140:

585:

between the die and punch are generally around 1% of the cut material thickness, which typically varies between 0.5–13 mm (0.020–0.512 in). Currently parts as thick as 19 mm (0.75 in) can be cut using fine blanking. Tolerances between ±0.0003–0.002 in (0.0076–0.0508 mm) are possible, depending on the base material thickness and tensile strength, and part layout.

448:

256:

181:

43:

517:

434:

to 0.025 mm (0.001 in). Shaving of metals is done in order to remove excess or scrap metal. A straight, smooth edge is provided and therefore shaving is frequently performed on instrument parts, watch and clock parts, and the like. Shaving is accomplished in shaving dies especially designed for the purpose.

337:

579:

around the perimeter of the die opening. Next, a counter pressure is applied opposite the punch, and finally, the die punch forces the material through the die opening. Since the guide plate holds the material so tightly, and since the counter pressure is applied, the material is cut in a manner more

433:

The shaving process is a finishing operation where a small amount of metal is sheared away from an already blanked part. Its main purpose is to obtain better dimensional accuracy, but secondary purposes include squaring the edge and smoothing the edge. Blanked parts can be shaved to an accuracy of up

323:

Material specific design guidelines are developed by companies in order to define the minimum acceptable values of hole diameters, bridge sizes, slot dimensions. Similarly, the strip lay-out must be determined (strip width and pitch). The bridge width between the parts and the edge allowance between

241:

Burrs and die roll are typical features of stamped components. Die roll is created when the material being stamped is compressed before the material begins to shear. Die roll takes the form of a radius around the outside edge of the blank and the pierced holes. After compression, the part shears for

379:

Normally lancing is done on a mechanical press, lancing requires the use of punches and dies to be used. The different punches and dies determine the shape and angle (or curvature) of the newly made section of the material. The dies and punches are needed to be made of tool steel to withstand the

584:

than typical punching. Mechanical properties of the cut benefit similarly with a hardened layer at the cut edge of the part. Because the material is so tightly held and controlled in this setup, part flatness remains very true, distortion is nearly eliminated, and edge burr is minimal. Clearances

424:

The process is often used on parts that do not have quantities that can justify a dedicated blanking die. The edge smoothness is determined by the shape of the cutting die and the amount the cuts overlap; naturally the more the cuts overlap, the cleaner the edge. For added accuracy and smoothness,

166:

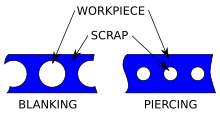

are used to produce parts from coil or sheet stock. Blanking produces the outside features of the component, while piercing produces internal holes or shapes. The web is created after multiple components have been produced and is considered scrap material. The "slugs" produced by piercing internal

574:

presses, but they have a few critical additional parts. A typical compound fine blanking press includes a hardened die punch (male), the hardened blanking die (female), and a guide plate of similar shape/size to the blanking die. The guide plate is the first applied to the material, impinging the

375:

Lancing can be used to make partial contours and free up material for other operations further down the production line. Along with these reasons, lancing is also used to make tabs (where the material is bent at a 90-degree angle to the material), vents (where the bend is around 45 degrees), and

420:

may be employed to do this. This allows for complex shapes to be formed in sheet metal up to 6 mm (0.25 in) thick using simple tools. that is essentially a small punch and die that reciprocates quickly; around 300–900 times per minute. Punches are available in various shape and sizes;

539:

Fine blanking is a specialized form of blanking where there is no fracture zone when shearing. This is achieved by compressing the whole part and then an upper and lower punch extract the blank. This allows the process to hold very tight tolerances, and perhaps eliminate secondary operations.

525:

634:

One of the main advantages of fine blanking is that slots or holes can be placed very near to the edges of the part, or near to each other. Also, fineblanking can produce holes that are much smaller (as compared to material thickness) than can be produced by conventional stamping.

242:

about 10% of the part thickness, and then fractures free of the strip or sheet. This fracturing produces a raised, jagged edge which is called a "burr". Burrs are typically removed by tumbling in a secondary process. Burr height can be used as an important indicator of tool wear.

421:

oblong and rectangular punches are common because they minimize waste and allow for greater distances between strokes, as compared to a round punch. Nibbling can occur on the exterior or interior of the material, however interior cuts require a hole to insert the tool.

319:

The punch/die clearance is a crucial parameter, which determines the load at the cutting edge of the tool, commonly known as point pressure. Excessive point pressure can accelerate tool wear. The surface quality of the trimmed piece is affected by the clearance, too.

364:

Lancing is a piercing operation in which the workpiece is sheared and bent with one strike of the die. A key part of this process is that there is not reduction of material, only a modification in its geometry. This operation is used to make tabs, vents, and

342:

341:

338:

343:

530:

529:

526:

531:

340:

630:

more economical for large production runs than traditional operations when additional machining cost and time are factored in (1000–20000 parts minimum, depending on secondary machining operations).

528:

372:

The cut made in lancing is not a closed cut, like in perforation even though a similar machine is used, but a side is left connected to be bent sharply or in more of a rounded manner.

1073:

604:

fine blanking operations, in which multiple operations are performed at the same pressing station. Due to the higher lifetime, blanking punches are usually covered by

339:

331:. While many dies perform complex procedures simultaneously, a pancake die may only perform one simple procedure with the finished product being removed by hand.

1035:

527:

508:

The trimming operation is the last operation performed, because it cuts away excess or unwanted irregular features from the walls of drawn sheets.

316:

The selection criteria of all process parameters are governed by the sheet thickness and by the strength of the work-piece material being pierced.

1066:

469:

277:

202:

60:

1059:

1028:

1005:

984:

965:

787:

753:

695:

495:

303:

228:

126:

107:

79:

473:

281:

206:

86:

64:

668:

588:

With standard compound fine blanking processes, multiple parts can often be completed in a single operation. Parts can be

356:

There are various types of blanking and piercing: lancing, perforating, notching, nibbling, shaving, cutoff, and dinking.

864:

Daniel, Josef; Žemlička, Radek; Grossman, Jan; Lümkemann, Andreas; Tapp, Peter; Galamand, Christian; Fořt, Tomáš (2020).

376:

louvers (where the piece is rounded or cupped). Lancing also helps to cut or slight shear of sheet on cylindrical shape.

1386:

1087:

1021:

93:

458:

266:

191:

866:"Comparison of Lifetime of the PVD Coatings in Laboratory Dynamic Impact Test and Industrial Fine Blanking Process"

824:

477:

462:

285:

270:

210:

195:

75:

53:

605:

1303:

1144:

1355:

1174:

1149:

1139:

593:

589:

571:

155:

1381:

1199:

1194:

1134:

1129:

1083:

597:

1184:

877:

601:

167:

features are also considered scrap. The terms "piercing" and "punching" can be used interchangeably.

159:

163:

100:

394:

Perforating is a piercing tooling that involves punching a large number of closely spaced holes.

1330:

1325:

1260:

1154:

1103:

1001:

980:

961:

905:

783:

691:

416:

The nibbling process cuts a contour by producing a series of overlapping slits or notches. A

895:

885:

1235:

1179:

564:

757:

881:

1283:

1204:

900:

865:

425:

most shapes created by nibbling undergo filing or grinding processes after completion.

408:

Notching is a piercing operation that removes material from the edge of the workpiece.

17:

1375:

1278:

1273:

923:

803:

615:

excellent dimensional control, accuracy, and repeatability through a production run;

139:

1214:

1169:

1044:

556:

995:

1113:

560:

447:

389:

328:

255:

180:

42:

1350:

1345:

1108:

1340:

1335:

1268:

1245:

1159:

782:(5th ed.). Upper Saddle River, NJ: Pearson Prentice Hall. p. 429.

581:

544:

909:

516:

1189:

646:

403:

831:

1360:

1320:

1298:

1293:

1250:

1230:

1209:

1164:

890:

417:

31:

1288:

552:

366:

645:

higher equipment costs, due to higher tooling cost when compared to

621:

straight, superior finished edges to other metal stamping processes;

1240:

548:

523:

515:

335:

138:

1055:

1017:

1013:

441:

249:

174:

36:

649:

operations and to higher tonnage requirements for the presses

627:

multiple features can be added simultaneously in 1 operation;

600:, often in a single operation. Some combinations may require

324:

the part and the edge of the strip also have to be selected.

975:

Degarmo, E. Paul; Black, J T.; Kohser, Ronald A. (2003).

642:

slightly slower than traditional punching operations;

1259:

1223:

1122:

1096:

994:Todd, Robert H.; Dell K. Allen; Leo Alting (1994),

67:. Unsourced material may be challenged and removed.

30:"Nibbling" redirects here. Not to be confused with

347:Modern CNC-Nibbling-Machine using different tools

778:Kalpakjian, Serope; Schmid, Steven R. (2006).

690:, New York: Industrial Press, pp. 84–85,

1067:

1029:

8:

721:

719:

717:

715:

570:Fine blanking presses are similar to other

543:Materials that can be fine blanked include

476:. Unsourced material may be challenged and

284:. Unsourced material may be challenged and

209:. Unsourced material may be challenged and

1074:

1060:

1052:

1036:

1022:

1014:

899:

889:

592:, partially pierced, offset (up to 75°),

520:Typical fine blanking press cross section

496:Learn how and when to remove this message

304:Learn how and when to remove this message

229:Learn how and when to remove this message

127:Learn how and when to remove this message

977:Materials and Processes in Manufacturing

780:Manufacturing Engineering and Technology

535:Using a Multitool with different punches

997:Manufacturing Processes Reference Guide

688:Manufacturing Processes Reference Guide

659:

958:Design for Manufacturability Handbook

611:The advantages of fine blanking are:

380:repetitious nature of the procedure.

7:

823:MPI International, Incعلى احمد على.

669:"How to do Designing and Machining?"

618:excellent part flatness is retained;

575:material with a sharp protrusion or

474:adding citations to reliable sources

282:adding citations to reliable sources

207:adding citations to reliable sources

65:adding citations to reliable sources

960:. New York, New York: McGraw-Hill.

327:A simple operation may only need a

25:

667:Burg, Doreen (13 February 2020).

446:

254:

179:

41:

624:little need to machine details;

52:needs additional citations for

1:

171:Die roll and burr formation

1403:

401:

387:

29:

1316:

1051:

956:Bralla, James G. (1999).

246:Tooling design guidelines

1145:Electrohydraulic forming

1000:, Industrial Press Inc,

924:"Fine blanking benefits"

143:Blanking versus piercing

1150:Electromagnetic forming

979:(9th ed.). Wiley.

804:"Fine blanking history"

638:The disadvantages are:

76:"Blanking and piercing"

18:Piercing (metalworking)

1135:Casting (metalworking)

942:Bralla, pp. 3.49–3.50.

854:Bralla, pp. 3.47–3.48.

608:protective coatings.

536:

521:

348:

144:

1356:Tools and terminology

534:

519:

346:

158:processes in which a

142:

1185:Progressive stamping

647:traditional punching

470:improve this section

278:improve this section

203:improve this section

61:improve this article

1387:Fabrication (metal)

1261:Finishing processes

882:2020Mate...13.2154D

891:10.3390/ma13092154

754:"Fineblanking 101"

537:

522:

349:

145:

27:Shearing processes

1369:

1368:

1312:

1311:

1224:Joining processes

1155:Explosive forming

1123:Forming processes

532:

506:

505:

498:

344:

314:

313:

306:

239:

238:

231:

137:

136:

129:

111:

16:(Redirected from

1394:

1091:

1076:

1069:

1062:

1053:

1038:

1031:

1024:

1015:

1010:

990:

971:

943:

940:

934:

933:

931:

930:

920:

914:

913:

903:

893:

861:

855:

852:

846:

845:

843:

842:

836:

830:. Archived from

829:

820:

814:

813:

811:

810:

800:

794:

793:

775:

769:

768:

766:

765:

756:. Archived from

750:

744:

743:Degarmo, p. 425.

741:

735:

734:Todd, pp. 97–98.

732:

726:

725:Degarmo, p. 428.

723:

710:

709:Degarmo, p. 427.

707:

701:

700:

683:

677:

676:

673:Eigenengineering

664:

565:stainless steels

533:

501:

494:

490:

487:

481:

450:

442:

352:Process variants

345:

309:

302:

298:

295:

289:

258:

250:

234:

227:

223:

220:

214:

183:

175:

132:

125:

121:

118:

112:

110:

69:

45:

37:

21:

1402:

1401:

1397:

1396:

1395:

1393:

1392:

1391:

1372:

1371:

1370:

1365:

1308:

1255:

1219:

1180:Press hardening

1118:

1092:

1090:, and finishing

1082:

1080:

1047:

1042:

1008:

993:

987:

974:

968:

955:

952:

947:

946:

941:

937:

928:

926:

922:

921:

917:

863:

862:

858:

853:

849:

840:

838:

834:

827:

822:

821:

817:

808:

806:

802:

801:

797:

790:

777:

776:

772:

763:

761:

752:

751:

747:

742:

738:

733:

729:

724:

713:

708:

704:

698:

685:

684:

680:

666:

665:

661:

656:

524:

514:

502:

491:

485:

482:

467:

451:

440:

431:

414:

406:

400:

392:

386:

362:

354:

336:

310:

299:

293:

290:

275:

259:

248:

235:

224:

218:

215:

200:

184:

173:

133:

122:

116:

113:

70:

68:

58:

46:

35:

28:

23:

22:

15:

12:

11:

5:

1400:

1398:

1390:

1389:

1384:

1374:

1373:

1367:

1366:

1364:

1363:

1358:

1353:

1348:

1343:

1338:

1333:

1328:

1323:

1317:

1314:

1313:

1310:

1309:

1307:

1306:

1301:

1296:

1291:

1286:

1284:Mass finishing

1281:

1276:

1271:

1265:

1263:

1257:

1256:

1254:

1253:

1248:

1243:

1238:

1233:

1227:

1225:

1221:

1220:

1218:

1217:

1212:

1207:

1202:

1197:

1192:

1187:

1182:

1177:

1172:

1167:

1162:

1157:

1152:

1147:

1142:

1137:

1132:

1126:

1124:

1120:

1119:

1117:

1116:

1111:

1106:

1100:

1098:

1094:

1093:

1081:

1079:

1078:

1071:

1064:

1056:

1049:

1048:

1043:

1041:

1040:

1033:

1026:

1018:

1012:

1011:

1006:

991:

985:

972:

966:

951:

948:

945:

944:

935:

915:

856:

847:

815:

795:

788:

770:

745:

736:

727:

711:

702:

696:

678:

658:

657:

655:

652:

651:

650:

643:

632:

631:

628:

625:

622:

619:

616:

572:metal stamping

513:

510:

504:

503:

454:

452:

445:

439:

436:

430:

427:

413:

410:

402:Main article:

399:

396:

388:Main article:

385:

382:

361:

358:

353:

350:

312:

311:

262:

260:

253:

247:

244:

237:

236:

187:

185:

178:

172:

169:

135:

134:

49:

47:

40:

26:

24:

14:

13:

10:

9:

6:

4:

3:

2:

1399:

1388:

1385:

1383:

1382:Metal forming

1380:

1379:

1377:

1362:

1359:

1357:

1354:

1352:

1349:

1347:

1344:

1342:

1339:

1337:

1334:

1332:

1329:

1327:

1324:

1322:

1319:

1318:

1315:

1305:

1302:

1300:

1297:

1295:

1292:

1290:

1287:

1285:

1282:

1280:

1279:Heat treating

1277:

1275:

1272:

1270:

1267:

1266:

1264:

1262:

1258:

1252:

1249:

1247:

1244:

1242:

1239:

1237:

1234:

1232:

1229:

1228:

1226:

1222:

1216:

1213:

1211:

1208:

1206:

1203:

1201:

1198:

1196:

1193:

1191:

1188:

1186:

1183:

1181:

1178:

1176:

1173:

1171:

1168:

1166:

1163:

1161:

1158:

1156:

1153:

1151:

1148:

1146:

1143:

1141:

1138:

1136:

1133:

1131:

1128:

1127:

1125:

1121:

1115:

1112:

1110:

1107:

1105:

1102:

1101:

1099:

1095:

1089:

1085:

1077:

1072:

1070:

1065:

1063:

1058:

1057:

1054:

1050:

1046:

1039:

1034:

1032:

1027:

1025:

1020:

1019:

1016:

1009:

1007:0-8311-3049-0

1003:

999:

998:

992:

988:

986:0-471-65653-4

982:

978:

973:

969:

967:0-07-007139-X

963:

959:

954:

953:

949:

939:

936:

925:

919:

916:

911:

907:

902:

897:

892:

887:

883:

879:

875:

871:

867:

860:

857:

851:

848:

837:on 2006-11-20

833:

826:

819:

816:

805:

799:

796:

791:

789:0-13-148965-8

785:

781:

774:

771:

760:on 2008-05-14

759:

755:

749:

746:

740:

737:

731:

728:

722:

720:

718:

716:

712:

706:

703:

699:

697:0-8311-3049-0

693:

689:

686:Todd (1994),

682:

679:

674:

670:

663:

660:

653:

648:

644:

641:

640:

639:

636:

629:

626:

623:

620:

617:

614:

613:

612:

609:

607:

603:

599:

595:

591:

586:

583:

578:

573:

568:

566:

562:

558:

554:

550:

546:

541:

518:

512:Fine blanking

511:

509:

500:

497:

489:

479:

475:

471:

465:

464:

460:

455:This section

453:

449:

444:

443:

437:

435:

428:

426:

422:

419:

411:

409:

405:

397:

395:

391:

383:

381:

377:

373:

370:

368:

359:

357:

351:

334:

332:

330:

325:

321:

317:

308:

305:

297:

287:

283:

279:

273:

272:

268:

263:This section

261:

257:

252:

251:

245:

243:

233:

230:

222:

212:

208:

204:

198:

197:

193:

188:This section

186:

182:

177:

176:

170:

168:

165:

161:

157:

153:

149:

141:

131:

128:

120:

109:

106:

102:

99:

95:

92:

88:

85:

81:

78: –

77:

73:

72:Find sources:

66:

62:

56:

55:

50:This article

48:

44:

39:

38:

33:

19:

1215:Tube bending

1170:Hydroforming

1045:Metalworking

996:

976:

957:

950:Bibliography

938:

927:. Retrieved

918:

873:

869:

859:

850:

839:. Retrieved

832:the original

825:"Guidelines"

818:

807:. Retrieved

798:

779:

773:

762:. Retrieved

758:the original

748:

739:

730:

705:

687:

681:

672:

662:

637:

633:

610:

587:

576:

569:

542:

538:

507:

492:

483:

468:Please help

456:

432:

423:

415:

407:

393:

378:

374:

371:

363:

355:

333:

326:

322:

318:

315:

300:

291:

276:Please help

264:

240:

225:

216:

201:Please help

189:

151:

147:

146:

123:

114:

104:

97:

90:

83:

71:

59:Please help

54:verification

51:

1326:Fabrication

1274:Galvanizing

1114:Sheet metal

1104:Fabrication

1088:fabrication

876:(9): 2154.

602:progressive

390:Perforation

384:Perforating

329:pancake die

1376:Categories

1346:Metallurgy

1289:Patination

1109:Piece work

929:2008-11-05

841:2008-11-05

809:2008-11-05

764:2008-11-05

654:References

486:March 2020

294:March 2020

219:March 2020

117:March 2020

87:newspapers

1341:Machining

1336:Jewellery

1304:Polishing

1269:Anodizing

1246:Soldering

1160:Extrusion

870:Materials

675:. Doreen.

582:extrusion

545:aluminium

457:does not

265:does not

190:does not

1351:Smithing

1241:Riveting

1236:Crimping

1205:Spinning

1190:Punching

1175:Stamping

910:32384814

594:embossed

438:Trimming

412:Nibbling

404:Notching

398:Notching

156:shearing

152:piercing

148:Blanking

1361:Welding

1331:Forming

1321:Casting

1299:Plating

1294:Peening

1251:Welding

1231:Brazing

1210:Swaging

1200:Sinking

1195:Rolling

1165:Forging

1140:Drawing

1130:Coining

1097:General

1084:Forming

901:7254225

878:Bibcode

590:pierced

577:stinger

478:removed

463:sources

429:Shaving

418:nibbler

367:louvers

360:Lancing

286:removed

271:sources

211:removed

196:sources

101:scholar

32:Nibling

1004:

983:

964:

908:

898:

786:

694:

598:coined

563:, and

557:carbon

555:, and

553:copper

103:

96:

89:

82:

74:

835:(PDF)

828:(PDF)

596:, or

580:like

561:alloy

549:brass

160:punch

108:JSTOR

94:books

1002:ISBN

981:ISBN

962:ISBN

906:PMID

784:ISBN

692:ISBN

461:any

459:cite

269:any

267:cite

194:any

192:cite

162:and

154:are

150:and

80:news

896:PMC

886:doi

606:PVD

472:by

280:by

205:by

164:die

63:by

1378::

1086:,

904:.

894:.

884:.

874:13

872:.

868:.

714:^

671:.

567:.

559:,

551:,

547:,

369:.

1075:e

1068:t

1061:v

1037:e

1030:t

1023:v

989:.

970:.

932:.

912:.

888::

880::

844:.

812:.

792:.

767:.

499:)

493:(

488:)

484:(

480:.

466:.

307:)

301:(

296:)

292:(

288:.

274:.

232:)

226:(

221:)

217:(

213:.

199:.

130:)

124:(

119:)

115:(

105:·

98:·

91:·

84:·

57:.

34:.

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.