591:

temperature. In locations where the blade temperature approaches the hot gas temperature, the cooling effectiveness approaches to zero. The cooling effectiveness is mainly affected by the coolant flow parameters and the injection geometry. Coolant flow parameters include the velocity, density, blowing and momentum ratios which are calculated using the coolant and mainstream flow characteristics. Injection geometry parameters consist of hole or slot geometry (i.e. cylindrical, shaped holes or slots) and injections angle. A United States Air Force program in the early 1970s funded the development of a turbine blade that was both film and convection cooled, and that method has become common in modern turbine blades. Injecting the cooler bleed into the flow reduces turbine isentropic efficiency; the compression of the cooling air (which does not contribute power to the engine) incurs an energetic penalty; and the cooling circuit adds considerable complexity to the engine. All of these factors have to be compensated by the increase in overall performance (power and efficiency) allowed by the increase in turbine temperature. In recent years, researchers have suggested using

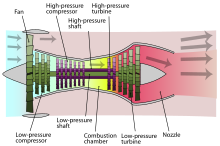

112:, a single turbine stage is made up of a rotating disk that holds many turbine blades and a stationary ring of nozzle guide vanes in front of the blades. The turbine is connected to a compressor using a shaft (the complete rotating assembly sometimes called a "spool"). Air is compressed, raising the pressure and temperature, as it passes through the compressor. The temperature is then increased by combustion of fuel inside the combustor which is located between the compressor and the turbine. The high-temperature, high-pressure gas then passes through the turbine. The turbine stages extract energy from this flow, lowering the pressure and temperature of the gas and transfer the kinetic energy to the compressor. The way the turbine works is similar to how the compressor works, only in reverse, in so far as energy exchange between the gas and the machine is concerned, for example. There is a direct relationship between how much the gas temperature changes (increase in compressor, decrease in turbine) and the shaft power input (compressor) or output (turbine).

478:

272:(or lost-wax processing). This process involves making a precise negative die of the blade shape that is filled with wax to form the blade shape. If the blade is hollow (i.e., it has internal cooling passages), a ceramic core in the shape of the passage is inserted into the middle. The wax blade is coated with a heat-resistant material to make a shell, and then that shell is filled with the blade alloy. This step can be more complicated for DS or SC materials, but the process is similar. If there is a ceramic core in the middle of the blade, it is dissolved in a solution that leaves the blade hollow. The blades are coated with a TBC, and then any cooling holes are machined.

44:

498:

air-cooling for its "FlexEfficiency" units. Liquid cooling seems to be more attractive because of high specific heat capacity and chances of evaporative cooling but there can be leakage, corrosion, choking and other problems which work against this method. On the other hand, air cooling allows the discharged air into main flow without any problem. Quantity of air required for this purpose is 1–3% of main flow and blade temperature can be reduced by 200–300 °C. There are many techniques of cooling used in gas turbine blades;

548:, works by hitting the inner surface of the blade with high velocity air. This allows more heat to be transferred by convection than regular convection cooling does. Impingement cooling is used in the regions of greatest heat loads. In case of turbine blades, the leading edge has maximum temperature and thus heat load. Impingement cooling is also used in mid chord of the vane. Blades are hollow with a core. There are internal cooling passages. Cooling air enters from the leading edge region and turns towards the trailing edge.

120:

there is a high-pressure spool and a low-pressure spool. Other gas turbines use three spools, adding an intermediate-pressure spool between the high- and low-pressure spool. The high-pressure turbine is exposed to the hottest, highest-pressure air, and the low-pressure turbine is subjected to cooler, lower-pressure air. The difference in conditions leads to the design of high-pressure and low-pressure turbine blades that are significantly different in material and cooling choices even though the

31:

516:

570:

100:

609:

537:

562:

635:

air. Transpiration-cooled blades generally consist of a rigid strut with a porous shell. Air flows through internal channels of the strut and then passes through the porous shell to cool the blade. As with film cooling, increased cooling air decreases turbine efficiency, therefore that decrease has to be balanced with improved temperature performance.

682:

Creep is the tendency of a solid material to slowly move or deform permanently under the influence of stresses. It occurs as a result of long term exposure to high levels of stress that are below the yield strength of the material. Creep is more severe in materials that are subjected to heat for long

625:

In the narrow trailing edge film cooling is used to enhance heat transfer from the blade. There is an array of pin fins on the blade surface. Heat transfer takes place from this array and through the side walls. As the coolant flows across the fins with high velocity, the flow separates and wakes are

497:

cooling in a combined cycle power plant. Water cooling has been extensively tested but has never been introduced. The

General Electric "H" class gas turbine has cooled rotating blades and static vanes using steam from a combined cycle steam turbine although GE was reported in 2012 to be going back to

137:

Turbine blades are subjected to very strenuous environments inside a gas turbine. They face high temperatures, high stresses, and a potential environment of high vibration. All three of these factors can lead to blade failures, potentially destroying the engine, therefore turbine blades are carefully

590:

of the blade material (1300–1400 kelvins). The ability of the film cooling system to cool the surface is typically evaluated using a parameter called cooling effectiveness. Higher cooling effectiveness (with maximum value of one) indicates that the blade material temperature is closer to the coolant

119:

unless the turbine speed can be increased by adding a gearbox between the turbine and fan in which case fewer stages are required. The number of turbine stages can have a great effect on how the turbine blades are designed for each stage. Many gas turbine engines are twin-spool designs, meaning that

634:

This is similar to film cooling in that it creates a thin film of cooling air on the blade, but it is different in that air is "leaked" through a porous shell rather than injected through holes. This type of cooling is effective at high temperatures as it uniformly covers the entire blade with cool

468:

of the engine increases as the turbine entry temperature (TET) increases. However, high temperatures can damage the turbine, as the blades are under large centrifugal stresses and materials are weaker at high temperature. So, turbine blade cooling is essential for the first stages but since the gas

178:

A limiting factor in early jet engines was the performance of the materials available for the hot section (combustor and turbine) of the engine. The need for better materials spurred much research in the field of alloys and manufacturing techniques, and that research resulted in a long list of new

38:

jet engine. This is a blade with an outer shroud which prevents gas leaking round the blade tip in which case it wouldn't contribute to the force on the aerofoil. The platform at the base of the aerofoil forms a continuous annulus ring which, together with cooling-air cavity purge flow prevents hot

128:

principles are the same. Under these severe operating conditions inside the gas and steam turbines, the blades face high temperature, high stresses, and potentially high vibrations. Steam turbine blades are critical components in power plants which convert the linear motion of high-temperature and

599:

plasma actuator was first proposed by Roy and Wang. A horseshoe-shaped plasma actuator, which is set in the vicinity of holes for gas flow, has been shown to improve the film cooling effectiveness significantly. Following the previous research, recent reports using both experimental and numerical

527:

through the blade, and then by convection into the air flowing inside of the blade. A large internal surface area is desirable for this method, so the cooling paths tend to be serpentine and full of small fins. The internal passages in the blade may be circular or elliptical in shape. Cooling is

616:

The blade surface is made of porous material which means having a large number of small orifices on the surface. Cooling air is forced through these porous holes which forms a film or cooler boundary layer. Besides this uniform cooling is caused by effusion of the coolant over the entire blade

581:

film cooling), a widely used type, allows for higher cooling effectiveness than either convection and impingement cooling. This technique consists of pumping the cooling air out of the blade through multiple small holes or slots in the structure. A thin layer (the film) of cooling air is then

469:

temperature drops through each stage it is not required for later stages such as in the low pressure turbine or a power turbine. Current modern turbine designs are operating with inlet temperatures higher than 1900 kelvins which is achieved by actively cooling the turbine components.

157:

failures. Additionally, the first stage (the stage directly following the combustor) of a modern gas turbine faces temperatures around 2,500 °F (1,370 °C), up from temperatures around 1,500 °F (820 °C) in early gas turbines. Modern military jet engines, like the

528:

achieved by passing the air through these passages from hub towards the blade tip. This cooling air comes from an air compressor. In case of gas turbine the fluid outside is relatively hot which passes through the cooling passage and mixes with the main stream at the blade tip.

502:, film, transpiration cooling, cooling effusion, pin fin cooling etc. which fall under the categories of internal and external cooling. While all methods have their differences, they all work by using cooler air taken from the compressor to remove heat from the turbine blades.

103:

Diagram of a twin spool jet engine. The high-pressure turbine is connected by a shaft to the high-pressure compressor to form one spool, or complete rotating assembly(purple)- and the low-pressure turbine is connected to the low-pressure compressor to form the other spool

249:

264:

coatings. Improved ceramic coatings became available in the 1980s. These coatings increased turbine blade temperature capability by about 200 °F (90 °C). The coatings also improve blade life, almost doubling the life of turbine blades in some cases.

79:

is a major source of failure in steam turbines and gas turbines. Fatigue is caused by the stress induced by vibration and resonance within the operating range of machinery. To protect blades from these high dynamic stresses, friction dampers are used.

1016:

Dexclaux, Jacques and Serre, Jacque (2003). "M88-2 E4: Advanced New

Generation Engine for Rafale Multirole Fighter". AIAA/ICAS International Air and Space Symposium and Exposition: The Next 100 Years. 14–17 July 2003, Dayton, Ohio. AIAA

356:– GE used IN-738 as a first stage blade material from 1971 until 1984, when it was replaced by GTD-111. It is now used as a second stage material. It was specifically designed for land-based turbines rather than aircraft gas turbines.

260:(TBC). Where DS and SC developments improved creep and fatigue resistance, TBCs improved corrosion and oxidation resistance, both of which became greater concerns as temperatures increased. The first TBCs, applied in the 1970s, were

39:

gas leakage onto the turbine discs. The short extension, or shank, between the platform and fir-tree fixing in the disc allows space for cooling-air entry to blade, may control blade vibration modes and heat transfer to disc rim.

162:, can see turbine temperatures of 2,900 °F (1,590 °C). Those high temperatures can weaken the blades and make them more susceptible to creep failures. The high temperatures can also make the blades susceptible to

1006:

Koff, Bernard L. (2003). "Gas

Turbine Technology Overview – A Designer's Perspective". AIAA/ICAS International Air and Space Symposium and Exposition: The Next 100 Years. 14–17 July 2003, Dayton, Ohio. AIAA

1733:

252:

A turbine blade with thermal barrier coating. This blade has no tip shroud so tip leakage is controlled by the clearance between the tip and a stationary shroud ring attached to the turbine case.

55:

is a radial aerofoil mounted in the rim of a turbine disc and which produces a tangential force which rotates a turbine rotor. Each turbine disc has many blades. As such they are used in

960:

1613:

S. Dai, Y. Xiao, L. He, T. Jin, P. Hou, Q. Zhang, Z. Zhao, Computational study of plasma actuator on film cooling performance for different shaped holes, AIP Adv. 5 (2015), 067104.

1604:

P. Audier, M., N. Benard, E. Moreau, Film cooling effectiveness enhancement using surface dielectric barrier discharge plasma actuator, Int. J. Heat Fluid Flow 62 (2016), 247–57.

1726:

1622:

Y. Xiao, S. Dai, L. He, T. Jin, Q. Zhang, P. Hou, Investigation of film cooling from cylindrical hole with plasma actuator on flat plate, Heat Mass Transf. 52 (2016), 1571–83.

1500:

1197:

1133:

1719:

282:, are being developed for use in turbine blades. The main advantage of CMCs over conventional superalloys is their light weight and high temperature capability.

67:. The turbine blades are often the limiting component of gas turbines. To survive in this difficult environment, turbine blades often use exotic materials like

1311:

P. Caron, Y. Ohta, Y.G. Nakagawa, T. Khan (1988): Superalloys 1988 (edited by S. Reichmann et al.), p. 215. The

Metallurgical Society of AIME, Warrendale, PA.

828:

2112:

923:

1536:

2102:

626:

formed. Many factors contribute towards heat transfer rate among which the type of pin fin and the spacing between fins are the most significant.

2075:

477:

43:

1702:

1683:

1662:

1181:

724:

313:

This material was used as a first stage (the most demanding stage) material in the 1960s, and is now used in later, less demanding, stages.

1116:

1237:"GE Successfully Tests World's First Rotating Ceramic Matrix Composite Material for Next-Gen Combat Engine | Press Release | GE Aviation"

2107:

1324:

1568:

1299:

935:

1396:

1046:

806:

1411:

Gas

Turbine Engineering Handbook Second Edition, Boyce, ISBN 0 88415 732 6, Fig. 9-23 General Electric "Water-cooled turbine blade"

1975:

482:

1510:

1211:

2024:

1545:

1476:

596:

1358:

2060:

582:

created on the external surface of the blade, reducing the heat transfer from main flow, whose temperature (1300–1800

1279:

706:

202:

improved the alloys used for turbine blades and increased turbine blade performance. Modern turbine blades often use

924:

https://www.researchgate.net/publication/267620184_Fundamental_Differences_Between_Conventional_and_Geared_Turbofans

2055:

1831:

654:

383:

222:

91:

are designed to operate in different conditions, which typically involve lower rotational speeds and temperatures.

382:(P&W)) is a single crystal superalloy jointly developed by NASA, GE Aviation, and Pratt & Whitney for the

1854:

644:

145:(turbine stages can rotate at tens of thousands of revolutions per minute (RPM)) and fluid forces that can cause

1028:

859:

63:. The blades are responsible for extracting energy from the high temperature, high pressure gas produced by the

2132:

2050:

1910:

283:

279:

275:

257:

195:

750:

Acharya, Sumanta; Kanani, Yousef (2017-01-01), Sparrow, Ephraim M.; Abraham, John P.; Gorman, John M. (eds.),

233:

in one direction (DS) or by eliminating grain boundaries altogether (SC). SC research began in the 1960s with

198:

in the 1950s greatly increased the temperature capability of turbine blades. Further processing methods like

2004:

1791:

878:"Study of corrosive fatigue and life enhancement of low pressure steam turbine blade using friction dampers"

386:(HSCT). While the HSCT program was cancelled, the alloy is still being considered for use by GE and P&W.

290:

fibers have been shown to withstand operating temperatures 200°-300 °F higher than nickel superalloys.

229:(SC) production methods. These methods help greatly increase strength against fatigue and creep by aligning

72:

1980:

1950:

1945:

1869:

1786:

1505:

199:

1533:

1421:

2217:

1985:

1955:

1935:

1191:

1148:

1072:

295:

294:

successfully demonstrated the use of such SiC/SiC composite blades for the low-pressure turbine of its

2202:

2165:

2117:

1879:

786:

751:

71:

and many different methods of cooling that can be categorized as internal and external cooling, and

684:

452:

430:

154:

150:

1236:

936:

https://www.yumpu.com/en/document/read/11154551/geared-fan-vki-aero-engine-design-mtu-aero-engines

368:

gas turbines in the first stage. Blades made from equiaxed GTD-111 are being used in later stages.

2070:

2019:

897:

851:

465:

426:

397:

269:

167:

76:

1386:

129:

high-pressure steam flowing down a pressure gradient into a rotary motion of the turbine shaft.

115:

For a turbofan engine the number of turbine stages required to drive the fan increases with the

523:

It works by passing cooling air through passages internal to the blade. Heat is transferred by

237:

and took about 10 years to be implemented. One of the first implementations of DS was with the

179:

materials and methods that make modern gas turbines possible. One of the earliest of these was

2097:

1889:

1698:

1679:

1658:

1564:

1392:

1177:

1156:

51st AIAA Aerospace

Sciences Meeting Including the New Horizons Forum and Aerospace Exposition

1127:

802:

720:

524:

234:

142:

35:

2238:

2197:

1990:

1960:

1930:

1864:

1321:

1302:. NASA Glenn's Research & Technology. Updated: 7 November 2007. Retrieved: 16 June 2010.

1167:

1159:

1149:"Evaluation of Ceramic Matrix Composite Technology for Aircraft Turbine Engine Applications"

889:

843:

794:

759:

416:

393:

2212:

2155:

1849:

1777:

1746:

1540:

1328:

592:

406:

287:

1521:

1711:

1762:

1693:

Boyce, Meherwan P. (2006). "Chapter 9: Axial Flow

Turbines and Chapter 11: Materials".

600:

methods demonstrated the effect of cooling enhancement by 15% using a plasma actuator.

230:

226:

125:

30:

798:

515:

256:

Another major improvement to turbine blade material technology was the development of

248:

2232:

2122:

1920:

1826:

1595:

S. Roy, C.-C. Wang, Plasma actuated heat transfer, Appl. Phys. Lett. 92 (2008) 231501

1362:

1340:

901:

877:

587:

184:

88:

60:

855:

569:

2176:

2150:

2140:

1970:

1925:

961:

Fractographic investigations of the failure of L-1 low pressure steam turbine blade

683:

periods, and near the melting point. Creep always increases with temperature. From

608:

536:

121:

84:

1355:

99:

2045:

2040:

1859:

1757:

1749:

763:

707:"Nomenclature of Cooled Axial Turbine Blade – Turbomachinery Aerodynamic Design"

664:

659:

291:

56:

1446:

1320:

S. Walston, A. Cetel, R. MacKay, K. O’Hara, D. Duhl, and R. Dreshfield (2004).

166:

failures. Finally, vibrations from the engine and the turbine itself can cause

1816:

1742:

893:

499:

191:

159:

109:

68:

17:

2207:

2065:

1915:

1874:

1811:

1172:

649:

561:

365:

261:

163:

64:

1212:"Ceramic Matrix Composites Allow GE Jet Engines to Fly Longer – GE Reports"

221:

Aside from alloy improvements, a major breakthrough was the development of

2181:

1940:

1884:

1806:

1801:

1782:

1653:

YAHYA, SM (2011). "Chapter 10: High temperature(cooled) turbine stages".

443:

to create wind turbine blades is in development in a partnership between

434:

364:

Blades made from directionally solidified GTD-111 are being used in many

207:

146:

116:

1678:. Cambridge Aerospace Series. New York, NY: Cambridge University Press.

1796:

1657:(4th ed.). New delhi: Tata McGraw Hill Education private limited.

1163:

347:

306:

Note: This list is not inclusive of all alloys used in turbine blades.

215:

180:

1534:

Aircraft propulsion. Thermal and mechanical limitations in jet engines

1501:

Volume 1. Performance Flight

Testing Phase. Chapter 7. Aero Propulsion

1965:

1821:

1300:

Low-Density, Creep-Resistant

Superalloys Developed for Turbine Blades

583:

211:

203:

847:

2145:

1546:

Technical

University of Madrid, School of Aeronautical Engineering

1322:

Joint Development of a Fourth Generation Single Crystal Superalloy

607:

568:

560:

535:

514:

476:

247:

242:

98:

42:

29:

1391:. New delhi: Tata McGraw-Hill Education, 2010. pp. 430–433.

565:

Rendering of a turbine blade with cooling holes for film cooling.

595:

for film cooling. The film cooling of turbine blades by using a

448:

444:

1715:

47:

The turbine blades have a golden colour in this engine cutaway.

1331:. NASA TM—2004-213062. December 2004. Retrieved: 16 June 2010.

963:. Case Studies in Engineering Failure Analysis, 1(2), pp.72–78

238:

1481:

4.2.2.2 Enhanced Internal Coolingof Turbine Blades and Vanes

481:

Laser-drilled holes permit film cooling in this first-stage

1674:

Flack, Ronald D. (2005). "Chapter 8: Axial Flow Turbines".

1047:"Single-Crystal Turbine Blades Earn ASME Milestone Status"

752:"Chapter Three - Advances in Film Cooling Heat Transfer"

1477:"Enhanced Internal Cooling of Turbine Blades and Vanes"

286:

consisting of a silicon carbide matrix reinforced by

955:

953:

2190:

2164:

2131:

2088:

2033:

2012:

2003:

1903:

1840:

1770:

1756:

1470:

1468:

1117:"Development of CMC Turbine Parts for Aero Engines"

789:, in Irvine, Thomas F.; Hartnett, James P. (eds.),

780:

778:

2113:Engine-indicating and crew-alerting system (EICAS)

2146:Full Authority Digital Engine/Electronics (FADEC)

1282:. GE Energy. August 2004. Retrieved: 25 May 2011.

719:The Cambridge Aerospace Dictionary, Bill Gunston,

1676:Fundamentals of Jet Propulsion with Applications

278:(CMC), where fibers are embedded in a matrix of

194:in the 1940s and new processing methods such as

27:Aerofoil; individual component of a turbine disc

2103:Electronic centralised aircraft monitor (ECAM)

1274:

1272:

1270:

1268:

1266:

1115:Takeshi, Takashi, Kuniyuki, Ken-ichi, Masato.

1727:

1506:Edwards Air Force Base, Air Force Test Center

8:

1447:https://patents.google.com/patent/US2966331A

1196:: CS1 maint: multiple names: authors list (

1132:: CS1 maint: multiple names: authors list (

882:Journal of Mechanical Science and Technology

141:Turbine blades are subjected to stress from

1280:Advanced Gas Turbine Materials and Coatings

1147:Halbig, Jaskowiak, Kiser, Zhu (June 2013).

793:, vol. 7, Elsevier, pp. 321–379,

758:, vol. 49, Elsevier, pp. 91–156,

2108:Electronic flight instrument system (EFIS)

2009:

1767:

1734:

1720:

1712:

827:Bogard, D. G.; Thole, K. A. (2006-03-01).

1171:

1582:

1580:

1380:

1378:

1376:

1374:

268:Most turbine blades are manufactured by

1458:

1456:

1454:

1433:

1431:

1002:

1000:

998:

996:

994:

992:

973:

971:

969:

698:

675:

392:was used for the turbine blades on the

1294:

1292:

1290:

1288:

1189:

1125:

876:Bhagi LK, Rastogi V, Gupta P (2017).

138:designed to resist these conditions.

7:

1071:Langston, Lee S. (6 February 2017).

959:Bhagi LK, Rastogi V, Gupta P (2013).

785:Goldstein, Richard J. (1971-01-01),

745:

743:

741:

206:-based superalloys that incorporate

1298:MacKay, Rebecca A., et al. (2007).

544:A variation of convection cooling,

1697:(3rd ed.). Oxford: Elsevier.

1045:Langston, Lee S. (16 March 2018).

1034:. United States Geological Survey.

791:Advances in Heat Transfer Volume 7

25:

1422:"Moving beyond the steam cooling"

1976:Thrust specific fuel consumption

1695:Gas Turbine Engineering Handbook

489:Turbine blades are cooled using

1563:(6 ed.). Rolls-Royce plc.

1475:Lesley M. Wright, Je-Chin Han.

836:Journal of Propulsion and Power

302:List of turbine blade materials

2025:Propeller speed reduction unit

1549:, 2015. Retrieved: April 2015.

464:At a constant pressure ratio,

441:3D printed thermoplastic resin

1:

1655:turbines, compressor and fans

1388:Turbines Compressors and Fans

1073:"Each Blade a Single Crystal"

799:10.1016/s0065-2717(08)70020-0

133:Environment and failure modes

1509:, February 1991. Size: 8MB.

597:dielectric barrier discharge

1936:Engine pressure ratio (EPR)

1029:"Mineral Yearbook: Rhenium"

764:10.1016/bs.aiht.2017.10.001

519:Blade cooling by convection

2255:

2203:Auxiliary power unit (APU)

1832:Rotating detonation engine

829:"Gas Turbine Film Cooling"

655:High temperature corrosion

577:Film cooling (also called

493:except for limited use of

384:High Speed Civil Transport

223:directional solidification

1341:"Metal Tidbits: Nimonic."

1077:www.americanscientist.org

894:10.1007/s12206-016-1203-5

756:Advances in Heat Transfer

645:Components of jet engines

276:Ceramic matrix composites

1911:Aircraft engine starting

1559:Rolls-Royce plc (2005).

1368:Retrieved: 5 March 2011.

1346:Retrieved: 5 March 2011.

280:polymer derived ceramics

258:thermal barrier coatings

196:vacuum induction melting

73:thermal barrier coatings

1792:Pulse detonation engine

1511:mirror of ADA320315.pdf

1327:15 October 2006 at the

1278:Schilke, P. W. (2004).

1981:Thrust to weight ratio

1951:Overall pressure ratio

1946:Jet engine performance

1870:Centrifugal compressor

1787:Gluhareff Pressure Jet

613:

574:

566:

541:

520:

486:

253:

200:hot isostatic pressing

183:, used in the British

105:

48:

40:

2218:Ice protection system

1986:Variable cycle engine

1956:Propulsive efficiency

1522:What is Film Cooling?

1051:www.machinedesign.com

630:Transpiration cooling

611:

572:

564:

539:

518:

480:

251:

102:

46:

34:Turbine blade from a

33:

2118:Flight data recorder

1880:Constant speed drive

1860:Afterburner (reheat)

1532:Martinez, Isidoro. "

437:supersonic airliner.

1385:Yahya, S M (2011).

1361:8 December 2012 at

1027:Magyar, Michael J.

685:Creep (deformation)

612:Cooling by effusion

546:impingement cooling

532:Impingement cooling

453:GE Renewable Energy

427:combustion chambers

190:The development of

2020:Propeller governor

1539:2015-07-01 at the

1241:www.geaviation.com

1164:10.2514/6.2013-539

614:

575:

567:

542:

521:

511:Convection cooling

487:

473:Methods of cooling

466:thermal efficiency

398:de Havilland Ghost

284:SiC/SiC composites

270:investment casting

254:

110:gas turbine engine

106:

49:

41:

2226:

2225:

2098:Annunciator panel

2084:

2083:

1999:

1998:

1890:Propelling nozzle

1704:978-0-7506-7846-9

1685:978-0-521-81983-1

1664:978-0-07-070702-3

1183:978-1-62410-181-6

586:) can exceed the

485:nozzle guide vane

235:Pratt and Whitney

143:centrifugal force

36:Turbo-Union RB199

16:(Redirected from

2246:

2213:Hydraulic system

2208:Bleed air system

2198:Air-start system

2061:Counter-rotating

2010:

1991:Windmill restart

1961:Specific impulse

1931:Compressor stall

1865:Axial compressor

1768:

1736:

1729:

1722:

1713:

1708:

1689:

1668:

1641:

1638:

1632:

1629:

1623:

1620:

1614:

1611:

1605:

1602:

1596:

1593:

1587:

1586:Boyce, p. 379-80

1584:

1575:

1574:

1556:

1550:

1530:

1524:

1519:

1513:

1498:

1492:

1491:

1489:

1487:

1472:

1463:

1460:

1449:

1444:

1438:

1435:

1426:

1425:

1418:

1412:

1409:

1403:

1402:

1382:

1369:

1353:

1347:

1338:

1332:

1318:

1312:

1309:

1303:

1296:

1283:

1276:

1261:

1258:

1252:

1251:

1249:

1247:

1233:

1227:

1226:

1224:

1222:

1208:

1202:

1201:

1195:

1187:

1175:

1173:2060/20130010774

1153:

1144:

1138:

1137:

1131:

1123:

1121:

1112:

1106:

1103:

1097:

1094:

1088:

1087:

1085:

1083:

1068:

1062:

1061:

1059:

1057:

1042:

1036:

1035:

1033:

1024:

1018:

1014:

1008:

1004:

987:

984:

978:

975:

964:

957:

948:

945:

939:

933:

927:

921:

915:

912:

906:

905:

873:

867:

866:

864:

858:. Archived from

833:

824:

818:

817:

816:

815:

782:

773:

772:

771:

770:

747:

736:

733:

727:

717:

711:

710:

703:

688:

680:

604:Cooling effusion

552:External cooling

506:Internal cooling

425:was used in the

417:Rolls-Royce Spey

415:was used on the

405:was used on the

394:Rolls-Royce Nene

231:grain boundaries

21:

2254:

2253:

2249:

2248:

2247:

2245:

2244:

2243:

2229:

2228:

2227:

2222:

2186:

2169:

2160:

2156:Thrust reversal

2133:Engine controls

2127:

2090:

2080:

2056:Contra-rotating

2029:

1995:

1899:

1850:Accessory drive

1842:

1836:

1778:Air turborocket

1760:

1752:

1740:

1705:

1692:

1686:

1673:

1665:

1652:

1644:

1639:

1635:

1631:Flack, p. 428-9

1630:

1626:

1621:

1617:

1612:

1608:

1603:

1599:

1594:

1590:

1585:

1578:

1571:

1558:

1557:

1553:

1541:Wayback Machine

1531:

1527:

1520:

1516:

1499:

1495:

1485:

1483:

1474:

1473:

1466:

1461:

1452:

1445:

1441:

1436:

1429:

1420:

1419:

1415:

1410:

1406:

1399:

1384:

1383:

1372:

1366:Special Metals.

1354:

1350:

1344:steelforge.com.

1339:

1335:

1329:Wayback Machine

1319:

1315:

1310:

1306:

1297:

1286:

1277:

1264:

1260:Boyce, p. 440-2

1259:

1255:

1245:

1243:

1235:

1234:

1230:

1220:

1218:

1210:

1209:

1205:

1188:

1184:

1151:

1146:

1145:

1141:

1124:

1119:

1114:

1113:

1109:

1105:Flack, p. 430-3

1104:

1100:

1095:

1091:

1081:

1079:

1070:

1069:

1065:

1055:

1053:

1044:

1043:

1039:

1031:

1026:

1025:

1021:

1015:

1011:

1005:

990:

985:

981:

976:

967:

958:

951:

946:

942:

934:

930:

922:

918:

913:

909:

875:

874:

870:

862:

848:10.2514/1.18034

831:

826:

825:

821:

813:

811:

809:

784:

783:

776:

768:

766:

749:

748:

739:

734:

730:

718:

714:

705:

704:

700:

696:

691:

681:

677:

673:

641:

632:

623:

621:Pin fin cooling

606:

593:plasma actuator

559:

554:

534:

513:

508:

475:

462:

431:Bristol Olympus

407:Bristol Proteus

304:

288:silicon carbide

241:engines of the

176:

135:

97:

28:

23:

22:

15:

12:

11:

5:

2252:

2250:

2242:

2241:

2231:

2230:

2224:

2223:

2221:

2220:

2215:

2210:

2205:

2200:

2194:

2192:

2188:

2187:

2185:

2184:

2179:

2173:

2171:

2162:

2161:

2159:

2158:

2153:

2148:

2143:

2137:

2135:

2129:

2128:

2126:

2125:

2120:

2115:

2110:

2105:

2100:

2094:

2092:

2086:

2085:

2082:

2081:

2079:

2078:

2076:Variable-pitch

2073:

2068:

2063:

2058:

2053:

2051:Constant-speed

2048:

2043:

2037:

2035:

2031:

2030:

2028:

2027:

2022:

2016:

2014:

2007:

2001:

2000:

1997:

1996:

1994:

1993:

1988:

1983:

1978:

1973:

1968:

1963:

1958:

1953:

1948:

1943:

1938:

1933:

1928:

1923:

1918:

1913:

1907:

1905:

1901:

1900:

1898:

1897:

1892:

1887:

1882:

1877:

1872:

1867:

1862:

1857:

1852:

1846:

1844:

1838:

1837:

1835:

1834:

1829:

1824:

1819:

1814:

1809:

1804:

1799:

1794:

1789:

1780:

1774:

1772:

1765:

1763:jet propulsion

1754:

1753:

1741:

1739:

1738:

1731:

1724:

1716:

1710:

1709:

1703:

1690:

1684:

1670:

1669:

1663:

1649:

1648:

1643:

1642:

1633:

1624:

1615:

1606:

1597:

1588:

1576:

1570:978-0902121232

1569:

1561:The Jet Engine

1551:

1525:

1514:

1493:

1464:

1462:Boyce, p. 370.

1450:

1439:

1427:

1413:

1404:

1397:

1370:

1348:

1333:

1313:

1304:

1284:

1262:

1253:

1228:

1203:

1182:

1139:

1107:

1098:

1089:

1063:

1037:

1019:

1009:

988:

979:

977:Flack, p. 429.

965:

949:

940:

928:

916:

907:

868:

865:on 2019-03-07.

842:(2): 249–270.

819:

807:

787:"Film Cooling"

774:

737:

735:Boyce, p. 368.

728:

712:

697:

695:

692:

690:

689:

674:

672:

669:

668:

667:

662:

657:

652:

647:

640:

637:

631:

628:

622:

619:

605:

602:

558:

555:

553:

550:

533:

530:

512:

509:

507:

504:

474:

471:

461:

458:

457:

456:

438:

420:

410:

400:

387:

369:

359:

358:

357:

344:

339:

334:

329:

324:

319:

314:

303:

300:

227:single crystal

175:

172:

134:

131:

96:

93:

89:water turbines

61:steam turbines

26:

24:

18:Turbine blades

14:

13:

10:

9:

6:

4:

3:

2:

2251:

2240:

2237:

2236:

2234:

2219:

2216:

2214:

2211:

2209:

2206:

2204:

2201:

2199:

2196:

2195:

2193:

2191:Other systems

2189:

2183:

2180:

2178:

2175:

2174:

2172:

2168:and induction

2167:

2163:

2157:

2154:

2152:

2149:

2147:

2144:

2142:

2139:

2138:

2136:

2134:

2130:

2124:

2123:Glass cockpit

2121:

2119:

2116:

2114:

2111:

2109:

2106:

2104:

2101:

2099:

2096:

2095:

2093:

2087:

2077:

2074:

2072:

2069:

2067:

2064:

2062:

2059:

2057:

2054:

2052:

2049:

2047:

2044:

2042:

2039:

2038:

2036:

2032:

2026:

2023:

2021:

2018:

2017:

2015:

2011:

2008:

2006:

2002:

1992:

1989:

1987:

1984:

1982:

1979:

1977:

1974:

1972:

1969:

1967:

1964:

1962:

1959:

1957:

1954:

1952:

1949:

1947:

1944:

1942:

1939:

1937:

1934:

1932:

1929:

1927:

1924:

1922:

1921:Brayton cycle

1919:

1917:

1914:

1912:

1909:

1908:

1906:

1902:

1896:

1895:Turbine blade

1893:

1891:

1888:

1886:

1883:

1881:

1878:

1876:

1873:

1871:

1868:

1866:

1863:

1861:

1858:

1856:

1853:

1851:

1848:

1847:

1845:

1839:

1833:

1830:

1828:

1825:

1823:

1820:

1818:

1815:

1813:

1810:

1808:

1805:

1803:

1800:

1798:

1795:

1793:

1790:

1788:

1784:

1781:

1779:

1776:

1775:

1773:

1769:

1766:

1764:

1759:

1755:

1751:

1748:

1744:

1737:

1732:

1730:

1725:

1723:

1718:

1717:

1714:

1706:

1700:

1696:

1691:

1687:

1681:

1677:

1672:

1671:

1666:

1660:

1656:

1651:

1650:

1646:

1645:

1640:Boyce, p. 375

1637:

1634:

1628:

1625:

1619:

1616:

1610:

1607:

1601:

1598:

1592:

1589:

1583:

1581:

1577:

1572:

1566:

1562:

1555:

1552:

1548:

1547:

1542:

1538:

1535:

1529:

1526:

1523:

1518:

1515:

1512:

1508:

1507:

1502:

1497:

1494:

1482:

1478:

1471:

1469:

1465:

1459:

1457:

1455:

1451:

1448:

1443:

1440:

1437:Flack, p.428.

1434:

1432:

1428:

1423:

1417:

1414:

1408:

1405:

1400:

1398:9780070707023

1394:

1390:

1389:

1381:

1379:

1377:

1375:

1371:

1367:

1364:

1363:archive.today

1360:

1357:

1352:

1349:

1345:

1342:

1337:

1334:

1330:

1326:

1323:

1317:

1314:

1308:

1305:

1301:

1295:

1293:

1291:

1289:

1285:

1281:

1275:

1273:

1271:

1269:

1267:

1263:

1257:

1254:

1242:

1238:

1232:

1229:

1217:

1213:

1207:

1204:

1199:

1193:

1185:

1179:

1174:

1169:

1165:

1161:

1157:

1150:

1143:

1140:

1135:

1129:

1118:

1111:

1108:

1102:

1099:

1096:Boyce, p. 449

1093:

1090:

1078:

1074:

1067:

1064:

1052:

1048:

1041:

1038:

1030:

1023:

1020:

1013:

1010:

1003:

1001:

999:

997:

995:

993:

989:

986:Flack, p. 410

983:

980:

974:

972:

970:

966:

962:

956:

954:

950:

947:Flack, p. 407

944:

941:

937:

932:

929:

925:

920:

917:

914:Flack, p. 406

911:

908:

903:

899:

895:

891:

887:

883:

879:

872:

869:

861:

857:

853:

849:

845:

841:

837:

830:

823:

820:

810:

808:9780120200078

804:

800:

796:

792:

788:

781:

779:

775:

765:

761:

757:

753:

746:

744:

742:

738:

732:

729:

726:

725:0 511 33833 3

722:

716:

713:

708:

702:

699:

693:

686:

679:

676:

670:

666:

663:

661:

658:

656:

653:

651:

648:

646:

643:

642:

638:

636:

629:

627:

620:

618:

610:

603:

601:

598:

594:

589:

588:melting point

585:

580:

571:

563:

556:

551:

549:

547:

538:

531:

529:

526:

517:

510:

505:

503:

501:

496:

492:

484:

479:

472:

470:

467:

459:

454:

450:

446:

442:

439:

436:

432:

428:

424:

421:

418:

414:

411:

408:

404:

401:

399:

395:

391:

388:

385:

381:

377:

373:

370:

367:

363:

360:

355:

352:

351:

350:

349:

345:

343:

340:

338:

335:

333:

330:

328:

325:

323:

320:

318:

315:

312:

309:

308:

307:

301:

299:

297:

293:

289:

285:

281:

277:

273:

271:

266:

263:

259:

250:

246:

244:

240:

236:

232:

228:

224:

219:

217:

213:

209:

205:

201:

197:

193:

188:

186:

182:

173:

171:

169:

165:

161:

156:

152:

148:

144:

139:

132:

130:

127:

126:thermodynamic

123:

118:

113:

111:

101:

94:

92:

90:

86:

85:wind turbines

81:

78:

74:

70:

66:

62:

58:

54:

53:turbine blade

45:

37:

32:

19:

2177:Flame holder

2151:Thrust lever

2141:Autothrottle

1971:Thrust lapse

1926:Bypass ratio

1894:

1758:Gas turbines

1750:gas turbines

1694:

1675:

1654:

1647:Bibliography

1636:

1627:

1618:

1609:

1600:

1591:

1560:

1554:

1544:

1528:

1517:

1504:

1503:page 7.122.

1496:

1484:. Retrieved

1480:

1442:

1416:

1407:

1387:

1365:

1351:

1343:

1336:

1316:

1307:

1256:

1244:. Retrieved

1240:

1231:

1219:. Retrieved

1215:

1206:

1192:cite journal

1155:

1142:

1110:

1101:

1092:

1080:. Retrieved

1076:

1066:

1054:. Retrieved

1050:

1040:

1022:

1012:

982:

943:

931:

926:, Fig.1.5-14

919:

910:

885:

881:

871:

860:the original

839:

835:

822:

812:, retrieved

790:

767:, retrieved

755:

731:

715:

701:

678:

633:

624:

615:

578:

576:

573:Film cooling

557:Film cooling

545:

543:

522:

494:

490:

488:

463:

440:

433:used on the

422:

412:

402:

389:

379:

375:

371:

361:

353:

346:

341:

336:

331:

326:

321:

316:

310:

305:

298:jet engine.

274:

267:

255:

220:

189:

177:

140:

136:

117:bypass-ratio

114:

107:

95:Introduction

82:

59:engines and

52:

50:

2091:instruments

2046:Blade pitch

2041:Autofeather

1743:Jet engines

1543:" page 19.

1356:"Products."

1082:25 November

1056:25 November

665:Superalloys

660:Gas turbine

540:Impingement

423:Nimonic 263

413:Nimonic 105

390:Nimonic 80a

292:GE Aviation

192:superalloys

122:aerodynamic

69:superalloys

57:gas turbine

2034:Principles

2013:Components

2005:Propellers

1904:Principles

1855:Air intake

1843:components

1841:Mechanical

1817:Turboshaft

1246:2 November

1221:2 November

1216:GE Reports

1007:2003-2722.

814:2019-08-30

769:2019-08-30

694:References

525:conduction

500:convection

403:Nimonic 90

170:failures.

160:Snecma M88

83:Blades of

2066:Proprotor

1916:Bleed air

1875:Combustor

1812:Turboprop

1017:2003-2610

902:115023151

888:: 17–27.

650:Combustor

617:surface.

366:GE Energy

262:aluminide

225:(DS) and

187:engines.

174:Materials

164:corrosion

65:combustor

2233:Category

2182:Jet fuel

2071:Scimitar

1941:Flameout

1885:Impeller

1807:Turbojet

1802:Turbofan

1783:Pulsejet

1747:aircraft

1537:Archived

1359:Archived

1325:Archived

1128:cite web

856:54063370

639:See also

435:Concorde

380:PWA 1497

208:chromium

151:yielding

147:fracture

104:(green).

75:. Blade

2239:Engines

2170:systems

1797:Propfan

584:kelvins

460:Cooling

429:of the

372:EPM-102

362:GTD-111

348:Inconel

342:CMSX-10

332:PWA1484

327:Rene N6

322:Rene N5

317:Rene 77

216:rhenium

185:Whittle

181:Nimonic

168:fatigue

77:fatigue

2089:Engine

1966:Thrust

1827:Rocket

1822:Ramjet

1701:

1682:

1661:

1567:

1486:27 May

1395:

1180:

938:, p.15

900:

854:

805:

723:

451:, and

378:(GE),

354:IN-738

337:CMSX-4

214:, and

212:cobalt

204:nickel

1771:Types

1152:(PDF)

1120:(PDF)

1032:(PDF)

898:S2CID

863:(PDF)

852:S2CID

832:(PDF)

671:Notes

495:steam

483:V2500

311:U-500

243:SR-71

155:creep

153:, or

108:In a

2166:Fuel

1761:and

1745:and

1699:ISBN

1680:ISBN

1659:ISBN

1565:ISBN

1488:2013

1393:ISBN

1248:2015

1223:2015

1198:link

1178:ISBN

1134:link

1084:2018

1058:2018

803:ISBN

721:ISBN

579:thin

449:NREL

445:ORNL

396:and

296:F414

124:and

87:and

1168:hdl

1160:doi

890:doi

844:doi

795:doi

760:doi

491:air

376:MX4

239:J58

2235::

1579:^

1479:.

1467:^

1453:^

1430:^

1373:^

1287:^

1265:^

1239:.

1214:.

1194:}}

1190:{{

1176:.

1166:.

1158:.

1154:.

1130:}}

1126:{{

1075:.

1049:.

991:^

968:^

952:^

896:.

886:31

884:.

880:.

850:.

840:22

838:.

834:.

801:,

777:^

754:,

740:^

447:,

245:.

218:.

210:,

149:,

51:A

1785:/

1735:e

1728:t

1721:v

1707:.

1688:.

1667:.

1573:.

1490:.

1424:.

1401:.

1250:.

1225:.

1200:)

1186:.

1170::

1162::

1136:)

1122:.

1086:.

1060:.

904:.

892::

846::

797::

762::

709:.

687:.

455:.

419:.

409:.

374:(

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.