291:

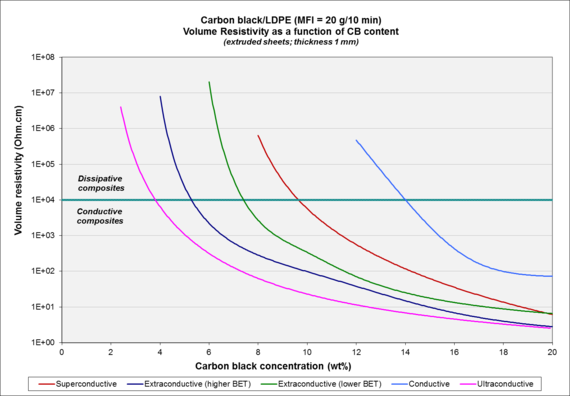

134:. At the same time, it consists of primary carbon particles and boasts a high degree of aggregation. Carbon black's grouping facilitates the formation of a conductive structure in plastics, rubbers and other composites. These characteristics predetermine electroconductive carbon black's primary area of application, i.e. electrical conductivity modification of nearly all types of plastic materials by adding a relatively low volume of carbon black. Such modifications can be used for numerous purposes, from establishing antistatic properties to adjusting polymer conductivity. Another valuable property of electroconductive carbon black is its excellent ability to absorb

341:

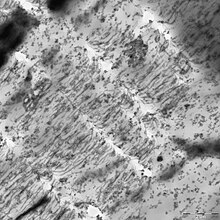

carbon black structure consists of branched chains with many secondarily created spaces in the aggregate. On the other hand, aggregate structure that is developed only a little represents smaller clusters of the spherical particles and thus also smaller spaces inside of the aggregate. The aggregate structure does not depend on the size of the particles. It has been established that particles of the same size can have aggregates with completely different structures. Generally speaking, carbon black that has a highly developed and complex structure is easier to disperse, has lower wettability, higher electric conductivity and higher viscosity.

368:

328:

307:

299:

190:

production principle lies in isolating carbon from the water using granulation petrol, where intensive homogenization causes the carbon to transform from its aqueous to an organic phase, i.e. transformation of the water-carbon suspension to petrol-carbon suspension in the form of carbonaceous granules. The carbonaceous granules are subsequently processed into a finished product – carbonaceous substrate. The two mediums’ proportionality primarily depends on carbon content and physical and chemical properties of the carbon black water and granulation petrol.

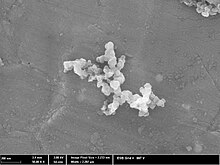

287:(aggregate) into chains or clusters. These aggregates then form the smallest carbon black units. They define what is known as the primary structure. Primary structure is characterized by the following: size of the primary particles, surface size, size and structure of the aggregates or chemical “composition” of the carbon black surface. These characteristics determine other carbon black features, such as adsorption properties, density, electrical conductivity, and absorption of UV radiation or visible light.

324:. It has been ascertained that the smaller the particles, the greater the size of their surface. Carbon black particle size is between 10 and 100 nm, while the surface particle size is between 20 and 1,500 m/g. Generally speaking, small carbon black particles with a high surface area are darker, have higher viscosity and lower wettability, are harder to disperse, retain greater conductivity and absorb UV radiation well.

263:

271:

22:

340:

Another significant characteristic of carbon black is its structure and the size of its aggregates. The size and complexity of the aggregate structure is determined by the volume of the carbon black spherical primary particles, which cluster together during the production process. The highly complex

189:

During the respective process, carbon black is captured into water through the method of scrubbing, thus creating carbon black water. The generated carbon black water with 7–15 g/L of carbon black is further processed at the production facility into several types of carbonaceous substrates. The main

150:

of what is referred to as partial oxidation, a process during which crude oil residues, such as vacuum residues from crude oil distillation or residues from the thermic cracking process, split due to the effects of the mixture of oxygen and water steam under high temperatures around 1,300 °C.

126:

or thermo-conductive characteristics of plastic materials and rubbers. By virtue of its pigmentation capabilities, it is also used for the production of special printing inks, paints and varnishes. Thanks to its advanced porous structure, it is also used as a catalyst carrier, and its notable

286:

Carbon black is essentially formed out of primary carbon, but its structure is much less arranged than that of, for example, graphite. Carbon black exists in the form of discrete particles, however, during the production process its spherical particles, also called primary particles, cluster

319:

The most important characteristic of carbon black is the size of its primary particles and the related surface area. The size of the primary particles describes the size of individual spherical particles that form a primary structure. The size of individual particles is determined using an

417:, such as Bare Conductive's Electric Paint, which can be used as a painted resistor element, a capacitive electrode, or as a conductor in designs that tolerate high resistivity when making circuits, as well as being painted onto gloves to allow people to use touchscreens in cold weather.

185:

formed from sulfurous compounds. Carbon black is formed as an undesired byproduct. The amount of carbon black grows as the injection's molecular weight increases. Methane gasification produces approx. 0.02% mass, crude oil residue gasification approx. 1-3% mass.

805:

Gubbels, F.; Jerome, R.; Teyssie, Ph; Vanlathem, E.; Deltour, R.; Calderone, A.; Parente, V.; Bredas, J. L. (2002-05-01). "Selective

Localization of Carbon Black in Immiscible Polymer Blends: A Useful Tool To Design Electrical Conductive Composites".

361:

groups appear on carbon black surfaces. These groups, which contain oxygen, can significantly affect chemical reactivity, wettability, carbon black catalytic characteristics, electric conductivity, etc.

86:) in its complex configuration, colloid dimensions and quasi-graphitic structure. Carbon black's purity and composition are practically free of inorganic pollutants and extractable organic substances.

495:

Pantea, Dana; Darmstadt, Hans; Kaliaguine, Serge; Roy, Christian (2003-07-15). "Electrical conductivity of conductive carbon blacks: influence of surface chemistry and topology".

114:

Carbon black can be characterized as a substance with over 97% amorphous carbon content. It is used extensively in many areas of industrial chemistry. It is often used in the

138:

on the visible spectrum, i.e. as a UV stabilizer for plastic materials, pigment in printer inks, paints and varnishes, or for coloring plastics, rubbers and sealants.

833:

Gubbels, R.; and collective (1994). "Selective

Localization of Carbon Black in Immiscible Polymer Blends: A Useful Tool To Design Electrical Conductive Composites".

130:

Carbon black predominantly includes a conductive type of carbon, which combines an extremely high specific surface and extensively developed structure –

703:

Herink, Tomáš; Raška, Stanislav; Nečesaný, František; Kubal, Petr (2008). "Application possibilities of the

Chezacarb soot produced at Unipetrol RPA".

98:– a specially produced type of carbon using the process of incomplete combustion with restricted oxygen access. The article addresses this type of

110:– auxiliary fuel (coal, hydrocarbons, crude oil) combustion product, which is considered to be a hazardous substance with carcinogenic properties.

770:

Tchoudakov, R.; Breuer, O.; Narkis, M.; Siegmann, A. (1996). "Conductive polymer blends with low carbon black loading: Polypropylene/polyamide".

674:

290:

721:

349:

Yet another noteworthy characteristic is carbon black's chemical surface composition. Chemisorbed complexes containing oxygen, such as

894:

367:

919:

899:

74:, carbon black is spherical in shape and arranged into aggregates and agglomerates. It differs from other carbon forms (

327:

306:

755:

Wiley, John (1997). "Agglomeration and electrical percolation behavior of carbon black dispersed in epoxy resin".

298:

924:

119:

611:

Bourrat, Xavier (1993-01-01). "Electrically conductive grades of carbon black: Structure and properties".

551:

Probst, Nicolaus; Grivei, Eusebiu (2002-02-01). "Structure and electrical properties of carbon black".

127:

sorption attributes are used for, in example, catching gaseous pollutants at waste incinerator plants.

842:

620:

560:

504:

51:

895:

http://www.unipetrolrpa.cz/CS/NabidkaProduktu/petrochemicke-produkty/chezacarb/Stranky/default.aspx

321:

32:

939:

920:

https://polymerchemistry.nouryon.com/products-applications/polymer-additives/conductive-blacks

900:

https://web.archive.org/web/20190209124223/https://www.orioncarbons.com/specialty-carbon-black

787:

670:

636:

576:

520:

457:

431:

182:

729:

438:(Ketjenblack), TIMCAL (Ensaco), BIRLA CARBON (Conductex) and ORION ENGINEERED CARBONS (XPB).

154:

Partial oxidation of various raw materials always creates a gaseous mixture containing CO, CO

850:

815:

779:

628:

568:

512:

174:

123:

944:

350:

846:

624:

564:

508:

405:

572:

516:

933:

632:

131:

914:

447:

135:

94:

83:

791:

640:

580:

524:

426:

Some of the world's main producers of electroconductive carbon black include

462:

452:

435:

427:

270:

147:

41:

925:

http://www.cabotcorp.com/solutions/applications/plastics/conductive-and-esd

21:

262:

79:

854:

819:

412:

390:

358:

354:

294:

Incorporated electroconductive carbon black in the polypropylene matrix

277:

Physical and chemical characteristics of electroconductive carbon black

167:

115:

75:

783:

261:

99:

71:

889:

398:

326:

305:

297:

289:

106:

374:

Picture: Diagram of carbon black structure and texture creation

904:

15:

909:

118:

and rubber manufacturing industries, where it improves

46:

36:

757:

Journal of

Applied Science: Applied Polymer Science

669:. Zlín: Czech Association of Industrial Chemistry.

555:. Third International Conference on Carbon Black.

915:http://www.imerys-graphite-and-carbon.com/brands/

722:"petroleum.cz, Výroba vodíku parciální oxidací"

89:A distinction is made between these two terms:

871:"World Market for Conductive Carbon Blacks".

8:

331:Electroconductive carbon black – Structure 3

310:Electroconductive carbon black – Structure 2

302:Electroconductive carbon black – Structure 1

269:

422:Electroconductive carbon black producers

197:

474:

194:Types of electroconductive carbon black

866:

864:

7:

750:

748:

746:

716:

714:

698:

696:

694:

692:

690:

688:

686:

660:

658:

656:

654:

652:

650:

606:

604:

602:

600:

598:

596:

594:

592:

590:

546:

544:

542:

540:

538:

536:

534:

490:

488:

486:

484:

482:

480:

478:

705:Chemical Sheets: Chemical Industry

14:

890:http://chezacarbcarbonblack.com/

366:

20:

1:

573:10.1016/S0008-6223(01)00174-9

517:10.1016/S0169-4332(03)00550-6

434:(Vulcan), DEGUSSA (Printex),

633:10.1016/0008-6223(93)90034-8

905:http://specialtyblacks.com/

772:Polymer Engineering Journal

961:

393:(compounds, concentrates)

146:Carbon black begins as a

910:https://birlacarbon.com/

665:Kliment, Josef (2008).

497:Applied Surface Science

345:Surface characteristics

120:electrical conductivity

35:, as no other articles

873:Notch Consulting Group

384:Composite applications

332:

311:

303:

295:

266:

236:extraconductive (cca)

225:superconductive (cca)

330:

309:

301:

293:

265:

855:10.1021/ma00085a049

847:1994MaMol..27.1972G

820:10.1021/ma00085a049

625:1993Carbo..31..287B

565:2002Carbo..40..201P

509:2003ApSS..217..181P

322:electron microscope

199:

70:Made up of primary

333:

312:

304:

296:

267:

198:

54:for suggestions.

44:to this page from

784:10.1002/pen.10528

778:(10): 1336–1346.

676:978-80-02-02004-2

458:Cabot Corporation

432:CABOT Corporation

257:

256:

214:conductive (cca)

68:

67:

952:

877:

876:

868:

859:

858:

841:(7): 1972–1974.

830:

824:

823:

814:(7): 1972–1974.

802:

796:

795:

767:

761:

760:

752:

741:

740:

738:

737:

728:. Archived from

726:www.petroleum.cz

718:

709:

708:

700:

681:

680:

662:

645:

644:

608:

585:

584:

548:

529:

528:

492:

370:

273:

247:ultraconductive

200:

63:

60:

49:

47:related articles

24:

16:

960:

959:

955:

954:

953:

951:

950:

949:

930:

929:

886:

881:

880:

870:

869:

862:

832:

831:

827:

804:

803:

799:

769:

768:

764:

754:

753:

744:

735:

733:

720:

719:

712:

702:

701:

684:

677:

664:

663:

648:

610:

609:

588:

550:

549:

532:

494:

493:

476:

471:

444:

424:

415:, paints, glues

381:

365:

347:

338:

317:

284:

279:

259:

196:

178:

171:

165:

161:

157:

144:

124:electromagnetic

64:

58:

55:

45:

42:introduce links

25:

12:

11:

5:

958:

956:

948:

947:

942:

932:

931:

928:

927:

922:

917:

912:

907:

902:

897:

892:

885:

884:External links

882:

879:

878:

860:

835:Macromolecules

825:

808:Macromolecules

797:

762:

742:

710:

682:

675:

646:

619:(2): 287–302.

586:

559:(2): 201–205.

530:

503:(1): 181–193.

473:

472:

470:

467:

466:

465:

460:

455:

450:

443:

440:

423:

420:

419:

418:

409:

402:

395:

380:

377:

346:

343:

337:

334:

316:

313:

283:

280:

278:

275:

255:

254:

251:

248:

244:

243:

240:

237:

233:

232:

229:

226:

222:

221:

218:

215:

211:

210:

207:

204:

195:

192:

176:

169:

163:

159:

155:

143:

140:

112:

111:

103:

66:

65:

52:Find link tool

28:

26:

19:

13:

10:

9:

6:

4:

3:

2:

957:

946:

943:

941:

938:

937:

935:

926:

923:

921:

918:

916:

913:

911:

908:

906:

903:

901:

898:

896:

893:

891:

888:

887:

883:

874:

867:

865:

861:

856:

852:

848:

844:

840:

836:

829:

826:

821:

817:

813:

809:

801:

798:

793:

789:

785:

781:

777:

773:

766:

763:

758:

751:

749:

747:

743:

732:on 2019-03-11

731:

727:

723:

717:

715:

711:

706:

699:

697:

695:

693:

691:

689:

687:

683:

678:

672:

668:

661:

659:

657:

655:

653:

651:

647:

642:

638:

634:

630:

626:

622:

618:

614:

607:

605:

603:

601:

599:

597:

595:

593:

591:

587:

582:

578:

574:

570:

566:

562:

558:

554:

547:

545:

543:

541:

539:

537:

535:

531:

526:

522:

518:

514:

510:

506:

502:

498:

491:

489:

487:

485:

483:

481:

479:

475:

468:

464:

461:

459:

456:

454:

451:

449:

446:

445:

441:

439:

437:

433:

430:(Chezacarb),

429:

421:

416:

414:

410:

408:

407:

403:

401:

400:

396:

394:

392:

388:

387:

386:

385:

378:

376:

375:

371:

369:

363:

360:

356:

352:

344:

342:

335:

329:

325:

323:

314:

308:

300:

292:

288:

281:

276:

274:

272:

264:

260:

252:

249:

246:

245:

241:

238:

235:

234:

230:

227:

224:

223:

219:

216:

213:

212:

208:

205:

203:Carbon black

202:

201:

193:

191:

187:

184:

180:

172:

152:

149:

141:

139:

137:

133:

132:microporosity

128:

125:

121:

117:

109:

108:

104:

101:

97:

96:

92:

91:

90:

87:

85:

81:

77:

73:

62:

59:November 2023

53:

48:

43:

39:

38:

34:

29:This article

27:

23:

18:

17:

872:

838:

834:

828:

811:

807:

800:

775:

771:

765:

756:

734:. Retrieved

730:the original

725:

704:

667:Carbon Black

666:

616:

612:

556:

552:

500:

496:

448:Carbon black

425:

411:

404:

397:

389:

383:

382:

379:Applications

373:

372:

364:

348:

339:

318:

285:

268:

258:

188:

153:

145:

136:UV radiation

129:

113:

105:

95:Carbon black

93:

88:

69:

56:

30:

934:Categories

736:2019-02-11

469:References

436:AKZO-Nobel

351:carboxylic

250:1300–1400

142:Production

50:; try the

37:link to it

940:Chemistry

792:0032-3888

641:0008-6223

581:0008-6223

525:0169-4332

463:AkzoNobel

453:Unipetrol

428:UNIPETROL

413:varnishes

282:Structure

253:> 600

239:800–1200

148:byproduct

40:. Please

442:See also

391:polymers

359:phenolic

355:quinonic

242:300–400

80:graphite

875:. 2012.

843:Bibcode

621:Bibcode

561:Bibcode

505:Bibcode

406:rubbers

336:Texture

315:Surface

116:plastic

76:diamond

945:Carbon

790:

707:: 102.

673:

639:

613:Carbon

579:

553:Carbon

523:

399:resins

100:carbon

72:carbon

33:orphan

31:is an

788:ISSN

671:ISBN

637:ISSN

577:ISSN

521:ISSN

231:180

228:250

220:100

217:120

209:OAN

206:BET

181:and

173:and

162:O, H

122:and

107:Soot

84:coke

851:doi

816:doi

780:doi

629:doi

569:doi

513:doi

501:217

357:or

183:COS

158:, H

936::

863:^

849:.

839:27

837:.

812:27

810:.

786:.

776:36

774:.

745:^

724:.

713:^

685:^

649:^

635:.

627:.

617:31

615:.

589:^

575:.

567:.

557:40

533:^

519:.

511:.

499:.

477:^

353:,

168:CH

166:,

82:,

78:,

857:.

853::

845::

822:.

818::

794:.

782::

759:.

739:.

679:.

643:.

631::

623::

583:.

571::

563::

527:.

515::

507::

179:S

177:2

175:H

170:4

164:2

160:2

156:2

102:.

61:)

57:(

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.