434:

Cubero-Sesin, Jorge M.; Davdian, Gregory; Demirtas, Muhammet; Divinski, Sergiy; Durst, Karsten; Dvorak, Jiri; Edalati, Parisa; Emura, Satoshi; Enikeev, Nariman A.; Faraji, Ghader; Figueiredo, Roberto B.; Floriano, Ricardo; Fouladvind, Marjan; Fruchart, Daniel; Fuji, Masayoshi; Fujiwara, Hiroshi; Gajdics, Marcell; Gheorghe, Diana; Gondek, Łukasz; González-Hernández, Joaquín E.; Gornakova, Alena; Grosdidier, Thierry; Gubicza, Jenő; Gunderov, Dmitry; He, Liqing; Higuera, Oscar Fabian; Hirosawa, Shoichi; Hohenwarter, Anton; Horita, Zenji; Horky, Jelena; Huang, Yi; Huot, Jacques; Ikoma, Yoshifumi; Ishihara, Tatsumi; Ivanisenko, Yulia; Jang, Jae-il; Jorge Jr, Alberto M.; Kawabata-Ota, Mie; Kawasaki, Megumi; Khelfa, Tarek; Kobayashi, Junya; Kommel, Lembit; Korneva, Anna; Kral, Petr; Kudriashova, Natalia; Kuramoto, Shigeru; Langdon, Terence G.; Lee, Dong-Hyun; Levitas, Valery I.; Li, Cong; Li, Hai-Wen; Li, Yongtao; Li, Zheng; Lin, Huai-Jun; Liss, Klaus-Dieter; Liu, Ying; Marulanda

Cardona, Diana Maritza; Matsuda, Kenji; Mazilkin, Andrey; Mine, Yoji; Miyamoto, Hiroyuki; Moon, Suk-Chun; Müller, Timo; Muñoz, Jairo Alberto; Murashkin, Maxim Yu.; Naeem, Muhammad; Novelli, Marc; Olasz, Dániel; Pippan, Reinhard; Popov, Vladimir V.; Popova, Elena N.; Purcek, Gencaga; de Rango, Patricia; Renk, Oliver; Retraint, Delphine; Révész, Ádám; Roche, Virginie; Rodriguez-Calvillo, Pablo; Romero-Resendiz, Liliana; Sauvage, Xavier; Sawaguchi, Takahiro; Sena, Hadi; Shahmir, Hamed; Shi, Xiaobin; Sklenicka, Vaclav; Skrotzki, Werner; Skryabina, Nataliya; Staab, Franziska; Straumal, Boris; Sun, Zhidan; Szczerba, Maciej; Takizawa, Yoichi; Tang, Yongpeng; Valiev, Ruslan Z.; Vozniak, Alina; Voznyak, Andrei; Wang, Bo; Wang, Jing Tao; Wilde, Gerhard; Zhang, Fan; Zhang, Meng; Zhang, Peng; Zhou, Jianqiang; Zhu, Xinkun; Zhu, Yuntian T. (2024).

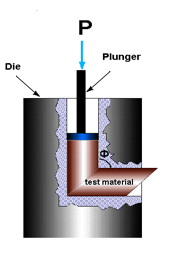

176:, strain is introduced by reduction in the cross sectional area. ECAE produces significant deformation strain without reducing the cross sectional area. This is accomplished by extruding the work piece around a corner. For example, a square cross section bar of metal is forced through a channel with a 90° degree angle. The cross section of the channel is equal on entry and exit. The complex deformation of the metal as it flows around the corner produces very high strain. Because the cross section remains the same, a work piece can be extruded multiple times with each pass introducing additional strain.

481:

22:

256:

Kawasaki, M.; Krǎl, P.; Kuramoto, S.; Langdon, T.G.; Leiva, D.R.; Levitas, V.I.; Mazilkin, A.; Mito, M.; Miyamoto, H.; Nishizaki, T.; Pippan, R.; Popov, V.V.; Popova, E.N.; Purcek, G.; Renk, O.; Révész, A.; Sauvage, X.; Sklenicka, V.; Skrotzki, W.; Straumal, B.B.; Suwas, S.; Toth, L.S.; Tsuji, N.; Valiev, R.Z.; Wilde, G.; Zehetbauer, M.J.; Zhu, X. (April 2022).

433:

Edalati, Kaveh; Ahmed, Anwar Q.; Akrami, Saeid; Ameyama, Kei; Aptukov, Valery; Asfandiyarov, Rashid N.; Ashida, Maki; Astanin, Vasily; Bachmaier, Andrea; Beloshenko, Victor; Bobruk, Elena V.; Bryła, Krzysztof; Cabrera, José María; Carvalho, Amanda P.; Chinh, Nguyen Q.; Choi, In-Chul; Chulist, Robert;

255:

Edalati, K.; Bachmaier, A.; Beloshenko, V.A.; Beygelzimer, Y.; Blank, V.D.; Botta, W.J.; Bryła, K.; Čížek, J.; Divinski, S.; Enikeev, N.A.; Estrin, Y.; Faraji, G.; Figueiredo, R.B.; Fuji, M.; Furuta, T.; Grosdidier, T.; Gubicza, J.; Hohenwarter, A.; Horita, Z.; Huot, J.; Ikoma, Y.; Janeček, M.;

223:

The behave during deformation and flow of the material, are analyzed by scientists and there are many articles on computer simulation, finite element method is one of the important approaches to understand the deformation occurring in the ECAE process.

137:(SPD) group, aimed at producing Ultra Fine Grained (UFG) material. The method was developed in the Soviet Union in 1973 by Segal. However, the dates are not always consistent. In industrial metalworking, it is an

201:

The process can be carried out in multiple passes. According to the rotation angle and direction between next passes, there can be four fundamental process routes named A, Ba, Bc, and C:

160:

ECAE is unique because significant cold work can be accomplished without reduction in the cross sectional area of the deformed workpiece. In conventional deformation processes like

193:

There are currently various modifications of the process for scaled-up or contnious production. Incremental ECAP (I-ECAP) is an example for the production of continuous products.

39:

518:

156:

During the ECAE process, the material is pressed through an angular die and experiences shear deformation, without changing its cross-sectional dimensions.

86:

237:

58:

149:. This process improves not only the strength but also other properties such as corrosion and wear resistance of alloys and compounds.

436:"Severe plastic deformation for producing superfunctional ultrafine-grainedand heterostructured materials: An interdisciplinary review"

65:

338:

311:

105:

72:

511:

187:

153:

43:

355:"Combining equal-channel angular pressing and heat treatment to obtain enhanced corrosion resistance in 6061 aluminum alloy"

54:

542:

504:

232:

134:

32:

79:

208:

Ba - the sample is rotated by 90° clockwise and counterclockwise around its longitudinal axis alternatively,

173:

146:

186:

and oil, and to reduce the forces, the process is sometimes carried out at elevated temperatures but then

161:

537:

354:

258:"Nanomaterials by severe plastic deformation: review of historical developments and recent advances"

394:"On dry sliding wear of ECAPed Al-Mg-Zn alloy: Wear rate and coefficient of friction relationship"

279:

480:

415:

374:

317:

307:

488:

182:

To reduce the friction of the pushed sample is lubricated with grease for example mixture of

447:

405:

366:

269:

392:

Elhefnawey, Maged; Shuai, G.L.; Li, Z.; Nemat-Alla, M.; Zhang, D.T.; Li, L. (2021-02-01).

142:

531:

283:

190:

can occur which can also leads to excessive grain growth at elevated temperature.

452:

435:

370:

274:

257:

469:

21:

410:

393:

353:

Nejadseyfi, Omid; Shokuhfar, Ali; Dabiri, Amirreza; Azimi, Amin (2015-11-05).

419:

378:

321:

334:

169:

138:

301:

211:

Bc - the sample is rotated by 90° clockwise around its longitudinal axis,

183:

145:

of metals and alloys, thereby improving their strength according to the

165:

151:

214:

C - the sample is rotated by 180° around its longitudinal axis.

152:

179:

Die design is critical because of the large forces required.

15:

492:

46:. Unsourced material may be challenged and removed.

512:

141:process, The technique is able to refine the

8:

519:

505:

451:

409:

273:

219:Finite element method in the ECAE process

106:Learn how and when to remove this message

247:

303:Severe plastic deformation technology

238:Strengthening mechanisms of materials

7:

477:

475:

295:

293:

44:adding citations to reliable sources

491:. You can help Knowledge (XXG) by

339:Russian Nanotechnology Corporation

14:

55:"Equal channel angular extrusion"

479:

20:

487:This metalworking article is a

440:Journal of Alloys and Compounds

359:Journal of Alloys and Compounds

335:Equal channel angular extrusion

119:Equal channel angular extrusion

31:needs additional citations for

398:Alexandria Engineering Journal

205:A - The sample in not rotated,

127:equal channel angular pressing

1:

453:10.1016/j.jallcom.2024.174667

371:10.1016/j.jallcom.2015.05.177

300:Rosochowski, Andrzej (2013).

275:10.1080/21663831.2022.2029779

133:) is one technique from the

559:

474:

262:Materials Research Letters

233:Severe plastic deformation

135:Severe Plastic Deformation

411:10.1016/j.aej.2020.10.021

306:. Whittles Publishing.

147:Hall-Petch relationship

157:

337:from encyclopedia of

155:

40:improve this article

543:Metalworking stubs

470:patent information

158:

500:

499:

188:recrystallization

116:

115:

108:

90:

550:

521:

514:

507:

483:

476:

458:

457:

455:

430:

424:

423:

413:

389:

383:

382:

350:

344:

343:

332:

326:

325:

297:

288:

287:

277:

252:

111:

104:

100:

97:

91:

89:

48:

24:

16:

558:

557:

553:

552:

551:

549:

548:

547:

528:

527:

526:

525:

466:

461:

432:

431:

427:

391:

390:

386:

352:

351:

347:

341:

333:

329:

314:

299:

298:

291:

254:

253:

249:

245:

230:

221:

199:

112:

101:

95:

92:

49:

47:

37:

25:

12:

11:

5:

556:

554:

546:

545:

540:

530:

529:

524:

523:

516:

509:

501:

498:

497:

484:

473:

472:

465:

464:External links

462:

460:

459:

425:

404:(1): 927–939.

384:

345:

327:

312:

289:

268:(4): 163–256.

246:

244:

241:

229:

226:

220:

217:

216:

215:

212:

209:

206:

198:

197:Process routes

195:

143:microstructure

125:) called also

114:

113:

28:

26:

19:

13:

10:

9:

6:

4:

3:

2:

555:

544:

541:

539:

536:

535:

533:

522:

517:

515:

510:

508:

503:

502:

496:

494:

490:

485:

482:

478:

471:

468:

467:

463:

454:

449:

445:

441:

437:

429:

426:

421:

417:

412:

407:

403:

399:

395:

388:

385:

380:

376:

372:

368:

364:

360:

356:

349:

346:

340:

336:

331:

328:

323:

319:

315:

313:9781849951197

309:

305:

304:

296:

294:

290:

285:

281:

276:

271:

267:

263:

259:

251:

248:

242:

240:

239:

235:

234:

227:

225:

218:

213:

210:

207:

204:

203:

202:

196:

194:

191:

189:

185:

180:

177:

175:

171:

167:

163:

154:

150:

148:

144:

140:

136:

132:

128:

124:

120:

110:

107:

99:

88:

85:

81:

78:

74:

71:

67:

64:

60:

57: –

56:

52:

51:Find sources:

45:

41:

35:

34:

29:This article

27:

23:

18:

17:

538:Metalworking

493:expanding it

486:

443:

439:

428:

401:

397:

387:

362:

358:

348:

342:(in Russian)

330:

302:

265:

261:

250:

236:

231:

222:

200:

192:

181:

178:

159:

130:

126:

122:

118:

117:

102:

96:January 2008

93:

83:

76:

69:

62:

50:

38:Please help

33:verification

30:

365:: 912–918.

532:Categories

446:: 174667.

243:References

66:newspapers

420:1110-0168

379:0925-8388

322:968912427

284:246959065

170:extrusion

139:extrusion

228:See also

184:graphite

174:drawing

166:forging

162:rolling

80:scholar

418:

377:

320:

310:

282:

172:, and

82:

75:

68:

61:

53:

280:S2CID

87:JSTOR

73:books

489:stub

444:1002

416:ISSN

375:ISSN

318:OCLC

308:ISBN

131:ECAP

123:ECAE

59:news

448:doi

406:doi

367:doi

363:648

270:doi

42:by

534::

442:.

438:.

414:.

402:60

400:.

396:.

373:.

361:.

357:.

316:.

292:^

278:.

266:10

264:.

260:.

168:,

164:,

520:e

513:t

506:v

495:.

456:.

450::

422:.

408::

381:.

369::

324:.

286:.

272::

129:(

121:(

109:)

103:(

98:)

94:(

84:·

77:·

70:·

63:·

36:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.