181:, which is a collar that is pressed over the head of the bushing and has a long tail. The tail may be bent at the end so it can lock around the edge of the jig plate or it may be left straight if it can butt up against another object. Another option to keep the renewable bushing from rotating is to pin it, either by putting a pin in the renewable bushing and a hole in the liner or vice versa. A more complicated version uses a hole in the bushing collar and a pin with a head; the head on the pin holds the edge of the collar down, but for removal the bushing can be rotated so that the hole lines up with the pin.

126:

169:

606:

134:

82:

613:

A common problem encountered is when two or more holes are too close for independent standard bushings. In this case one large renewable bushing can be made with two (or more) holes in the proper location (the first example in the image). Another possibility is to make a custom bushing with an

141:

Renewable bushings are installed in liner bushings. This type of bushing is used in large production runs where a bushing will wear out over time or when multiple renewable bushings are used in one liner to provide various sized holes. There are two types of renewable bushings:

176:

Renewable bushings must be secured in their liner bushing, otherwise the tool can cause it to spin, which rapidly wears out the liner, or chips can force the bushing out of the liner. There are many different types of locking systems for renewable bushings. One system is a

618:

hole and then notches on the outside of the head are used to locate the proper position of the bushing for each location (the middle example in the image). Another common need for a custom bushing is when the hole needed is perpendicular jig plate; in this case a

289:

inch (7.94 mm, 9.53 mm, 12.7 mm, 19.05 mm, 25.4 mm, 34.93 mm and 44.45 mm). The letter "U" is used after the OD number to designate that extra stock should be left on the OD for

85:

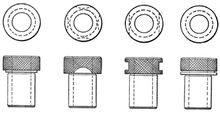

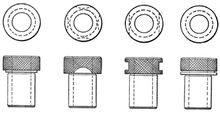

Types of drilling bushings: A. Headless wearing press-fit bushing B. Head wearing press-fit bushing C. Headless liner bushing with renewable bushing D. Head liner bushing with renewable bushing

137:

Four types of dogs. Key (A) shows how the end of the dog can be bent down to wrap around the edge of the jig plate; key (B) shows how a pin can be used to keep the dog from rotating.

113:, are permanently installed into the jig and accept liners that can easily be replaced. Press-fit wearing bushings are used in short run applications or in applications where the

157:

with a given sized liner so that two different sized slip renewable bushings can be used in one liner bushing. This facilitates the ability to do multiple

153:

Fixed renewable bushings are used in applications where the liner is meant to be used until it wears out. Slip renewable bushings are designed to be

776:

62:

73:

bushings are standardized via ASME B94.33.1. There are over 50,000 standard configurations of customary sized bushings.

795:

291:

161:

operations that require different inner diameter (ID) bushings, such as drilling and reaming. They usually have

97:

bushings. Other classification methods include by head type, by use, and by liner type (or lack thereof).

129:

Four features that can be incorporated into small renewable bushings for easy removal with a screwdriver.

615:

197:

Where the ID is specified as a decimal, drill letter size, drill number size, or fraction; the OD is an

154:

114:

707:

221:

th of an inch. The lengths of press-fit bushings are standardized to typical jig plate thicknesses:

125:

168:

772:

211:

th of an inch (0.40 mm); the length is an integer that relates to a multiple of a

605:

789:

117:

on a hole location is so tight that it cannot facilitate the use of a liner bushing.

70:

81:

39:

32:

133:

766:

755:

639:

In general, a drill bushing's length should be at least 2 times the nominal ID.

51:

47:

35:

628:

158:

43:

189:

Customary bushings are specified using the following specification layout:

198:

162:

58:. They are designed to guide, position, and support the cutting tool.

55:

708:

http://catalog.asme.org/Codes/PrintBook/B94331_1998_Jig_Bushings.cfm

624:

604:

167:

132:

124:

80:

335:

The following two tables give the tolerances for the ID and OD.

66:

46:. Other tools that are commonly used in a drill bushing include

28:

105:

Press fit are available in two types with liners or without (

623:

is used. It is a hardened piece of right angle steel that

294:

to size. The type is a letter referring to the following:

754:Colvin, Fred Herbert; Haas, Lucian Levant (1922),

609:Three more common types of custom drill bushings

89:Drill bushings can generally be classified as:

721:

719:

717:

715:

691:

689:

687:

685:

683:

681:

668:

666:

664:

8:

109:bushings). Liner bushings, sometimes called

737:

655:

172:Various methods to lock renewable bushings

725:

695:

672:

760:(2nd ed.), McGraw-Hill, p. 44.

456:

337:

648:

627:to the jig plate and is located with

165:heads so they can be easily removed.

7:

14:

201:that relates to a multiple of a

65:bushings are standardized via

1:

768:Jig and fixture design manual

765:Henriksen, Erik Karl (1973),

812:

771:, Industrial Press Inc.,

458:OD grinding tolerances

738:Colvin & Haas 1922

656:Colvin & Haas 1922

610:

173:

138:

130:

86:

608:

171:

136:

128:

84:

325:- Headless press-fit

459:

413:19.05–38.10 mm

340:

796:Metalworking tools

740:, pp. 45, 47.

611:

457:

390:6.35–19.05 mm

387:0.25–0.75 in

338:

174:

139:

131:

121:Renewable bushings

101:Press-fit bushings

87:

23:, also known as a

778:978-0-8311-1098-7

757:Jigs and fixtures

598:

597:

547:7.94–5.16 mm

505:3.97–6.35 mm

455:

454:

410:0.75–1.5 in

367:0.00–6.35 mm

307:- Fixed renewable

193:ID-Type-OD-Length

16:Metalworking tool

803:

782:

761:

741:

735:

729:

723:

710:

705:

699:

693:

676:

670:

659:

653:

575:

574:

570:

543:

542:

538:

533:

532:

528:

501:

500:

496:

491:

490:

486:

460:

451:0.00762 mm

428:0.00508 mm

405:0.00254 mm

382:0.00254 mm

341:

331:- Head press-fit

313:- Headless liner

301:- Slip renewable

288:

287:

283:

280:

274:

273:

269:

266:

260:

259:

255:

250:

249:

245:

240:

239:

235:

230:

229:

225:

220:

219:

215:

210:

209:

205:

42:, most commonly

811:

810:

806:

805:

804:

802:

801:

800:

786:

785:

779:

764:

753:

750:

745:

744:

736:

732:

724:

713:

706:

702:

694:

679:

671:

662:

654:

650:

645:

637:

621:bracket bushing

603:

601:Custom bushings

572:

568:

567:

540:

536:

535:

530:

526:

525:

498:

494:

493:

488:

484:

483:

448:0.0003 in

445:0.01778 mm

442:0.0007 in

425:0.0002 in

422:0.01524 mm

419:0.0006 in

402:0.0001 in

396:0.0005 in

379:0.0001 in

376:0.01016 mm

373:0.0004 in

364:0–0.25 in

285:

281:

278:

276:

271:

267:

264:

262:

257:

253:

252:

247:

243:

242:

237:

233:

232:

227:

223:

222:

217:

213:

212:

207:

203:

202:

187:

155:interchangeable

123:

111:master bushings

103:

79:

63:Customary sized

17:

12:

11:

5:

809:

807:

799:

798:

788:

787:

784:

783:

777:

762:

749:

746:

743:

742:

730:

728:, p. 156.

726:Henriksen 1973

711:

700:

698:, p. 155.

696:Henriksen 1973

677:

675:, p. 154.

673:Henriksen 1973

660:

647:

646:

644:

641:

636:

633:

602:

599:

596:

595:

594:0.508 mm

592:

591:0.020 in

589:

586:

585:0.015 in

583:

580:

577:

564:

563:

562:0.381 mm

560:

559:0.015 in

557:

554:

553:0.010 in

551:

548:

545:

522:

521:

520:0.254 mm

518:

517:0.010 in

515:

512:

511:0.005 in

509:

506:

503:

480:

479:

477:

474:

472:

469:

466:

464:

453:

452:

449:

446:

443:

440:

437:

434:

430:

429:

426:

423:

420:

417:

414:

411:

407:

406:

403:

400:

399:0.0127 mm

397:

394:

391:

388:

384:

383:

380:

377:

374:

371:

368:

365:

361:

360:

358:

355:

353:

350:

347:

345:

339:ID tolerances

333:

332:

326:

320:

314:

308:

302:

195:

194:

186:

183:

122:

119:

102:

99:

78:

75:

15:

13:

10:

9:

6:

4:

3:

2:

808:

797:

794:

793:

791:

780:

774:

770:

769:

763:

759:

758:

752:

751:

747:

739:

734:

731:

727:

722:

720:

718:

716:

712:

709:

704:

701:

697:

692:

690:

688:

686:

684:

682:

678:

674:

669:

667:

665:

661:

658:, p. 44.

657:

652:

649:

642:

640:

634:

632:

630:

626:

622:

617:

607:

600:

593:

590:

588:0.381 mm

587:

584:

581:

578:

566:

565:

561:

558:

556:0.254 mm

555:

552:

549:

546:

524:

523:

519:

516:

514:0.127 mm

513:

510:

507:

504:

482:

481:

478:

475:

473:

470:

467:

465:

462:

461:

450:

447:

444:

441:

438:

435:

432:

431:

427:

424:

421:

418:

415:

412:

409:

408:

404:

401:

398:

395:

392:

389:

386:

385:

381:

378:

375:

372:

369:

366:

363:

362:

359:

356:

354:

351:

348:

346:

343:

342:

336:

330:

327:

324:

321:

318:

315:

312:

309:

306:

303:

300:

297:

296:

295:

293:

200:

192:

191:

190:

185:Specification

184:

182:

180:

170:

166:

164:

160:

156:

151:

149:

145:

135:

127:

120:

118:

116:

112:

108:

100:

98:

96:

92:

83:

76:

74:

72:

68:

64:

59:

57:

53:

49:

45:

41:

40:cutting tools

37:

34:

30:

26:

22:

21:drill bushing

767:

756:

748:Bibliography

733:

703:

651:

638:

620:

612:

582:Greater than

579:12.7 mm

439:Greater than

436:38.1 mm

433:1.5 in

334:

328:

322:

319:- Head liner

316:

310:

304:

298:

196:

188:

178:

175:

152:

147:

143:

140:

110:

106:

104:

94:

93:bushings or

90:

88:

61:In the USA,

60:

52:countersinks

48:counterbores

33:metalworking

24:

20:

18:

463:Nominal OD

344:Nominal ID

69:B94.33 and

25:jig bushing

643:References

629:dowel pins

44:drill bits

616:eccentric

576: in

544: in

502: in

370:including

159:machining

115:tolerance

95:renewable

91:press fit

38:to guide

790:Category

476:Minimum

471:Maximum

357:Minimum

352:Maximum

292:grinding

31:used in

571:⁄

539:⁄

529:⁄

497:⁄

487:⁄

284:⁄

275:, and

270:⁄

256:⁄

246:⁄

236:⁄

226:⁄

216:⁄

206:⁄

199:integer

163:knurled

107:wearing

56:reamers

27:, is a

775:

635:Design

625:screws

261:, 1 ,

71:metric

54:, and

416:incl.

393:incl.

144:fixed

77:Types

773:ISBN

148:slip

146:and

67:ASME

36:jigs

29:tool

179:dog

792::

714:^

680:^

663:^

631:.

541:64

537:13

531:16

489:32

317:HL

251:,

241:,

231:,

228:16

218:16

208:64

150:.

50:,

19:A

781:.

573:2

569:1

550:_

534:–

527:5

508:_

499:4

495:1

492:–

485:5

468:_

349:_

329:H

323:P

311:L

305:F

299:S

286:4

282:3

279:+

277:1

272:8

268:3

265:+

263:1

258:4

254:3

248:2

244:1

238:8

234:3

224:5

214:1

204:1

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.