259:

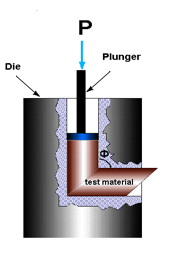

per second with shots of an attached ball to the horn in the range of 1K-100K per square millimeter. The strikes, which can be described as cold-forging, introduce SPD to produce a NC surface layer by refining the coarse grains until nanometer scale without changing the chemical composition of a material which render the high strength and high ductility. This UNSM technique does not only improve the mechanical and tribological properties of a material, but also produces a corrugated structure having numerous of desired dimples on the treated surface.

677:

is still useful as it implies that all other things remaining equal, reducing the stacking fault energy, a property that is a function of the alloying elements, will allow for better grain refinement. A few studies, however, suggested that despite the significance of stacking fault energy on the grain refinement at the early stages of straining, the steady-state grain size at large strains is mainly controlled by the homologous temperature in pure metals and by the interaction of solute atoms and dislocations in single-phase alloys.

1548:

180:, bonding the 2 sheets together. This sheet is cut in half, the 2 halves are stacked, and the process is repeated several times. Compared to other SPD processes, ARB has the benefit that it does not require specialized equipment or tooling, only a conventional rolling mill. However, the surfaces to be joined must be well-cleaned before rolling to ensure good bonding.

722:

Kawasaki, M.; Krǎl, P.; Kuramoto, S.; Langdon, T.G.; Leiva, D.R.; Levitas, V.I.; Mazilkin, A.; Mito, M.; Miyamoto, H.; Nishizaki, T.; Pippan, R.; Popov, V.V.; Popova, E.N.; Purcek, G.; Renk, O.; Révész, A.; Sauvage, X.; Sklenicka, V.; Skrotzki, W.; Straumal, B.B.; Suwas, S.; Toth, L.S.; Tsuji, N.; Valiev, R.Z.; Wilde, G.; Zehetbauer, M.J.; Zhu, X. (April 2022).

602:

271:

relation. Conventionally processed industrial metals typically have a grain size from 10–100 μm. Reducing the grain size from 10 μm to 1 μm can increase the yield strength of metals by more than 100%. Techniques that use bulk materials such as ECAE can provide reliable and relatively inexpensive ways

258:

An ultrasonic nanocrystalline surface modification (UNSM) technique is also one of the newly developed surface modification technique. In the UNSM process, not only the static load, but also the dynamic load are exerted. The processing is conducted striking a workpiece surface up to 20K or more times

676:

While the model was developed specifically for mechanical milling, it has also been successfully applied to other SPD processes. Frequently only a portion of the model is used (typically the term involving the stacking fault energy) as the other terms are often unknown and difficult to measure. This

188:

Repetitive corrugation and straightening (RCS) is a severe plastic deformation technique used to process sheet metals. In RCS, a sheet is pressed between two corrugated dies followed by pressing between two flat dies. RCS has gained wide popularity to produce fine grained sheet metals. Endeavors to

197:

In asymmetric rolling (ASR), a rolling mill is modified such that one roll has a higher velocity than the other. This is typically done with either independent speed control or by using rolls of different size. This creates a region in which the frictional forces on the top and bottom of the sheet

125:

Equal channel angular extrusion (ECAE, sometimes called Equal channel angular pressing, ECAP) was developed in the 1970s. In this process, a metal billet is pressed through an angled (typically 90 degrees) channel. To achieve optimal results, the process may be repeated several times, changing the

58:

The significance of SPD was known from the ancient times, at least during the transition from the Bronze Age to the Iron Age, when repeated hammering and folding was employed for processing strategic tools such as swords. The development of the principles underlying SPD techniques goes back to the

1189:

Mirab, Saeideh; Nili-Ahmadabadi, Mahmoud; Khajezade, Ali; Abshirini, Mohamad; Parsa, Mohammad Habibi; Soltani, Naser (August 2016). "On the

Deformation Analysis during RCSR Process Aided by Finite Element Modeling and Digital Image Correlation: On the Deformation Analysis during RCSR Process…".

721:

Edalati, K.; Bachmaier, A.; Beloshenko, V.A.; Beygelzimer, Y.; Blank, V.D.; Botta, W.J.; Bryła, K.; Čížek, J.; Divinski, S.; Enikeev, N.A.; Estrin, Y.; Faraji, G.; Figueiredo, R.B.; Fuji, M.; Furuta, T.; Grosdidier, T.; Gubicza, J.; Hohenwarter, A.; Horita, Z.; Huot, J.; Ikoma, Y.; Janeček, M.;

94:

component. However, the mechanisms that lead to grain refinement in SPD are the same as those originally developed for mechanical alloying, a powder process that has been characterized as "severe plastic deformation" by authors as early as 1983. Additionally, some more recent processes such as

1277:

Asghari-Rad, Peyman; Nili-Ahmadabadi, Mahmoud; Shirazi, Hassan; Hossein Nedjad, Syamak; Koldorf, Sebastian (March 2017). "A Significant

Improvement in the Mechanical Properties of AISI 304 Stainless Steel by a Combined RCSR and Annealing Process: A Significant Improvement in the Mechanical

385:

1225:

Shahmir, Hamed; Nili-Ahmadabadi, Mahmoud; Razzaghi, Alireza; Mohammadi, Mahdi; Wang, Chuan Ting; Jung, Jai Myun; Kim, Hyoung Seop; Langdon, Terence G. (June 2015). "Using dilatometry to study martensitic stabilization and recrystallization kinetics in a severely deformed NiTi alloy".

1161:

Mirsepasi, Arya; Nili-Ahmadabadi, Mahmoud; Habibi-Parsa, Mohammad; Ghasemi-Nanesa, Hadi; Dizaji, Ahmad F. (August 2012). "Microstructure and mechanical behavior of martensitic steel severely deformed by the novel technique of repetitive corrugation and straightening by rolling".

1731:

Edalati, K.; Akama, D.; Nishio, A.; Lee, S.; Yonenaga, Y.; Cubero-Sesin, J.; Horita, Z. (2014). "Influence of dislocation-solute atom interactions and stacking fault energy on grain size of single-phase alloys after severe plastic deformation using high-pressure torsion".

1546:, Zhu, Y.T.; Lowe, T.C.; Valiev, R.Z.; Stolyarov, V.V.; Latysh, V.V.; Raab, G.J., "Ultrafine-grained titanium for medical implants", issued 2002-06-04, assigned to The Regents Of The University Of California

898:

Qu, S.; An, X.H.; Yang, H.J.; Huang, C.X.; Yang, G.; Zang, Q.S.; Wang, Z.G.; Wu, S.D.; Zhang, Z.F. (2009). "Microstructural evolution and mechanical properties of Cu–Al alloys subjected to equal channel angular pressing".

1406:

Zhang, X.; Wang, H.; Kassem, M.; Narayan, J.; Koch, C.C. (10 May 2002). "Preparation of bulk ultrafine-grained and nanostructured Zn, Al and their alloys by in situ consolidation of powders during mechanical attrition".

202:

throughout the material in addition to the normal compressive stress from rolling. Unlike other SPD processes, ASR does not maintain the same net shape, but the effect on the microstructure of the material is similar.

597:{\displaystyle {\frac {d_{min}}{b}}=A_{3}\left(e^{-{\tfrac {\beta Q}{4RT}}}\right){\left({\frac {D_{p0}Gb^{2}}{\nu _{0}kT}}\right)}^{0.25}{\left({\frac {\gamma }{Gb}}\right)}^{0.5}{\left({\frac {G}{H}}\right)}^{1.25}}

641:

is the activation energy for vacancy migration, and Q is the activation energy for self-diffusion), βQ represents the activation energy for recovery, R is the gas constant, and T is the processing temperature.

238:

More recently, the principles behind SPD have been used to develop surface treatments that create a nanocrystalline layer on the surface of a material. In the surface mechanical attrition treatment (SMAT), an

225:

together, resulting in large deformations. The end product is generally a powder that must then be consolidated in some way (often using other SPD processes), but some alloys have the ability to consolidate

95:

asymmetric rolling, do result in a change in the dimensions of the workpiece, while still producing an ultrafine grain structure. The principles behind SPD have even been applied to surface treatments.

150:, though its use in metal processing is considerably more recent. In this method, a disk of the material to be strained is placed between 2 anvils. A large compressive stress (typically several

694:

Wei, Q; Cheng, S; Ramesh, K.T; Ma, E (15 September 2004). "Effect of nanocrystalline and ultrafine grain sizes on the strain rate sensitivity and activation volume: fcc versus bcc metals".

189:

improve this technique lead to introduce

Repetitive Corrugation and Straightening by Rolling (RCSR), a novel SPD method. Applicability of this new method approved in the various materials.

247:

on top of the horn. The workpiece is mounted a small distance above the horn. The high frequency results in a large number of collisions between the balls and the surface, creating a

158:

force. HPT can be performed unconstrained, in which the material is free to flow outward, fully constrained, or to some degree between in which outward flow is allowed, but limited.

1516:

Senkov, O.N.; Senkova, S.V.; Scott, J.M.; Miracle, D.B. (25 February 2005). "Compaction of amorphous aluminum alloy powder by direct extrusion and equal channel angular extrusion".

1461:

Amanov, A.; Cho, I.S.; Pyun, Y.S.; Lee, C.S.; Park, I.G. (15 May 2012). "Micro-dimpled surface by ultrasonic nanocrystalline surface modification and its tribological effects".

1088:

Saito, Y.; Utsunomiya, H.; Tsuji, N.; Sakai, T. (1999). "Novel ultra-high straining process for bulk materials—development of the accumulative roll-bonding (ARB) process".

329:

The presence of a high hydrostatic pressure, in combination with large shear strains, is essential for producing high densities of crystal lattice defects, particularly

90:

Some definitions of SPD describe it as a process in which high strain is applied without any significant change in the dimensions of the workpiece, resulting in a large

103:

SPD methods are classified into three main groups of bulk-SPD methods, surface-SPD methods and powder-SPD methods. Here some popular SPD methods are briefly explained.

1565:

Mishra, A; Kad, B; Gregori, F; Meyers, M (1 January 2007). "Microstructural evolution in copper subjected to severe plastic deformation: Experiments and analysis".

380:. The model is based on the concept that the grain size is dependent on the rates at which dislocations are generated and annihilated. The full model is given by

67:

in the 1930s. This work concerned the effects on solids of combining large hydrostatic pressures with concurrent shear deformation and it led to the award of the

365:

describe a process in which dislocation motion becomes restricted due to the small subgrain size and grain rotation becomes more energetically favorable. Mishra

138:

During the constrained HPT process, the material experiences shear deformation between a fixed and a rotating anvil, without losing its original dimensions.

115:

During the ECAE process, the material is pressed through an angular die and experiences shear deformation, without changing its cross-sectional dimensions.

267:

Most research into SPD has focused on grain refinement, which has obvious applications in the development of high-strength materials as a result of the

1315:"Regulating of tensile properties through microstructure engineering in Fe-Ni-C TRIP steel processed by different strain routes of severe deformation"

1676:"High-pressure torsion of pure metals: influence of atomic bond parameters and stacking fault energy on grain size and correlation with hardness"

344:, which are initially distributed throughout the grains, rearrange and group together into dislocation "cells" to reduce the total strain energy.

221:

such as a shaker mill or planetary mill will also induce severe plastic deformation in metals. During milling, particles are fractured and

1057:"Severe plastic deformation for producing superfunctional ultrafine-grainedand heterostructured materials: An interdisciplinary review"

1371:

936:

1500:

71:

in

Physics in 1946. Very successful early implementations of these principles, described in more detail below, are the processes of

1346:

Mousavi, S.A.A. Akbari; Ebrahimi, S.M.; Madoliat, R. (12 June 2007). "Three dimensional numerical analyses of asymmetric rolling".

1020:

Zhu, K.Y.; Vassel, A.; Brisset, F.; Lu, K.; Lu, J. (16 August 2004). "Nanostructure formation mechanism of α-titanium using SMAT".

1773:

1434:

Dai, K.; Shaw, L. (15 August 2007). "Comparison between shot peening and surface nanocrystallization and hardening processes".

120:

173:

112:

72:

854:

Valiev, Ruslan Z.; Estrin, Yuri; Horita, Zenji; Langdon, Terence G.; Zechetbauer, Michael J.; Zhu, Yuntian T. (April 2006).

797:

Zhilyaev, A; Langdon, T (1 August 2008). "Using high-pressure torsion for metal processing: Fundamentals and applications".

347:

As deformation continues and more dislocations are generated, misorientation develops between the cells, forming "subgrains"

135:

334:

251:

on the order of 10–10 s. The NC surface layer developed can be on the order of 50 μm thick. The process is similar to

230:

during milling. Mechanical alloying also allows powders of different metals to be alloyed together during processing.

80:

30:

techniques involving very large strains typically involving a complex stress state or high shear, resulting in a high

1602:"Microstructure and evolution of mechanically-induced ultrafine grain in surface layer of AL-alloy subjected to USSP"

350:

The process repeats within the subgrains until the size becomes sufficiently small such that the subgrains can rotate

1783:

1491:

Segal, Vladimir M.; Beyerlein, Irene J.; Tome, Carlos N.; Chuvil'deev, Vladimir N.; Kopylov, Vladimir I. (2010).

167:

302:

and composites without the need for the high temperatures used in conventional consolidation processes such as

827:

Segal, V.M. (1 November 1999). "Equal channel angular extrusion: from macromechanics to structure formation".

126:

orientation of the billet with each pass. This produces a uniform shear throughout the bulk of the material.

60:

31:

76:

1778:

353:

Additional deformation causes the subgrains to rotate into high-angle grain boundaries, typically with an

303:

177:

147:

665:

649:

280:

1639:

Mohamed, Farghalli A. (2003). "A dislocation model for the minimum grain size obtainable by milling".

1543:

974:

Cui, Q.; Ohori, K. (October 2000). "Grain refinement of high purity aluminium by asymmetric rolling".

1741:

1687:

1648:

1613:

1574:

1380:

1235:

1097:

1029:

983:

945:

908:

867:

284:

91:

724:"Nanomaterials by severe plastic deformation: review of historical developments and recent advances"

172:

In accumulative roll bonding (ARB), 2 sheets of the same material are stacked, heated (to below the

377:

212:

155:

1713:

1295:

1259:

1207:

1140:

999:

745:

661:

64:

1496:

1251:

354:

299:

1749:

1703:

1695:

1656:

1621:

1582:

1525:

1466:

1443:

1416:

1388:

1351:

1326:

1287:

1243:

1199:

1171:

1132:

1105:

1068:

1037:

991:

953:

916:

875:

836:

806:

772:

735:

703:

370:

292:

272:

of producing ultrafine grain materials compared to rapid solidification techniques such as

307:

240:

47:

1745:

1691:

1652:

1617:

1578:

1392:

1384:

1239:

1101:

1033:

987:

957:

949:

912:

871:

79:, derived from Bridgman's work, but not widely developed until the 1980s at the Russian

612:

244:

143:

1660:

1625:

1420:

1109:

840:

1767:

1717:

1355:

1299:

1263:

1211:

1144:

1003:

764:

749:

653:

273:

84:

1123:

Ratna Sunil, B. (2015). "Repetitive corrugation and straightening of sheet metals".

330:

288:

283:

modification also have potential industrial applications as properties such as the

252:

199:

27:

1753:

1699:

1586:

1073:

1056:

1041:

920:

810:

740:

723:

1136:

1601:

341:

248:

68:

39:

1529:

1470:

1447:

1331:

1314:

1175:

995:

776:

707:

1247:

880:

855:

376:

F.A. Mohamad has proposed a model for the minimum grain size achievable using

314:

268:

151:

1255:

369:

propose a slightly different explanation, in which the rotation is aided by

318:

313:

Some known commercial application of SPD processes are in the production of

306:, allowing desirable characteristics such as nanocrystalline grain sizes or

222:

218:

1313:

Hossein Zadeh, S.; Jafarian, H.R.; Park, N.; Eivani, A.R. (February 2020).

1291:

1203:

142:

High pressure torsion (HPT) can be traced back to the experiments that won

856:"Producing bulk ultrafine-grained materials by severe plastic deformation"

1369:

Koch, C C (1 August 1989). "Materials

Synthesis by Mechanical Alloying".

669:

373:

along the grain boundaries (which is much faster than through the bulk).

43:

35:

75:(ECAP) developed by V.M. Segal and co-workers in Minsk in the 1970s and

1675:

1708:

337:. Grain refinement in SPD processes occurs by a multi-step process:

243:

is connected to an ultrasonic (20 kHz) transducer), with small

361:

The mechanism by which the subgrains rotate is less understood. Wu

298:

Processes such as ECAE and HPT have also been used to consolidate

110:

637:

is the activation energy for pipe diffusion along dislocations, Q

217:

Mechanical alloying/milling (MA/MM) performed in a high-energy

111:

255:, but the kinetic energy of the balls is much higher in SMAT.

134:

934:

Gilman, P.S.; Benjamin, J.S. (1983). "Mechanical alloying".

765:"A review on high-pressure torsion (HPT) from 1935 to 1988"

1493:

Fundamentals and engineering of severe plastic deformation

438:

648:

is the temperature-independent component of the pipe

388:

154:) is applied, while one anvil is rotated to create a

1600:

Wu, X; Tao, N; Hong, Y; Xu, B; Lu, J; Lu, K (2002).

1156:

1154:

596:

1560:

1558:

8:

1495:. Hauppauge, N.Y.: Nova Science Publishers.

1486:

1484:

1482:

1480:

1319:Journal of Materials Research and Technology

893:

891:

1348:Journal of Materials Processing Technology

1015:

1013:

26:) is a generic term describing a group of

1707:

1330:

1072:

879:

739:

588:

573:

568:

561:

541:

536:

529:

509:

497:

481:

474:

469:

437:

433:

419:

395:

389:

387:

969:

967:

184:Repetitive corrugation and straightening

133:

686:

611:is the minimum grain size and b is the

321:and UFG titanium for medical implants.

279:However, other effects of SPD, such as

822:

820:

660:is the dislocation velocity, k is the

291:processes) and magnetic properties of

1125:Materials and Manufacturing Processes

792:

790:

788:

786:

50:(NC) structure (d < 100 nm).

7:

1518:Materials Science and Engineering: A

1436:Materials Science and Engineering: A

1164:Materials Science and Engineering: A

1055:Edalati, Kaveh; et al. (2024).

829:Materials Science and Engineering: A

769:Materials Science and Engineering: A

763:Kaveh Edalati, Zenji Horita (2016).

696:Materials Science and Engineering: A

333:, which can result in a significant

198:being rolled are opposite, creating

1393:10.1146/annurev.ms.19.080189.001005

958:10.1146/annurev.ms.13.080183.001431

607:On the left side of the equation: d

1372:Annual Review of Materials Science

937:Annual Review of Materials Science

14:

295:are highly dependent on texture.

1674:Edalati, K.; Horita, Z. (2011).

1356:10.1016/j.jmatprotec.2006.11.045

976:Materials Science and Technology

16:Group of metalworking techniques

1061:Journal of Alloys and Compounds

121:Equal channel angular extrusion

1280:Advanced Engineering Materials

1192:Advanced Engineering Materials

107:Equal channel angular Pressing

73:equal-channel angular pressing

1:

1754:10.1016/j.actamat.2014.01.036

1700:10.1016/j.actamat.2011.07.046

1661:10.1016/S1359-6454(03)00230-1

1626:10.1016/S1359-6454(02)00051-4

1587:10.1016/j.actamat.2006.07.008

1421:10.1016/S1359-6462(02)00048-9

1110:10.1016/S1359-6454(98)00365-6

1074:10.1016/j.jallcom.2024.174667

1042:10.1016/j.actamat.2004.05.023

921:10.1016/j.actamat.2008.12.002

841:10.1016/S0921-5093(99)00248-8

811:10.1016/j.pmatsci.2008.03.002

799:Progress in Materials Science

741:10.1080/21663831.2022.2029779

1228:Journal of Materials Science

1137:10.1080/10426914.2014.973600

81:Institute of Metals Physics

1800:

1530:10.1016/j.msea.2004.09.061

1471:10.1016/j.wear.2011.06.001

1448:10.1016/j.msea.2006.07.159

1332:10.1016/j.jmrt.2020.01.041

1176:10.1016/j.msea.2012.04.073

996:10.1179/026708300101507019

777:10.1016/j.msea.2015.11.074

728:Materials Research Letters

708:10.1016/j.msea.2004.03.064

325:Grain refinement mechanism

210:

165:

118:

20:Severe plastic deformation

1248:10.1007/s10853-015-8957-5

881:10.1007/s11837-006-0213-7

168:Accumulative roll bonding

162:Accumulative roll bonding

1774:Deformation (mechanics)

1292:10.1002/adem.201600663

1204:10.1002/adem.201600100

771:. 0921–5093: 325–352.

598:

335:refining of the grains

304:hot isostatic pressing

148:Nobel Prize in Physics

139:

116:

46:< 1000 nm) or

1544:US patent 6399215

666:stacking fault energy

650:diffusion coefficient

599:

137:

130:High pressure torsion

114:

77:high-pressure torsion

1465:. 286–287: 136–144.

1350:. 187–188: 725–729.

386:

308:amorphous structures

285:Lankford coefficient

92:hydrostatic pressure

1746:2014AcMat..69...68E

1692:2011AcMat..59.6831E

1653:2003AcMat..51.4107M

1618:2002AcMat..50.2075W

1579:2007AcMat..55...13M

1385:1989AnRMS..19..121K

1240:2015JMatS..50.4003S

1102:1999AcMat..47..579S

1034:2004AcMat..52.4101Z

988:2000MatST..16.1095C

950:1983AnRMS..13..279G

913:2009AcMat..57.1586Q

872:2006JOM....58d..33V

213:Mechanical alloying

207:Mechanical alloying

59:pioneering work of

1409:Scripta Materialia

662:Boltzmann constant

594:

460:

378:mechanical milling

234:Surface treatments

193:Asymmetric rolling

176:temperature), and

140:

117:

65:Harvard University

1784:Materials science

1686:(17): 6831–6836.

1647:(14): 4107–4119.

1234:(11): 4003–4011.

1131:(10): 1262–1271.

1028:(14): 4101–4110.

982:(20): 1095–1101.

581:

554:

522:

459:

410:

174:recrystallization

1791:

1758:

1757:

1728:

1722:

1721:

1711:

1671:

1665:

1664:

1636:

1630:

1629:

1612:(8): 2075–2084.

1597:

1591:

1590:

1562:

1553:

1552:

1551:

1547:

1540:

1534:

1533:

1513:

1507:

1506:

1488:

1475:

1474:

1458:

1452:

1451:

1431:

1425:

1424:

1403:

1397:

1396:

1366:

1360:

1359:

1343:

1337:

1336:

1334:

1325:(3): 2903–2913.

1310:

1304:

1303:

1274:

1268:

1267:

1222:

1216:

1215:

1198:(8): 1434–1443.

1186:

1180:

1179:

1158:

1149:

1148:

1120:

1114:

1113:

1085:

1079:

1078:

1076:

1052:

1046:

1045:

1017:

1008:

1007:

971:

962:

961:

931:

925:

924:

907:(5): 1586–1601.

895:

886:

885:

883:

851:

845:

844:

835:(1–2): 322–333.

824:

815:

814:

794:

781:

780:

760:

754:

753:

743:

718:

712:

711:

691:

603:

601:

600:

595:

593:

592:

587:

586:

582:

574:

566:

565:

560:

559:

555:

553:

542:

534:

533:

528:

527:

523:

521:

514:

513:

503:

502:

501:

489:

488:

475:

467:

463:

462:

461:

458:

447:

439:

424:

423:

411:

406:

405:

390:

310:to be retained.

293:electrical steel

1799:

1798:

1794:

1793:

1792:

1790:

1789:

1788:

1764:

1763:

1762:

1761:

1734:Acta Materialia

1730:

1729:

1725:

1680:Acta Materialia

1673:

1672:

1668:

1641:Acta Materialia

1638:

1637:

1633:

1606:Acta Materialia

1599:

1598:

1594:

1567:Acta Materialia

1564:

1563:

1556:

1549:

1542:

1541:

1537:

1515:

1514:

1510:

1503:

1490:

1489:

1478:

1460:

1459:

1455:

1433:

1432:

1428:

1405:

1404:

1400:

1368:

1367:

1363:

1345:

1344:

1340:

1312:

1311:

1307:

1276:

1275:

1271:

1224:

1223:

1219:

1188:

1187:

1183:

1160:

1159:

1152:

1122:

1121:

1117:

1090:Acta Materialia

1087:

1086:

1082:

1054:

1053:

1049:

1022:Acta Materialia

1019:

1018:

1011:

973:

972:

965:

933:

932:

928:

901:Acta Materialia

897:

896:

889:

853:

852:

848:

826:

825:

818:

796:

795:

784:

762:

761:

757:

720:

719:

715:

693:

692:

688:

683:

668:, and H is the

659:

647:

640:

636:

632:

628:

621:

610:

569:

567:

546:

537:

535:

505:

504:

493:

477:

476:

470:

468:

448:

440:

429:

425:

415:

391:

384:

383:

327:

287:(important for

265:

241:ultrasonic horn

236:

215:

209:

195:

186:

170:

164:

132:

123:

109:

101:

56:

48:nanocrystalline

17:

12:

11:

5:

1797:

1795:

1787:

1786:

1781:

1776:

1766:

1765:

1760:

1759:

1723:

1666:

1631:

1592:

1554:

1535:

1524:(1–2): 12–21.

1508:

1501:

1476:

1453:

1442:(1–2): 46–53.

1426:

1415:(9): 661–665.

1398:

1379:(1): 121–143.

1361:

1338:

1305:

1286:(3): 1600663.

1269:

1217:

1181:

1150:

1115:

1096:(2): 579–583.

1080:

1047:

1009:

963:

926:

887:

846:

816:

805:(6): 893–979.

782:

755:

734:(4): 163–256.

713:

702:(1–2): 71–79.

685:

684:

682:

679:

674:

673:

657:

645:

642:

638:

634:

630:

626:

623:

622:is a constant.

619:

616:

613:Burgers vector

608:

591:

585:

580:

577:

572:

564:

558:

552:

549:

545:

540:

532:

526:

520:

517:

512:

508:

500:

496:

492:

487:

484:

480:

473:

466:

457:

454:

451:

446:

443:

436:

432:

428:

422:

418:

414:

409:

404:

401:

398:

394:

359:

358:

351:

348:

345:

326:

323:

264:

261:

235:

232:

211:Main article:

208:

205:

200:shear stresses

194:

191:

185:

182:

166:Main article:

163:

160:

144:Percy Bridgman

131:

128:

119:Main article:

108:

105:

100:

97:

83:in modern-day

55:

52:

32:defect density

15:

13:

10:

9:

6:

4:

3:

2:

1796:

1785:

1782:

1780:

1779:Metal forming

1777:

1775:

1772:

1771:

1769:

1755:

1751:

1747:

1743:

1739:

1735:

1727:

1724:

1719:

1715:

1710:

1705:

1701:

1697:

1693:

1689:

1685:

1681:

1677:

1670:

1667:

1662:

1658:

1654:

1650:

1646:

1642:

1635:

1632:

1627:

1623:

1619:

1615:

1611:

1607:

1603:

1596:

1593:

1588:

1584:

1580:

1576:

1572:

1568:

1561:

1559:

1555:

1545:

1539:

1536:

1531:

1527:

1523:

1519:

1512:

1509:

1504:

1502:9781616681906

1498:

1494:

1487:

1485:

1483:

1481:

1477:

1472:

1468:

1464:

1457:

1454:

1449:

1445:

1441:

1437:

1430:

1427:

1422:

1418:

1414:

1410:

1402:

1399:

1394:

1390:

1386:

1382:

1378:

1374:

1373:

1365:

1362:

1357:

1353:

1349:

1342:

1339:

1333:

1328:

1324:

1320:

1316:

1309:

1306:

1301:

1297:

1293:

1289:

1285:

1281:

1278:Properties".

1273:

1270:

1265:

1261:

1257:

1253:

1249:

1245:

1241:

1237:

1233:

1229:

1221:

1218:

1213:

1209:

1205:

1201:

1197:

1193:

1185:

1182:

1177:

1173:

1169:

1165:

1157:

1155:

1151:

1146:

1142:

1138:

1134:

1130:

1126:

1119:

1116:

1111:

1107:

1103:

1099:

1095:

1091:

1084:

1081:

1075:

1070:

1066:

1062:

1058:

1051:

1048:

1043:

1039:

1035:

1031:

1027:

1023:

1016:

1014:

1010:

1005:

1001:

997:

993:

989:

985:

981:

977:

970:

968:

964:

959:

955:

951:

947:

943:

939:

938:

930:

927:

922:

918:

914:

910:

906:

902:

894:

892:

888:

882:

877:

873:

869:

865:

861:

857:

850:

847:

842:

838:

834:

830:

823:

821:

817:

812:

808:

804:

800:

793:

791:

789:

787:

783:

778:

774:

770:

766:

759:

756:

751:

747:

742:

737:

733:

729:

725:

717:

714:

709:

705:

701:

697:

690:

687:

680:

678:

671:

667:

663:

655:

654:shear modulus

651:

643:

624:

617:

614:

606:

605:

604:

589:

583:

578:

575:

570:

562:

556:

550:

547:

543:

538:

530:

524:

518:

515:

510:

506:

498:

494:

490:

485:

482:

478:

471:

464:

455:

452:

449:

444:

441:

434:

430:

426:

420:

416:

412:

407:

402:

399:

396:

392:

381:

379:

374:

372:

368:

364:

356:

352:

349:

346:

343:

340:

339:

338:

336:

332:

324:

322:

320:

316:

311:

309:

305:

301:

300:metal powders

296:

294:

290:

286:

282:

277:

275:

274:melt spinning

270:

262:

260:

256:

254:

250:

246:

242:

233:

231:

229:

224:

220:

214:

206:

204:

201:

192:

190:

183:

181:

179:

175:

169:

161:

159:

157:

153:

149:

145:

136:

129:

127:

122:

113:

106:

104:

98:

96:

93:

88:

86:

85:Yekaterinburg

82:

78:

74:

70:

66:

62:

61:P.W. Bridgman

53:

51:

49:

45:

41:

37:

33:

29:

25:

21:

1740:(8): 68–77.

1737:

1733:

1726:

1683:

1679:

1669:

1644:

1640:

1634:

1609:

1605:

1595:

1573:(1): 13–28.

1570:

1566:

1538:

1521:

1517:

1511:

1492:

1462:

1456:

1439:

1435:

1429:

1412:

1408:

1401:

1376:

1370:

1364:

1347:

1341:

1322:

1318:

1308:

1283:

1279:

1272:

1231:

1227:

1220:

1195:

1191:

1184:

1167:

1163:

1128:

1124:

1118:

1093:

1089:

1083:

1064:

1060:

1050:

1025:

1021:

979:

975:

941:

935:

929:

904:

900:

866:(4): 33–39.

863:

859:

849:

832:

828:

802:

798:

768:

758:

731:

727:

716:

699:

695:

689:

675:

382:

375:

366:

362:

360:

342:Dislocations

331:dislocations

328:

312:

297:

289:deep drawing

278:

266:

263:Applications

257:

253:shot peening

237:

227:

216:

196:

187:

171:

141:

124:

102:

89:

57:

42:(UFG) size (

38:"ultrafine"

28:metalworking

23:

19:

18:

944:: 279–300.

664:, γ is the

652:, G is the

317:targets by

249:strain rate

223:cold welded

152:gigapascals

69:Nobel Prize

1768:Categories

1709:2324/25601

1067:: 174667.

681:References

315:Sputtering

269:Hall-Petch

1718:137003355

1300:136241453

1264:137364496

1256:0022-2461

1212:138744444

1170:: 32–39.

1145:136416712

1004:137413931

750:246959065

544:γ

507:ν

442:β

435:−

371:diffusion

319:Honeywell

219:ball mill

146:the 1946

670:hardness

355:equiaxed

36:equiaxed

1742:Bibcode

1688:Bibcode

1649:Bibcode

1614:Bibcode

1575:Bibcode

1381:Bibcode

1236:Bibcode

1098:Bibcode

1030:Bibcode

984:Bibcode

946:Bibcode

909:Bibcode

868:Bibcode

281:texture

228:in-situ

156:torsion

99:Methods

54:History

1716:

1550:

1499:

1298:

1262:

1254:

1210:

1143:

1002:

748:

367:et al.

363:et al.

357:shape.

178:rolled

1714:S2CID

1296:S2CID

1260:S2CID

1208:S2CID

1141:S2CID

1000:S2CID

746:S2CID

633:/Q (Q

245:balls

40:grain

1497:ISBN

1463:Wear

1252:ISSN

1065:1002

590:1.25

531:0.25

34:and

1750:doi

1704:hdl

1696:doi

1657:doi

1622:doi

1583:doi

1526:doi

1522:393

1467:doi

1444:doi

1440:463

1417:doi

1389:doi

1352:doi

1327:doi

1288:doi

1244:doi

1200:doi

1172:doi

1168:551

1133:doi

1106:doi

1069:doi

1038:doi

992:doi

954:doi

917:doi

876:doi

860:JOM

837:doi

833:271

807:doi

773:doi

736:doi

704:doi

700:381

656:, ν

625:β=Q

609:min

563:0.5

63:at

24:SPD

1770::

1748:.

1738:69

1736:.

1712:.

1702:.

1694:.

1684:59

1682:.

1678:.

1655:.

1645:51

1643:.

1620:.

1610:50

1608:.

1604:.

1581:.

1571:55

1569:.

1557:^

1520:.

1479:^

1438:.

1413:46

1411:.

1387:.

1377:19

1375:.

1321:.

1317:.

1294:.

1284:19

1282:.

1258:.

1250:.

1242:.

1232:50

1230:.

1206:.

1196:18

1194:.

1166:.

1153:^

1139:.

1129:30

1127:.

1104:.

1094:47

1092:.

1063:.

1059:.

1036:.

1026:52

1024:.

1012:^

998:.

990:.

980:16

978:.

966:^

952:.

942:13

940:.

915:.

905:57

903:.

890:^

874:.

864:58

862:.

858:.

831:.

819:^

803:53

801:.

785:^

767:.

744:.

732:10

730:.

726:.

698:.

646:p0

629:−Q

276:.

87:.

1756:.

1752::

1744::

1720:.

1706::

1698::

1690::

1663:.

1659::

1651::

1628:.

1624::

1616::

1589:.

1585::

1577::

1532:.

1528::

1505:.

1473:.

1469::

1450:.

1446::

1423:.

1419::

1395:.

1391::

1383::

1358:.

1354::

1335:.

1329::

1323:9

1302:.

1290::

1266:.

1246::

1238::

1214:.

1202::

1178:.

1174::

1147:.

1135::

1112:.

1108::

1100::

1077:.

1071::

1044:.

1040::

1032::

1006:.

994::

986::

960:.

956::

948::

923:.

919::

911::

884:.

878::

870::

843:.

839::

813:.

809::

779:.

775::

752:.

738::

710:.

706::

672:.

658:0

644:D

639:m

635:p

631:m

627:p

620:3

618:A

615:.

584:)

579:H

576:G

571:(

557:)

551:b

548:G

539:(

525:)

519:T

516:k

511:0

499:2

495:b

491:G

486:0

483:p

479:D

472:(

465:)

456:T

453:R

450:4

445:Q

431:e

427:(

421:3

417:A

413:=

408:b

403:n

400:i

397:m

393:d

44:d

22:(

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.