47:

349:

magazines in excess of 1 million copies, mail order catalogs, consumer packaging, Sunday newspaper ad inserts, wallpaper and laminates for furniture where quality and consistency are desired. Another application area of gravure printing is in the flexible-packaging sector. A wide range of substrates such as polyethylene, polypropylene, polyester, BOPP, etc. can be printed in the gravure press. Gravure printing is one of the common processes used in the

104:

251:

different colour intensities on the paper, the dimensions of the cells must be carefully set: deeper or larger cells will produce more intense colours whereas smaller cells will produce less intense ones. There are three methods of photoengraving that have been used for engraving of gravure cylinders, where the cell open size or the depth of cells can be uniform or variable:

303:

image) is transferred to the cylinder before etching. The resist protects the non-image areas of the cylinder from the etchant. After etching, the resist is stripped off. The operation is analogous to the manufacture of printed circuit boards. Following engraving, the cylinder is proofed and tested, reworked if necessary, and then chrome plated.

348:

Gravure is an industrial printing process capable of consistent high quality printing. Since the

Gravure printing process requires the creation of one cylinder for each colour of the final image, it is expensive for short runs and best suited for high volume printing. Typical uses include long-run

368:

or other substrates, rather than sheets. (Sheetfed gravure is a small, specialty market.) Rotary gravure presses are the fastest and widest presses in operation, printing everything from narrow labels to 12-foot-wide (3.66-meter-wide) rolls of vinyl flooring. For maximum efficiency, gravure presses

302:

Gravure cylinders are usually made of steel and plated with copper, though other materials, e.g. ceramics can also be used. The desired pattern is achieved by engraving with a laser or a diamond tool, or by chemical etching. If the cylinder is chemically etched, a resist (in the form of a negative

319:

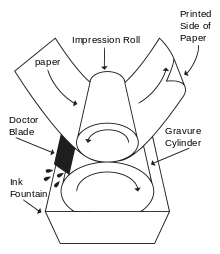

Next, the substrate gets sandwiched between the impression roller and the gravure cylinder: this is where the ink gets transferred from the recessed cells to the web. The purpose of the impression roller is to apply force, ensuring that the entire substrate is brought into contact with the gravure

250:

The first step of

Gravure is to create the cylinder with the engraved images that need to be printed: the engraving process will create on the cylinder surface the cells that will contain the ink in order to transfer it to the paper. Since the amount of ink contained in the cells corresponds to

385:

Although the rotogravure printing process is not the most popular printing process used in flexible-packaging manufacturing, it does have the ability to print on thin film such as polyester, polypropylene, nylon, and polyethylene, which come in a wide range of thicknesses, commonly 10 to 30

340:

Because gravure is capable of transferring more ink to the paper than most other printing processes, it is noted for its remarkable density range (light to shadow) and hence is a process of choice for fine art and photography reproduction, though not typically as clean an image as that of

316:, the doctor blade scrapes the cylinder before it makes contact with the paper, removing the excess ink from the non-printing (non-recessed) areas and leaving in the cells the right amount of ink required. The position of the blade relative to the nip is normally variable.

345:. A shortcoming of gravure is that all images, including type and "solids," are actually printed as dots, and unless the ink and substrate combination is set up to allow solid areas to flow together, the screen pattern of these dots can be visible to the naked eye.

356:

Rotogravure presses for publication run at 45 feet (14 m) per second and more, with paper reel widths of over 10 feet (3 m), enabling an eight-unit press to print about seven million four-color pages per hour.

323:

Then the inked substrate goes through a dryer because it must be completely dry before going through the next color unit and accepting another coat of ink. A rotogravure printing press has one printing unit for each

311:

While the press is in operation, the engraved cylinder is partially immersed in the ink tray, filling the recessed cells. As the cylinder rotates, it draws excess ink onto its surface and into the cells. Acting as a

168:

In 1912 Messrs

Bruckman in Munich produced proofs for Bavarian postage stamps which went into production in 1914. Also in 1912 newspaper supplements printed by reel-fed gravure were on sale in London and Berlin

320:

cylinder, which in turn ensures even and maximum coverage of the ink. Once in contact with the substrate, the ink's surface tension pulls (part of) the ink out of the cell and transfers it to the substrate.

164:

and Samuel

Fawcett, in Lancaster resulted in the founding of the Rembrandt Intaglio Printing Company in 1895, which company produced art prints. In 1906 they marketed the first multi-colour gravure print.

160:

mentions in 1852 the use of a textile in the photographic process to create half-tones in the printing plate. A French patent in 1860 describes a reel-fed gravure press. A collaboration between

148:

Once a staple of newspaper photo features, the rotogravure process is still used for commercial printing of magazines, postcards, and corrugated (cardboard) and other product packaging.

218:

In direct gravure printing, the ink is applied directly to the cylinder and from the cylinder it is transferred to the substrate. One printing unit consists of the following components:

424:

rotogravure cylinder manufacturing utilizes

Hexavalent Chromium electroplating. OSHA states "All hexavalent chromium compounds are considered carcinogenic to workers"

242:

For indirect gravure processes, the engraved cylinder transfers ink in the desired areas to a transfer roller, and the transfer roller transfers it to the substrate.

332:

or cyan, magenta, yellow and key (printing terminology for black), but the number of units varies depending on what colors are required to produce the final image.

189:

specifically refers to this type of supplements in the lines "the photographers will snap us, and you'll find that you're in the rotogravure." And the song "

193:" contains the line "…armed with photos from local rotos" referring to young actresses hoping to make it in the movie industry. In 1976, ex-Beatle

68:

222:

an engraved cylinder (also known as "gravure cylinder") whose circumference can differ according to the layout of the product being made.

499:

90:

369:

operate at high speeds producing large diameter, wide rolls. These are then cut or slit down to the finished roll size on a

156:

In the 19th century, a number of developments in photography allowed the production of photo-mechanical printing plates.

171:

61:

55:

72:

600:

528:

500:"The Rotogravure Process, Articles & Essays, Newspaper Pictorials: World War I Rotogravures, 1914-1919"

199:

119:

457:

142:

190:

186:

542:

421:

long lead time for cylinder preparation, which is offsite as the techniques used are so specialized

361:

207:

130:

595:

373:

machine or slitter rewinder. Additional operations may be in line with a gravure press, such as

157:

161:

442:

425:

342:

134:

30:"Gravure" redirects here. For the similar photographic process using copper plates, see

393:

printing cylinders that can last through large-volume runs without the image degrading

206:

Gravure is one of several printing techniques being actively used in the new field of

103:

589:

452:

415:

374:

182:

447:

229:

129:

the image onto an image carrier. In gravure printing, the image is engraved onto a

35:

31:

523:

Tarr, John

Charles (1949). "Chapter X. Printing Processes To-Day: Photogravure".

412:

high start-up costs: hundreds of thousands of copies needed to make it profitable

437:

194:

138:

350:

126:

370:

313:

122:

17:

580:

360:

The vast majority of gravure presses print on rolls (also known as

365:

325:

102:

329:

40:

570:

426:

https://www.osha.gov/hexavalent-chromium/health-effects

575:

408:

Shortcomings of the gravure printing process include:

488:(first English ed.). London: Lund Humphries.

486:History of Industrial Gravure Printing up to 1920

399:low per-unit costs running high volume production

504:Library of Congress, Washington, D.C. 20540 USA

8:

377:facilities for magazine or brochure work.

91:Learn how and when to remove this message

479:

477:

475:

473:

253:

54:This article includes a list of general

469:

34:. For the type of Japanese model, see

279:"Two positive" or "Lateral hard dot"

7:

389:Other appreciated features include:

576:Gravure Association of the Americas

60:it lacks sufficient corresponding

25:

571:European Rotogravure Association

45:

396:good quality image reproduction

543:"Rotogravure printing process"

107:Diagram of rotogravure process

1:

527:(revised ed.). London:

172:The Illustrated London News

617:

29:

197:released an album titled

484:Lilien, Otto M. (1972).

125:process, which involves

118:for short) is a type of

529:Oxford University Press

152:History and development

75:more precise citations.

214:Process and components

108:

458:Rotary printing press

143:rotary printing press

106:

235:an impression roller

191:Hooray for Hollywood

208:printed electronics

200:Ringo's Rotogravure

581:Heliograph holding

343:offset lithography

109:

300:

299:

246:Engraved cylinder

101:

100:

93:

16:(Redirected from

608:

558:

557:

555:

553:

539:

533:

532:

520:

514:

513:

511:

510:

496:

490:

489:

481:

375:saddle stitching

290:Direct transfer

254:

158:Henry Fox Talbot

96:

89:

85:

82:

76:

71:this article by

62:inline citations

49:

48:

41:

27:Printing process

21:

616:

615:

611:

610:

609:

607:

606:

605:

601:Relief printing

586:

585:

567:

562:

561:

551:

549:

541:

540:

536:

525:Printing to-day

522:

521:

517:

508:

506:

498:

497:

493:

483:

482:

471:

466:

443:Offset printing

434:

418:lines and texts

406:

383:

338:

309:

248:

225:an ink fountain

216:

187:"Easter Parade"

177:Der Weltspiegel

154:

135:offset printing

97:

86:

80:

77:

67:Please help to

66:

50:

46:

39:

28:

23:

22:

15:

12:

11:

5:

614:

612:

604:

603:

598:

588:

587:

584:

583:

578:

573:

566:

565:External links

563:

560:

559:

534:

531:. p. 110.

515:

491:

468:

467:

465:

462:

461:

460:

455:

450:

445:

440:

433:

430:

429:

428:

422:

419:

413:

405:

402:

401:

400:

397:

394:

382:

379:

337:

334:

308:

305:

298:

297:

294:

291:

287:

286:

283:

280:

276:

275:

272:

269:

265:

264:

261:

258:

247:

244:

240:

239:

236:

233:

226:

223:

215:

212:

153:

150:

133:because, like

99:

98:

53:

51:

44:

26:

24:

14:

13:

10:

9:

6:

4:

3:

2:

613:

602:

599:

597:

594:

593:

591:

582:

579:

577:

574:

572:

569:

568:

564:

548:

544:

538:

535:

530:

526:

519:

516:

505:

501:

495:

492:

487:

480:

478:

476:

474:

470:

463:

459:

456:

454:

453:Roll slitting

451:

449:

446:

444:

441:

439:

436:

435:

431:

427:

423:

420:

417:

414:

411:

410:

409:

404:Disadvantages

403:

398:

395:

392:

391:

390:

387:

386:micrometers.

380:

378:

376:

372:

367:

363:

358:

354:

352:

346:

344:

335:

333:

331:

327:

321:

317:

315:

306:

304:

295:

292:

289:

288:

284:

281:

278:

277:

273:

270:

268:Conventional

267:

266:

262:

259:

256:

255:

252:

245:

243:

237:

234:

231:

227:

224:

221:

220:

219:

213:

211:

209:

204:

202:

201:

196:

192:

188:

184:

183:Irving Berlin

180:

178:

174:

173:

166:

163:

159:

151:

149:

146:

144:

140:

136:

132:

128:

124:

121:

117:

113:

105:

95:

92:

84:

74:

70:

64:

63:

57:

52:

43:

42:

37:

33:

19:

550:. Retrieved

546:

537:

524:

518:

507:. Retrieved

503:

494:

485:

448:Photogravure

407:

388:

384:

359:

355:

347:

339:

328:, typically

322:

318:

310:

301:

249:

241:

230:doctor blade

217:

205:

198:

181:

176:

170:

167:

155:

147:

141:, it uses a

115:

111:

110:

87:

78:

59:

36:Gravure idol

32:Photogravure

552:11 November

438:Flexography

263:cell depth

195:Ringo Starr

139:flexography

112:Rotogravure

81:August 2012

73:introducing

590:Categories

509:2023-10-19

416:rasterized

381:Advantages

353:industry.

351:converting

260:cell size

162:Karel Klič

56:references

596:Engraving

293:variable

285:variable

282:variable

274:variable

127:engraving

432:See also

371:slitting

336:Features

314:squeegee

296:uniform

271:uniform

232:assembly

185:'s song

131:cylinder

123:printing

120:intaglio

307:Process

257:Method

238:a dryer

116:gravure

69:improve

18:Gravure

58:, but

547:BOBST

464:Notes

366:paper

364:) of

326:color

554:2020

362:webs

330:CMYK

175:and

137:and

114:(or

179:).

592::

545:.

502:.

472:^

228:a

210:.

203:.

145:.

556:.

512:.

169:(

94:)

88:(

83:)

79:(

65:.

38:.

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.