183:

207:

195:

219:

243:

231:

44:

85:

170:

buildup, e.g. making sure that the cargo placed in containers and on pallets is packed securely and efficiently. Specifically, shoring is done to affix cargo to the ULD and adapt different form factors of cargo items to maximize the use of the available ULD volume. Typically, wooden beams and various

148:

This consists of a timber member jammed on a pad piece on either the deck or deck head depending on water levels in the compartment and a strong point, this is called the proud. Then there is a horizontal timber cut to size to fit between this and what it is shoring up, e.g. a splinter box, bulkhead

135:

Shoring is used on board when damage has been caused to a vessel's integrity, and to hold leak-stopping devices in place to reduce or stop incoming water. Generally consists of timber 100 mm x 100 mm and used in conjunction with wedges, to further jam shoring in place, pad pieces to spread

126:

Soil nailing is a technique in which soil slopes, excavations or retaining walls are reinforced by the insertion of relatively slender elements – normally steel reinforcing bars. The bars are usually installed into a pre-drilled hole and then grouted into place or drilled and grouted simultaneously.

56:

In this method, inclined members called rakers are used to give temporary lateral support to an unsafe wall. One or more timbers slope between the face of the structure to be supported and the ground. The most effective support is given if the raker meets the wall at an angle of 60 to 70 degrees. A

69:

Shoring is commonly used when installing the foundation of a building. A shoring system such as piles and lagging or shotcrete will support the surrounding loads until the underground levels of the building are constructed. Commonly used shoring equipment includes post shores, shoring beams, and

117:

Beam and plate steel I-beams are driven into the ground and steel plates are slid in amongst them. A similar method that uses wood planks is called soldier boarding. Hydraulics tend to be faster and easier; the other methods tend to be used for longer term applications or larger excavations.

108:

Hydraulic shoring is the use of hydraulic pistons that can be pumped outward until they press up against the trench walls. They are typically combined with steel plate or plywood, either being 1-1/8" thick plywood, or special heavy

Finland Form (FINFORM) 7/8″ thick.

157:

This is to support a hatch or splint box on the deck, consisting of a vertical timber between the deck and deck head, with two wedges used opposing each other to tighten it. Pad pieces are used to spread the load on weak structures.

171:

forms of boards are used. Most often, shoring material is re-used but as the airfreight industry uses high-quality timber, shoring material often disappears and is a non-insignificant cost of cargo transport.

96:. Shoring is designed to prevent collapse where shielding is only designed to protect workers when collapses occur. Concrete-structure and stone-building shoring, in these cases also referred to as

206:

127:

They are usually installed untensioned at a slight downward inclination. A rigid or flexible facing (often sprayed concrete) or isolated soil nail heads may be used at the surface.

92:

During excavation, shoring systems speed up excavation and provide safety for workers since trenches can be prone to collapse. In this case, shoring should not be confused with

140:

to hold it together. Also used on board is mechanical shoring as a quick, temporary solution, however it isn't favoured due to its inability to move with the vessel.

194:

22:

is the process of temporarily supporting a building, vessel, structure, or trench with shores (props) when in danger of collapse or during repairs or alterations.

218:

308:

182:

230:

326:

242:

79:

346:

100:, provides temporary support until the concrete becomes hard and achieves the desired strength to support loads.

327:

An illustrated glossary of the terms used in temporary types of construction work. Formwork, scaffolding etc.

137:

167:

212:

Sketch of a timber double raking shore. Projected centre lines of floors and shores meet.

302:

340:

297:

264:

93:

43:

312:. Vol. 24 (11th ed.). Cambridge University Press. pp. 1004–1007.

149:

or door. Timber wedges are then used to tighten up the structure if necessary.

58:

97:

88:

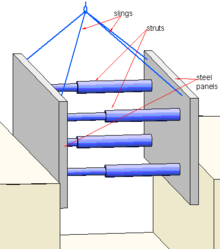

Schematic sketch of a modern steel trench shore being lowered into a trench.

84:

30:, a timber or metal prop. Shoring may be vertical, angled, or horizontal.

259:

200:

Angkor Wat complex, simple combination of timber raking and dead shores.

47:

Single steel raking shore system specifically for tilt slab shoring.

236:

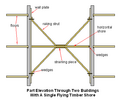

Sketch of a timber single flying shore between adjacent buildings.

224:

Carpentry detail of the joint at the top of a timber raking shore.

83:

42:

287:

Second

Edition on CD-ROM (v. 4.0) © Oxford University Press 2009

301:

188:

Vertical or dead shore system, typically used in formwork.

332:

331:

61:is typically used to increase the area of support.

8:

166:Shoring is a term used in the process of

248:Traditional trench shoring or Timbering.

276:

178:

168:air freight container and pallet (ULD)

7:

16:Supporting a structure using props

14:

241:

229:

217:

205:

193:

181:

80:Geotechnical shoring structures

1:

363:

77:

285:Oxford English Dictionary

309:Encyclopædia Britannica

283:"shore, n. 3." def, 1.

162:Shoring in air freight

89:

48:

87:

46:

90:

49:

347:Civil engineering

104:Hydraulic shoring

354:

314:

313:

305:

294:

288:

281:

245:

233:

221:

209:

197:

185:

153:Vertical shoring

131:Shoring in ships

362:

361:

357:

356:

355:

353:

352:

351:

337:

336:

323:

318:

317:

303:"Shoring"

296:

295:

291:

282:

278:

273:

256:

249:

246:

237:

234:

225:

222:

213:

210:

201:

198:

189:

186:

177:

164:

155:

146:

133:

124:

115:

106:

82:

76:

67:

54:

41:

36:

17:

12:

11:

5:

360:

358:

350:

349:

339:

338:

335:

334:

329:

322:

321:External links

319:

316:

315:

300:, ed. (1911).

298:Chisholm, Hugh

289:

275:

274:

272:

269:

268:

267:

262:

255:

252:

251:

250:

247:

240:

238:

235:

228:

226:

223:

216:

214:

211:

204:

202:

199:

192:

190:

187:

180:

176:

173:

163:

160:

154:

151:

145:

142:

132:

129:

123:

120:

114:

113:Beam and plate

111:

105:

102:

78:Main article:

75:

72:

70:timber jacks.

66:

63:

53:

50:

40:

37:

35:

32:

15:

13:

10:

9:

6:

4:

3:

2:

359:

348:

345:

344:

342:

333:

330:

328:

325:

324:

320:

311:

310:

304:

299:

293:

290:

286:

280:

277:

270:

266:

265:House raising

263:

261:

258:

257:

253:

244:

239:

232:

227:

220:

215:

208:

203:

196:

191:

184:

179:

174:

172:

169:

161:

159:

152:

150:

143:

141:

139:

136:the load and

130:

128:

121:

119:

112:

110:

103:

101:

99:

95:

86:

81:

73:

71:

64:

62:

60:

52:Raking shores

51:

45:

38:

33:

31:

29:

25:

21:

307:

292:

284:

279:

165:

156:

147:

134:

125:

122:Soil nailing

116:

107:

91:

68:

55:

27:

23:

19:

18:

65:Foundations

26:comes from

271:References

59:wall-plate

98:falsework

94:shielding

39:Buildings

341:Category

260:Box crib

254:See also

74:Trenches

175:Gallery

34:Methods

24:Shoring

20:Shoring

144:Proud

28:shore

138:dogs

343::

306:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.