2313:

2309:

2303:

2300:

2298:

2295:

2293:

2290:

2288:

2285:

2283:

2280:

2278:

2275:

2273:

2270:

2268:

2265:

2263:

2260:

2258:

2255:

2254:

2252:

2248:

2242:

2239:

2237:

2234:

2232:

2229:

2228:

2226:

2222:

2216:

2213:

2211:

2208:

2206:

2203:

2201:

2198:

2196:

2193:

2191:

2188:

2187:

2185:

2177:

2171:

2168:

2166:

2163:

2161:

2158:

2152:

2149:

2147:

2144:

2143:

2142:

2139:

2138:

2137:

2134:

2132:

2129:

2125:

2122:

2121:

2120:

2117:

2116:

2114:

2112:

2108:

2102:

2099:

2097:

2094:

2092:

2089:

2087:

2086:Piezoelectric

2084:

2082:

2081:Electrostatic

2079:

2077:

2074:

2072:

2069:

2067:

2064:

2062:

2059:

2057:

2054:

2052:

2049:

2047:

2044:

2042:

2039:

2037:

2034:

2032:

2029:

2025:

2022:

2020:

2017:

2015:

2012:

2010:

2007:

2006:

2005:

2002:

1998:

1995:

1993:

1990:

1986:

1983:

1981:

1978:

1976:

1973:

1971:

1968:

1967:

1966:

1963:

1962:

1961:

1958:

1957:

1955:

1953:

1949:

1943:

1940:

1938:

1935:

1934:

1932:

1930:

1926:

1920:

1917:

1915:

1912:

1910:

1907:

1905:

1902:

1900:

1897:

1895:

1892:

1890:

1887:

1885:

1882:

1880:

1877:

1875:

1872:

1870:

1867:

1865:

1862:

1861:

1859:

1851:

1845:

1841:

1839:

1835:

1833:

1829:

1827:

1823:

1822:

1819:

1815:

1808:

1803:

1801:

1796:

1794:

1789:

1788:

1785:

1778:

1775:

1772:

1769:

1766:

1762:

1759:

1756:

1752:

1749:

1746:

1742:

1739:

1738:

1734:

1729:

1727:9780982692615

1723:

1719:

1718:

1712:

1708:

1704:

1703:

1697:

1694:

1692:9780306446986

1688:

1684:

1683:

1677:

1674:

1672:9781420014235

1668:

1665:, CRC Press,

1664:

1663:

1657:

1654:

1652:9780824743949

1648:

1645:, CRC Press,

1644:

1643:

1637:

1636:

1632:

1617:

1613:

1606:

1603:

1600:

1599:

1593:

1582:

1578:

1571:

1568:

1563:

1557:

1553:

1552:

1544:

1541:

1536:

1530:

1526:

1525:

1517:

1514:

1509:

1503:

1499:

1498:

1490:

1487:

1482:

1476:

1472:

1471:

1463:

1460:

1455:

1449:

1445:

1444:

1436:

1433:

1430:

1426:

1422:

1416:

1413:

1408:

1404:

1398:

1396:

1392:

1381:

1377:

1371:

1368:

1364:

1359:

1356:

1351:

1347:

1341:

1338:

1325:

1321:

1315:

1312:

1301:

1300:Blue Robotics

1297:

1291:

1288:

1276:

1270:

1267:

1256:

1250:

1247:

1243:

1238:

1235:

1224:

1218:

1214:

1210:

1206:

1205:

1197:

1194:

1183:

1177:

1174:

1169:

1163:

1159:

1158:

1150:

1147:

1142:

1136:

1132:

1131:

1123:

1121:

1119:

1117:

1113:

1108:

1102:

1098:

1097:

1089:

1087:

1085:

1083:

1079:

1074:

1068:

1064:

1063:

1055:

1053:

1051:

1049:

1045:

1039:

1036:

1023:

1017:

1014:

1010:

1005:

1002:

992:

988:

984:

980:

976:

972:

968:

961:

958:

951:

947:

944:

942:

939:

938:

934:

933:Trains portal

928:

923:

918:

916:

913:

912:Nitro engines

908:

906:

902:

898:

894:

886:

884:

882:

878:

873:

871:

866:

861:

857:

853:

849:

841:

836:

830:Aeromodelling

829:

827:

825:

820:

816:

812:

808:

804:

800:

796:

795:linear motors

791:

789:

784:

780:

774:

772:

768:

764:

760:

756:

752:

747:

743:

739:

731:

729:

727:

723:

722:refrigeration

719:

711:

709:

707:

703:

699:

698:reciprocating

695:

691:

687:

679:

677:

675:

671:

666:

662:

658:

654:

650:

642:

640:

638:

634:

630:

626:

621:

612:

607:

600:

598:

596:

590:

588:

583:

579:

570:

560:

557:

549:

539:

535:

531:

525:

524:

520:

515:This section

513:

509:

504:

503:

497:

495:

477:

473:

469:

464:

459:

455:

432:

428:

405:

401:

393:

388:

385:

380:

376:

375:controllers.

374:

370:

366:

362:

353:

351:

349:

348:stepper motor

344:

340:

336:

334:

329:

326:

325:microstepping

322:

317:

315:

311:

306:

304:

299:

295:

293:

288:

284:

283:semiconductor

276:

274:

272:

268:

260:

256:

252:

248:

243:

241:

238:

234:

231:

227:

226:

225:

222:

220:

216:

215:

205:

203:

201:

197:

193:

189:

185:

181:

177:

173:

168:

166:

162:

155:

153:

150:

145:

143:

139:

135:

131:

127:

123:

119:

115:

110:

108:

104:

100:

96:

92:

88:

84:

80:

76:

72:

68:

60:

57:DC brushless

55:

48:

44:

39:

34:

30:

19:

2018:

1716:

1707:the original

1701:

1685:, Springer,

1681:

1661:

1641:

1619:. Retrieved

1615:

1605:

1596:

1591:

1584:. Retrieved

1580:

1570:

1550:

1543:

1523:

1516:

1496:

1489:

1469:

1462:

1442:

1435:

1415:

1407:the original

1383:. Retrieved

1379:

1370:

1358:

1349:

1340:

1328:. Retrieved

1324:the original

1314:

1303:. Retrieved

1299:

1290:

1279:. Retrieved

1269:

1258:. Retrieved

1249:

1237:

1226:. Retrieved

1203:

1196:

1185:. Retrieved

1176:

1156:

1149:

1129:

1095:

1061:

1038:

1026:. Retrieved

1016:

1004:

994:, retrieved

974:

970:

960:

909:

890:

874:

845:

799:transmission

792:

775:

735:

715:

690:leaf blowers

683:

646:

616:

601:Applications

594:

591:

575:

552:

543:

528:Please help

516:

389:

381:

377:

372:

357:

345:

341:

337:

330:

318:

307:

300:

296:

280:

264:

223:

212:

209:

186:, made of a

169:

159:

146:

111:

74:

70:

66:

64:

42:

29:

2205:Lynch motor

1970:Shaded-pole

1856:accessories

1380:30v4160.com

1346:"home page"

1330:23 November

903:(Li-Po) or

852:helicopters

771:CNC machine

759:servomotors

720:(HVAC) and

637:performance

620:hard drives

384:comparators

287:transistors

45:, with the

38:floppy disk

2443:Categories

2101:Axial flux

2091:Ultrasonic

2066:Servomotor

2046:Doubly fed

2041:Reluctance

1937:Alternator

1929:Generators

1899:Field coil

1884:Commutator

1844:commutated

1842:SC - Self-

1621:2023-12-23

1586:2 February

1385:2023-12-23

1305:2024-01-12

1281:2021-12-02

1260:2021-11-01

1228:2023-12-23

1187:2021-04-29

1106:085296921X

996:2024-05-20

952:References

850:including

803:ballscrews

373:sensorless

251:inductance

244:brush drop

200:commutator

156:Background

130:outrunners

107:commutator

91:controller

59:ducted fan

2449:DC motors

2418:Steinmetz

2333:Davenport

2131:Amplidyne

2031:Universal

2009:Homopolar

1997:Repulsion

1909:Slip ring

1581:heavy.com

1350:.ebikekit

870:glow fuel

807:leadscrew

763:actuators

726:AC motors

643:Transport

582:outrunner

517:does not

237:hard disk

138:inrunners

43:outrunner

2423:Sturgeon

2353:Ferraris

2338:Davidson

2160:Metadyne

2076:Traction

2024:Unipolar

2004:DC motor

1960:AC motor

1864:Armature

1425:Archived

977:: 7–13,

919:See also

881:mufflers

767:extruder

694:circular

692:, saws (

578:inrunner

546:May 2018

369:back-EMF

303:armature

292:bearings

230:friction

219:graphite

120:, or an

95:windings

87:electric

81:using a

2413:Sprague

2408:Siemens

2383:Maxwell

2348:Faraday

2297:Starter

2236:Railgun

2231:Coilgun

2071:Stepper

1919:Winding

1763:at the

1753:at the

1743:at the

1028:11 June

979:Bibcode

773:tools.

706:drivers

700:), and

663:. Most

538:removed

523:sources

339:curve.

214:brushes

128:and be

77:, is a

2403:Saxton

2388:Ørsted

2373:Jedlik

2368:Jacobi

2358:Gramme

2323:Barlow

2311:People

2136:Drives

2051:Linear

1952:Motors

1914:Stator

1724:

1689:

1669:

1649:

1558:

1531:

1504:

1477:

1450:

1219:

1164:

1137:

1103:

1069:

856:drones

702:drills

659:, and

180:stator

172:torque

134:stator

103:torque

47:stator

2428:Tesla

2398:Pixii

2363:Henry

2328:Botto

2318:Arago

1904:Rotor

1874:Brush

1836:PM -

1830:DC -

1824:AC -

819:gears

363:or a

269:(AC)

176:rotor

142:axial

132:(the

99:speed

85:(DC)

2393:Park

2378:Lenz

2096:TEFC

1722:ISBN

1687:ISBN

1667:ISBN

1647:ISBN

1588:2015

1556:ISBN

1529:ISBN

1502:ISBN

1475:ISBN

1448:ISBN

1332:2020

1217:ISBN

1162:ISBN

1135:ISBN

1101:ISBN

1067:ISBN

1030:2019

854:and

696:and

627:for

521:any

519:cite

310:watt

228:The

188:coil

101:and

71:BLDC

1616:MUO

1209:doi

987:doi

815:cam

744:or

611:fan

532:by

494:).

2445::

1614:.

1590:.

1579:.

1394:^

1378:.

1348:.

1298:.

1215:.

1115:^

1081:^

1047:^

985:,

973:,

969:,

817:,

813:,

809:,

805:,

761:,

757:,

753:,

688:,

655:,

651:,

639:.

294:.

202:.

192:DC

65:A

1806:e

1799:t

1792:v

1624:.

1564:.

1537:.

1510:.

1483:.

1456:.

1388:.

1352:.

1334:.

1308:.

1284:.

1263:.

1231:.

1211::

1190:.

1170:.

1143:.

1109:.

1075:.

1032:.

989::

981::

975:3

704:/

595:Y

593:(

559:)

553:(

548:)

544:(

540:.

526:.

478:e

474:K

470:1

465:=

460:V

456:K

433:e

429:K

406:T

402:K

69:(

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.