20:

149:

methods are used and results are based only on the cross-sectional area at the notch (J/m). The dimensions of a standard specimen for ASTM D256 are 63.5 × 12.7 × 3.2 mm (2.5 × 0.5 × 0.125 in). The most common specimen thickness is 3.2 mm (0.13 in), but the width can vary between 3.0 and 12.7 mm (0.12 and 0.50 in).

148:

standard for Izod Impact testing of plastics is ASTM D256. The results are expressed in energy lost per unit of thickness (such as ft·lb/in or J/cm) at the notch. Alternatively, the results may be reported as energy lost per unit cross-sectional area at the notch (J/m or ft·lb/in). In Europe, ISO 180

115:

A material's toughness is a factor of its ability to absorb energy during relatively slow plastic deformation, though the rate at which strain occurs matters. Brittle materials have low toughness as a result of the small amount of plastic deformation they can endure at any rate. However, ductile

93:

and energy, and its effect is different when the same amount of energy is transferred more gradually. Everyday engineering structures are subjected to it and may develop cracks that, over time, propagate to a point where catastrophic failure would result.

79:

54:

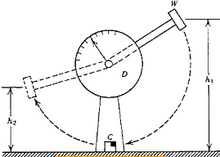

but uses a different arrangement of the specimen under test. The Izod impact test differs from the Charpy impact test in that the sample is held in a cantilevered beam configuration as opposed to a three-point bending configuration.

46:

sample, breaking the specimen. The energy absorbed by the sample is calculated from the height the arm swings to after hitting the sample. A notched sample is generally used to determine impact energy and notch sensitivity.

340:

19:

333:

326:

196:

357:

BS EN ISO 13802:2006 - "Plastics. Verification of pendulum impact-testing machines. Charpy, Izod and tensile impact-testing"

38:

standard method of determining the impact resistance of materials. A pivoting arm is raised to a specific height (constant

370:

375:

289:

380:

279:

24:

294:

116:

materials may behave like brittle materials under high-energy impact, hence the need for this kind of test.

299:

104:

of various materials under the same test conditions, or of one material versus temperature to determine its

269:

112:

transition temperature where a steep descent in impact strength with decreasing temperature is observed.

59:

314:

284:

249:

89:, by definition, is a large force applied for a very short time, resulting in a sudden transfer of

63:

43:

274:

254:

163:

145:

101:

86:

51:

129:

the mass of the hammer which together with the velocity determines its kinetic energy at impact;

244:

192:

168:

39:

98:

123:

the dimensions of the usually rectangular cross section of the sample below the notch;

364:

304:

158:

126:

the height of the hammer at the start position, determining its velocity at impact;

78:

239:

264:

234:

90:

259:

119:

The test conditions are governed by many variables, most importantly:

109:

105:

354:

BS EN ISO 180:2001 - "Plastics. Determination of Izod impact strength"

82:

Scheme for the determination of Izod impact strength test results.

77:

18:

16:

Equipment and procedure to determine materials' impact resistance

309:

35:

62:(1876–1946), who described it in his 1903 address to the

42:) and then released. The arm swings down hitting a

208:Izod, Gilbert, 'Testing brittleness of steel',

132:the sharpness, or tip curvature, of the notch;

334:

58:The test is named after the English engineer

8:

341:

327:

223:

226:

180:

97:Impact tests are used in comparing the

189:Industrial Design of Plastics Products

7:

14:

212:, 25 September 1903, pp. 431-2

135:the temperature of the sample.

1:

66:, subsequently published in

290:Metal-induced embrittlement

50:The test is similar to the

397:

280:Liquid metal embrittlement

25:Blists Hill Victorian Town

295:Stress corrosion cracking

74:The need for impact tests

32:Izod impact strength test

227:Mechanical failure modes

300:Sulfide stress cracking

270:Hydrogen embrittlement

187:M. Joseph Gordon, Jr.

140:ASTM test for plastics

83:

27:

23:Izod impact tester in

81:

22:

371:Continuum mechanics

285:Mechanical overload

64:British Association

376:Fracture mechanics

164:Fracture mechanics

146:ASTM International

102:fracture toughness

84:

60:Edwin Gilbert Izod

52:Charpy impact test

28:

381:Materials testing

351:

350:

245:Corrosion fatigue

169:Shock (mechanics)

388:

343:

336:

329:

224:

213:

206:

200:

185:

40:potential energy

396:

395:

391:

390:

389:

387:

386:

385:

361:

360:

347:

222:

220:Further reading

217:

216:

207:

203:

186:

182:

177:

155:

142:

76:

17:

12:

11:

5:

394:

392:

384:

383:

378:

373:

363:

362:

359:

358:

355:

349:

348:

346:

345:

338:

331:

323:

320:

319:

318:

317:

312:

307:

302:

297:

292:

287:

282:

277:

272:

267:

262:

257:

252:

247:

242:

237:

229:

228:

221:

218:

215:

214:

201:

191:, Wiley 2003,

179:

178:

176:

173:

172:

171:

166:

161:

154:

151:

141:

138:

137:

136:

133:

130:

127:

124:

75:

72:

15:

13:

10:

9:

6:

4:

3:

2:

393:

382:

379:

377:

374:

372:

369:

368:

366:

356:

353:

352:

344:

339:

337:

332:

330:

325:

324:

322:

321:

316:

313:

311:

308:

306:

305:Thermal shock

303:

301:

298:

296:

293:

291:

288:

286:

283:

281:

278:

276:

273:

271:

268:

266:

263:

261:

258:

256:

253:

251:

248:

246:

243:

241:

238:

236:

233:

232:

231:

230:

225:

219:

211:

205:

202:

198:

197:0-471-23151-7

194:

190:

184:

181:

174:

170:

167:

165:

162:

160:

157:

156:

152:

150:

147:

139:

134:

131:

128:

125:

122:

121:

120:

117:

113:

111:

107:

103:

100:

95:

92:

88:

80:

73:

71:

69:

65:

61:

56:

53:

48:

45:

41:

37:

33:

26:

21:

209:

204:

188:

183:

159:Impact force

143:

118:

114:

96:

85:

67:

57:

49:

31:

29:

210:Engineering

68:Engineering

365:Categories

175:References

240:Corrosion

315:Yielding

265:Fracture

235:Buckling

153:See also

91:momentum

260:Fouling

255:Fatigue

110:brittle

106:ductile

44:notched

275:Impact

195:

87:Impact

34:is an

250:Creep

199:p.199

99:shear

310:Wear

193:ISBN

144:The

108:-to-

36:ASTM

30:The

367::

70:.

342:e

335:t

328:v

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.