43:

104:

meaning that secondary, backscattered and forward scattered (if the beam dwells on already deposited material) electrons contribute to the deposition. As these electrons can leave the substrate up to several microns away from the point of impact of the electron beam (depending on its energy), material deposition is not necessarily confined to the irradiated spot. To overcome this problem, compensation algorithms can be applied, which is typical for electron beam lithography.

278:

290:

1570:

306:

322:

232:(FIB) setup, which strongly limits characterization of the deposit during or right after the deposition. Only SEM-like imaging using secondary electrons is possible, and even that imaging is restricted to short observations due to sample damaging by the Ga beam. The use of a dual beam instrument, that combines a FIB and an SEM in one, circumvents this limitation.

1582:

51:

94:

Primary electron energies in SEMs or STEMs are usually between 10 and 300 keV, where reactions induced by electron impact, i.e. precursor dissociation, have a relatively low cross section. The majority of decomposition occurs via low energy electron impact: either by low energy secondary electrons,

85:

In the presence of the precursor gas, the electron beam is scanned over the substrate, resulting in deposition of material. The scanning is usually computer-controlled. The deposition rate depends on a variety of processing parameters, such as the partial precursor pressure, substrate temperature,

103:

Primary S(T)EM electrons can be focused into spots as small as ~0.045 nm. While the smallest structures deposited so far by EBID are point deposits of ~0.7 nm diameter, deposits usually have a larger lateral size than the beam spot size. The reason are the so-called proximity effects,

81:

When deposition occurs at a high temperature or involves corrosive gases, a specially designed deposition chamber is used; it is isolated from the microscope, and the beam is introduced into it through a micrometre-sized orifice. The small orifice size maintains differential pressure in the

252:

Nanostructures of virtually any 3-dimensional shape can be deposited using computer-controlled scanning of electron beam. Only the starting point has to be attached to the substrate, the rest of the structure can be free standing. The achieved shapes and devices are remarkable:

850:

Luxmoore, I; Ross, I; Cullis, A; Fry, P; Orr, J; Buckle, P; Jefferson, J (2007). "Low temperature electrical characterisation of tungsten nano-wires fabricated by electron and ion beam induced chemical vapour deposition".

218:, usually 30 keV Ga, is used instead of the electron beam. In both techniques, it is not the primary beam, but secondary electrons which cause the deposition. IBID has the following disadvantages as compared to EBID:

78:, and introduced, at accurately controlled rate, into the high-vacuum chamber of the electron microscope. Alternatively, solid precursors can be sublimated by the electron beam itself.

30:

is a process of decomposing gaseous molecules by an electron beam leading to deposition of non-volatile fragments onto a nearby substrate. The electron beam is usually provided by a

150:, etc.) result in cleaner deposition, but are more difficult to handle as they are toxic and corrosive. Compound materials are deposited from specially crafted, exotic gases, e.g. D

1214:

112:

As of 2008 the range of materials deposited by EBID included Al, Au, amorphous carbon, diamond, Co, Cr, Cu, Fe, GaAs, GaN, Ge, Mo, Nb, Ni, Os, Pd, Pt, Rh, Ru, Re, Si, Si

1197:

1192:

143:. They are easily available, however, due to incorporation of carbon atoms from the CO ligands, deposits often exhibit a low metal content. Metal-halogen complexes (

1341:

1044:

1331:

934:

1234:

1207:

167:

Very flexible regarding deposit shape and composition; the electron beam is lithographically controlled and a multitude of potential precursors is available

1142:

34:, which results in high spatial accuracy (potentially below one nanometer) and the possibility to produce free-standing, three-dimensional structures.

1202:

510:

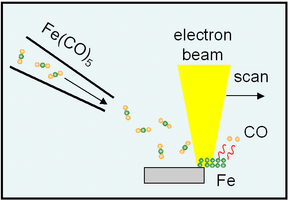

Kiyohara, Shuji; Takamatsu, Hideaki; Mori, Katsumi (2002). "Microfabrication of diamond films by localized electron beam chemical vapour deposition".

369:

63:

1346:

128:, W, and was being expanded. The limiting factor is the availability of appropriate precursors, gaseous or having a low sublimation temperature.

202:

Controlling the elemental or chemical deposit composition is still a major challenge, as the precursor decomposition pathways are mostly unknown

1162:

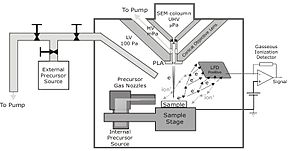

277:

95:

which cross the substrate-vacuum interface and contribute to the total current density, or inelastically scattered (backscattered) electrons.

1286:

1152:

1099:

902:

907:

1541:

1269:

1254:

1180:

225:

Ga ions introduce additional contamination and radiation damage to the deposited structure, which is important for electronic applications.

182:

74:

is applied instead. Precursor materials are typically liquid or solid and gasified prior to deposition, usually through vaporization or

908:

K. Molhave: "Tools for in-situ manipulations and characterization of nanostructures", PhD thesis, Technical

University of Denmark, 2004

1291:

1124:

977:

927:

894:

1279:

1274:

1172:

1147:

1114:

545:

Nayak, A.; Banerjee, H. D. (1995). "Electron beam activated plasma chemical vapour deposition of polycrystalline diamond films".

374:

289:

174:

1351:

1336:

1316:

1054:

305:

1119:

962:

889:"Nanofabrication: Fundamentals and Applications" Ed.: Ampere A. Tseng, World Scientific Publishing Company (March 4, 2008),

1586:

1296:

1259:

1104:

1613:

1574:

1134:

920:

364:

59:

31:

802:

Van Dorp, Willem F. (2005). "Approaching the

Resolution Limit of Nanometer-Scale Electron Beam-Induced Deposition".

42:

1321:

1239:

67:

700:"Fabrication and characterization of nanostructures on insulator substrates by electron-beam-induced deposition"

82:

microscope (vacuum) and deposition chamber (no vacuum). Such deposition mode has been used for EBID of diamond.

1546:

1500:

1326:

591:

Randolph, S.; Fowlkes, J.; Rack, P. (2006). "Focused, Nanoscale

Electron-Beam-Induced Deposition and Etching".

359:

1536:

1618:

1249:

1185:

1059:

1018:

75:

1608:

1439:

1444:

1264:

401:

Carden, Will G.; Lu, Hang; Spencer, Julie A.; Fairbrother, D. Howard; McElwee-White, Lisa (2018-06-01).

312:

199:

Serial material deposition and low deposition rates in general limit throughput and thus mass production

144:

1449:

1008:

860:

811:

768:

711:

654:

600:

554:

519:

453:

442:"Advances in Focused Ion Beam Tomography for Three-Dimensional Characterization in Materials Science"

189:) during or right after deposition. In situ electrical and optical characterization is also possible.

186:

86:

electron beam parameters, applied current density, etc. It usually is in the order of 10 nm/s.

1414:

1399:

1306:

1301:

1244:

1109:

1091:

1023:

1013:

957:

943:

339:

321:

222:

Angular spread of secondary electrons is larger in IBID thus resulting in lower spatial resolution.

440:

Mura, Francesco; Cognigni, Flavio; Ferroni, Matteo; Morandi, Vittorio; Rossi, Marco (2023-08-24).

1485:

1064:

1028:

616:

380:

17:

1429:

1424:

898:

890:

827:

784:

737:

680:

489:

471:

422:

1379:

1311:

868:

819:

776:

727:

719:

670:

662:

608:

562:

527:

479:

461:

414:

344:

229:

215:

71:

1434:

214:

Ion-beam-induced deposition (IBID) is very similar to EBID with the major difference that

864:

815:

772:

715:

658:

604:

558:

523:

484:

457:

441:

1389:

1003:

732:

723:

699:

675:

666:

642:

349:

132:

531:

173:

The deposited material can be characterized using the electron microscopy techniques (

1602:

1465:

1409:

1069:

296:

1516:

620:

170:

Lateral size of the produced structures and accuracy of deposition are unprecedented

1526:

1490:

1384:

1374:

1049:

998:

780:

403:"Mechanism-based design of precursors for focused electron beam-induced deposition"

140:

1470:

1404:

1394:

643:"Nanofabrication by advanced electron microscopy using intense and focused beam"

354:

1551:

972:

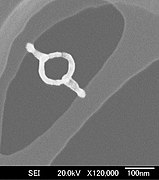

967:

872:

612:

475:

426:

1419:

1074:

566:

831:

788:

741:

684:

493:

1521:

987:

418:

1531:

1475:

1157:

466:

912:

823:

402:

50:

1495:

756:

131:

The most popular precursors for deposition of elemental solids are

264:

49:

41:

1480:

178:

916:

205:

Proximity effects can lead to unintended structure broadening

757:"Atomic-Resolution Imaging with a Sub-50-pm Electron Probe"

755:

Erni, Rolf; Rossell, MD; Kisielowski, C; Dahmen, U (2009).

593:

Critical

Reviews of Solid State and Materials Sciences

283:

Snapshots of growing a doll-like nanostructure by IBID

1509:

1458:

1367:

1360:

1227:

1171:

1133:

1090:

1083:

1037:

986:

950:

1342:Serial block-face scanning electron microscopy

1045:Detectors for transmission electron microscopy

928:

8:

66:(STEM) is commonly used. Another method is

1364:

1087:

935:

921:

913:

731:

674:

483:

465:

370:Scanning transmission electron microscopy

64:scanning transmission electron microscope

845:

843:

841:

393:

273:

28:Electron-beam-induced deposition (EBID)

505:

503:

636:

634:

632:

630:

7:

1581:

586:

584:

582:

580:

578:

576:

512:Semiconductor Science and Technology

25:

978:Timeline of microscope technology

1580:

1569:

1568:

375:Transmission electron microscopy

320:

304:

288:

276:

18:Electron beam induced deposition

1337:Precession electron diffraction

58:The focused electron beam of a

781:10.1103/PhysRevLett.102.096101

698:M. Song and K. Furuya (2008).

1:

724:10.1088/1468-6996/9/2/023002

667:10.1088/1468-6996/9/1/014110

365:Scanning electron microscope

236:The advantages of IBID are:

60:scanning electron microscope

32:scanning electron microscope

532:10.1088/0268-1242/17/10/311

240:Much higher deposition rate

210:Ion-beam-induced deposition

68:ion-beam-induced deposition

1635:

1322:Immune electron microscopy

1240:Annular dark-field imaging

1055:Everhart–Thornley detector

46:Scheme of the EBID process

1564:

1476:Hitachi High-Technologies

873:10.1016/j.tsf.2007.02.029

613:10.1080/10408430600930438

270:Superconducting nanowires

263:Nanoloops (potential nano

1501:Thermo Fisher Scientific

1327:Geometric phase analysis

1215:Aberration-Corrected TEM

704:Sci. Technol. Adv. Mater

647:Sci. Technol. Adv. Mater

360:Organometallic chemistry

108:Materials and precursors

1250:Charge contrast imaging

1060:Field electron emission

761:Physical Review Letters

567:10.1002/pssa.2211510112

547:Physica Status Solidi A

228:Deposition occurs in a

1440:Thomas Eugene Everhart

327:Letter Φ grown by EBID

55:

47:

1445:Vernon Ellis Cosslett

1265:Dark-field microscopy

313:Leaning Tower of Pisa

257:World smallest magnet

53:

45:

1450:Vladimir K. Zworykin

1100:Correlative light EM

1009:Electron diffraction

187:electron diffraction

90:Deposition mechanism

1614:Electron microscopy

1415:Manfred von Ardenne

1400:Gerasimos Danilatos

1307:Electron tomography

1302:Electron holography

1245:Cathodoluminescence

1024:Secondary electrons

1014:Electron scattering

958:Electron microscopy

944:Electron microscopy

865:2007TSF...515.6791L

816:2005NanoL...5.1303V

773:2009PhRvL.102i6101E

716:2008STAdM...9b3002S

659:2008STAdM...9a4110F

605:2006CRSSM..31...55R

559:1995PSSAR.151..107N

524:2002SeScT..17.1096K

458:2023Mate...16.5808M

419:10.1557/mrc.2018.77

340:Electron microscopy

1537:Digital Micrograph

1143:Environmental SEM

1065:Field emission gun

1029:X-ray fluorescence

641:K. Furuya (2008).

467:10.3390/ma16175808

407:MRS Communications

381:Lisa McElwee-White

379:Researcher :

99:Spatial resolution

56:

48:

1596:

1595:

1560:

1559:

1430:Nestor J. Zaluzec

1425:Maximilian Haider

1223:

1222:

903:978-981-270-076-6

824:10.1021/nl050522i

260:Fractal nanotrees

16:(Redirected from

1626:

1584:

1583:

1572:

1571:

1380:Bodo von Borries

1365:

1125:Photoemission EM

1088:

937:

930:

923:

914:

877:

876:

853:Thin Solid Films

847:

836:

835:

799:

793:

792:

752:

746:

745:

735:

695:

689:

688:

678:

638:

625:

624:

588:

571:

570:

542:

536:

535:

507:

498:

497:

487:

469:

437:

431:

430:

398:

345:Focused ion beam

324:

308:

292:

280:

230:focused ion beam

216:focused ion beam

72:focused ion beam

70:(IBID), where a

21:

1634:

1633:

1629:

1628:

1627:

1625:

1624:

1623:

1599:

1598:

1597:

1592:

1556:

1505:

1454:

1435:Ondrej Krivanek

1356:

1219:

1167:

1129:

1115:Liquid-Phase EM

1079:

1038:Instrumentation

1033:

991:

982:

946:

941:

886:

881:

880:

849:

848:

839:

801:

800:

796:

754:

753:

749:

697:

696:

692:

640:

639:

628:

590:

589:

574:

544:

543:

539:

509:

508:

501:

439:

438:

434:

400:

399:

395:

390:

385:

335:

328:

325:

316:

309:

300:

293:

284:

281:

250:

212:

196:

164:

157:

153:

148:

138:

133:metal carbonyls

127:

123:

119:

115:

110:

101:

92:

40:

23:

22:

15:

12:

11:

5:

1632:

1630:

1622:

1621:

1619:Nanotechnology

1616:

1611:

1601:

1600:

1594:

1593:

1591:

1590:

1578:

1565:

1562:

1561:

1558:

1557:

1555:

1554:

1549:

1544:

1542:Direct methods

1539:

1534:

1529:

1524:

1519:

1513:

1511:

1507:

1506:

1504:

1503:

1498:

1493:

1488:

1483:

1478:

1473:

1468:

1462:

1460:

1456:

1455:

1453:

1452:

1447:

1442:

1437:

1432:

1427:

1422:

1417:

1412:

1407:

1402:

1397:

1392:

1390:Ernst G. Bauer

1387:

1382:

1377:

1371:

1369:

1362:

1358:

1357:

1355:

1354:

1349:

1344:

1339:

1334:

1329:

1324:

1319:

1314:

1309:

1304:

1299:

1294:

1289:

1284:

1283:

1282:

1272:

1267:

1262:

1257:

1252:

1247:

1242:

1237:

1231:

1229:

1225:

1224:

1221:

1220:

1218:

1217:

1212:

1211:

1210:

1200:

1195:

1190:

1189:

1188:

1177:

1175:

1169:

1168:

1166:

1165:

1160:

1155:

1150:

1145:

1139:

1137:

1131:

1130:

1128:

1127:

1122:

1117:

1112:

1107:

1102:

1096:

1094:

1085:

1081:

1080:

1078:

1077:

1072:

1067:

1062:

1057:

1052:

1047:

1041:

1039:

1035:

1034:

1032:

1031:

1026:

1021:

1016:

1011:

1006:

1004:Bremsstrahlung

1001:

995:

993:

984:

983:

981:

980:

975:

970:

965:

960:

954:

952:

948:

947:

942:

940:

939:

932:

925:

917:

911:

910:

905:

885:

884:External links

882:

879:

878:

837:

794:

747:

690:

626:

572:

553:(1): 107–112.

537:

499:

432:

413:(2): 343–357.

392:

391:

389:

386:

384:

383:

377:

372:

367:

362:

357:

352:

350:Metal carbonyl

347:

342:

336:

334:

331:

330:

329:

326:

319:

317:

310:

303:

301:

294:

287:

285:

282:

275:

272:

271:

268:

261:

258:

249:

246:

245:

244:

241:

234:

233:

226:

223:

211:

208:

207:

206:

203:

200:

195:

192:

191:

190:

171:

168:

163:

160:

155:

151:

146:

136:

125:

121:

117:

113:

109:

106:

100:

97:

91:

88:

39:

36:

24:

14:

13:

10:

9:

6:

4:

3:

2:

1631:

1620:

1617:

1615:

1612:

1610:

1609:Electron beam

1607:

1606:

1604:

1589:

1588:

1579:

1577:

1576:

1567:

1566:

1563:

1553:

1550:

1548:

1545:

1543:

1540:

1538:

1535:

1533:

1530:

1528:

1525:

1523:

1520:

1518:

1515:

1514:

1512:

1508:

1502:

1499:

1497:

1494:

1492:

1489:

1487:

1484:

1482:

1479:

1477:

1474:

1472:

1469:

1467:

1466:Carl Zeiss AG

1464:

1463:

1461:

1459:Manufacturers

1457:

1451:

1448:

1446:

1443:

1441:

1438:

1436:

1433:

1431:

1428:

1426:

1423:

1421:

1418:

1416:

1413:

1411:

1410:James Hillier

1408:

1406:

1403:

1401:

1398:

1396:

1393:

1391:

1388:

1386:

1383:

1381:

1378:

1376:

1373:

1372:

1370:

1366:

1363:

1359:

1353:

1350:

1348:

1345:

1343:

1340:

1338:

1335:

1333:

1330:

1328:

1325:

1323:

1320:

1318:

1315:

1313:

1310:

1308:

1305:

1303:

1300:

1298:

1295:

1293:

1290:

1288:

1285:

1281:

1278:

1277:

1276:

1273:

1271:

1268:

1266:

1263:

1261:

1258:

1256:

1253:

1251:

1248:

1246:

1243:

1241:

1238:

1236:

1233:

1232:

1230:

1226:

1216:

1213:

1209:

1206:

1205:

1204:

1201:

1199:

1196:

1194:

1191:

1187:

1184:

1183:

1182:

1179:

1178:

1176:

1174:

1170:

1164:

1163:Ultrafast SEM

1161:

1159:

1156:

1154:

1151:

1149:

1146:

1144:

1141:

1140:

1138:

1136:

1132:

1126:

1123:

1121:

1120:Low-energy EM

1118:

1116:

1113:

1111:

1108:

1106:

1103:

1101:

1098:

1097:

1095:

1093:

1089:

1086:

1082:

1076:

1073:

1071:

1070:Magnetic lens

1068:

1066:

1063:

1061:

1058:

1056:

1053:

1051:

1048:

1046:

1043:

1042:

1040:

1036:

1030:

1027:

1025:

1022:

1020:

1019:Kikuchi lines

1017:

1015:

1012:

1010:

1007:

1005:

1002:

1000:

997:

996:

994:

989:

985:

979:

976:

974:

971:

969:

966:

964:

961:

959:

956:

955:

953:

949:

945:

938:

933:

931:

926:

924:

919:

918:

915:

909:

906:

904:

900:

896:

895:981-270-076-5

892:

888:

887:

883:

874:

870:

866:

862:

858:

854:

846:

844:

842:

838:

833:

829:

825:

821:

817:

813:

810:(7): 1303–7.

809:

805:

798:

795:

790:

786:

782:

778:

774:

770:

767:(9): 096101.

766:

762:

758:

751:

748:

743:

739:

734:

729:

725:

721:

717:

713:

710:(2): 023002.

709:

705:

701:

694:

691:

686:

682:

677:

672:

668:

664:

660:

656:

653:(1): 014110.

652:

648:

644:

637:

635:

633:

631:

627:

622:

618:

614:

610:

606:

602:

598:

594:

587:

585:

583:

581:

579:

577:

573:

568:

564:

560:

556:

552:

548:

541:

538:

533:

529:

525:

521:

517:

513:

506:

504:

500:

495:

491:

486:

481:

477:

473:

468:

463:

459:

455:

451:

447:

443:

436:

433:

428:

424:

420:

416:

412:

408:

404:

397:

394:

387:

382:

378:

376:

373:

371:

368:

366:

363:

361:

358:

356:

353:

351:

348:

346:

343:

341:

338:

337:

332:

323:

318:

315:grown by IBID

314:

307:

302:

299:grown by IBID

298:

297:bacteriophage

291:

286:

279:

274:

269:

266:

262:

259:

256:

255:

254:

247:

243:Higher purity

242:

239:

238:

237:

231:

227:

224:

221:

220:

219:

217:

209:

204:

201:

198:

197:

194:Disadvantages

193:

188:

184:

180:

176:

172:

169:

166:

165:

161:

159:

149:

142:

139:structure or

134:

129:

107:

105:

98:

96:

89:

87:

83:

79:

77:

73:

69:

65:

61:

52:

44:

37:

35:

33:

29:

19:

1585:

1573:

1527:EM Data Bank

1491:Nion Company

1385:Dennis Gabor

1375:Albert Crewe

1153:Confocal SEM

1050:Electron gun

999:Auger effect

859:(17): 6791.

856:

852:

807:

804:Nano Letters

803:

797:

764:

760:

750:

707:

703:

693:

650:

646:

596:

592:

550:

546:

540:

518:(10): 1096.

515:

511:

452:(17): 5808.

449:

445:

435:

410:

406:

396:

251:

235:

213:

141:metallocenes

130:

111:

102:

93:

84:

80:

57:

27:

26:

1471:FEI Company

1405:Harald Rose

1395:Ernst Ruska

1084:Microscopes

992:with matter

990:interaction

355:Metallocene

311:A model of

295:A model of

76:sublimation

1603:Categories

1552:Multislice

1368:Developers

1228:Techniques

973:Microscope

968:Micrograph

388:References

162:Advantages

54:EBID setup

1420:Max Knoll

1075:Stigmator

599:(3): 55.

476:1996-1944

446:Materials

427:2159-6867

158:for GaN.

135:of Me(CO)

62:(SEM) or

1575:Category

1522:CrysTBox

1510:Software

1181:Cryo-TEM

988:Electron

832:16178228

789:19392535

742:27877950

685:27877936

621:93769658

494:37687502

485:10488958

333:See also

1587:Commons

1235:4D STEM

1208:4D STEM

1186:Cryo-ET

1158:SEM-XRF

1148:CryoSEM

1105:Cryo-EM

963:History

861:Bibcode

812:Bibcode

769:Bibcode

733:5099707

712:Bibcode

676:5099805

655:Bibcode

601:Bibcode

555:Bibcode

520:Bibcode

454:Bibcode

267:device)

38:Process

1532:EMsoft

1517:CASINO

1496:TESCAN

1361:Others

1260:cryoEM

951:Basics

901:

893:

830:

787:

740:

730:

683:

673:

619:

492:

482:

474:

425:

248:Shapes

1486:Leica

1332:PINEM

1198:HRTEM

1193:EFTEM

617:S2CID

265:SQUID

124:, TiO

120:, SiO

1547:IUCr

1481:JEOL

1352:WBDF

1347:WDXS

1297:EBIC

1292:EELS

1287:ECCI

1275:EBSD

1255:CBED

1203:STEM

899:ISBN

891:ISBN

828:PMID

785:PMID

738:PMID

681:PMID

490:PMID

472:ISSN

423:ISSN

179:EELS

1317:FEM

1312:FIB

1280:TKD

1270:EDS

1173:TEM

1135:SEM

1110:EMP

869:doi

857:515

820:doi

777:doi

765:102

728:PMC

720:doi

671:PMC

663:doi

609:doi

563:doi

551:151

528:doi

480:PMC

462:doi

415:doi

183:EDS

175:TEM

154:GaN

1605::

1092:EM

897:,

867:.

855:.

840:^

826:.

818:.

806:.

783:.

775:.

763:.

759:.

736:.

726:.

718:.

706:.

702:.

679:.

669:.

661:.

649:.

645:.

629:^

615:.

607:.

597:31

595:.

575:^

561:.

549:.

526:.

516:17

514:.

502:^

488:.

478:.

470:.

460:.

450:16

448:.

444:.

421:.

409:.

405:.

185:,

181:,

177:,

145:WF

936:e

929:t

922:v

875:.

871::

863::

834:.

822::

814::

808:5

791:.

779::

771::

744:.

722::

714::

708:9

687:.

665::

657::

651:9

623:.

611::

603::

569:.

565::

557::

534:.

530::

522::

496:.

464::

456::

429:.

417::

411:8

156:3

152:2

147:6

137:x

126:x

122:x

118:4

116:N

114:3

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.