86:, which have a high operating friction and are subject to steam forces on both sides of the valve. This friction meant that if the Johnson Bar is unlatched while the engine is operating under high steam pressure (wide regulator openings and high cut-off) or at high speeds, the forces that are supposed to act on the slide valves can instead be transmitted back through the linkage to the now-free reversing lever. This will suddenly and violently throw the lever into the full cut-off position, carrying with it the real danger of injury to the driver, damage to the valve gear and triggering wheel slip in the locomotive. The only way to prevent this is to close the regulator and allow the steam pressure in the valve chest to drop. The reversing lever can then be unlatched and set to a new cut-off position and then the regulator could be opened again. During this process the locomotive is not under power. On ascending gradients it was a matter of great skill to reduce the regulator opening by enough to safely unlatch the Johnson Bar while maintaining sufficient steam pressure to the cylinders. Each time the regulator was re-opened was a chance to encounter wheel slip and in

75:

position of the notches is chosen by the locomotive designer or constructor with a view to the locomotive's intended purpose. In general engines designed for freight will have fewer notches with a 'longer' minimum cut-off (providing high tractive effort at low speeds but poor efficiency at high speeds) while a passenger locomotive will have more notches and a shorter minimum cut-off (allowing efficiency at high speeds at the expense of tractive effort). If the minimum cut-off provided for by the notches was too high, it would not be possible to run the locomotive in the efficient way described above (with a fully open regulator) without leading to steam wastage or 'choking' of the steam passages, so the regulator would have to be closed. That limits efficiency.

121:

139:

160:

possible. The wheel is fitted with a locking lever to prevent creep and there is an indicator to show the percentage of cutoff in use. This method of altering the cutoff offers finer control than the sector lever, but it has the disadvantage of slow operation. It is most suitable for long-distance passenger engines where frequent changes of cutoff are not required and where fine adjustments offer the most benefit. On locomotives fitted with

31:

177:

operator worked a valve that admitted steam to one side or the other of a cylinder connected to the reversing mechanism until the indicator showed the intended position. A second mechanism—usually a piston in an oil-filled cylinder held in position by closing a control cock—was required to keep the linkages in place.

54:

This is the most common form of reverser. It is also known as a

Johnson bar in the United States. It consists of a long lever mounted parallel to the direction of travel, on the driver’s side of the cab. It has a handle and sprung trigger at the top and is pivoted at the bottom to pass between two

159:

in the UK), the reversing rod is controlled by a screw and nut, worked by a wheel in the cab. The nut either operates on the reversing rod directly or through a lever, as above. The screw and nut may be cut with a double thread (aka 2-start) and a coarse pitch to move the mechanism as quickly as

176:

With larger engines, the linkages involved in controlling cutoff and direction grew progressively heavier and there was a need for power assistance in adjusting them. Steam (later, compressed air) powered reversing gears were developed in the late 19th and early 20th centuries. Typically, the

168:, it was common to use the screw housing as an air cylinder, with the nut extended to form a piston. Compressed air from the brake reservoirs was applied to one side of the piston to reduce the effort required to lift the heavy expansion link, with gravity assisting in the opposite direction.

74:

The reversing lever has a catch mechanism which engages with a series of notches to hold the lever at the desired cut-off position. This means that the operator does not have a full choice of cut-off positions between maximum and mid-gear, but only those which correspond with the notches. The

245:

mounted on a single piston rod. Both pistons are double-ended. One is a steam piston to move the rod as required. The other, containing oil, holds the rod in a fixed position when the steam is turned off. Control is by a small three-way steam valve (“forward”, “stop”, “back”) and a separate

271:

was explicitly used by the developers of some later power reverse mechanisms. The use of feedback control in these later power reverse mechanisms eliminated the need for a second cylinder for a hydraulic locking mechanism, and it restored the simplicity of a single operating lever that both

267:. The power reverse amplified small motions of the reversing lever made in the locomotive cab with modest force into much larger and more forceful motions of the reach rod that controlled the engine cutoff and direction. It was usually air powered, but could also be steam powered. The term

107:. For switching, which required frequent changes of direction from full-ahead to full-reverse gear, the Johnson Bar was favored because the change could be made quickly in a single motion instead of the multiple turns of the handle of a low-geared screw reverser.

103:. From 1939 all new-build steam locomotives had to be fitted with power reversers and from 1942 Johnson Bar-fitted engines undergoing heavy overhaul or rebuilding had to be retro-fitted with power reverse. Exceptions existed for light, low-powered locomotives and

250:

connecting the two ends of the locking piston is also closed, thus holding the mechanism in position. The piston rod connects by levers to the reversing gear, which operates in the usual way, according to the type of valve gear in use.

82:, being connected to the various linkages and arms in order to serve its function in adjusting them. This means that the forces in the valve gear can be transmitted to the lever. This is especially the case if the engine has

63:, either above or below the pivot, in such a position as to give good leverage. A square pin is arranged to engage with the notches in the plates and hold the lever in the desired position when the trigger is released.

288:

used the

Ragonnet reversing gear, and other US builders generally abandoned positive locking features sooner than later. Many American locomotives were built, or retro-fitted, with power reversers, including the

98:

The dangers of the traditional

Johnson Bar (which grew as locomotive power, weight and operating steam pressures increased through the first half of the 20th century) led to it being banned in the USA by the

90:

trains each closure and opening of the regulator set up dynamic forces throughout the length of the train which risked broken couplings. The screw reverser overcame all these issues.

305:, but in Britain locking cylinders remained in use. The Hadfield reversing gear, patented in 1950, was in most particulars a Ragonnet reversing gear with added locking cylinder. Most

221:, his successor at that company, incorporated them into most of his designs, which were in production about thirty years after Stirling’s innovation. Later still the forward-looking

284:

was a major impetus to the development of power reverse systems, because these typically had two or even three sets of reverse gear, instead of just one on a simple locomotive. The

1033:

633:

66:

The advantages of this design are that change between forward and reverse gear can be made very quickly (as is needed in, for example, a shunting engine).

638:

540:

209:, but they found them little to their liking, mainly because of maintenance difficulties: any oil leakage from the locking cylinder, either through the

1026:

1908:

1019:

1483:

1478:

485:

366:

190:

1942:

1854:

981:

936:

821:

682:

533:

213:

or the cock, allowed the mechanism to creep, or worse “nose-dive”, into full forward gear while running. Stirling moved to the

1913:

1748:

1557:

100:

1201:

702:

246:

indicator showing the position of the rod and thus the percentage of cutoff in use. When the steam valve is at “stop”, an

672:

1587:

1577:

1781:

1645:

1626:

1617:

1501:

1113:

1056:

241:

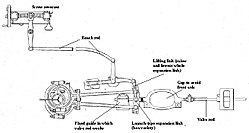

Patented in 1882, the

Henszey's reversing gear illustrates a typical early solution. Henszey's device consists of two

1395:

526:

214:

206:

186:

1947:

1936:

1493:

926:

756:

1721:

1653:

285:

1983:

1957:

1952:

1873:

1597:

1542:

1264:

1220:

408:

194:

1962:

1860:

1701:

1582:

1233:

1171:

832:

796:

737:

281:

230:

218:

911:

1918:

1827:

1552:

1473:

1446:

1176:

1161:

1071:

811:

732:

697:

662:

628:

318:

222:

198:

165:

127:

43:

1887:

1572:

1511:

1372:

1238:

1186:

1123:

1076:

1000:

896:

707:

1881:

1415:

1289:

1206:

1196:

960:

727:

687:

446:

1814:

1808:

1802:

1794:

1789:

1377:

886:

677:

610:

1678:

1526:

1516:

1465:

1420:

1400:

1387:

1367:

1349:

1294:

1248:

1118:

1061:

766:

620:

481:

433:

362:

161:

1754:

1742:

1715:

1441:

1359:

1329:

1181:

876:

722:

667:

558:

120:

1927:

1660:

1602:

1521:

1410:

1405:

1319:

1274:

970:

871:

138:

1846:

1695:

1667:

1344:

1243:

1166:

1156:

1066:

965:

955:

916:

856:

851:

816:

712:

692:

643:

264:

226:

144:

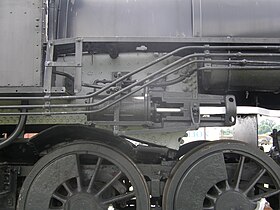

The two pistons of the steam reverser can be seen at the extreme left on this

Bulleid

1977:

1634:

1607:

1506:

1425:

1261:

945:

891:

866:

861:

786:

761:

202:

1835:

1592:

1339:

1324:

1279:

1133:

1128:

1042:

906:

791:

771:

210:

87:

42:

is used to control the direction of travel of the locomotive. It also adjusts the

1760:

1734:

1687:

1284:

1258:

1228:

1106:

1101:

921:

901:

881:

801:

575:

477:

247:

83:

1766:

1709:

1334:

1269:

1253:

1191:

1148:

1138:

841:

806:

776:

717:

653:

585:

563:

549:

459:

420:

79:

56:

17:

434:

Transactions of the

International Engineering Congress -- Railway Engineering

395:

382:

1562:

1547:

990:

600:

595:

580:

567:

30:

458:

James

Hadfield, Hydraulic Locking Cylinder for Locomotive Reversing Gear,

1451:

995:

590:

260:

104:

950:

846:

306:

302:

294:

290:

1567:

1304:

605:

298:

242:

518:

515: : Volume one; Seventh edition; London, Virtue and Company Ltd.

1086:

781:

747:

60:

29:

1011:

55:

notched sector plates. The reversing rod, which connects to the

1015:

522:

432:

George R. Henderson, Recent

Locomotive Development, Paper 90,

272:

controlled the reversing linkage and indicated its position.

506:

Locomotive

Practice and Performance in the Twentieth Century

394:

Eugine L. Ragonnet, Controlling

Mechanism for Locomotives,

259:

The Ragonnet power reverse, patented in 1909, was a true

233:

of locomotives, but they were mostly removed at rebuild.

185:

The first locomotive engineer to fit such a device was

193:

in 1873. Several engineers then tried them, including

474:

Illustrated Encyclopedia of World Railway Locomotives

381:

William P. Henszey, Reversing-Gear for Locomotives,

155:

In the screw reverser mechanism (sometimes called a

1901:

1872:

1845:

1826:

1780:

1733:

1686:

1677:

1644:

1625:

1616:

1535:

1492:

1464:

1434:

1386:

1358:

1312:

1303:

1219:

1147:

1094:

1085:

1049:

979:

935:

830:

746:

652:

619:

557:

361:. Avenel, New Jersey: Crescent Books. p. 105.

407:Jacob H Yoder, Locomotive Valves and Valve Gears,

78:The Johnson Bar is effectively part of the entire

462:, Sept. 26, 1950 (Oct. 7, 1944 in Great Britain).

445:Charles McShane, Locomotive Power Reverse Gears,

1027:

534:

436:, San Francisco, Sept. 20-25, 1915; page 491.

8:

357:Canestrari, Guido; Greggio, Luciano (1985).

27:Controller for the valves on a steam engine

1683:

1622:

1309:

1091:

1034:

1020:

1012:

541:

527:

519:

34:Steam reverser on a Southern Railway 2-8-0

419:Lincoln A. Lang, Servo Motor Mechanism,

410:, Van Nostrand, New York, 1917; page 131

1909:Glossary of steam locomotive components

330:

309:locomotives used the Hadfield system.

346:. Sutton, England: 638. January 1946.

7:

508:; W. Heffer and Sons Ltd.; Cambridge

449:, Griffin & Winters, 1921; 413.

1761:National Museum of Scotland engine

25:

191:Glasgow and South Western Railway

1943:List of steam technology patents

472:Ransome-Wallis, Patrick (2001).

137:

119:

822:Schwartzkopff-Eckhardt II bogie

59:, is attached to this (handle)

1928:Murdoch's model steam carriage

1914:History of steam road vehicles

130:controlled by a screw reverser

101:Interstate Commerce Commission

1:

1855:Murray's Hypocycloidal Engine

1578:Return connecting rod engine

1502:Condensing steam locomotive

255:The Ragonnet power reverser

38:On a steam locomotive, the

2000:

1809:"Coalbrookdale Locomotive"

338:"Railway Gazette :".

229:fitted them to his famous

1815:"Pen-y-Darren" locomotive

1484:Single- and double-acting

757:AAR type A switcher truck

511:Bell, A. Morton; (1950);

447:The Locomotive Up to Date

70:Limitations and drawbacks

46:of the steam locomotive.

1654:Newcomen Memorial Engine

504:Allen, Cecil J; (1949);

286:Baldwin Locomotive Works

237:Henszey's reversing gear

1958:Timeline of steam power

1953:Stationary steam engine

1836:Woolf's compound engine

1743:Soho Manufactory engine

1598:Steeple compound engine

1265:straight line mechanism

282:articulated locomotives

84:unbalanced slide valves

1963:Water-returning engine

1937:Lean's Engine Reporter

1710:Chacewater Mine engine

1583:Six-column beam engine

797:Krauss-Helmholtz bogie

219:Harry Smith Wainwright

162:Westinghouse air brake

35:

1803:London Steam Carriage

812:Radial steering truck

629:AAR wheel arrangement

476:. Mineola, New York:

460:U.S. Patent 2,523,696

421:U.S. Patent 1,480,940

319:Vehicular Johnson bar

276:Power reverse impetus

215:South Eastern Railway

207:North Eastern Railway

166:Stephenson valve gear

128:Stephenson valve gear

33:

1749:Bradley Works engine

1573:Reciprocating engine

1396:Babcock & Wilcox

1239:Centrifugal governor

639:Swiss classification

1290:Sun and planet gear

396:U.S. Patent 930,225

383:U.S. Patent 259,538

280:The development of

231:Merchant Navy Class

1790:Richard Trevithick

1388:Water-tube boilers

1202:Gresley conjugated

887:Klien-Lindner axle

634:UIC classification

611:Dual Control Stand

172:Power reverse gear

36:

1971:

1970:

1897:

1896:

1776:

1775:

1460:

1459:

1360:Fire-tube boilers

1215:

1214:

1009:

1008:

912:Road–rail vehicle

897:Luttermöller axle

767:Articulated bogie

621:Wheel arrangement

359:Steam Locomotives

16:(Redirected from

1991:

1921:fardier à vapeur

1755:Whitbread Engine

1716:Smethwick Engine

1684:

1623:

1442:Feedwater heater

1310:

1092:

1036:

1029:

1022:

1013:

782:Cleminson system

543:

536:

529:

520:

492:

491:

469:

463:

456:

450:

443:

437:

430:

424:

417:

411:

405:

399:

392:

386:

385:, June 13, 1882.

379:

373:

372:

354:

348:

347:

335:

223:Southern Railway

141:

123:

21:

1999:

1998:

1994:

1993:

1992:

1990:

1989:

1988:

1974:

1973:

1972:

1967:

1893:

1868:

1841:

1822:

1772:

1729:

1673:

1661:Fairbottom Bobs

1646:Newcomen engine

1640:

1612:

1558:Expansion valve

1531:

1517:Watt's separate

1488:

1456:

1430:

1382:

1354:

1299:

1275:Parallel motion

1211:

1162:Stephenson link

1143:

1081:

1050:Operating cycle

1045:

1040:

1010:

1005:

975:

931:

872:Equalising beam

826:

742:

648:

615:

562:

553:

547:

501:

496:

495:

488:

480:. p. 278.

471:

470:

466:

457:

453:

444:

440:

431:

427:

423:, Jan 15, 1924.

418:

414:

406:

402:

398:, Aug. 9, 1909.

393:

389:

380:

376:

369:

356:

355:

351:

340:Railway Gazette

337:

336:

332:

327:

315:

278:

174:

153:

152:

151:

150:

149:

142:

133:

132:

131:

124:

113:

96:

72:

52:

50:Reversing lever

28:

23:

22:

15:

12:

11:

5:

1997:

1995:

1987:

1986:

1984:Piston engines

1976:

1975:

1969:

1968:

1966:

1965:

1960:

1955:

1950:

1945:

1940:

1933:

1932:

1931:

1925:

1911:

1905:

1903:

1899:

1898:

1895:

1894:

1892:

1891:

1885:

1878:

1876:

1870:

1869:

1867:

1866:

1858:

1851:

1849:

1843:

1842:

1840:

1839:

1832:

1830:

1824:

1823:

1821:

1820:

1819:

1818:

1812:

1806:

1800:

1786:

1784:

1778:

1777:

1774:

1773:

1771:

1770:

1764:

1758:

1752:

1746:

1739:

1737:

1731:

1730:

1728:

1727:

1719:

1713:

1707:

1699:

1696:Kinneil Engine

1692:

1690:

1681:

1675:

1674:

1672:

1671:

1668:Elsecar Engine

1665:

1657:

1650:

1648:

1642:

1641:

1639:

1638:

1631:

1629:

1620:

1614:

1613:

1611:

1610:

1605:

1600:

1595:

1590:

1588:Steeple engine

1585:

1580:

1575:

1570:

1565:

1560:

1555:

1550:

1545:

1539:

1537:

1533:

1532:

1530:

1529:

1524:

1519:

1514:

1509:

1504:

1498:

1496:

1490:

1489:

1487:

1486:

1481:

1476:

1470:

1468:

1462:

1461:

1458:

1457:

1455:

1454:

1449:

1447:Feedwater pump

1444:

1438:

1436:

1432:

1431:

1429:

1428:

1423:

1418:

1413:

1408:

1403:

1398:

1392:

1390:

1384:

1383:

1381:

1380:

1375:

1370:

1364:

1362:

1356:

1355:

1353:

1352:

1347:

1342:

1337:

1332:

1327:

1322:

1316:

1314:

1313:Simple boilers

1307:

1301:

1300:

1298:

1297:

1295:Watt's linkage

1292:

1287:

1282:

1277:

1272:

1267:

1256:

1251:

1246:

1244:Connecting rod

1241:

1236:

1231:

1225:

1223:

1217:

1216:

1213:

1212:

1210:

1209:

1204:

1199:

1194:

1189:

1184:

1179:

1174:

1169:

1164:

1159:

1153:

1151:

1145:

1144:

1142:

1141:

1136:

1131:

1126:

1121:

1116:

1111:

1110:

1109:

1098:

1096:

1089:

1083:

1082:

1080:

1079:

1074:

1069:

1064:

1059:

1053:

1051:

1047:

1046:

1041:

1039:

1038:

1031:

1024:

1016:

1007:

1006:

1004:

1003:

998:

993:

987:

985:

982:exhaust system

977:

976:

974:

973:

968:

963:

958:

953:

948:

942:

940:

937:Exhaust system

933:

932:

930:

929:

924:

919:

917:Trailing wheel

914:

909:

904:

899:

894:

889:

884:

879:

874:

869:

864:

859:

857:Carrying wheel

854:

852:Beugniot lever

849:

844:

838:

836:

828:

827:

825:

824:

819:

817:Scheffel bogie

814:

809:

804:

799:

794:

789:

784:

779:

774:

769:

764:

759:

753:

751:

744:

743:

741:

740:

735:

730:

725:

720:

715:

710:

705:

700:

695:

690:

685:

680:

675:

670:

665:

659:

657:

650:

649:

647:

646:

644:Whyte notation

641:

636:

631:

625:

623:

617:

616:

614:

613:

608:

603:

598:

593:

588:

583:

578:

572:

570:

555:

554:

548:

546:

545:

538:

531:

523:

517:

516:

509:

500:

497:

494:

493:

486:

464:

451:

438:

425:

412:

400:

387:

374:

367:

349:

329:

328:

326:

323:

322:

321:

314:

311:

277:

274:

265:servomechanism

257:

256:

239:

238:

227:Oliver Bulleid

187:James Stirling

183:

182:

173:

170:

164:equipment and

143:

136:

135:

134:

125:

118:

117:

116:

115:

114:

112:

111:Screw reverser

109:

95:

92:

71:

68:

51:

48:

40:reversing gear

26:

24:

18:Steam reverser

14:

13:

10:

9:

6:

4:

3:

2:

1996:

1985:

1982:

1981:

1979:

1964:

1961:

1959:

1956:

1954:

1951:

1949:

1946:

1944:

1941:

1939:

1938:

1934:

1929:

1926:

1923:

1922:

1917:

1916:

1915:

1912:

1910:

1907:

1906:

1904:

1900:

1889:

1886:

1883:

1880:

1879:

1877:

1875:

1871:

1864:

1863:

1859:

1856:

1853:

1852:

1850:

1848:

1844:

1837:

1834:

1833:

1831:

1829:

1825:

1816:

1813:

1810:

1807:

1804:

1801:

1798:

1797:

1796:Puffing Devil

1793:

1792:

1791:

1788:

1787:

1785:

1783:

1782:High-pressure

1779:

1768:

1765:

1762:

1759:

1756:

1753:

1750:

1747:

1744:

1741:

1740:

1738:

1736:

1735:Rotative beam

1732:

1725:

1724:

1720:

1717:

1714:

1711:

1708:

1705:

1704:

1700:

1697:

1694:

1693:

1691:

1689:

1685:

1682:

1680:

1676:

1669:

1666:

1663:

1662:

1658:

1655:

1652:

1651:

1649:

1647:

1643:

1636:

1635:Savery Engine

1633:

1632:

1630:

1628:

1624:

1621:

1619:

1615:

1609:

1608:Working fluid

1606:

1604:

1601:

1599:

1596:

1594:

1591:

1589:

1586:

1584:

1581:

1579:

1576:

1574:

1571:

1569:

1566:

1564:

1561:

1559:

1556:

1554:

1551:

1549:

1546:

1544:

1541:

1540:

1538:

1534:

1528:

1525:

1523:

1520:

1518:

1515:

1513:

1510:

1508:

1505:

1503:

1500:

1499:

1497:

1495:

1491:

1485:

1482:

1480:

1477:

1475:

1472:

1471:

1469:

1467:

1463:

1453:

1450:

1448:

1445:

1443:

1440:

1439:

1437:

1433:

1427:

1424:

1422:

1419:

1417:

1414:

1412:

1409:

1407:

1404:

1402:

1399:

1397:

1394:

1393:

1391:

1389:

1385:

1379:

1376:

1374:

1371:

1369:

1366:

1365:

1363:

1361:

1357:

1351:

1348:

1346:

1343:

1341:

1338:

1336:

1333:

1331:

1328:

1326:

1323:

1321:

1318:

1317:

1315:

1311:

1308:

1306:

1302:

1296:

1293:

1291:

1288:

1286:

1285:Rotative beam

1283:

1281:

1278:

1276:

1273:

1271:

1268:

1266:

1263:

1262:hypocycloidal

1260:

1257:

1255:

1252:

1250:

1247:

1245:

1242:

1240:

1237:

1235:

1232:

1230:

1227:

1226:

1224:

1222:

1218:

1208:

1205:

1203:

1200:

1198:

1195:

1193:

1190:

1188:

1185:

1183:

1180:

1178:

1175:

1173:

1170:

1168:

1165:

1163:

1160:

1158:

1155:

1154:

1152:

1150:

1146:

1140:

1137:

1135:

1132:

1130:

1127:

1125:

1122:

1120:

1117:

1115:

1112:

1108:

1105:

1104:

1103:

1100:

1099:

1097:

1093:

1090:

1088:

1084:

1078:

1075:

1073:

1070:

1068:

1065:

1063:

1060:

1058:

1055:

1054:

1052:

1048:

1044:

1043:Steam engines

1037:

1032:

1030:

1025:

1023:

1018:

1017:

1014:

1002:

999:

997:

994:

992:

989:

988:

986:

983:

978:

972:

969:

967:

964:

962:

959:

957:

954:

952:

949:

947:

944:

943:

941:

938:

934:

928:

925:

923:

920:

918:

915:

913:

910:

908:

905:

903:

900:

898:

895:

893:

892:Leading wheel

890:

888:

885:

883:

880:

878:

877:Gölsdorf axle

875:

873:

870:

868:

867:Driving wheel

865:

863:

862:Coupled wheel

860:

858:

855:

853:

850:

848:

845:

843:

840:

839:

837:

834:

829:

823:

820:

818:

815:

813:

810:

808:

805:

803:

800:

798:

795:

793:

790:

788:

787:Grovers bogie

785:

783:

780:

778:

775:

773:

770:

768:

765:

763:

762:Arnoux system

760:

758:

755:

754:

752:

749:

745:

739:

736:

734:

731:

729:

726:

724:

721:

719:

716:

714:

711:

709:

706:

704:

701:

699:

696:

694:

691:

689:

686:

684:

681:

679:

676:

674:

673:Bagnall–Price

671:

669:

666:

664:

661:

660:

658:

655:

651:

645:

642:

640:

637:

635:

632:

630:

627:

626:

624:

622:

618:

612:

609:

607:

604:

602:

599:

597:

594:

592:

589:

587:

584:

582:

579:

577:

574:

573:

571:

569:

565:

560:

556:

551:

544:

539:

537:

532:

530:

525:

524:

521:

514:

510:

507:

503:

502:

498:

489:

487:0-486-41247-4

483:

479:

475:

468:

465:

461:

455:

452:

448:

442:

439:

435:

429:

426:

422:

416:

413:

409:

404:

401:

397:

391:

388:

384:

378:

375:

370:

368:0-517-48366-1

364:

360:

353:

350:

345:

341:

334:

331:

324:

320:

317:

316:

312:

310:

308:

307:Beyer Garratt

304:

300:

296:

292:

287:

283:

275:

273:

270:

266:

262:

254:

253:

252:

249:

244:

236:

235:

234:

232:

228:

224:

220:

216:

212:

208:

204:

203:Vincent Raven

200:

196:

192:

188:

181:Stirling gear

180:

179:

178:

171:

169:

167:

163:

158:

147:

146:Merchant Navy

140:

129:

122:

110:

108:

106:

102:

94:Ban in the US

93:

91:

89:

88:loose coupled

85:

81:

76:

69:

67:

64:

62:

58:

49:

47:

45:

41:

32:

19:

1948:Modern steam

1935:

1920:

1882:Porter-Allen

1861:

1795:

1722:

1702:

1659:

1593:Safety valve

1522:"Pickle-pot"

1416:Thimble tube

907:Railway tire

833:running gear

792:Jacobs bogie

772:Bissel truck

561:positioning

512:

505:

473:

467:

454:

441:

428:

415:

403:

390:

377:

358:

352:

343:

339:

333:

279:

268:

258:

240:

211:piston gland

195:William Dean

184:

175:

157:bacon slicer

156:

154:

145:

97:

77:

73:

65:

53:

39:

37:

1679:Watt engine

1479:Oscillating

1435:Boiler feed

1280:Plate chain

1259:Tusi couple

1172:Walschaerts

1057:Atmospheric

922:Train wheel

902:Radial axle

882:Journal box

802:Mason Bogie

738:Walschaerts

576:Cab forward

513:Locomotives

478:Dover Books

263:controlled

126:Diagram of

1888:Ljungström

1874:High-speed

1767:Lap Engine

1723:Resolution

1627:Precursors

1512:Kirchweger

1474:Locomotive

1421:Three-drum

1401:Field-tube

1368:Locomotive

1350:Lancashire

1270:Link chain

1254:Crankshaft

1221:Mechanisms

1149:Valve gear

842:Adams axle

807:Pony truck

777:Blomberg B

733:Stephenson

718:Kuhn slide

654:Valve gear

586:Steeplecab

564:Short hood

550:Locomotive

325:References

269:servomotor

80:valve gear

57:valve gear

1919:Cugnot's

1862:Salamanca

1563:Hydrolock

1548:Crosshead

1494:Condenser

1330:Egg-ended

991:Blastpipe

708:Hackworth

601:Cowl unit

596:Hood unit

581:Sharknose

568:Long hood

225:engineer

105:switchers

1978:Category

1902:See also

1828:Compound

1703:Old Bess

1543:Blowback

1466:Cylinder

1452:Injector

1411:Stirling

1406:Sentinel

1320:Haystack

1234:Cataract

1207:Southern

1197:Caprotti

1072:Compound

996:Smokebox

984:elements

961:Lemaître

927:Wheelset

835:elements

728:Southern

688:Caprotti

591:Cab unit

313:See also

261:feedback

248:oil cock

1618:History

1527:Surface

1345:Cornish

1305:Boilers

1187:Corliss

1124:Corliss

1107:D slide

1077:Uniflow

1067:Cornish

1001:Chimney

980:Common

971:Lemprex

951:Kylchap

847:Axlebox

703:Gresley

683:Bulleid

678:Baguley

499:Sources

303:PRR L1s

295:PRR N1s

291:PRR K4s

243:pistons

205:of the

197:of the

189:of the

1930:(1784)

1924:(1769)

1890:(1908)

1884:(1862)

1865:(1812)

1857:(1805)

1847:Murray

1838:(1803)

1817:(1804)

1811:(1803)

1805:(1803)

1799:(1801)

1769:(1788)

1763:(1786)

1757:(1785)

1751:(1783)

1745:(1782)

1726:(1781)

1718:(1779)

1712:(1778)

1706:(1777)

1698:(1768)

1670:(1795)

1664:(1760)

1656:(1725)

1637:(1698)

1603:Stroke

1568:Piston

1553:Cutoff

1426:Yarrow

1378:Launch

1373:Scotch

1134:Sleeve

1129:Poppet

1114:Piston

1095:Valves

1087:Valves

966:Lempor

956:Kylpor

831:Other

606:Boxcab

552:design

484:

365:

301:, and

299:PRR B6

44:cutoff

1536:Other

1340:Flued

1325:Wagon

1249:Crank

1192:Lentz

1182:Baker

1177:Allan

1102:Slide

946:Giesl

939:types

750:types

748:Bogie

723:Lentz

698:Gooch

668:Baker

663:Allan

656:types

148:class

61:lever

1688:Beam

1229:Beam

1139:Bash

1119:Drop

1062:Watt

482:ISBN

363:ISBN

217:and

201:and

1507:Jet

1335:Box

1167:Joy

1157:Gab

713:Joy

693:Gab

559:Cab

199:GWR

1980::

566:/

344:86

342:.

297:,

293:,

1035:e

1028:t

1021:v

542:e

535:t

528:v

490:.

371:.

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.