17:

95:, forming the wall of the column, while at the same time, the horizontal band interlocks the continuous spiral seam of the vertical band. When the column lowers, the bands separate and retract into two compact coils. The bands are combined, separated and stored by an assembly located at the base of the column. The result is an efficient (50%-80%) telescoping lifting column.

63:

The piston rods of a hydraulic lift extend below the platform they support by more than the length that the lift travels. For lifts at grade, housings for the rods are often sunk into support holes, known as caissons, that are inaccessible and often complicated by groundwater levels. If placed

67:

Another significant issue with hydraulic lifts is platform drift, the tendency of a platform to lower due to depressurization of the hydraulic system over time. Helical band actuators do not suffer from platform drift because they are rigid mechanical devices.

193:

64:

above ground, the space occupied by the rod housings is unusable. Gagnon's actuator eliminates caissons and reduces the volume of unusable space below the platform of the lift.

87:

The telescoping column is formed by a pair of interlocking stainless steel bands. One band has a vertical rectangular profile and the other horizontal, much like an oversized

210:

106:. Helical band actuators require a separate lateral support mechanism, usually provided in the form of guide rails or self-guiding frame, such as a

98:

To incorporate the device into a lift system, multiple helical band actuators are arranged below the lift platform where they are powered by an

44:

lifts. The actuator forms a high-capacity telescoping tubular column (lifting capacities to 25,000 pounds, travel to 40 feet).

172:

41:

52:

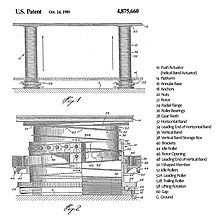

Pierre Gagnon was awarded a US patent for the “Push

Actuator” in 1989. Gagnon developed the actuator to substitute

103:

79:

can also be effective at addressing these issues with hydraulic jacks, and are also used for stage lifts.

188:

111:

76:

60:

were the predominant push actuators used in performing arts facilities, but they had their issues.

191:, Gagnon, Pierre & LaForest, Pierre, "Push actuator", published 1989-10-24

230:

132: – spindle consisting of discrete elements that can be assembled and disassembled on the fly

53:

129:

176:

123:

33:

99:

224:

57:

169:

16:

215:

107:

144:

72:

138:

37:

88:

92:

15:

147: – German computer scientist and engineer (1910–1995)

91:. The vertical band spirals up on itself into a stacked

20:

Patent

Drawing for Spiralift Actuator(1989), with legend.

149:

Pages displaying short descriptions of redirect targets

126: – Actuator that creates motion in a straight line

134:

Pages displaying wikidata descriptions as a fallback

56:in stage and orchestra lift systems. Hydraulic

170:http://www.galainfo.com/pdfs/spiralift3_eng.pdf

8:

161:

7:

28:, generally known by the trademark

14:

141: – Vertical transport device

216:Video - Spiralift: How It Works

32:, is a complex and specialized

1:

247:

168:Spiralift Specifications:

211:I-Lock Spiralift Brochure

83:Principle of operation

21:

102:(s) and synchronized

77:rigid chain actuators

26:helical band actuator

19:

54:hydraulic cylinders

175:2011-07-11 at the

47:

22:

130:Segmented spindle

42:material handling

238:

198:

197:

196:

192:

185:

179:

166:

151:(by Konrad Zuse)

150:

135:

246:

245:

241:

240:

239:

237:

236:

235:

221:

220:

207:

202:

201:

194:

187:

186:

182:

177:Wayback Machine

167:

163:

158:

148:

133:

124:Linear actuator

120:

85:

50:

34:linear actuator

12:

11:

5:

244:

242:

234:

233:

223:

222:

219:

218:

213:

206:

205:External links

203:

200:

199:

180:

160:

159:

157:

154:

153:

152:

142:

136:

127:

119:

116:

100:electric motor

84:

81:

71:Traveling nut

49:

46:

13:

10:

9:

6:

4:

3:

2:

243:

232:

229:

228:

226:

217:

214:

212:

209:

208:

204:

190:

184:

181:

178:

174:

171:

165:

162:

155:

146:

143:

140:

137:

131:

128:

125:

122:

121:

117:

115:

113:

109:

105:

101:

96:

94:

90:

82:

80:

78:

74:

69:

65:

61:

59:

55:

48:Raison d'être

45:

43:

39:

35:

31:

27:

18:

183:

164:

112:scissor lift

104:transmission

97:

86:

70:

66:

62:

51:

29:

25:

23:

139:Stage lifts

73:screw jacks

38:stage lifts

189:US 4875660

156:References

108:pantograph

231:Actuators

145:Helixturm

30:Spiralift

225:Category

173:Archived

118:See also

110:(e.g. a

36:used in

195:

89:Slinky

93:helix

58:jacks

75:and

40:and

114:).

227::

24:A

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.