47:

31:

95:

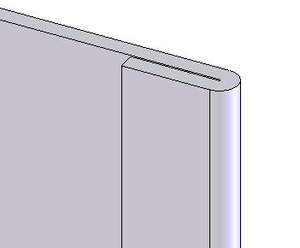

The process for both hemming and seaming are the same, except that the tonnage (amount of force exerted) requirement is greater for seaming. The process starts by bending the edge to an acute angle. A flattening die is then used to flatten the hem.

39:

112:. Closed hems are completely flush while open hems have an air pocket in the bend. The major difference is that the tonnage required for a closed hem is much greater than that for an open hem.

69:

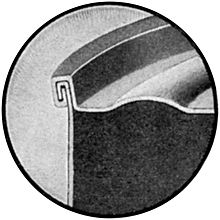

edge is rolled over onto itself. Hemming is the process in which the edge is rolled flush to itself, while a seam joins the edges of two materials.

310:

338:

357:

327:

Drozda, Tom; Wick, Charles; Bakerjian, Ramon; Veilleux, Raymond F.; Petro, Louis (10 December 1984),

243:

72:

Hems are commonly used to reinforce an edge, hide burrs and rough edges, and improve appearance.

334:

306:

46:

30:

76:

17:

351:

62:

328:

300:

84:

66:

238:

80:

116:

Tons per meter requirement for hemming cold-rolled steel and stainless steel

38:

45:

29:

75:

Seams are commonly used in the food industry on canned goods, on

302:

Press brake technology: a guide to precision sheet metal bending

330:Tool and manufacturing engineers handbook: Forming

8:

278:

276:

263:

261:

259:

114:

37:

255:

282:

267:

333:, vol. 2, SME, p. 4-9,

104:There are two types of hemmed edges:

7:

87:), and in the automotive industry.

25:

1:

374:

299:Benson, Steve D. (1997),

51:

43:

35:

18:Seaming (metalworking)

65:processes in which a

49:

41:

33:

121:Material thickness

27:Metalworking Process

117:

244:Automotive hemming

115:

52:

44:

36:

312:978-0-87263-483-1

230:

229:

16:(Redirected from

365:

343:

315:

286:

280:

271:

265:

118:

61:are two similar

21:

373:

372:

368:

367:

366:

364:

363:

362:

348:

347:

341:

326:

323:

321:Further reading

313:

298:

295:

290:

289:

281:

274:

266:

257:

252:

235:

102:

93:

34:hemming process

28:

23:

22:

15:

12:

11:

5:

371:

369:

361:

360:

350:

349:

346:

345:

339:

322:

319:

318:

317:

311:

294:

291:

288:

287:

285:, p. 138.

272:

270:, p. 137.

254:

253:

251:

248:

247:

246:

241:

234:

231:

228:

227:

224:

221:

217:

216:

213:

210:

206:

205:

202:

199:

195:

194:

191:

188:

184:

183:

180:

177:

173:

172:

169:

166:

162:

161:

158:

155:

151:

150:

147:

144:

140:

139:

136:

133:

129:

128:

125:

122:

101:

98:

92:

89:

77:amusement park

26:

24:

14:

13:

10:

9:

6:

4:

3:

2:

370:

359:

358:Metal forming

356:

355:

353:

342:

340:0-87263-135-4

336:

332:

331:

325:

324:

320:

314:

308:

304:

303:

297:

296:

292:

284:

279:

277:

273:

269:

264:

262:

260:

256:

249:

245:

242:

240:

237:

236:

232:

225:

222:

219:

218:

214:

211:

208:

207:

203:

200:

197:

196:

192:

189:

186:

185:

181:

178:

175:

174:

170:

167:

164:

163:

159:

156:

153:

152:

148:

145:

142:

141:

137:

134:

131:

130:

126:

123:

120:

119:

113:

111:

107:

99:

97:

90:

88:

86:

82:

81:metal roofing

78:

73:

70:

68:

64:

60:

56:

48:

40:

32:

19:

329:

301:

293:Bibliography

109:

105:

103:

94:

74:

71:

63:metalworking

58:

54:

53:

42:A closed hem

283:Benson 1997

268:Benson 1997

127:Closed hem

106:closed hems

85:roof seamer

67:sheet metal

250:References

239:Can seamer

124:Open hem

110:open hems

79:cars, in

352:Category

233:See also

83:(with a

305:, SME,

91:Process

59:seaming

55:Hemming

337:

309:

50:A seam

100:Types

335:ISBN

307:ISBN

226:200

215:100

108:and

57:and

223:105

220:4.5

209:3.2

204:90

198:2.6

193:80

187:2.0

182:63

176:1.6

171:50

165:1.2

160:40

154:1.0

149:32

143:0.8

138:23

132:0.6

354::

275:^

258:^

212:70

201:55

190:30

179:24

168:17

157:15

146:12

344:.

316:.

135:9

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.