318:

131:

66:

155:

828:) and has the capability of monitoring the resin cure throughout the entire cycle, from the liquid to the rubber to the solid state. It is capable of monitoring phase separation in complex resin blends curing also within a fibrous perform. The same attributes belong to the more recent development of the dielectric technique, namely microdielectrometry.

831:

Several versions of dielectric sensors are available commercially. The most suitable format for use in cure monitoring applications are the flat interdigital capacitive structures bearing a sensing grid on their surface. Depending on their design (specifically those on durable substrates) they have

358:

As shown in Figure 4, after an "induction time", G' and G" start to increase, with an abrupt change in slope. At a certain point they cross each other; afterwards, the rates of G' and G" decrease, and the moduli tend to a plateau. When they reach the plateau the reaction is concluded.

679:

1166:

Harkous, Ali; Colomines, Gaël; Leroy, Eric; Mousseau, Pierre; Deterre, Rémi (April 2016). "The kinetic behavior of Liquid

Silicone Rubber: A comparison between thermal and rheological approaches based on gel point determination".

497:

211:

that largely comprise them. When paint is described as "drying" it is in fact hardening by crosslinking. Oxygen atoms serve as the crosslinks, analogous to the role played by sulfur in the vulcanization of rubber.

501:

The degree of curing starts from zero (at the beginning of the reaction) and grows until one (the end of the reaction). The slope of the curve changes with time and has his maximum about at half of the reaction.

227:

In many cases, the resin is provided as a solution or mixture with a thermally-activated catalyst, which induces crosslinking but only upon heating. For example, some acrylate-based resins are formulated with

362:

When the system is liquid, the storage modulus is very low: the system behaves like a liquid. Then the reaction continues and the system starts to react more like a solid: the storage modulus increases.

809:

Also in this case the degree of curing goes from zero (no bonds created) to one (no more reactions occur) with a slope that changes in time and has its maximum about at half of the reaction.

122:

The curing methodology depends on the resin and the application. Particular attention is paid to the shrinkage induced by the curing. Usually small values of shrinkage (2–3%) are desirable.

69:

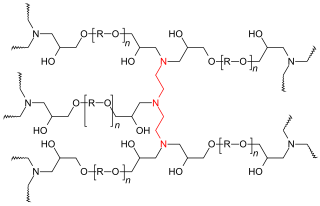

Figure 1: Structure of a cured epoxy glue. The triamine hardener is shown in red, the resin in black. The resin's epoxide groups have reacted with the hardener. The material is highly

558:

1273:

I.Partridge and G.Maistros, 'Dielectric Cure

Monitoring for Process Control', Chapter 17, Vol. 5, Encyclopaedia of Composite Materials (2001), Elsevier Science, London, page 413

1055:

980:

750:

551:

384:

804:

777:

721:

701:

1018:

Chambon, Francois; Winter, H. Henning (November 1987). "Linear

Viscoelasticity at the Gel Point of a Crosslinking PDMS with Imbalanced Stoichiometry".

849:

77:

During the curing process, single monomers and oligomers, mixed with or without a curing agent, react to form a tridimensional polymeric network.

325:

A simple way to monitor the change in viscosity, and thus, the extent of the reaction, in a curing process is to measure the variation of the

1264:

1243:

1147:

1097:

119:. An intermediate case involves a mixture of resin and additives that requires external stimulus (light, heat, radiation) to induce curing.

518:

created, higher is the heat released in the reaction. At the end of the reaction, no more heat will be released. To measure the heat flow

391:

134:

Figure 2: General representation of the chemical structure of vulcanized natural rubber showing the crosslinking of two polymer chains (

1072:

997:

88:

increases in time with the extent of the reaction until the network size is equal to the size of the system. The system has lost its

519:

53:, the term "curing" can be used for all the processes where a solid product is obtained from a liquid solution, such as with PVC

832:

some reusability, while flexible substrate sensors can be used also in the bulk of the resin systems as embedded sensors.

317:

232:. Upon heating the mixture, the peroxide converts to a free radical, which adds to an acrylate, initiating crosslinking.

81:

1294:

349:

345:

341:

1289:

871:

196:. The degree of crosslinking determines the rigidity and durability, as well as other properties of the material.

674:{\displaystyle \alpha ={\frac {Q}{Q_{T}}}={\frac {\int _{0}^{s}{\dot {Q}}\,dt}{\int _{0}^{s_{f}}{\dot {Q}}\,dt}}}

263:

the system is relatively mobile, after it the mobility is very limited, the micro-structure of the resin and the

1276:

P.Ciriscioli and G.Springer, 'Smart

Autoclave cure in Composites', (1991), Technomic Publishing, Lancaster, PA.

890:

cure monitoring methods are based on the relationships between changes in the characteristics of propagating

166:. In the second step, the hydroperoxide combines with another unsaturated side chain to generate a crosslink.

1203:

Hong, In-Kwon; Lee, Sangmook (January 2013). "Cure kinetics and modeling the reaction of silicone rubber".

514:, the crosslinking rate can be related to the heat released during the process. Higher is the number of

290:

Cure monitoring is, for example, an essential component for the control of the manufacturing process of

279:

158:

Figure 3: Simplified chemical reactions associated with curing of a drying oil. In the first step, the

50:

111:: curing "might or might not require mixing with a chemical curing agent". Thus, two broad classes are

130:

1027:

185:

355:

can be measured. The variation of G' and G" in time can indicate the extent of the curing reaction.

875:

511:

291:

38:

853:

267:

is fixed and severe diffusion limitations to further cure are created. Thus, in order to achieve

264:

229:

726:

224:, curing entails the formation of silicate crosslinks. The process is not induced by additives.

321:

Figure 4: Evolution in time of storage modulus G' and loss modulus G" during a curing reaction.

184:, the curing is also induced by the addition of a crosslinker. The resulting process is called

107:

Curing can be induced by heat, radiation, electron beams, or chemical additives. To quote from

100:

start to coexist with the macroscopic network until they react with the network creating other

1260:

1239:

1233:

1143:

1093:

1068:

993:

825:

817:

Conventional dielectrometry is carried out typically in a parallel plate configuration of the

34:

1254:

536:

369:

104:. The crosslink density increases until the system reaches the end of the chemical reaction.

1212:

1176:

1117:

1060:

1035:

985:

955:

860:

268:

200:

85:

782:

755:

1180:

333:

326:

1031:

706:

686:

1283:

919:

906:

526:

515:

204:

193:

163:

65:

864:

845:

1114:

Patterning

Dewetting in Thin Polymer Films by Spatially Directed Photocrosslinking

989:

947:

1229:

840:

The curing process can be monitored by measuring changes in various parameters:

271:

in the resin, it is usually necessary to increase the process temperature after

1216:

1121:

924:

891:

887:

818:

309:

Cure monitoring relies on monitoring various physical or chemical properties.

208:

189:

89:

46:

1064:

960:

898:

ultrasonic time of flight, both in through-transmission and pulse-echo modes;

49:

of polymer chains. Even if it is strongly associated with the production of

530:

337:

303:

244:

240:

236:

174:

101:

93:

70:

54:

17:

272:

260:

252:

248:

221:

97:

154:

1112:

Gregory T. Carroll, Nicholas J. Turro and

Jeffrey T. Koberstein (2010)

247:

interconnect. This process continues until a tridimensional network of

42:

894:

and the real-time mechanical properties of a component, by measuring:

173:

are typically cured by the use of additives, often called hardeners.

1039:

821:

295:

181:

147:

492:{\displaystyle \alpha ={\frac {G'(t)-G'_{min}}{G'_{max}-G'_{min}}}}

902:

316:

299:

256:

235:

Some organic resins are cured with heat. As heat is applied, the

170:

159:

153:

129:

108:

64:

306:

is the most important property that changes during the process.

1116:

Journal of

Colloid and Interface Science, Vol. 351, pp 556-560

177:

are often used. The amine groups ring-open the epoxide rings.

73:

and contains many OH groups, which confer adhesive properties.

844:

the concentration of specific reactive resin species using

533:

releases the same amount of energy, the degree of curing,

27:

Chemical process by which polymeric materials are hardened

1053:

Ulrich Poth (2002). "Drying Oils and

Related Products".

978:

Pham, Ha Q.; Marks, Maurice J. (2012). "Epoxy Resins".

785:

758:

729:

709:

689:

561:

539:

394:

372:

1140:

Rheology: principles, measurements, and applications

510:If the reactions occurring during crosslinking are

798:

771:

744:

715:

695:

673:

545:

491:

378:

84:with various architectures are formed, and their

112:

1205:Journal of Industrial and Engineering Chemistry

207:that catalyze cross-linking of the unsaturated

41:that produces the toughening or hardening of a

1056:Ullmann's Encyclopedia of Industrial Chemistry

981:Ullmann's Encyclopedia of Industrial Chemistry

901:natural frequency using impact excitation and

116:

8:

243:, whereupon it increases as the constituent

1235:Materials science of polymers for engineers

115:(also called curing agents, hardeners) and

703:is the heat released up to a certain time

1088:James E. Mark; Burak Erman, eds. (2005).

973:

971:

959:

790:

784:

763:

757:

731:

730:

728:

708:

688:

661:

650:

649:

641:

636:

631:

618:

607:

606:

600:

595:

588:

577:

568:

560:

538:

471:

449:

428:

401:

393:

371:

251:chains is created – this stage is termed

188:. Sulfur breaks down to form polysulfide

779:is the total amount of heat released in

1161:

1159:

942:

940:

936:

239:of the resin drops before the onset of

80:In the very first part of the reaction

874:(mechanical property) with the use of

752:is the instantaneous rate of heat and

259:this marks an important stage: before

199:Paints and varnishes commonly contain

1198:

1196:

1194:

1192:

1190:

1181:10.1016/j.reactfunctpolym.2016.01.020

1133:

1131:

1129:

1013:

1011:

1009:

7:

1259:. Vincentz Network. pp. 11–16.

298:, at the end of the process will be

255:. In terms of processability of the

113:curing induced by chemical additives

1238:. Hanser Verlag. pp. 334–335.

192:(bridges) between sections of the

117:curing in the absence of additives

33:is a chemical process employed in

25:

520:differential scanning calorimetry

282:, the process is called UV cure.

162:undergoes autoxidation to give a

96:tends to infinite. The remaining

1169:Reactive and Functional Polymers

1138:Macosko, Christopher W. (1994).

1090:Science and technology of rubber

867:of the resin (optical property);

278:When catalysts are activated by

806:, when the reaction finishes.

418:

412:

1:

990:10.1002/14356007.a09_547.pub2

553:, can be defined as follows:

336:of a system during curing, a

386:, can be defined as follow:

342:dynamic mechanical analysis

126:Curing induced by additives

1311:

1253:Glöckner, Patrick (2009).

1217:10.1016/j.jiec.2012.05.006

1122:10.1016/j.jcis.2010.07.070

745:{\displaystyle {\dot {Q}}}

294:. The material, initially

876:Fiber Bragg grating (FBG)

1232:; Menges, Georg (2003).

1065:10.1002/14356007.a09_055

961:10.1351/goldbook.CT07137

813:Dielectrometric analysis

216:Curing without additives

1059:. Weinheim: Wiley-VCH.

984:. Weinheim: Wiley-VCH.

546:{\displaystyle \alpha }

379:{\displaystyle \alpha }

836:Spectroscopic analysis

800:

773:

746:

717:

697:

675:

547:

493:

380:

366:The degree of curing,

322:

167:

151:

74:

51:thermosetting polymers

909:velocity measurement.

846:spectroscopic methods

801:

799:{\displaystyle s_{f}}

774:

772:{\displaystyle Q_{T}}

747:

718:

698:

676:

548:

494:

381:

320:

280:ultraviolet radiation

157:

133:

82:branches of molecules

68:

1142:. VCH. p. 568.

783:

756:

727:

707:

687:

559:

537:

392:

370:

346:storage modulus (G')

313:Rheological analysis

186:sulfur vulcanization

1032:1987JRheo..31..683C

1020:Journal of Rheology

883:Ultrasonic analysis

870:the internal resin

648:

605:

525:Assuming that each

485:

463:

442:

292:composite materials

150:(n = 0, 1, 2, 3 …).

39:process engineering

1295:Chemical processes

796:

769:

742:

713:

693:

671:

627:

591:

543:

529:formed during the

489:

467:

445:

424:

376:

340:can be used. With

323:

286:Monitoring methods

265:composite material

230:dibenzoyl peroxide

168:

152:

75:

1290:Polymer chemistry

1266:978-3-86630-907-4

1245:978-1-56990-348-3

1149:978-0-471-18575-8

1099:978-0-12-464786-2

905:-induced surface

826:capacitance probe

739:

716:{\displaystyle s}

696:{\displaystyle Q}

669:

658:

615:

583:

487:

201:oil drying agents

35:polymer chemistry

16:(Redirected from

1302:

1270:

1256:Radiation Curing

1249:

1221:

1220:

1200:

1185:

1184:

1163:

1154:

1153:

1135:

1124:

1110:

1104:

1103:

1085:

1079:

1078:

1050:

1044:

1043:

1040:10.1122/1.549955

1015:

1004:

1003:

975:

966:

965:

963:

944:

861:refractive index

805:

803:

802:

797:

795:

794:

778:

776:

775:

770:

768:

767:

751:

749:

748:

743:

741:

740:

732:

722:

720:

719:

714:

702:

700:

699:

694:

680:

678:

677:

672:

670:

668:

660:

659:

651:

647:

646:

645:

635:

625:

617:

616:

608:

604:

599:

589:

584:

582:

581:

569:

552:

550:

549:

544:

506:Thermal analysis

498:

496:

495:

490:

488:

486:

481:

459:

443:

438:

411:

402:

385:

383:

382:

377:

145:

139:

86:molecular weight

21:

1310:

1309:

1305:

1304:

1303:

1301:

1300:

1299:

1280:

1279:

1267:

1252:

1246:

1230:Osswald, Tim A.

1228:

1225:

1224:

1202:

1201:

1188:

1165:

1164:

1157:

1150:

1137:

1136:

1127:

1111:

1107:

1100:

1092:. p. 768.

1087:

1086:

1082:

1075:

1052:

1051:

1047:

1017:

1016:

1007:

1000:

977:

976:

969:

946:

945:

938:

933:

916:

885:

838:

815:

786:

781:

780:

759:

754:

753:

725:

724:

705:

704:

685:

684:

637:

626:

590:

573:

557:

556:

535:

534:

508:

444:

404:

403:

390:

389:

368:

367:

350:loss modulus (G

334:elastic modulus

332:To measure the

327:elastic modulus

315:

288:

220:In the case of

218:

141:

135:

128:

63:

28:

23:

22:

15:

12:

11:

5:

1308:

1306:

1298:

1297:

1292:

1282:

1281:

1278:

1277:

1274:

1271:

1265:

1250:

1244:

1223:

1222:

1186:

1155:

1148:

1125:

1105:

1098:

1080:

1074:978-3527306732

1073:

1045:

1026:(8): 683–697.

1005:

999:978-3527306732

998:

967:

952:IUPAC Goldbook

935:

934:

932:

929:

928:

927:

922:

915:

912:

911:

910:

899:

884:

881:

880:

879:

868:

857:

837:

834:

814:

811:

793:

789:

766:

762:

738:

735:

712:

692:

667:

664:

657:

654:

644:

640:

634:

630:

624:

621:

614:

611:

603:

598:

594:

587:

580:

576:

572:

567:

564:

542:

507:

504:

484:

480:

477:

474:

470:

466:

462:

458:

455:

452:

448:

441:

437:

434:

431:

427:

423:

420:

417:

414:

410:

407:

400:

397:

375:

314:

311:

287:

284:

217:

214:

205:metallic soaps

194:polymer chains

127:

124:

62:

61:Curing process

59:

26:

24:

14:

13:

10:

9:

6:

4:

3:

2:

1307:

1296:

1293:

1291:

1288:

1287:

1285:

1275:

1272:

1268:

1262:

1258:

1257:

1251:

1247:

1241:

1237:

1236:

1231:

1227:

1226:

1218:

1214:

1210:

1206:

1199:

1197:

1195:

1193:

1191:

1187:

1182:

1178:

1174:

1170:

1162:

1160:

1156:

1151:

1145:

1141:

1134:

1132:

1130:

1126:

1123:

1119:

1115:

1109:

1106:

1101:

1095:

1091:

1084:

1081:

1076:

1070:

1066:

1062:

1058:

1057:

1049:

1046:

1041:

1037:

1033:

1029:

1025:

1021:

1014:

1012:

1010:

1006:

1001:

995:

991:

987:

983:

982:

974:

972:

968:

962:

957:

953:

949:

943:

941:

937:

930:

926:

923:

921:

920:Vulcanization

918:

917:

913:

908:

907:acoustic wave

904:

900:

897:

896:

895:

893:

889:

882:

877:

873:

869:

866:

862:

858:

855:

851:

847:

843:

842:

841:

835:

833:

829:

827:

823:

820:

812:

810:

807:

791:

787:

764:

760:

736:

733:

710:

690:

681:

665:

662:

655:

652:

642:

638:

632:

628:

622:

619:

612:

609:

601:

596:

592:

585:

578:

574:

570:

565:

562:

554:

540:

532:

528:

523:

522:can be used.

521:

517:

513:

505:

503:

499:

482:

478:

475:

472:

468:

464:

460:

456:

453:

450:

446:

439:

435:

432:

429:

425:

421:

415:

408:

405:

398:

395:

387:

373:

364:

360:

356:

354:

353:

347:

343:

339:

335:

330:

328:

319:

312:

310:

307:

305:

301:

297:

293:

285:

283:

281:

276:

274:

270:

269:vitrification

266:

262:

258:

254:

250:

246:

242:

238:

233:

231:

225:

223:

215:

213:

210:

206:

202:

197:

195:

191:

187:

183:

178:

176:

172:

165:

164:hydroperoxide

161:

156:

149:

144:

138:

132:

125:

123:

120:

118:

114:

110:

105:

103:

99:

95:

91:

87:

83:

78:

72:

67:

60:

58:

56:

52:

48:

47:cross-linking

44:

40:

36:

32:

19:

1255:

1234:

1211:(1): 42–47.

1208:

1204:

1172:

1168:

1139:

1113:

1108:

1089:

1083:

1054:

1048:

1023:

1019:

979:

951:

886:

865:fluorescence

839:

830:

816:

808:

682:

555:

531:crosslinking

524:

509:

500:

388:

365:

361:

357:

351:

331:

324:

308:

289:

277:

241:crosslinking

234:

226:

219:

198:

179:

171:Epoxy resins

169:

142:

136:

121:

106:

79:

76:

45:material by

30:

29:

18:Curing agent

209:drying oils

190:cross-links

71:crosslinked

1284:Categories

931:References

925:Cross-link

892:ultrasound

888:Ultrasonic

819:dielectric

512:exothermic

203:, usually

175:Polyamines

102:crosslinks

90:solubility

55:plastisols

1175:: 20–27.

737:˙

656:˙

629:∫

613:˙

593:∫

563:α

541:α

465:−

422:−

396:α

374:α

338:rheometer

304:viscosity

245:oligomers

237:viscosity

98:molecules

94:viscosity

954:. 2014.

948:"curing"

914:See also

878:sensors.

848:such as

483:′

461:′

440:′

409:′

348:and the

273:gelation

261:gelation

253:gelation

249:oligomer

222:concrete

92:and its

1028:Bibcode

146:) with

43:polymer

1263:

1242:

1146:

1096:

1071:

996:

872:strain

852:&

822:sensor

683:where

344:, the

296:liquid

182:rubber

148:sulfur

31:Curing

903:laser

854:Raman

516:bonds

300:solid

257:resin

160:diene

143:green

109:IUPAC

1261:ISBN

1240:ISBN

1144:ISBN

1094:ISBN

1069:ISBN

994:ISBN

859:the

850:FTIR

527:bond

140:and

137:blue

37:and

1213:doi

1177:doi

1173:101

1118:doi

1061:doi

1036:doi

986:doi

956:doi

863:or

180:In

1286::

1209:19

1207:.

1189:^

1171:.

1158:^

1128:^

1067:.

1034:.

1024:31

1022:.

1008:^

992:.

970:^

950:.

939:^

723:,

329:.

302::

275:.

57:.

1269:.

1248:.

1219:.

1215::

1183:.

1179::

1152:.

1120::

1102:.

1077:.

1063::

1042:.

1038::

1030::

1002:.

988::

964:.

958::

856:;

824:(

792:f

788:s

765:T

761:Q

734:Q

711:s

691:Q

666:t

663:d

653:Q

643:f

639:s

633:0

623:t

620:d

610:Q

602:s

597:0

586:=

579:T

575:Q

571:Q

566:=

479:n

476:i

473:m

469:G

457:x

454:a

451:m

447:G

436:n

433:i

430:m

426:G

419:)

416:t

413:(

406:G

399:=

352:)

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.