513:, creating a new company called Robert Heath And Low Moor Ltd. Efforts were made to reduce costs, although this affected quality. Attempts to use high-sulphur coal created serious problems and destroyed the reputation of the works as a supplier of high quality iron, while a slump in heavy industry in the 1920s further reduced demand. The company poured money into attempts to diversify the operations, but did not succeed. In 1928 the company was declared bankrupt, and the Low Moor assets bought by Thos. W. Ward Ltd. Many of the mines, tracks and plant were closed or dismantled. Some buildings were sold or leased to other companies, and some plant was modernised. Wrought iron production finally ended in 1957. As of 1971 new owners were producing alloy steel, making about 350 tons per week.

424:

America, India, and, in fact, all over the world, are the principal manufactures here; but guns (from 32 to 68-pounders) are also made here... Every runlet of water for miles around is damned up to supply the works, and every drop is carefully economised. The great furnaces, with broad, flaring flames rising from them, of course attract attention as the works are approached. In form they resemble an ordinary lime-kiln, and, on the summit, in the midst of the eager flames, are strange-looking wheels–appendages of the machinery by means of which the ironstone and other matters are dragged up an inclined plane on iron waggons to the mouths of the furnaces, which waggons, self-acting, where no living power could perform the office, turn topsy-turvy, and there unload their contents.

494:

502:

continued demand for "Best

Yorkshire Iron" for applications where safety was critically important. In 1888 Low Moor was converted to a limited liability company, although descendants of the founders retained control. The directors planned two new blast furnaces at the New Works, each 70 feet (21 m) high, with capacities of 340 and 240 tons per week. The first came into operation in 1892. In 1905 an electrical power station was built at the New Works, with boilers fired by gas from the blast furnaces. Apart from the heaviest machines, steam drives were replaced by electrical drives. The outbreak of

277:

imported iron but by 1803 using Low Moor pig iron. In 1803 a regiment of volunteers was formed at Low Moor ready to repel the expected French invasion. The works were gradually mechanised. By 1805 there was a self-tipping inclined railway to charge the furnaces, a nail slitting mill, two nose-helve hammers and a plate-rolling mill. As the iron works grew, the company built workers' cottages in the district that took the name of North

Brierley and a hostel for the boys who worked in the pits. The boys were given free clothing and schooling. The company also ran several public houses.

395:, inventing the self-acting motion that made it possible to adjust the force of the blow delivered by the hammer – a critically important improvement. Nasmyth's steam hammers could now vary the force of the blow across a wide range. Nasmyth's first steam hammer was built for the Low Moor Works. They rejected the machine, but on 18 August 1843 accepted an improved version with a self-acting gear. From 1845 to 1856 Robert Wilson was employed by the Low Moor Ironworks. While at Low Moor he improved the steam hammer with the "circular balanced valve". In

55:

486:

371:

39:

329:

62:

477:

aesthetics. An 1876 description said "the natural effect of the perpetual smoke-canopy under which the vegetation of the district exists is to give to it a dinginess not pleasant to look upon... The appearance created by the works themselves and their surroundings has been not inaptly likened to that in the vicinity of the crater of some volcano."

234:

207:

Most of the land occupied by the iron works was part of the Royds Hall estate. Operation of a coal mine on the estate is mentioned in 1673. In 1744 the owner, Edward Rookes Leeds, began to actively develop the coal mines. About 1780 a wooden railway was built from the Low Moor mines to the coal yard

198:

The ironworks depended on the excellent resources of high-quality coal and iron ore found in the vicinity. The "better bed" coal came from a seam about 18 to 28 inches (460 to 710 mm) thick resting on hard sandstone. This coal is particularly low in sulphur. About 120 feet (37 m) above this

189:

in

Yorkshire, England. The works were built to exploit the high-quality iron ore and low-sulphur coal found in the area. Low Moor made wrought iron products from 1801 until 1957 for export around the world. At one time it was the largest ironworks in Yorkshire, a major complex of mines, piles of coal

501:

The company began to run into difficulty in the late 1880s. Its mines were increasingly scattered and expensive. The rail network had a variety of gauges and used a mix of stationary engines and locomotives. Some of the plant was obsolete and operations were generally inefficient. However, there was

423:

The accumulation of cinders and calcined shale actually overspreads the country, and will soon rival in cubic bulk the mass of the

Pyramids. In some cases the hillocks of rubbish have been levelled, and covered with soil brought from a distance... Iron plates, bars and railway tires, sent to Russia,

241:

Construction of the plant began in June 1790, including blast furnaces and casting shops. The furnaces had square bases, tapering as they rose to about 50 feet (15 m) in height. The two furnaces were blown in on 13 August 1791 and the first casting was made by the forgemen three days later. At

215:

In 1788 the estate was sold to a partnership of

Richard Hird, a country gentleman, John Preston and John Jarratt for £34,000. After some sales of shares the partners were Richard Hird, Joseph Dawson, a minister, and John Hardy, a solicitor. Dawson was interested in metallurgy and chemistry and was

311:

By 1835 the works were handling a growing volume of orders. There was no room to expand in the original site, which was crowded by industrial works, offices and workers houses. Construction started on a new site to the southeast, and in 1836 two oven-topped blast furnaces came into operation there.

418:

By 1863 there were 3,600 employees at the works including 1,993 miners, 420 furnacemen, 770 forgemen and 323 engineers. In 1864 a second steam hammer with an 8-ton ram was installed for heavy forgings. In 1871 a third steam hammer of 7 tons was installed. New rolling mills were also built to meet

415:(1857–58). The arms business declined after this, as the government increasingly took charge of weapons production. The works turned to making weldless railway tyres, steam engine boilers, sugar pans for refineries in the West Indies, water pipes and heavy iron components for industrial purposes.

476:

The Low Moor mines produced about 60,000 tons of ore yearly by 1876. The iron was prized for its uniform and brilliant grain, commanding premium prices. The quality seemed to be due in part to the nature of the ore and coal and in part to the manufacturing process. Production came at the cost of

344:

involved first converting the coal to coke to remove water and sulphur, a process that took 48 hours if done in piles in the yard, or 24 hours if done in ovens. About 32% of the better bed coal would be lost in coking. The ironstone was allowed to weather for some time to free it from shale.

276:

The ironworks were owned by the families of the founders throughout the 19th century, with the addition of the

Wickhams, who married into the Hirds. The annually employed capital grew from £52,000 in 1793 to £250,000 in 1818. The company started to produce wrought iron in 1801, at first using

203:

coal beds lie about 230 yards (210 m) below the better bed. At the time the ironworks were developed recent technological advances had made it practical to smelt iron using coal rather than charcoal and to use steam engines to power the steps in production of iron goods.

190:

and ore, kilns, blast furnaces, forges and slag heaps connected by railway lines. The surrounding countryside was littered with waste, and smoke from the furnaces and machinery blackened the sky. Today Low Moor is still industrial, but the pollution has been mostly eliminated.

406:

The Low Moor company bought the

Bierley Ironworks in 1854. By 1855 Low Moor was producing 21,840 tons of iron per year, and was the largest ironworks in Yorkshire. The foundries at Low Moor produced quantities of guns, shells and shot for troops fighting in the

353:

The ironstone was baked with coke and limestone in a kiln, then emptied into a furnace, from which it came out as ore. This was cast into pigs with crystalline or granular structure, and then refined by cold blast, coming out flaky. There were four

224:

named

Smalley to build the blast engine. Smalley called on Thomas Woodcock to prepare plans for the furnaces, casting houses and other works. Woodcock moved to Low Moor, and was to be architect and general manager until his death in 1833.

428:

In 1868 617,628 tons of Low Moor ironstone were raised, the peak production. In 1876 about 2,000 coal miners were employed in pits ranging in depth from 30 to 150 yards (27 to 137 m) in the surrounding townships of North

Bierley,

242:

first the works produced domestic goods, but soon began producing industrial products including parts for steam engines. In 1795 the company won contracts to provide guns, shot and shells to the government, which had been at war with

349:

to help separate clay from the iron ore. In 1832 it took 9,750 pounds (4,420 kg) of coal, 2,800 pounds (1,300 kg) of limestone and 8,500 pounds (3,900 kg) of ironstone to make 2,240 pounds (1,020 kg) of pig iron.

280:

By the end of the war with France in 1814 the works were producing 33 tons of pig iron weekly. Prices fell for a while as demand slackened after the war, but demand for gas pipes and street lights began to pick up in 1822. The

362:, becoming granular and malleable. The steam hammers forged the glowing iron into malleable slabs, which were rolled into wrought iron plates. Large quantities of slag from the blast furnaces were sold for use in road-making.

312:

In 1842 the company installed a new mill to roll iron plate for engine boilers. In 1843 four pairs of forge hammers were installed, driven by steam engines, and in 1844 the company decided to install one of

403:

in London the ironworks exhibited an enormous cannon. The company also provided samples of ore, coal, pig iron and wrought iron, a smaller gun, a sugar cane mill, an olive mill and an elliptograph.

212:. Soon after, Leeds went bankrupt. The property was twice offered for sale by auction, in December 1786 and October 1787, but no suitable offer was made. Leeds committed suicide in 1787.

542:, a poorly paying position. To make ends meet he also worked as a farmer, teacher, doctor and coal-master. He invested his savings in the Low Moor ironworks, and became a wealthy man.

1584:

419:

demand for iron plates in shipbuilding, supplied by slabs forged in the works. By 1867 there were about 4,000 employees. A description of the works at that time said

1198:

739:

1579:

1574:

54:

1589:

258:

1522:

1376:

1348:

1320:

1267:

1220:

453:. Thirteen pumping engines were used to drain water from the mines. The company also employed about 800 miners in collieries to the east at

493:

116:

509:

After the war it was clear that future demand for wrought iron was uncertain. The company was taken over by Robert Heath & Sons of

506:(1914–1918) caused a temporary surge in demand for shell casings and drop forgings, including shoes for the tracks of the first tanks.

220:. He seems to have been the prime mover in the enterprise. The partners planned to found an ironworks, and engaged an engineer from

237:

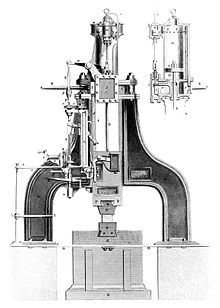

Blast furnace for production of pig iron. Later the Low Moor furnaces used self-tipping wagons to deliver ore, coke and limestone.

1569:

1240:

Round about

Bradford: A Series of Sketches (descriptive and Semi-historical) of Forty-two Places Within Six Miles of Bradford

1418:

Papers on iron and steel: practical and experimental: a series of original communications made to the Philosophical magazine

748:

250:

per year, from which iron goods were made that ranged from columns used in mill construction to garden furniture.

473:. Minerals were carried to the works by horse-drawn wagons or by wagons on tramways drawn by stationary engines.

209:

199:

coal seam there is a layer of "black bed" coal. The ironstone lies above this layer, holding about 32% iron. The

1285:

384:

534:

Joseph Dawson came from a poor family, but was helped by a gentleman to attend school and then study at the

485:

442:

200:

370:

1312:

Building the Steam Navy: Dockyards, Technology and the Creation of the Victorian Battle Fleet, 1830–1906

535:

434:

359:

539:

396:

1206:

270:

1496:

1514:

History and Description of the Crystal Palace: And the Exhibition of the World's Industry in 1851

1192:

400:

182:

103:

1257:

391:'s Bridgewater foundry in Patricroft near Manchester, had improved Nasmyth's 1842 design for a

1539:

1518:

1512:

1450:

1416:

1372:

1344:

1316:

1263:

1216:

1174:

243:

1471:

1366:

1338:

1310:

1238:

1210:

1176:

Official catalogue of the Great Exhibition of the Works of Industry of All Nations, 1851 ...

217:

1400:

1439:

1490:

38:

454:

438:

266:

70:

613:

611:

1563:

1435:

510:

412:

388:

374:

355:

313:

466:

462:

430:

392:

378:

341:

317:

178:

1394:

269:. The colliery had closed by May 1807. The waggonway was replaced in 1809 by the

503:

450:

446:

408:

17:

328:

131:

118:

233:

747:. Vol. 1. Yorkshire Archaeological Trust. August 2012. Archived from

458:

337:

282:

247:

186:

994:

208:

in the centre of Bradford, from where the coal could be carried via the

346:

358:, with the air delivered by powerful steam engines. The iron was then

1030:

784:

711:

629:

617:

590:

578:

492:

484:

470:

369:

327:

232:

221:

1368:

Class Formation and Urban Industrial Society: Bradford, 1750–1850

246:

since 1793. By 1799 the works were producing about 2,000 tons of

265:

was constructed connecting the colliery to Barnby Basin on the

273:

which ran over much of its trackbed, and operated until 1870.

1455:

The Poetical Works of John Nicholson ... (the Airedale Poet)

1116:

1114:

1041:

1039:

867:

865:

722:

720:

695:

693:

906:

904:

656:

654:

652:

650:

562:

560:

558:

1393:

Murray, John (1867). "Route 34.–Low Moor Ironworks".

261:. This mine worked the "Silkstone Seam". In 1802 the

1259:

Biographical Dictionary of the History of Technology

741:

Silkstone Waggonway, South Yorkshire: Survey Report

163:

155:

147:

110:

99:

84:

31:

1173:Commissioners for the Exhibition of 1851 (1851).

1340:Nineteenth-century Torpedoes and Their Inventors

1212:The First Industrialists: The Problem of Origins

1473:History of the Steam Hammer: With Illustrations

421:

287:

181:foundry established in 1791 in the village of

995:Commissioners for the Exhibition of 1851 1851

934:

8:

1197:: CS1 maint: numeric names: authors list (

922:

772:

61:

28:

1585:Manufacturing companies based in Bradford

1256:Day, Lance; McNeil, Ian (15 April 2013).

1156:

1144:

1132:

1120:

1105:

1093:

1045:

1031:The Low Moor Company: London Society 1879

1018:

958:

856:

844:

832:

820:

808:

796:

785:The Low Moor Company: London Society 1879

726:

712:The Low Moor Company: London Society 1879

699:

684:

630:The Low Moor Company: London Society 1879

618:The Low Moor Company: London Society 1879

602:

591:The Low Moor Company: London Society 1879

579:The Low Moor Company: London Society 1879

1441:James Nasmyth Engineer: An Autobiography

1081:

1006:

895:

871:

672:

660:

566:

300:For horse-shoe nails, or thund'ring guns

641:

554:

527:

294:The roaring blast, the quiv'ring flame,

1365:Koditschek, Theodore (30 March 1990).

1190:

1069:

1057:

982:

910:

883:

1343:. Naval Institute Press. p. 77.

946:

185:about 3 miles (4.8 km) south of

7:

1580:Buildings and structures in Bradford

1396:Handbook for travellers in Yorkshire

970:

332:Puddling furnace (1881 illustration)

1575:Ironworks and steelworks in England

497:Monument to the Low Moor Iron Works

285:poet John Nicholson wrote in 1829,

1457:. Simpkin, Marshall, & Company

304:No pen can write, no mind can soar

290:When first the shapeless sable ore

25:

306:To tell the wonders of Low Moor.

292:Is laid in heaps around Low Moor,

489:Low Moor industrial area in 2007

336:The process to convert ore into

298:White as the sun the metal runs,

253:In 1800, the company opened the

60:

53:

37:

1590:History of the City of Bradford

1546:. William Clowes and Sons. 1879

1284:Dodsworth, Charles (May 1971).

1517:. Cambridge University Press.

1371:. Cambridge University Press.

1215:. Cambridge University Press.

296:Give to the mass another name:

1:

1309:Evans, David (January 2004).

1286:"Low Moor Ironworks Bradford"

1511:Tallis, John (19 May 2011).

1337:Gray, Edwyn (January 2004).

1179:Spicer brothers. p. 110

345:Limestone was brought from

1606:

1489:Scoresby, William (1839).

1470:Rowlandson, T. S. (1875).

1237:Cudworth, William (1876).

538:. He became a minister at

263:Low Moor Furnace Waggonway

1492:Magnetical investigations

935:Nasmyth & Smiles 1883

210:Leeds and Liverpool Canal

80:

48:

43:The ironworks around 1855

36:

1449:Nicholson, John (1876).

88:13 August 1791

1421:. J. Weale. p. 901

259:Walter Spencer Stanhope

255:Barnby Furnace Colliery

1540:"The Low Moor Company"

1444:. London: John Murray.

1415:Mushet, David (1840).

1290:Industrial Archaeology

498:

490:

426:

381:

333:

309:

238:

216:a close friend of Dr.

132:53.752762°N 1.768988°W

1570:Industrial Revolution

1451:"Low Moor Iron Works"

1399:. J. Murray. p.

959:Day & McNeil 2013

536:University of Glasgow

496:

488:

373:

331:

236:

540:Idle, West Yorkshire

397:the Great Exhibition

257:on land leased from

244:revolutionary France

137:53.752762; -1.768988

1315:. Conway Maritime.

1209:(30 October 2008).

387:, Works Manager at

271:Silkstone Waggonway

128: /

1072:, p. 409-410.

835:, p. 265-266.

499:

491:

411:(1853–56) and the

401:the Crystal Palace

382:

334:

316:'s newly invented

239:

175:Low Moor Ironworks

104:Low Moor, Bradford

32:Low Moor Ironworks

1524:978-1-108-02671-0

1476:. Palmer and Howe

1378:978-0-521-32771-8

1350:978-1-59114-341-3

1322:978-0-85177-959-1

1269:978-1-134-65020-0

1222:978-0-521-08871-8

1207:Crouzet, François

171:

170:

16:(Redirected from

1597:

1555:

1553:

1551:

1535:

1533:

1531:

1507:

1505:

1503:

1485:

1483:

1481:

1466:

1464:

1462:

1445:

1434:Nasmyth, James;

1430:

1428:

1426:

1411:

1409:

1407:

1389:

1387:

1385:

1361:

1359:

1357:

1333:

1331:

1329:

1305:

1303:

1301:

1280:

1278:

1276:

1252:

1250:

1248:

1233:

1231:

1229:

1202:

1196:

1188:

1186:

1184:

1160:

1154:

1148:

1142:

1136:

1130:

1124:

1118:

1109:

1103:

1097:

1091:

1085:

1084:, p. 56-57.

1079:

1073:

1067:

1061:

1055:

1049:

1043:

1034:

1028:

1022:

1016:

1010:

1004:

998:

992:

986:

980:

974:

968:

962:

956:

950:

944:

938:

932:

926:

920:

914:

908:

899:

893:

887:

881:

875:

869:

860:

854:

848:

842:

836:

830:

824:

818:

812:

806:

800:

794:

788:

782:

776:

770:

764:

763:

761:

759:

754:on 11 March 2016

753:

746:

736:

730:

724:

715:

709:

703:

697:

688:

682:

676:

675:, p. 57-58.

670:

664:

658:

645:

639:

633:

627:

621:

615:

606:

600:

594:

588:

582:

576:

570:

564:

543:

532:

218:Joseph Priestley

143:

142:

140:

139:

138:

133:

129:

126:

125:

124:

121:

95:

93:

64:

63:

57:

41:

29:

21:

18:Low Moor Company

1605:

1604:

1600:

1599:

1598:

1596:

1595:

1594:

1560:

1559:

1558:

1549:

1547:

1538:

1529:

1527:

1525:

1510:

1501:

1499:

1488:

1479:

1477:

1469:

1460:

1458:

1448:

1433:

1424:

1422:

1414:

1405:

1403:

1392:

1383:

1381:

1379:

1364:

1355:

1353:

1351:

1336:

1327:

1325:

1323:

1308:

1299:

1297:

1283:

1274:

1272:

1270:

1255:

1246:

1244:

1236:

1227:

1225:

1223:

1205:

1189:

1182:

1180:

1172:

1163:

1155:

1151:

1143:

1139:

1131:

1127:

1119:

1112:

1104:

1100:

1092:

1088:

1080:

1076:

1068:

1064:

1056:

1052:

1044:

1037:

1029:

1025:

1017:

1013:

1005:

1001:

993:

989:

981:

977:

969:

965:

961:, p. 1318.

957:

953:

945:

941:

933:

929:

923:Rowlandson 1875

921:

917:

909:

902:

894:

890:

882:

878:

870:

863:

855:

851:

843:

839:

831:

827:

819:

815:

807:

803:

795:

791:

783:

779:

773:Koditschek 1990

771:

767:

757:

755:

751:

744:

738:

737:

733:

725:

718:

710:

706:

698:

691:

683:

679:

671:

667:

659:

648:

640:

636:

628:

624:

616:

609:

601:

597:

589:

585:

577:

573:

565:

556:

547:

546:

533:

529:

519:

483:

368:

366:Full production

326:

308:

305:

303:

301:

299:

297:

295:

293:

291:

231:

196:

136:

134:

130:

127:

122:

119:

117:

115:

114:

91:

89:

76:

75:

74:

73:

67:

66:

65:

44:

23:

22:

15:

12:

11:

5:

1603:

1601:

1593:

1592:

1587:

1582:

1577:

1572:

1562:

1561:

1557:

1556:

1544:London Society

1536:

1523:

1508:

1486:

1467:

1446:

1436:Smiles, Samuel

1431:

1412:

1390:

1377:

1362:

1349:

1334:

1321:

1306:

1281:

1268:

1253:

1234:

1221:

1203:

1169:

1162:

1161:

1157:Dodsworth 1971

1149:

1145:Dodsworth 1971

1137:

1133:Dodsworth 1971

1125:

1121:Dodsworth 1971

1110:

1106:Dodsworth 1971

1098:

1094:Dodsworth 1971

1086:

1074:

1062:

1060:, p. 411.

1050:

1046:Dodsworth 1971

1035:

1033:, p. 350.

1023:

1019:Dodsworth 1971

1011:

999:

997:, p. 110.

987:

985:, p. 167.

975:

963:

951:

939:

937:, p. 259.

927:

915:

913:, p. 410.

900:

898:, p. 333.

888:

886:, p. 901.

876:

861:

857:Dodsworth 1971

849:

845:Dodsworth 1971

837:

833:Nicholson 1876

825:

821:Dodsworth 1971

813:

809:Dodsworth 1971

801:

797:Dodsworth 1971

789:

787:, p. 351.

777:

765:

731:

727:Dodsworth 1971

716:

714:, p. 347.

704:

700:Dodsworth 1971

689:

685:Dodsworth 1971

677:

665:

646:

634:

632:, p. 343.

622:

620:, p. 344.

607:

603:Dodsworth 1971

595:

593:, p. 345.

583:

581:, p. 346.

571:

553:

545:

544:

526:

525:

518:

515:

482:

479:

367:

364:

356:blast furnaces

340:and then into

325:

322:

288:

267:Barnsley Canal

230:

227:

195:

192:

169:

168:

165:

161:

160:

157:

153:

152:

149:

145:

144:

112:

108:

107:

101:

97:

96:

86:

82:

81:

78:

77:

71:West Yorkshire

68:

59:

58:

52:

51:

50:

49:

46:

45:

42:

34:

33:

24:

14:

13:

10:

9:

6:

4:

3:

2:

1602:

1591:

1588:

1586:

1583:

1581:

1578:

1576:

1573:

1571:

1568:

1567:

1565:

1545:

1541:

1537:

1526:

1520:

1516:

1515:

1509:

1498:

1494:

1493:

1487:

1475:

1474:

1468:

1456:

1452:

1447:

1443:

1442:

1437:

1432:

1420:

1419:

1413:

1402:

1398:

1397:

1391:

1380:

1374:

1370:

1369:

1363:

1352:

1346:

1342:

1341:

1335:

1324:

1318:

1314:

1313:

1307:

1295:

1291:

1287:

1282:

1271:

1265:

1262:. Routledge.

1261:

1260:

1254:

1242:

1241:

1235:

1224:

1218:

1214:

1213:

1208:

1204:

1200:

1194:

1178:

1177:

1171:

1170:

1168:

1167:

1159:, p. 23.

1158:

1153:

1150:

1147:, p. 22.

1146:

1141:

1138:

1135:, p. 20.

1134:

1129:

1126:

1123:, p. 21.

1122:

1117:

1115:

1111:

1108:, p. 19.

1107:

1102:

1099:

1096:, p. 18.

1095:

1090:

1087:

1083:

1082:Cudworth 1876

1078:

1075:

1071:

1066:

1063:

1059:

1054:

1051:

1048:, p. 17.

1047:

1042:

1040:

1036:

1032:

1027:

1024:

1021:, p. 16.

1020:

1015:

1012:

1009:, p. 58.

1008:

1007:Cudworth 1876

1003:

1000:

996:

991:

988:

984:

979:

976:

973:, p. 77.

972:

967:

964:

960:

955:

952:

949:, p. 58.

948:

943:

940:

936:

931:

928:

925:, p. 34.

924:

919:

916:

912:

907:

905:

901:

897:

896:Scoresby 1839

892:

889:

885:

880:

877:

874:, p. 59.

873:

872:Cudworth 1876

868:

866:

862:

859:, p. 15.

858:

853:

850:

847:, p. 14.

846:

841:

838:

834:

829:

826:

823:, p. 10.

822:

817:

814:

810:

805:

802:

798:

793:

790:

786:

781:

778:

775:, p. 44.

774:

769:

766:

750:

743:

742:

735:

732:

728:

723:

721:

717:

713:

708:

705:

701:

696:

694:

690:

686:

681:

678:

674:

673:Cudworth 1876

669:

666:

663:, p. 57.

662:

661:Cudworth 1876

657:

655:

653:

651:

647:

644:, p. 82.

643:

638:

635:

631:

626:

623:

619:

614:

612:

608:

604:

599:

596:

592:

587:

584:

580:

575:

572:

569:, p. 56.

568:

567:Cudworth 1876

563:

561:

559:

555:

552:

551:

541:

537:

531:

528:

524:

523:

516:

514:

512:

511:Staffordshire

507:

505:

495:

487:

480:

478:

474:

472:

468:

464:

460:

456:

452:

448:

444:

440:

436:

432:

425:

420:

416:

414:

413:Indian Mutiny

410:

404:

402:

398:

394:

390:

389:James Nasmyth

386:

385:Robert Wilson

380:

376:

375:James Nasmyth

372:

365:

363:

361:

357:

351:

348:

343:

339:

330:

323:

321:

319:

318:steam hammers

315:

314:James Nasmyth

307:

286:

284:

278:

274:

272:

268:

264:

260:

256:

251:

249:

245:

235:

228:

226:

223:

219:

213:

211:

205:

202:

193:

191:

188:

184:

180:

176:

166:

162:

158:

154:

150:

146:

141:

113:

109:

105:

102:

98:

87:

83:

79:

72:

56:

47:

40:

35:

30:

27:

19:

1548:. Retrieved

1543:

1528:. Retrieved

1513:

1500:. Retrieved

1491:

1478:. Retrieved

1472:

1459:. Retrieved

1454:

1440:

1423:. Retrieved

1417:

1404:. Retrieved

1395:

1382:. Retrieved

1367:

1354:. Retrieved

1339:

1326:. Retrieved

1311:

1298:. Retrieved

1293:

1289:

1273:. Retrieved

1258:

1245:. Retrieved

1239:

1226:. Retrieved

1211:

1181:. Retrieved

1175:

1165:

1164:

1152:

1140:

1128:

1101:

1089:

1077:

1065:

1053:

1026:

1014:

1002:

990:

978:

966:

954:

942:

930:

918:

891:

879:

852:

840:

828:

816:

811:, p. 9.

804:

799:, p. 7.

792:

780:

768:

756:. Retrieved

749:the original

740:

734:

729:, p. 6.

707:

702:, p. 4.

687:, p. 3.

680:

668:

642:Crouzet 2008

637:

625:

605:, p. 2.

598:

586:

574:

549:

548:

530:

521:

520:

508:

500:

475:

467:Potternewton

463:Osmondthorpe

427:

422:

417:

405:

393:steam hammer

383:

379:steam hammer

352:

342:wrought iron

335:

310:

289:

279:

275:

262:

254:

252:

240:

214:

206:

197:

179:wrought iron

174:

172:

159:Wrought iron

69:Low Moor in

26:

1070:Murray 1867

1058:Murray 1867

983:Tallis 2011

911:Murray 1867

884:Mushet 1840

504:World War I

451:Cleckheaton

447:Hipperholme

433:, Bowling,

409:Crimean War

399:of 1851 at

151:Ironworking

135: /

111:Coordinates

1564:Categories

1495:. p.

1243:. T. Brear

947:Evans 2004

517:References

377:'s patent

194:Background

120:53°45′10″N

92:1791-08-13

1550:14 August

1530:14 August

1502:14 August

1480:11 August

1461:14 August

1425:14 August

1406:14 August

1384:14 August

1356:13 August

1328:12 August

1300:13 August

1275:13 August

1247:14 August

1228:14 August

1193:cite book

1183:14 August

971:Gray 2004

758:10 August

550:Citations

229:Expansion

123:1°46′08″W

106:, England

1438:(1883).

459:Churwell

338:pig iron

283:Airedale

248:pig iron

187:Bradford

183:Low Moor

156:Products

148:Industry

100:Location

1166:Sources

481:Decline

469:, near

455:Beeston

443:Clifton

360:puddled

347:Skipton

324:Process

201:Halifax

164:Defunct

90: (

1521:

1375:

1347:

1319:

1266:

1219:

177:was a

752:(PDF)

745:(PDF)

522:Notes

471:Leeds

435:Shelf

222:Wigan

85:Built

1552:2013

1532:2013

1519:ISBN

1504:2013

1482:2013

1463:2013

1427:2013

1408:2013

1386:2013

1373:ISBN

1358:2013

1345:ISBN

1330:2013

1317:ISBN

1302:2013

1277:2013

1264:ISBN

1249:2013

1230:2013

1217:ISBN

1199:link

1185:2013

760:2019

465:and

449:and

439:Wyke

431:Tong

173:The

167:1920

1497:333

1401:409

1296:(2)

302:...

1566::

1542:.

1453:.

1294:18

1292:.

1288:.

1195:}}

1191:{{

1113:^

1038:^

903:^

864:^

719:^

692:^

649:^

610:^

557:^

461:,

457:,

445:,

441:,

437:,

320:.

1554:.

1534:.

1506:.

1484:.

1465:.

1429:.

1410:.

1388:.

1360:.

1332:.

1304:.

1279:.

1251:.

1232:.

1201:)

1187:.

762:.

94:)

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.