321:

38:

212:

719:

359:

347:

136:

128:

302:, is angled upward, more liquid will have a chance to condense and flow back into the boiler leading to increased reflux. Typical results can increase production as high as 50% over the basic worm type condenser. The addition of a copper "boiling ball" in the path creates an area where expansion of gasses into the ball causes cooling and subsequent condensation and reflux. In a

260:, where it cools until it condenses into a liquid. The separation can be enhanced with the addition of more trays (to a practical limitation of heat, flow, etc.). The process continues until all the most volatile components in the liquid feed boil out of the mixture. This point can be recognized by the rise in temperature shown on the thermometer. For

247:

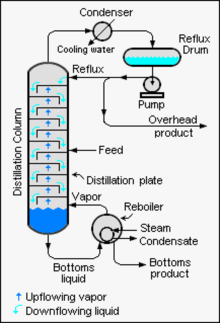

on the glass platforms (known as plates or trays) inside the column and runs back down into the liquid below, thereby refluxing the upflowing distillate vapor. The hottest tray is at the bottom of the column and the coolest tray is at the top. At steady state conditions, the vapor and liquid on each

107:

In that context, reflux refers to the portion of the overhead liquid product from a distillation column or fractionator that is returned to the upper part of the column as shown in the schematic diagram of a typical industrial distillation column. Inside the column, the downflowing reflux liquid

163:

the reaction mixture; vapours produced from the mixture are condensed by the condenser, and return to the vessel through gravity. The purpose is to thermally accelerate the reaction by conducting it at an elevated, controlled temperature (i.e. the

320:

119:, the better is the column's separation of lower boiling materials from higher boiling materials. Conversely, for a given desired separation, the more reflux is provided, the fewer theoretical plates are required.

288:), or post distillation flavored spirits (gin, absinthe), a process of multiple distillations or charcoal filtering may be applied to obtain a product lacking in any suggestion of its original source material for

276:

may be used to ensure that higher boiling point components are returned to the flask while lighter elements are passed out to a secondary condenser. This is useful in producing high quality

536:

540:

478:

346:

650:

563:

452:

358:

306:, the addition of inert materials in the column (e.g., packing) creates surfaces for early condensation and leads to increased reflux.

718:

512:

487:

427:

881:

52:

of vapors and the return of this condensate to the system from which it originated. It is used in industrial and laboratory

876:

708:

249:

871:

779:

643:

257:

693:

37:

835:

810:

590:

825:

820:

800:

738:

383:

261:

232:

85:

28:

211:

805:

156:

866:

830:

636:

176:

743:

622:

393:

388:

240:

224:

81:

845:

418:

289:

235:. The liquid feed mixture to be distilled is placed into the round-bottomed flask along with a few

159:, which is typically open to the atmosphere at the top. The reaction vessel is heated in order to

840:

733:

556:

Chemical engineering design : principles, practice and economics of plant and process design

530:

445:

Handbook of laboratory distillation : with an introduction into the pilot plant distillation

378:

243:

is fitted into the top. As the mixture is heated and boils, vapor rises up the column. The vapor

152:

27:

This article is about using reflux in chemical engineering and chemistry. For other usage, see

774:

698:

569:

559:

518:

508:

483:

458:

448:

423:

144:

116:

65:

815:

703:

220:

216:

135:

688:

292:. The geometry of the still also plays a role in determining how much reflux occurs. In a

277:

678:

673:

200:

97:

112:

of the upflowing vapors thereby increasing the efficiency of the distillation column.

860:

748:

281:

256:

form all the way to the top. The vapor at the top of the column then passes into the

184:

169:

93:

618:

659:

334:

244:

236:

231:

The apparatus shown in the diagram represents a batch distillation as opposed to a

109:

89:

53:

49:

272:

By controlling the temperature of the condenser, often called a dephlegmator, a

101:

284:) are returned to the primary flask. For high quality neutral spirits (such as

215:

Laboratory apparatus using reflux to supply energy to chemical reactions. An

573:

462:

769:

337:

294:

196:

192:

180:

57:

522:

127:

447:( completely rev. 2nd ed.). Amsterdam: Elsevier Scientific Pub. Co.

188:

17:

764:

326:

223:

is used to carry out the condensation. Here the distillation head and

172:) and ambient pressure without losing large quantities of the mixture.

165:

160:

148:

330:

61:

340:

before it is distilled to give pure oxygen- and water-free toluene.

784:

285:

210:

187:

is not generally suitable, and alternatives such as a water bath,

134:

126:

36:

34:

Condensation of vapors and their return to where they originated

632:

628:

253:

41:

The reflux system in a typical industrial distillation column

558:. Sinnott, R. K. Amsterdam: Elsevier/Butterworth-Heinemann.

298:, if the tube leading from the boiler to the condenser, the

175:

The diagram shows a typical reflux apparatus. It includes a

131:

Laboratory reflux apparatus for heating a chemical reaction

80:

is very widely used in industries that utilize large-scale

179:

to indirectly heat the mixture. As many solvents used are

280:, while ensuring that less desirable components (such as

352:

Industrial fractionating columns all of which use reflux

264:, the feed mixture enters in the middle of the column.

595:

University of

Toronto Scarborough - Chemistry Online

793:

757:

726:

666:

252:. Only the most volatile of the vapors stays in

115:The more reflux provided for a given number of

644:

503:King, C. Judson (Cary Judson), 1934- (1980).

476:Perry, Robert H. & Green, Don W. (1984).

155:. This vessel is connected to a water-cooled

8:

535:: CS1 maint: multiple names: authors list (

585:

583:

651:

637:

629:

539:) CS1 maint: numeric names: authors list (

151:is placed in a suitable vessel, such as a

411:

409:

364:Organic synthesis apparatus using reflux

405:

316:

528:

507:(2d ed.). New York: McGraw-Hill.

219:is used as a receiving flask, while a

7:

479:Perry's Chemical Engineers' Handbook

25:

207:Reflux in laboratory distillation

72:Reflux in industrial distillation

717:

357:

345:

319:

268:Reflux in beverage distillation

619:Distillation column components

1:

482:(6th ed.). McGraw-Hill.

422:(1st ed.). McGraw-Hill.

48:is a technique involving the

139:Laboratory reflux apparatus.

123:Reflux in chemical reactions

68:over a long period of time.

898:

780:Spinning band distillation

227:are combined in one piece.

26:

715:

554:Towler, Gavin P. (2008).

416:Kister, Henry Z. (1992).

709:Vapor–liquid equilibrium

183:, direct heating with a

739:Continuous distillation

384:Fractional distillation

262:continuous distillation

233:continuous distillation

29:Reflux (disambiguation)

443:Krell, Erich. (1982).

228:

140:

132:

42:

882:Laboratory techniques

237:anti-bumping granules

214:

138:

130:

108:provides cooling and

56:. It is also used in

40:

877:Industrial processes

744:Fractionating column

727:Industrial processes

694:McCabe–Thiele method

623:Newcastle University

505:Separation processes

394:McCabe-Thiele method

389:Fractionating column

241:fractionating column

225:fractionating column

90:petroleum refineries

82:distillation columns

419:Distillation Design

278:alcoholic beverages

104:processing plants.

872:Chemical processes

758:Laboratory methods

734:Batch distillation

379:Batch distillation

229:

197:electric hot plate

153:round bottom flask

141:

133:

117:theoretical plates

43:

854:

853:

775:Rotary evaporator

699:Theoretical plate

625:, United Kingdom.

621:, Dr. Ming Tham,

591:"What is Reflux?"

565:978-0-08-055695-6

454:978-0-08-087549-1

329:is refluxed with

16:(Redirected from

889:

721:

704:Partial pressure

653:

646:

639:

630:

606:

605:

603:

601:

587:

578:

577:

551:

545:

544:

534:

526:

500:

494:

493:

473:

467:

466:

440:

434:

433:

413:

361:

349:

323:

221:Liebig condenser

217:Erlenmeyer flask

21:

897:

896:

892:

891:

890:

888:

887:

886:

857:

856:

855:

850:

789:

753:

722:

713:

689:Fenske equation

662:

657:

615:

613:Further reading

610:

609:

599:

597:

589:

588:

581:

566:

553:

552:

548:

527:

515:

502:

501:

497:

490:

475:

474:

470:

455:

442:

441:

437:

430:

415:

414:

407:

402:

375:

370:

369:

368:

365:

362:

353:

350:

341:

324:

312:

270:

209:

125:

98:chemical plants

74:

35:

32:

23:

22:

15:

12:

11:

5:

895:

893:

885:

884:

879:

874:

869:

859:

858:

852:

851:

849:

848:

843:

838:

833:

828:

823:

818:

813:

808:

803:

797:

795:

791:

790:

788:

787:

782:

777:

772:

767:

761:

759:

755:

754:

752:

751:

746:

741:

736:

730:

728:

724:

723:

716:

714:

712:

711:

706:

701:

696:

691:

686:

681:

676:

670:

668:

664:

663:

658:

656:

655:

648:

641:

633:

627:

626:

614:

611:

608:

607:

579:

564:

546:

513:

495:

488:

468:

453:

435:

428:

404:

403:

401:

398:

397:

396:

391:

386:

381:

374:

371:

367:

366:

363:

356:

354:

351:

344:

342:

325:

318:

315:

314:

313:

311:

308:

282:fusel alcohols

269:

266:

208:

205:

203:are employed.

201:heating mantle

124:

121:

73:

70:

33:

24:

14:

13:

10:

9:

6:

4:

3:

2:

894:

883:

880:

878:

875:

873:

870:

868:

865:

864:

862:

847:

844:

842:

839:

837:

834:

832:

829:

827:

824:

822:

819:

817:

814:

812:

809:

807:

804:

802:

799:

798:

796:

792:

786:

783:

781:

778:

776:

773:

771:

768:

766:

763:

762:

760:

756:

750:

749:Spinning cone

747:

745:

742:

740:

737:

735:

732:

731:

729:

725:

720:

710:

707:

705:

702:

700:

697:

695:

692:

690:

687:

685:

682:

680:

677:

675:

672:

671:

669:

665:

661:

654:

649:

647:

642:

640:

635:

634:

631:

624:

620:

617:

616:

612:

596:

592:

586:

584:

580:

575:

571:

567:

561:

557:

550:

547:

542:

538:

532:

524:

520:

516:

514:0-07-034612-7

510:

506:

499:

496:

491:

489:0-07-049479-7

485:

481:

480:

472:

469:

464:

460:

456:

450:

446:

439:

436:

431:

429:0-07-034909-6

425:

421:

420:

412:

410:

406:

399:

395:

392:

390:

387:

385:

382:

380:

377:

376:

372:

360:

355:

348:

343:

339:

336:

332:

328:

322:

317:

309:

307:

305:

301:

297:

296:

291:

287:

283:

279:

275:

267:

265:

263:

259:

255:

251:

246:

242:

238:

234:

226:

222:

218:

213:

206:

204:

202:

198:

194:

190:

186:

185:Bunsen burner

182:

178:

173:

171:

170:boiling point

167:

162:

158:

154:

150:

146:

143:A mixture of

137:

129:

122:

120:

118:

113:

111:

105:

103:

99:

95:

94:petrochemical

91:

87:

86:fractionators

83:

79:

71:

69:

67:

63:

59:

55:

54:distillations

51:

47:

39:

30:

19:

867:Distillation

846:Vacuum-based

683:

679:Dalton's law

674:Raoult's law

660:Distillation

598:. Retrieved

594:

555:

549:

504:

498:

477:

471:

444:

438:

417:

335:benzophenone

304:column still

303:

299:

293:

290:fermentation

274:reflux still

273:

271:

230:

174:

142:

114:

110:condensation

106:

77:

75:

50:condensation

45:

44:

841:Steam-based

836:Salt-effect

811:Destructive

600:October 21,

250:equilibrium

248:tray is at

102:natural gas

861:Categories

826:Fractional

821:Extractive

801:Azeotropic

794:Techniques

667:Principles

400:References

239:, and the

177:water bath

60:to supply

806:Catalytic

770:Kugelrohr

574:191735762

531:cite book

463:305628802

338:desiccant

295:pot still

258:condenser

245:condenses

193:sand bath

181:flammable

157:condenser

145:reactants

76:The term

66:reactions

58:chemistry

18:Refluxing

831:Reactive

373:See also

300:lyne arm

189:oil bath

88:such as

765:Alembic

523:4882985

327:Toluene

310:Gallery

254:gaseous

166:solvent

149:solvent

684:Reflux

572:

562:

521:

511:

486:

461:

451:

426:

331:sodium

100:, and

78:reflux

62:energy

46:Reflux

785:Still

286:vodka

602:2017

570:OCLC

560:ISBN

541:link

537:link

519:OCLC

509:ISBN

484:ISBN

459:OCLC

449:ISBN

424:ISBN

161:boil

147:and

96:and

84:and

816:Dry

199:or

168:'s

64:to

863::

593:.

582:^

568:.

533:}}

529:{{

517:.

457:.

408:^

195:,

191:,

92:,

652:e

645:t

638:v

604:.

576:.

543:)

525:.

492:.

465:.

432:.

333:-

31:.

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.