775:

gases. In addition, the liquid fuel vapor is about 5 times the density of a gaseous fuel, providing much greater "punch". A high velocity cutting flame is produced by the huge volume expansion when the liquid transitions to a vapor, so the cutting flame will easily cut across air voids between plates. A diesel/oxygen torch can cut through paint, dirt, rust and other surface contaminants on steel. This system provides almost 100% oxidation during cutting so it leaves virtually no molten steel in the slag, preventing the "sticking together" of the cut materials. The operating cost for a diesel torch is typically 75-90% less than using propane or acetylene. Growing use in the demolition or scrap industries

1255:

flames because the combustible gases will not have to search so far to find the necessary amount of oxygen, nor heat up as much thermally inert carbon. It is called an oxidizing flame because of its effect on metal. This flame adjustment is generally not preferred. The oxidizing flame creates undesirable oxides to the structural and mechanical detriment of most metals. In an oxidizing flame, the inner cone acquires a purplish tinge and gets pinched and smaller at the tip, and the sound of the flame gets harsh. A slightly oxidizing flame is used in braze-welding and bronze-surfacing while a more strongly oxidizing flame is used in fusion welding certain brasses and bronzes

679:

887:, is a saturated hydrocarbon. Butane and propane do not react with each other and are regularly mixed. Butane boils at 0.6 °C. Propane is more volatile, with a boiling point of -42 °C. Vaporization is rapid at temperatures above the boiling points. The calorific (heat) values of the two are almost equal. Both are thus mixed to attain the vapor pressure that is required by the end user and depending on the ambient conditions. If the ambient temperature is very low, propane is preferred to achieve higher vapor pressure at the given temperature.

43:

1440:

1223:

793:. It can be used at a higher pressure than acetylene and is therefore useful for underwater welding and cutting. It is a good type of flame to use when heating large amounts of material. The flame temperature is high, about 2,000 °C for hydrogen gas in air at atmospheric pressure, and up to 2800 °C when pre-mixed in a 2:1 ratio with pure oxygen (oxyhydrogen). Hydrogen is not used for welding steels and other ferrous materials, because it causes

1325:

1173:'. In the case of hydrogen, the product of combustion is simply water. For the other hydrocarbon fuels, water and carbon dioxide are produced. The heat is released because the molecules of the products of combustion have a lower energy state than the molecules of the fuel and oxygen. In oxy-fuel cutting, oxidation of the metal being cut (typically iron) produces nearly all of the heat required to "burn" through the workpiece.

512:

1432:

124:

1333:

471:. Although it has an upper flammability limit in air of 81%, acetylene's explosive decomposition behaviour makes this irrelevant. If a detonation wave enters the acetylene tank, the tank will be blown apart by the decomposition. Ordinary check valves that normally prevent backflow cannot stop a detonation wave because they are not capable of closing before the wave passes around the gate. For that reason a

1341:

415:. The adjustable second stage of the regulator controls the pressure reduction from the intermediate pressure to the low outlet pressure. The regulator has two pressure gauges, one indicating cylinder pressure, the other indicating hose pressure. The adjustment knob of the regulator is sometimes roughly calibrated for pressure, but an accurate setting requires observation of the gauge.

100:

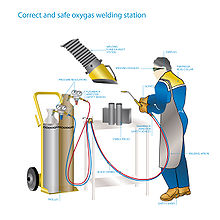

1510:: the tank valve, the regulator valve, and the torch valve. Each gas in the system will have each of these three valves. The regulator converts the high pressure gas inside of the tanks to a low pressure stream suitable for welding. Acetylene cylinders must be maintained in an upright position to prevent the internal acetone and acetylene from separating in the filler material.

697:

108:

116:

1310:

a single flame makes it possible to change the direction of the cut as desired without changing the position of the nozzle or the angle which the torch makes with the direction of the cut, as well as giving a better preheat balance. Manufacturers have developed custom tips for Mapp, propane, and propylene gases to optimize the flames from these alternate fuel gases.

915:

1276:

same size at the beginning of the weld as at the end. If the bead gets too wide, the welder increases the speed of welding travel. If the bead gets too narrow or if the weld puddle is lost, the welder slows down the speed of travel. Welding in the vertical or overhead positions is typically slower than welding in the flat or horizontal positions.

607:

419:

Welding regulators, unlike simpler LPG heating regulators, retain their outlet (hose) pressure gauge and do not rely on the calibration of the adjustment knob. The cheaper single-stage regulators may sometimes omit the cylinder contents gauge, or replace the accurate dial gauge with a cheaper and less precise "rising button" gauge.

1419:. High-carbon steels are difficult to cut because the melting point of the slag is closer to the melting point of the parent metal, so that the slag from the cutting action does not eject as sparks but rather mixes with the clean melt near the cut. This keeps the oxygen from reaching the clean metal and burning it. In the case of

1231:

point for all other flame adjustments because it is so easily defined. This flame is attained when welders, as they slowly open the oxygen valve on the torch body, first see only two flame zones. At that point, the acetylene is being completely burned in the welding oxygen and surrounding air. The flame is chemically neutral.

1503:)) when full. If the tank falls over and damages the valve, the tank can be jettisoned by the compressed oxygen escaping the cylinder at high speed. Tanks in this state are capable of breaking through a brick wall. For this reason, an oxygen tank should never be moved around without its valve cap screwed in place.

1474:

should be worn at all times, including to protect the eyes against glare and flying sparks. Special safety eyewear must be used—both to protect the welder and to provide a clear view through the yellow-orange flare given off by the incandescing flux. In the 1940s cobalt melters’ glasses were borrowed

1254:

The oxidizing flame is the third possible flame adjustment. It occurs when the ratio of oxygen to acetylene required for a neutral flame has been changed to give an excess of oxygen. This flame type is observed when welders add more oxygen to the neutral flame. This flame is hotter than the other two

1230:

The welder can adjust the oxy-acetylene flame to be carburizing (aka reducing), neutral, or oxidizing. Adjustment is made by adding more or less oxygen to the acetylene flame. The neutral flame is the flame most generally used when welding or cutting. The welder uses the neutral flame as the starting

774:

Diesel is a new option in the liquid fuel cutting torch market. Diesel torches claim several advantages over gaseous fuels and gasoline. Diesel is inherently safer and more powerful than gasoline or gaseous fuel such as acetylene and propane, and will cut steel faster and cheaper than either of those

427:

The hoses are designed for use in welding and cutting metal. A double-hose or twinned design can be used, meaning that the oxygen and fuel hoses are joined. If separate hoses are used, they should be clipped together at intervals approximately 3 feet (1 m) apart, although that is not recommended

1364:

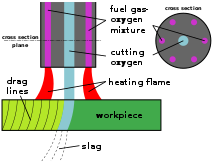

The oxidation of iron by this method is highly exothermic. Once it has started, steel can be cut at a surprising rate, far faster than if it were merely melted through. At this point, the pre-heat jets are there purely for assistance. The rise in temperature will be obvious by the intense glare from

1348:

Cutting is initiated by heating the edge or leading face (as in cutting shapes such as round rod) of the steel to the ignition temperature (approximately bright cherry red heat) using the pre-heat jets only, then using the separate cutting oxygen valve to release the oxygen from the central jet. The

1309:

For cutting, the setup is a little different. A cutting torch has a 60- or 90-degree angled head with orifices placed around a central jet. The outer jets are for preheat flames of oxygen and acetylene. The central jet carries only oxygen for cutting. The use of several preheating flames rather than

1275:

Welding gas pressures using oxy-acetylene are set in accordance with the manufacturer's recommendations. The welder will modify the speed of welding travel to maintain a uniform bead width. Uniformity is a quality attribute indicating good workmanship. Trained welders are taught to keep the bead the

1250:

operations or backhand pipe welding techniques. The feather is caused by incomplete combustion of the acetylene to cause an excess of carbon in the flame. Some of this carbon is dissolved by the molten metal to carbonize it. The carbonizing flame will tend to remove the oxygen from iron oxides which

1234:

The two parts of this flame are the light blue inner cone and the darker blue to colorless outer cone. The inner cone is where the acetylene and the oxygen combine. The tip of this inner cone is the hottest part of the flame. It is approximately 6,000 °F (3,320 °C) and provides enough heat

418:

Some simpler or cheaper oxygen-fuel regulators have only a single-stage regulator, or only a single gauge. A single-stage regulator will tend to allow a reduction in outlet pressure as the cylinder is emptied, requiring manual readjustment. For low-volume users, this is an acceptable simplification.

345:

In short, oxy-fuel equipment is quite versatile, not only because it is preferred for some sorts of iron or steel welding but also because it lends itself to brazing, braze-welding, metal heating (for annealing or tempering, bending or forming), rust, or scale removal, the loosening of corroded nuts

270:

Torches that do not mix fuel with oxygen (combining, instead, atmospheric air) are not considered oxy-fuel torches and can typically be identified by a single tank (oxy-fuel cutting requires two isolated supplies, fuel and oxygen). Most metals cannot be melted with a single-tank torch. Consequently,

1392:

Robotic oxy-fuel cutters sometimes use a high-speed divergent nozzle. This uses an oxygen jet that opens slightly along its passage. This allows the compressed oxygen to expand as it leaves, forming a high-velocity jet that spreads less than a parallel-bore nozzle, allowing a cleaner cut. These are

1279:

The welder must add the filler rod to the molten puddle. The welder must also keep the filler metal in the hot outer flame zone when not adding it to the puddle to protect filler metal from oxidation. Do not let the welding flame burn off the filler metal. The metal will not wet into the base metal

850:

are similar fuels, because LPG gas is liquefied petroleum gas mixed with MPS. It has the storage and shipping characteristics of LPG and has a heat value a little lower than that of acetylene. Because it can be shipped in small containers for sale at retail stores, it is used by hobbyists and large

1372:

Since the melted metal flows out of the workpiece, there must be room on the opposite side of the workpiece for the spray to exit. When possible, pieces of metal are cut on a grate that lets the melted metal fall freely to the ground. The same equipment can be used for oxyacetylene blowtorches and

1267:

The flame is applied to the base metal and held until a small puddle of molten metal is formed. The puddle is moved along the path where the weld bead is desired. Usually, more metal is added to the puddle as it is moved along by dipping metal from a welding rod or filler rod into the molten metal

540:

The melting point of the iron oxide is around half that of the metal being cut. As the metal burns, it immediately turns to liquid iron oxide and flows away from the cutting zone. However, some of the iron oxide remains on the workpiece, forming a hard "slag" which can be removed by gentle tapping

431:

The hoses are color-coded for visual identification. The color of the hoses varies between countries. In the United States, the oxygen hose is green and the fuel hose is red. In the UK and other countries, the oxygen hose is blue (black hoses may still be found on old equipment), and the acetylene

228:

Oxy-acetylene welding is still used for metal-based artwork and in smaller home-based shops, as well as situations where accessing electricity (e.g., via an extension cord or portable generator) would present difficulties. The oxy-acetylene (and other oxy-fuel gas mixtures) welding torch remains a

1295:

is welded but soldered copper flashing is much more common in

America. In the automotive body repair industry before the 1980s, oxyacetylene gas torch welding was seldom used to weld sheet metal, since warping was a byproduct as well as excess heat. Automotive body repair methods at the time were

761:

Oxy-gasoline torches can also cut through paint, dirt, rust and other contaminating surface materials coating old steel. This system provides almost 100% oxidation during cutting, leaving almost no molten steel in the slag to prevent "sticking" together cut material. Operating cost for a gasoline

536:

When cutting, the metal is first heated by the flame until it is cherry red. Once this temperature is attained, oxygen is supplied to the heated parts by pressing the oxygen-blast trigger. This oxygen reacts with the metal, producing more heat and forming an oxide which is then blasted out of the

498:

A check valve lets gas flow in one direction only. It is usually a chamber containing a ball that is pressed against one end by a spring. Gas flow one way pushes the ball out of the way, and a lack of flow or a reverse flow allows the spring to push the ball into the inlet, blocking it. Not to be

1360:

The oxygen flow rate is critical; too little will make a slow ragged cut, while too much will waste oxygen and produce a wide concave cut. Oxygen lances and other custom made torches do not have a separate pressure control for the cutting oxygen, so the cutting oxygen pressure must be controlled

765:

The gasoline can be fed either from a pressurized tank (whose pressure can be hand-pumped or fed from a gas cylinder) or a non-pressurized tank, with the fuel being drawn into the torch by a venturi action created by the pressurized oxygen flow. Another low cost approach commonly used by jewelry

507:

The torch is the tool that the welder holds and manipulates to make the weld. It has a connection and valve for the fuel gas and a connection and valve for the oxygen, a handle for the welder to grasp, and a mixing chamber (set at an angle) where the fuel gas and oxygen mix, with a tip where the

858:

On 30 April 2008 the

Petromont Varennes plant closed its methylacetylene/propadiene crackers. As it was the only North American plant making MAPP gas, many substitutes were introduced by companies that had repackaged the Dow and Varennes product(s) - most of these substitutes are propylene, see

478:

Between the regulator and hose, and ideally between hose and torch on both oxygen and fuel lines, a flashback arrestor and/or non-return valve (check valve) should be installed to prevent flame or oxygen-fuel mixture being pushed back into either cylinder and damaging the equipment or causing a

1559:

metal. When a metal like this is welded or cut, high concentrations of toxic beryllium fumes are released. Long-term exposure to beryllium may result in shortness of breath, chronic cough, and significant weight loss, accompanied by fatigue and general weakness. Other alloying elements such as

1518:

A less obvious hazard of welding is exposure to harmful chemicals. Exposure to certain metals, metal oxides, or carbon monoxide can often lead to severe medical conditions. Damaging chemicals can be produced from the fuel, from the work-piece, or from a protective coating on the work-piece. By

757:

Tests showed that an oxy-gasoline torch can cut steel plate up to 0.5 in (13 mm) thick at the same rate as oxy-acetylene. In plate thicknesses greater than 0.5 in (13 mm) the cutting rate was better than that of oxy-acetylene; at 4.5 in (110 mm) it was three times

489:

from downstream coming back up the hoses and entering the cylinder, possibly rupturing it, as there are quantities of fuel/oxygen mixtures inside parts of the equipment (specifically within the mixer and blowpipe/nozzle) that may explode if the equipment is incorrectly shut down, and acetylene

1320:

The torch's trigger blows extra oxygen at higher pressures down the torch's third tube out of the central jet into the workpiece, causing the metal to burn and blowing the resulting molten oxide through to the other side. The ideal kerf is a narrow gap with a sharp edge on either side of the

1258:

The size of the flame can be adjusted to a limited extent by the valves on the torch and by the regulator settings, but in the main it depends on the size of the orifice in the tip. In fact, the tip should be chosen first according to the job at hand, and then the regulators set accordingly.

1242:

An excess of acetylene creates a reducing (sometimes called carbonizing) flame. This flame is characterized by three flame zones; the hot inner cone, a white-hot "acetylene feather", and the blue-colored outer cone. This is the type of flame observed when oxygen is first added to the burning

1482:

eyewear, developed for glassblowers in the 1960s, was also borrowed—until many complained of eye problems from excessive infrared, blue light, and insufficient shading. Today very good eye protection can be found designed especially for gas-welding aluminum that cuts the sodium orange flare

854:

Further, more of it can be stored in a single place at one time, as the increased compressibility allows for more gas to be put into a tank. MAPP gas can be used at much higher pressures than acetylene, sometimes up to 40 or 50 psi in high-volume oxy-fuel cutting torches which can cut up to

248:, a welding torch is used to weld metals. Welding metal results when two pieces are heated to a temperature that produces a shared pool of molten metal. The molten pool is generally supplied with additional metal called filler. Filler material selection depends upon the metals to be welded.

200:

electrodes in the late 1920s that were capable of making sound welds in steel, oxy-acetylene welding was the only process capable of making welds of exceptionally high quality in virtually all metals in commercial use at the time. These included not only carbon steel but also alloy steels,

388:

There are also examples of both non-pressurized and pressurized liquid fuel cutting torches, usually using gasoline (petrol). These are used for their increased cutting power over gaseous fuel systems and also greater portability compared to systems requiring two high pressure tanks.

1300:

became the industry standard. Since the 1970s, when high strength steel became the standard for automotive manufacturing, electric welding became the preferred method. After the 1980s, oxyacetylene torches fell out of use for sheet metal welding in the industrialized world.

443:

The threaded connectors on the hoses are handed to avoid accidental mis-connection: the thread on the oxygen hose is right-handed (as normal), while the fuel gas hose has a left-handed thread. The left-handed threads also have an identifying groove cut into their nuts.

758:

faster. Additionally the liquid fuel vapour is about 4x the density of a gaseous fuel. A high velocity cutting flame is produced by the huge volume expansion while the liquid transitions to a vapour so the cutting flame can cut across voids (air space between plates).

624:

Acetylene is the primary fuel for oxy-fuel welding and is the fuel of choice for repair work and general cutting and welding. Acetylene gas is shipped in special cylinders designed to keep the gas dissolved. The cylinders are packed with porous materials (e.g.

524:

A welding torch head is used to weld metals. It can be identified by having only one or two pipes running to the nozzle, no oxygen-blast trigger, and two valve knobs at the bottom of the handle letting the operator adjust the oxygen and fuel flow respectively.

1271:

The amount of heat applied to the metal is a function of the welding tip size, the speed of travel, and the welding position. The flame size is determined by the welding tip size. The proper tip size is determined by the metal thickness and the joint design.

1543:

and water vapor. When the secondary reaction does not burn all of the reactants from the primary reaction, the welding process can often produce large amounts of carbon monoxide. Carbon monoxide is also the byproduct of many other incomplete fuel reactions.

1389:. Oxy-acetylene torches can easily cut through ferrous materials in excess of 200 mm (7.9 in). Oxygen lances are used in scrapping operations and cut sections thicker than 200 mm. Cut-off grinders are useless for these kinds of application.

1630:

is usually employed. The flame burns backwards into the hose, causing a popping or squealing noise. It can cause an explosion in the hose with the potential to injure or kill the operator. Using a lower pressure than recommended can cause a flashback.

410:

Most regulators have two stages. The first stage is a fixed-pressure regulator, which releases gas from the cylinder at a constant intermediate pressure, despite the pressure in the cylinder falling as the gas in it is consumed. This is similar to the

2058:

Modern methods of welding as applied to workshop practice, describing various methods: oxy-acetylene welding, electric seam welding ... eye protection in welding operations .... New York: D. Van

Nostrand Company, 1922. Print. Chapter 2 Lead Burning,

855:

12-inch-thick (300 mm) steel. Other welding gases that develop comparable temperatures need special procedures for safe shipping and handling. MPS and MAPP are recommended for cutting applications in particular, rather than welding applications.

428:

for cutting applications, because beads of molten metal given off by the process can become lodged between the hoses where they are held together, and burn through, releasing the pressurized gas inside, which in the case of fuel gas usually ignites.

307:

In stone working for "flaming" where the stone is heated and a top layer crackles and breaks. A steel circular brush is attached to an angle grinder and used to remove the first layer leaving behind a bumpy surface similar to hammered

1280:

and will look like a series of cold dots on the base metal. There is very little strength in a cold weld. When the filler metal is properly added to the molten puddle, the resulting weld will be stronger than the original base metal.

808:

The oxygen and the hydrogen are led off the electrolysis cell separately and are fed into the two gas connections of an ordinary oxy-gas torch. This happens in the water torch, which is sometimes used in small torches used in making

499:

confused with a flashback arrestor, a check valve is not designed to block a shock wave. The shock wave could occur while the ball is so far from the inlet that the wave will get past the ball before it can reach its off position.

1522:

The most common fuel used in welding is acetylene, which has a two-stage reaction. The primary chemical reaction involves the acetylene disassociating in the presence of oxygen to produce heat, carbon monoxide, and hydrogen gas:

561:

A typical oxy-fuel torch, called an equal-pressure torch, merely mixes the two gases. In an injector torch, high-pressure oxygen comes out of a small nozzle inside the torch head which drags the fuel gas along with it, using the

1361:

using the oxygen regulator. The oxygen cutting pressure should match the cutting tip oxygen orifice. The tip manufacturer's equipment data should be reviewed for the proper cutting oxygen pressures for the specific cutting tip.

867:

Propylene is used in production welding and cutting. It cuts similarly to propane. When propylene is used, the torch rarely needs tip cleaning. There is often a substantial advantage to cutting with an injector torch (see the

1180:

of liquefied air and shipped to the welding site in high-pressure vessels (commonly called "tanks" or "cylinders") at a pressure of about 21,000 kPa (3,000 lbf/in² = 200 atmospheres). It is also shipped as a liquid in

890:

Propane does not burn as hot as acetylene in its inner cone, and so it is rarely used for welding. Propane, however, has a very high number of BTUs per cubic foot in its outer cone, and so with the right torch

1451:

More than 1/7 the capacity of the cylinder should not be used per hour. This causes the acetone inside the acetylene cylinder to come out of the cylinder and contaminate the hose and possibly the torch.

1243:

acetylene. The feather is adjusted and made ever smaller by adding increasing amounts of oxygen to the flame. A welding feather is measured as 2X or 3X, with X being the length of the inner flame cone.

1423:, graphite between the grains and the shape of the grains themselves interfere with the cutting action of the torch. Stainless steels cannot be cut either because the material does not burn readily.

2109:

984:

with

Gasoline was 25% that of propane and 10% that of acetylene. Numbers will vary depending on source of oxygen or fuel and on the type of cutting and the cutting environment or situation.

872:

section) rather than an equal-pressure torch when using propylene. Quite a few North

American suppliers have begun selling propylene under proprietary trademarks such as FG2 and Fuel-Max.

1491:

Fuel and oxygen tanks should be fastened securely and upright to a wall, post, or portable cart. An oxygen tank is especially dangerous because the gas is stored at a pressure of 21

490:

decomposes at excessive pressures or temperatures. In case the pressure wave has created a leak downstream of the flashback arrestor, it will remain switched off until someone resets it.

1393:

not used for cutting by hand since they need very accurate positioning above the work. Their ability to produce almost any shape from large steel plates gives them a secure future in

851:

industrial companies and shipyards because it does not polymerize at high pressures — above 15 psi or so (as acetylene does) and is therefore much less dangerous than acetylene.

1291:' was much more common in the 19th century to make some pipe connections and tanks. Great skill is required, but it can be quickly learned. In building construction today some lead

675:

As acetylene is unstable at a pressure roughly equivalent to 33 ft (10 m) underwater, water-submerged cutting and welding is reserved for hydrogen rather than acetylene.

1381:-driven cut-off grinder. The advantages when cutting large sections are obvious: an oxy-fuel torch is light, small and quiet and needs very little effort to use, whereas an

1169:, which chemically combines with the fuel to produce the heat for welding. This is called 'oxidation', but the more specific and more commonly used term in this context is '

1483:

completely and provides the necessary protection from ultraviolet, infrared, blue light and impact, according to ANSI Z87-1989 safety standards for a

Special Purpose Lens.

2381:

1408:

for joule than acetylene, although propane does not produce acetylene's very neat cut profile. Propane also finds a place in production, for cutting very large sections.

549:

A rose bud torch is used to heat metals for bending, straightening, etc. where a large area needs to be heated. It is so-called because the flame at the end looks like a

537:

cut. It is the heat that continues the cutting process. The cutting torch only heats the metal to start the process; further heat is provided by the burning metal.

1837:

2343:

939:

766:

makers in Asia is using air bubbled through a gasoline container by a foot-operated air pump, and burning the fuel-air mixture in a specialized welding torch.

1447:

Oxyacetylene welding/cutting is generally considered not to be difficult, but there are a good number of subtle safety points that should be learned such as:

403:

The regulator ensures that pressure of the gas from the tanks matches the required pressure in the hose. The flow rate is then adjusted by the operator using

185:/air flame burns at about 2,250 K (1,980 °C; 3,590 °F), a propane/oxygen flame burns at about 2,526 K (2,253 °C; 4,087 °F), an

1204:) pass. This gives a purity of oxygen of about 93%. This method works well for brazing, but higher-purity oxygen is necessary to produce a clean, slag-free

440:, is used, the fuel hose should be orange, indicating that it is compatible with LPG. LPG will damage an incompatible hose, including most acetylene hoses.

1246:

The unburned carbon insulates the flame and drops the temperature to approximately 5,000 °F (2,760 °C). The reducing flame is typically used for

2271:

1996:

314:

In jewelry production for "water welding" using a water torch (an oxyhydrogen torch whose gas supply is generated immediately by electrolysis of water).

2116:

820:

The mixed oxygen and hydrogen are drawn from the electrolysis cell and are led into a special torch designed to prevent flashback. See oxyhydrogen.

2993:

3003:

2374:

672:), the highest among commonly used gaseous fuels. As a fuel, acetylene's primary disadvantage in comparison to other fuels is its high price.

2696:

2212:

2169:

1904:

533:

A cutting torch head is used to cut materials. It is similar to a welding torch, but can be identified by the oxygen blast trigger or lever.

482:

European practice is to fit flashback arrestors at the regulator and check valves at the torch. US practice is to fit both at the regulator.

1268:

puddle. The metal puddle will travel towards where the metal is the hottest. This is accomplished through torch manipulation by the welder.

614:

with water. This is used where acetylene cylinders are not available. The term 'Las Karbit' means acetylene (carbide) welding in

Indonesian.

707:

64:

3050:

2968:

1876:

726:

2367:

2336:

2247:

1968:

1792:

1742:

1718:

1385:

is heavy and noisy and needs considerable operator exertion and may vibrate severely, leading to stiff hands and possible long-term

957:

744:

86:

1626:

is the condition of the flame propagating down the hoses of an oxy-fuel welding and cutting system. To prevent such a situation a

1519:

increasing ventilation around the welding environment, exposure to harmful chemicals are significantly reduced from any source.

1900:

2286:

3045:

830:

2020:

1478:

However, the lack of protection from impact, ultra-violet, infrared and blue light caused severe eyestrain and eye damage.

1217:

678:

2329:

1841:

2316:

930:

2464:

2044:

1862:

722:

598:. Liquid fuel cutting systems use such fuels as Gasoline (Petrol) Diesel, Kerosene and possibly some aviation fuels.

354:

The apparatus used in gas welding consists basically of an oxygen source and a fuel gas source (usually contained in

57:

51:

895:) can make a faster and cleaner cut than acetylene, and is much more useful for heating and bending than acetylene.

2889:

2441:

1650:

1292:

197:

1377:

For a basic oxy-acetylene rig, the cutting speed in light steel section will usually be nearly twice as fast as a

3080:

3008:

2689:

2456:

1640:

980: in (13 mm) plate. Costing is based on an average cost for oxygen and different fuels in May 2012. The

475:

is needed. It is designed to operate before the detonation wave makes it from the hose side to the supply side.

362:

regulators and two flexible hoses (one for each cylinder), and a torch. This sort of torch can also be used for

68:

2734:

2431:

1655:

218:

2973:

2963:

2958:

2834:

2658:

2406:

1401:

1297:

583:

433:

2296:

1758:

2998:

2988:

2514:

2421:

1539:. A secondary reaction follows where the carbon monoxide and hydrogen combine with more oxygen to produce

1386:

794:

234:

1349:

oxygen chemically combines with the iron in the ferrous material to oxidize the iron quickly into molten

2978:

2864:

2499:

2494:

2469:

2446:

2426:

1645:

1496:

646:

237:, preparation, and localized heat treating. In addition, oxy-fuel cutting is still widely used, both in

1932:

259:. A stream of oxygen is then trained on the metal, burning it into a metal oxide that flows out of the

1611:". This condition rarely lasts longer than 24 hours, but severe cases can be fatal. Not unlike common

508:

flame forms. Two basic types of torches are positive pressure type and low pressure or injector type.

3018:

3013:

2939:

2789:

2682:

2565:

2509:

1314:

256:

925:

166:

or cut metals. French engineers Edmond Fouché and

Charles Picard became the first to develop oxygen-

2983:

2909:

2824:

2474:

2239:

1439:

1235:

to easily melt steel. In the inner cone the acetylene breaks down and partly burns to hydrogen and

574:

Oxy-fuel processes may use a variety of fuel gases (or combustible liquids), the most common being

385:-sized) gas cylinders worn on the user's back in a backpack harness, for rescue work, and similar.

1732:

3060:

2591:

2529:

2504:

2479:

2436:

2411:

2140:

1685:

1675:

1627:

630:

472:

398:

294:

Neutral flame is used for joining and cutting of all ferrous and non-ferrous metals except brass.

291:

Heating metal: in automotive and other industries for the purposes of loosening seized fasteners.

804:

of water in an apparatus which is connected directly to the torch. Types of this sort of torch:

660:

There is about 1,700 kPa (247 psi) pressure in the tank when full. When combined with

1222:

2869:

2794:

2633:

2628:

2281:

2243:

2208:

2165:

2159:

1964:

1788:

1738:

1714:

1670:

1500:

1455:

1192:

It is also possible to separate oxygen from air by passing the air, under pressure, through a

981:

447:

Gas-tight connections between the flexible hoses and rigid fittings are made by using crimped

1615:, fevers, chills, nausea, cough, and fatigue are common effects of high zinc oxide exposure.

898:

The maximum neutral flame temperature of propane in oxygen is 2,822 °C (5,112 °F).

718:

407:

on the torch. Accurate flow control with a needle valve relies on a constant inlet pressure.

3075:

3065:

3040:

2934:

2489:

2390:

1608:

412:

2141:"Zinc Metal Fume Fever : A Case Study : Blacksmithing How-to on anvilfire iForge"

455:, often referred to as 'O' clips, over barbed spigots. The use of worm-drive hose clips or

3070:

3055:

2601:

1660:

1471:

1324:

1236:

1166:

626:

611:

382:

175:

1353:, producing the cut. Initiating a cut in the middle of a workpiece is known as piercing.

178:

to allow localized melting of the workpiece material (e.g. steel) in a room environment.

2191:

1321:

workpiece; overheating the workpiece and thus melting through it causes a rounded edge.

511:

2919:

2859:

2596:

2560:

1665:

1540:

1431:

1332:

563:

339:

works, as platinum is fusible only in the oxyhydrogen flame and in an electric furnace.

238:

123:

1239:, which in the outer cone combine with more oxygen from the surrounding air and burn.

553:. A welding torch can also be used to heat small areas such as rusted nuts and bolts.

3034:

2914:

2879:

2814:

2809:

2739:

2575:

2570:

2534:

2484:

2416:

2232:

1908:

1680:

1492:

1382:

1366:

1251:

may be present, a fact which has caused the flame to be known as a "reducing flame".

642:

1369:

is a tool that also uses rapid oxidation of iron to cut through almost any material.

213:. In recent decades it has been superseded in almost all industrial uses by various

2854:

2799:

2764:

2759:

2555:

2524:

2352:

1416:

1412:

1394:

1340:

1288:

1177:

801:

456:

404:

355:

2301:

1373:

welding torches, by exchanging the part of the torch in front of the torch valves.

2202:

1782:

641:, as acetylene is soluble in acetone. This method is necessary because above 207

196:

During the early 20th century, before the development and availability of coated

2944:

2779:

2749:

2606:

2398:

2096:

1182:

814:

784:

650:

587:

378:

214:

186:

2904:

2884:

2819:

2705:

2653:

2648:

2311:

1604:

1600:

1575:

More common are the anti-rust coatings on many manufactured metal components.

1350:

1247:

1170:

669:

486:

298:

111:

Torch-cut pipe with visible drag lines (a signature of the torch's oxygen jet)

17:

2929:

2924:

2899:

2874:

2844:

2754:

2721:

2643:

2638:

2550:

1612:

1596:

1565:

1552:

1420:

1400:

Oxy-propane torches are usually used for cutting up scrap to save money, as

790:

654:

619:

579:

575:

468:

448:

329:

325:

272:

210:

206:

202:

190:

167:

107:

99:

1461:

Proper ventilation when welding will help to avoid large chemical exposure.

115:

1855:

193:/oxygen flame burns at about 3,773 K (3,500 °C; 6,332 °F).

2839:

2804:

2716:

1584:

1479:

1197:

834:

634:

595:

591:

550:

359:

336:

222:

155:

151:

31:

2849:

2829:

2769:

2744:

2663:

2623:

1580:

1561:

1193:

1186:

884:

810:

665:

638:

452:

437:

367:

276:

230:

182:

163:

606:

2894:

1569:

1556:

1548:

1435:

Oxygas welding station (keep cylinders and hoses away from the flame)

1378:

880:

800:

For some oxyhydrogen torches the oxygen and hydrogen are produced by

661:

363:

159:

1313:

The flame is not intended to melt the metal, but to bring it to its

1205:

260:

2784:

2291:

1592:

1507:

1438:

1430:

1405:

1339:

1331:

1323:

1201:

677:

515:

The top torch is a welding torch and the bottom is a cutting torch

510:

318:

264:

189:

flame burns at 3,073 K (2,800 °C; 5,072 °F) and an

122:

114:

98:

1588:

1576:

1551:, aluminum, and other base metals are occasionally alloyed with

1547:

Almost every piece of metal is an alloy of one type or another.

1475:

from steel foundries and were still available until the 1980s.

1284:

762:

torch is typically 75-90% less than using propane or

Acetylene.

371:

346:

and bolts, and is a ubiquitous means of cutting ferrous metals.

2678:

2363:

2325:

2321:

2674:

908:

690:

171:

36:

1458:(15 psi) pressure. It is unstable and explosively decomposes.

1344:

Cutting a rail just before renewing the rails and the ballast

869:

467:

Acetylene is not just flammable; in certain conditions it is

1820:

1818:

1816:

1814:

1812:

1810:

1808:

1806:

1804:

1572:, and aluminum can cause sickness to those who are exposed.

970:

The following is a comparison of operating costs in cutting

901:

Propane is cheaper than acetylene and easier to transport.

150:

are processes that use fuel gases (or liquid fuels such as

2306:

1961:

Chemical

Discovery and Invention in the Twentieth Century

1506:

On an oxyacetylene torch system there are three types of

459:

is specifically forbidden in the UK and other countries.

221:, the capability of welding very reactive metals such as

1787:. Tata McGraw-Hill Education. 2000-05-01. p. 106.

714:

682:

Compressed gas cylinders containing oxygen and MAPP gas

370:. The cylinders are often carried in a special wheeled

1856:"Safety in gas welding, cutting and similar processes"

1882:. Virginia Polytechnic Institute and State University

1365:

the ejected material, even through proper goggles. A

1713:, p.365. John Wright & Songs, Inc., New Jersey.

1226:

Reducing, neutral and oxidizing oxyacetylene flames.

725:, and by adding encyclopedic content written from a

2584:

2543:

2455:

2397:

2260:(ninth ed.). The Welding Engineer staff. 1938.

2110:"Oxygen And Acetylene Use And Safety - AR Training"

2045:"DAVCO SUPACUT Oxy-Petrol/Gasoline Cutting Systems"

1997:"DH3 Lightweight Gas Cutting & Welding Torches"

1824:

The Oxy-Acetylene Handbook, Union Carbide Corp 1975

1734:

CRC Handbook of Chemistry and Physics, 85th Edition

1603:metals have a very heavy zinc coating. Exposure to

610:Acetylene generator as used in Bali by reaction of

217:methods offering greater speed and, in the case of

2231:

2083:Authentic Aluminum Gas Welding: The Method Revived

1189:jar) to places that use large amounts of oxygen.

935:obsolete and proprietary non matching information.

789:Hydrogen has a clean flame and is good for use on

2282:Using Oxy-Fuel Welding on Aircraft Aluminum Sheet

1356:It is worth noting several things at this point:

30:"Oxyacetylene" redirects here. For the song, see

2207:(4th, illustrated ed.). Cengage Learning.

271:single-tank torches are typically suitable for

1711:Scientific American Inventions and Discoveries

297:Depositing metal to build up a surface, as in

119:A cutting torch being used to cut a steel pipe

27:Metalworking technique using a fuel and oxygen

2690:

2375:

2337:

1443:Gas welding/cutting goggles and safety helmet

8:

1832:

1830:

332:, in theatres or optical ("magic") lanterns.

287:Oxy-fuel torches are or have been used for:

241:and light industrial and repair operations.

2297:An e-book about oxy-gas cutting and welding

637:), then filled to around 50% capacity with

311:In the glass industry for "fire polishing".

2697:

2683:

2675:

2382:

2368:

2360:

2344:

2330:

2322:

1411:Oxy-acetylene can cut only low- to medium-

1963:. Adamant Media Corporation. p. 80.

958:Learn how and when to remove this message

745:Learn how and when to remove this message

170:welding in 1903. Pure oxygen, instead of

87:Learn how and when to remove this message

2272:"Welding and Cutting with Oxyacetylene"

1959:William Augustus Tilden (January 1999).

1221:

1176:Oxygen is usually produced elsewhere by

986:

876:Butane, propane and butane/propane mixes

605:

317:In automotive repair, removing a seized

106:

50:This article includes a list of general

1702:

413:first stage of a scuba-diving regulator

255:, a torch is used to heat metal to its

2230:Althouse; Turnquist; Bowditch (1970).

2068:

1983:

1927:

1925:

1838:"Fundamentals of Professional Welding"

1296:crude and yielded improprieties until

706:contains content that is written like

328:to obtain a bright white light called

2164:. Pearson South Africa. p. 286.

1033:Oxygen consumption, litres per minute

7:

2204:Welding: Principles and Applications

2099:Discovery Channel, October 18, 2006.

1651:Shielded metal arc ("stick") welding

1607:fumes can lead to a sickness named "

664:, acetyline burns at 3,200 to 3,500

649:) (absolute pressure), acetylene is

304:Also, oxy-hydrogen flames are used:

1646:Gas metal arc ("MIG"/"MAG") welding

1196:sieve that selectively adsorbs the

1005:Fuel consumption, litres per minute

892:

578:. Other gases that may be used are

127:Oxy-acetylene Welding (OAW) station

1656:Tungsten inert gas ("TIG") welding

1165:Oxygen is not the fuel. It is the

56:it lacks sufficient corresponding

25:

2302:Oxy-fuel torch at Everything2.com

1877:"Portable Oxy-Fuel Gas Equipment"

1019:Fuel consumption, litres per hour

913:

695:

485:The flashback arrestor prevents

229:mainstay heat source for manual

41:

2442:Shielded metal (Stick/MMA/SMAW)

2432:Gas tungsten (Heliarc/TIG/GTAW)

2312:Video of how to weld lead sheet

2025:AES Industrial Supplies Limited

2001:AES Industrial Supplies Limited

1840:. 23 April 2008. Archived from

1454:Acetylene is dangerous above 1

2427:Gas metal (Microwire/MIG/GMAW)

2292:welding history at Welding.com

2158:Swift, P.; Murray, J. (2008).

1901:"Special Hazards of Acetylene"

1397:and in many other industries.

1328:Oxygen-rich butane torch flame

831:Methylacetylene-propadiene gas

154:or petrol, diesel, biodiesel,

1:

2190:Miller, Samuel Wylie (1916).

1759:"Adiabatic Flame Temperature"

1737:. CRC Press. pp. 15–52.

1731:Lide, David R. (2004-06-29).

1218:Oxidizing and reducing flames

2407:Atomic hydrogen (Athydo/AHW)

1784:Basic Mech Engg,3E Tnc Syllb

1336:Fuel-rich butane torch flame

377:There have been examples of

1185:type vessels (like a large

933:. The specific problem is:

324:Formerly, to heat lumps of

3097:

3051:Metalworking cutting tools

1763:www.engineeringtoolbox.com

1587:are often used to protect

1470:Proper protection such as

1215:

1047:Millimetres cut per minute

929:to meet Knowledge (XXG)'s

840:Methylacetylene-propadiene

828:

782:

617:

396:

174:, is used to increase the

146:in the United States) and

29:

2953:

2730:

2712:

2619:

2465:Electric resistance (ERW)

2359:

2307:Torch Brazing Information

2201:Jeffus, Larry F. (1997).

1709:Carlisle, Rodney (2004).

1641:List of welding processes

1200:and lets the oxygen (and

381:cutting sets with small (

103:Principle of burn cutting

2994:Machine and metalworking

2258:The Welding Encyclopedia

219:gas tungsten arc welding

3004:Measuring and alignment

2317:Working with lead sheet

2196:. The Industrial Press.

2095:"Air Cylinder Rocket."

1145:Cost to cut 100 ft

584:liquified petroleum gas

434:liquefied petroleum gas

432:(fuel) hose is red. If

71:more precise citations.

2047:, Retrieved 2022-12-23

1444:

1436:

1387:vibration white finger

1345:

1337:

1329:

1227:

863:Propylene and fuel gas

795:hydrogen embrittlement

683:

647:pounds per square inch

615:

516:

128:

120:

112:

104:

3046:Hydrogen technologies

2865:Random orbital sander

2659:Tools and terminology

2193:Oxy-acetylene Welding

2021:"Gas Cutting Torches"

1487:Safety with cylinders

1442:

1434:

1343:

1335:

1327:

1225:

1131:Cutting cost per foot

727:neutral point of view

681:

609:

514:

479:cylinder to explode.

279:but not for welding.

126:

118:

110:

102:

2969:Cutting and abrasive

2790:Electric motor brake

2287:More on oxyacetylene

2081:White, Kent (2008),

1933:"Oxy-Gasoline Torch"

1555:, which is a highly

1315:ignition temperature

1075:Oxygen cost per hour

940:improve this article

436:(LPG) fuel, such as

257:kindling temperature

136:oxyacetylene welding

2495:Friction stir (FSW)

2470:Electron-beam (EBW)

2240:Goodheart - Willcox

1103:Metres cut per hour

988:

719:promotional content

2592:Heat-affected zone

2520:Oxyacetylene (OAW)

1686:Underwater welding

1676:Plasma arc cutting

1628:flashback arrestor

1445:

1437:

1346:

1338:

1330:

1228:

1161:The role of oxygen

1061:Fuel cost per hour

987:

721:and inappropriate

684:

670:degrees Fahrenheit

631:diatomaceous earth

616:

517:

473:flashback arrestor

399:Pressure regulator

129:

121:

113:

105:

3028:

3027:

2870:Reciprocating saw

2672:

2671:

2615:

2614:

2475:Electroslag (ESW)

2422:Flux-cored (FCAW)

2274:Popular Mechanics

2214:978-0-8273-8240-4

2171:978-1-77025-226-4

2145:www.anvilfire.com

2085:, TM Technologies

1671:Oxyhydrogen flame

1514:Chemical exposure

1158:

1157:

1117:Feet cut per hour

968:

967:

960:

931:quality standards

922:This article may

755:

754:

747:

541:and/or grinding.

176:flame temperature

148:oxy-fuel cutting

134:(commonly called

97:

96:

89:

16:(Redirected from

3088:

3081:Industrial gases

2935:Thickness planer

2699:

2692:

2685:

2676:

2505:Laser beam (LBW)

2412:Electrogas (EGW)

2384:

2377:

2370:

2361:

2346:

2339:

2332:

2323:

2278:pp. 948–953

2261:

2253:

2237:

2218:

2197:

2176:

2175:

2155:

2149:

2148:

2137:

2131:

2130:

2128:

2127:

2121:

2115:. Archived from

2114:

2106:

2100:

2093:

2087:

2086:

2078:

2072:

2066:

2060:

2054:

2048:

2041:

2035:

2034:

2032:

2031:

2017:

2011:

2010:

2008:

2007:

1993:

1987:

1981:

1975:

1974:

1956:

1950:

1949:

1947:

1946:

1937:

1929:

1920:

1919:

1917:

1916:

1907:. Archived from

1897:

1891:

1890:

1888:

1887:

1881:

1873:

1867:

1866:

1860:

1852:

1846:

1845:

1834:

1825:

1822:

1799:

1798:

1779:

1773:

1772:

1770:

1769:

1755:

1749:

1748:

1728:

1722:

1707:

1609:metal fume fever

989:

979:

978:

974:

963:

956:

952:

949:

943:

917:

916:

909:

825:MPS and MAPP gas

750:

743:

739:

736:

730:

708:an advertisement

699:

698:

691:

668:(5,790 to 6,330

633:, or (formerly)

586:(LPG), propane,

463:Non-return valve

253:oxy-fuel cutting

246:oxy-fuel welding

132:Oxy-fuel welding

92:

85:

81:

78:

72:

67:this article by

58:inline citations

45:

44:

37:

21:

3096:

3095:

3091:

3090:

3089:

3087:

3086:

3085:

3031:

3030:

3029:

3024:

3023:

2949:

2845:Power miter saw

2726:

2708:

2703:

2673:

2668:

2611:

2602:Residual stress

2580:

2539:

2457:Other processes

2451:

2447:Submerged (SAW)

2393:

2388:

2355:

2350:

2276:, December 1935

2268:

2256:

2250:

2229:

2226:

2224:Further reading

2221:

2215:

2200:

2189:

2185:

2180:

2179:

2172:

2157:

2156:

2152:

2139:

2138:

2134:

2125:

2123:

2119:

2112:

2108:

2107:

2103:

2094:

2090:

2080:

2079:

2075:

2067:

2063:

2056:Davies, J. H..

2055:

2051:

2042:

2038:

2029:

2027:

2019:

2018:

2014:

2005:

2003:

1995:

1994:

1990:

1982:

1978:

1971:

1958:

1957:

1953:

1944:

1942:

1935:

1931:

1930:

1923:

1914:

1912:

1899:

1898:

1894:

1885:

1883:

1879:

1875:

1874:

1870:

1858:

1854:

1853:

1849:

1836:

1835:

1828:

1823:

1802:

1795:

1781:

1780:

1776:

1767:

1765:

1757:

1756:

1752:

1745:

1730:

1729:

1725:

1708:

1704:

1699:

1694:

1661:Air-arc cutting

1637:

1621:

1538:

1534:

1530:

1526:

1516:

1489:

1472:welding goggles

1468:

1429:

1404:is far cheaper

1307:

1265:

1237:carbon monoxide

1220:

1214:

1167:oxidizing agent

1163:

976:

972:

971:

964:

953:

947:

944:

937:

918:

914:

907:

905:Operating costs

878:

865:

837:

829:Main articles:

827:

787:

781:

772:

751:

740:

734:

731:

712:

700:

696:

689:

666:degrees Celsius

622:

612:calcium carbide

604:

572:

559:

547:

531:

522:

505:

496:

465:

425:

401:

395:

352:

285:

93:

82:

76:

73:

63:Please help to

62:

46:

42:

35:

28:

23:

22:

15:

12:

11:

5:

3094:

3092:

3084:

3083:

3078:

3073:

3068:

3063:

3058:

3053:

3048:

3043:

3033:

3032:

3026:

3025:

3022:

3021:

3016:

3011:

3006:

3001:

2996:

2991:

2986:

2981:

2976:

2971:

2966:

2961:

2959:Types of tools

2955:

2954:

2951:

2950:

2948:

2947:

2942:

2937:

2932:

2927:

2922:

2920:Soldering iron

2917:

2912:

2907:

2902:

2897:

2892:

2887:

2882:

2877:

2872:

2867:

2862:

2860:Radial arm saw

2857:

2852:

2847:

2842:

2837:

2832:

2827:

2822:

2817:

2812:

2807:

2802:

2797:

2792:

2787:

2782:

2777:

2772:

2767:

2762:

2757:

2752:

2747:

2742:

2737:

2731:

2728:

2727:

2725:

2724:

2719:

2713:

2710:

2709:

2704:

2702:

2701:

2694:

2687:

2679:

2670:

2669:

2667:

2666:

2661:

2656:

2651:

2646:

2641:

2636:

2631:

2626:

2620:

2617:

2616:

2613:

2612:

2610:

2609:

2604:

2599:

2597:Photokeratitis

2594:

2588:

2586:

2582:

2581:

2579:

2578:

2573:

2568:

2563:

2558:

2553:

2547:

2545:

2541:

2540:

2538:

2537:

2532:

2527:

2522:

2517:

2515:Magnetic pulse

2512:

2507:

2502:

2497:

2492:

2487:

2482:

2477:

2472:

2467:

2461:

2459:

2453:

2452:

2450:

2449:

2444:

2439:

2434:

2429:

2424:

2419:

2414:

2409:

2403:

2401:

2395:

2394:

2389:

2387:

2386:

2379:

2372:

2364:

2357:

2356:

2351:

2349:

2348:

2341:

2334:

2326:

2320:

2319:

2314:

2309:

2304:

2299:

2294:

2289:

2284:

2279:

2267:

2266:External links

2264:

2263:

2262:

2254:

2248:

2234:Modern Welding

2225:

2222:

2220:

2219:

2213:

2198:

2186:

2184:

2181:

2178:

2177:

2170:

2161:FCS Welding L2

2150:

2132:

2101:

2088:

2073:

2061:

2049:

2036:

2012:

1988:

1976:

1969:

1951:

1921:

1892:

1868:

1847:

1844:on 2008-04-23.

1826:

1800:

1793:

1774:

1750:

1743:

1723:

1701:

1700:

1698:

1695:

1693:

1690:

1689:

1688:

1683:

1678:

1673:

1668:

1666:Flame cleaning

1663:

1658:

1653:

1648:

1643:

1636:

1633:

1620:

1617:

1541:carbon dioxide

1536:

1532:

1528:

1524:

1515:

1512:

1488:

1485:

1467:

1466:Eye protection

1464:

1463:

1462:

1459:

1452:

1428:

1425:

1375:

1374:

1370:

1362:

1306:

1303:

1264:

1261:

1216:Main article:

1213:

1212:Types of flame

1210:

1208:when cutting.

1162:

1159:

1156:

1155:

1152:

1149:

1146:

1142:

1141:

1138:

1135:

1132:

1128:

1127:

1124:

1121:

1118:

1114:

1113:

1110:

1107:

1104:

1100:

1099:

1096:

1093:

1090:

1089:Total per hour

1086:

1085:

1082:

1079:

1076:

1072:

1071:

1068:

1065:

1062:

1058:

1057:

1054:

1051:

1048:

1044:

1043:

1040:

1037:

1034:

1030:

1029:

1026:

1023:

1020:

1016:

1015:

1012:

1009:

1006:

1002:

1001:

998:

995:

992:

966:

965:

921:

919:

912:

906:

903:

893:injector style

877:

874:

864:

861:

826:

823:

822:

821:

818:

780:

777:

771:

768:

753:

752:

723:external links

703:

701:

694:

688:

685:

603:

600:

571:

568:

564:Venturi effect

558:

557:Injector torch

555:

546:

545:Rose bud torch

543:

530:

527:

521:

518:

504:

501:

495:

492:

464:

461:

424:

421:

397:Main article:

394:

391:

351:

348:

343:

342:

341:

340:

333:

322:

315:

312:

309:

302:

295:

292:

284:

281:

239:heavy industry

95:

94:

49:

47:

40:

26:

24:

14:

13:

10:

9:

6:

4:

3:

2:

3093:

3082:

3079:

3077:

3074:

3072:

3069:

3067:

3064:

3062:

3059:

3057:

3054:

3052:

3049:

3047:

3044:

3042:

3039:

3038:

3036:

3020:

3017:

3015:

3012:

3010:

3007:

3005:

3002:

3000:

2997:

2995:

2992:

2990:

2987:

2985:

2982:

2980:

2977:

2975:

2972:

2970:

2967:

2965:

2962:

2960:

2957:

2956:

2952:

2946:

2943:

2941:

2938:

2936:

2933:

2931:

2928:

2926:

2923:

2921:

2918:

2916:

2915:Soldering gun

2913:

2911:

2908:

2906:

2903:

2901:

2898:

2896:

2893:

2891:

2888:

2886:

2883:

2881:

2880:Rotary hammer

2878:

2876:

2873:

2871:

2868:

2866:

2863:

2861:

2858:

2856:

2853:

2851:

2848:

2846:

2843:

2841:

2838:

2836:

2833:

2831:

2828:

2826:

2823:

2821:

2818:

2816:

2815:Impact wrench

2813:

2811:

2810:Impact driver

2808:

2806:

2803:

2801:

2798:

2796:

2793:

2791:

2788:

2786:

2783:

2781:

2778:

2776:

2775:Cutting torch

2773:

2771:

2768:

2766:

2763:

2761:

2758:

2756:

2753:

2751:

2748:

2746:

2743:

2741:

2740:Angle grinder

2738:

2736:

2733:

2732:

2729:

2723:

2720:

2718:

2715:

2714:

2711:

2707:

2700:

2695:

2693:

2688:

2686:

2681:

2680:

2677:

2665:

2662:

2660:

2657:

2655:

2652:

2650:

2647:

2645:

2642:

2640:

2637:

2635:

2632:

2630:

2627:

2625:

2622:

2621:

2618:

2608:

2605:

2603:

2600:

2598:

2595:

2593:

2590:

2589:

2587:

2585:Related terms

2583:

2577:

2576:Shielding gas

2574:

2572:

2569:

2567:

2564:

2562:

2559:

2557:

2554:

2552:

2549:

2548:

2546:

2542:

2536:

2533:

2531:

2528:

2526:

2523:

2521:

2518:

2516:

2513:

2511:

2508:

2506:

2503:

2501:

2500:Friction stud

2498:

2496:

2493:

2491:

2488:

2486:

2483:

2481:

2478:

2476:

2473:

2471:

2468:

2466:

2463:

2462:

2460:

2458:

2454:

2448:

2445:

2443:

2440:

2438:

2435:

2433:

2430:

2428:

2425:

2423:

2420:

2418:

2415:

2413:

2410:

2408:

2405:

2404:

2402:

2400:

2396:

2392:

2385:

2380:

2378:

2373:

2371:

2366:

2365:

2362:

2358:

2354:

2347:

2342:

2340:

2335:

2333:

2328:

2327:

2324:

2318:

2315:

2313:

2310:

2308:

2305:

2303:

2300:

2298:

2295:

2293:

2290:

2288:

2285:

2283:

2280:

2277:

2275:

2270:

2269:

2265:

2259:

2255:

2251:

2249:9780870061097

2245:

2241:

2236:

2235:

2228:

2227:

2223:

2216:

2210:

2206:

2205:

2199:

2195:

2194:

2188:

2187:

2182:

2173:

2167:

2163:

2162:

2154:

2151:

2146:

2142:

2136:

2133:

2122:on 2016-03-04

2118:

2111:

2105:

2102:

2098:

2092:

2089:

2084:

2077:

2074:

2071:, p. 270

2070:

2065:

2062:

2053:

2050:

2046:

2040:

2037:

2026:

2022:

2016:

2013:

2002:

1998:

1992:

1989:

1986:, p. 742

1985:

1980:

1977:

1972:

1970:0-543-91646-4

1966:

1962:

1955:

1952:

1941:

1940:www.dndkm.org

1934:

1928:

1926:

1922:

1911:on 2016-01-22

1910:

1906:

1902:

1896:

1893:

1878:

1872:

1869:

1864:

1857:

1851:

1848:

1843:

1839:

1833:

1831:

1827:

1821:

1819:

1817:

1815:

1813:

1811:

1809:

1807:

1805:

1801:

1796:

1794:9780074636626

1790:

1786:

1785:

1778:

1775:

1764:

1760:

1754:

1751:

1746:

1744:9780849304859

1740:

1736:

1735:

1727:

1724:

1720:

1719:0-471-24410-4

1716:

1712:

1706:

1703:

1696:

1691:

1687:

1684:

1682:

1681:Thermal lance

1679:

1677:

1674:

1672:

1669:

1667:

1664:

1662:

1659:

1657:

1654:

1652:

1649:

1647:

1644:

1642:

1639:

1638:

1634:

1632:

1629:

1625:

1618:

1616:

1614:

1610:

1606:

1602:

1598:

1594:

1590:

1586:

1582:

1578:

1573:

1571:

1567:

1563:

1558:

1554:

1550:

1545:

1542:

1520:

1513:

1511:

1509:

1504:

1502:

1498:

1494:

1486:

1484:

1481:

1476:

1473:

1465:

1460:

1457:

1453:

1450:

1449:

1448:

1441:

1433:

1426:

1424:

1422:

1418:

1414:

1413:carbon steels

1409:

1407:

1403:

1398:

1396:

1390:

1388:

1384:

1383:angle grinder

1380:

1371:

1368:

1367:thermal lance

1363:

1359:

1358:

1357:

1354:

1352:

1342:

1334:

1326:

1322:

1318:

1316:

1311:

1304:

1302:

1299:

1294:

1290:

1286:

1281:

1277:

1273:

1269:

1262:

1260:

1256:

1252:

1249:

1244:

1240:

1238:

1232:

1224:

1219:

1211:

1209:

1207:

1203:

1199:

1195:

1190:

1188:

1184:

1179:

1174:

1172:

1168:

1160:

1153:

1150:

1147:

1144:

1143:

1139:

1136:

1133:

1130:

1129:

1125:

1122:

1119:

1116:

1115:

1111:

1108:

1105:

1102:

1101:

1097:

1094:

1091:

1088:

1087:

1083:

1080:

1077:

1074:

1073:

1069:

1066:

1063:

1060:

1059:

1055:

1052:

1049:

1046:

1045:

1041:

1038:

1035:

1032:

1031:

1027:

1024:

1021:

1018:

1017:

1013:

1010:

1007:

1004:

1003:

999:

996:

993:

991:

990:

985:

983:

962:

959:

951:

948:December 2022

941:

936:

932:

928:

927:

920:

911:

910:

904:

902:

899:

896:

894:

888:

886:

882:

875:

873:

871:

862:

860:

856:

852:

849:

845:

841:

836:

832:

824:

819:

816:

812:

807:

806:

805:

803:

798:

796:

792:

786:

778:

776:

769:

767:

763:

759:

749:

746:

738:

728:

724:

720:

716:

710:

709:

704:This section

702:

693:

692:

686:

680:

676:

673:

671:

667:

663:

658:

656:

652:

648:

644:

640:

636:

632:

628:

621:

613:

608:

601:

599:

597:

593:

589:

585:

581:

577:

569:

567:

565:

556:

554:

552:

544:

542:

538:

534:

529:Cutting torch

528:

526:

520:Welding torch

519:

513:

509:

502:

500:

493:

491:

488:

483:

480:

476:

474:

470:

462:

460:

458:

457:Jubilee Clips

454:

450:

445:

441:

439:

435:

429:

422:

420:

416:

414:

408:

406:

405:needle valves

400:

392:

390:

386:

384:

380:

375:

373:

369:

365:

361:

357:

349:

347:

338:

335:Formerly, in

334:

331:

327:

323:

320:

316:

313:

310:

306:

305:

303:

300:

296:

293:

290:

289:

288:

282:

280:

278:

274:

268:

266:

262:

258:

254:

249:

247:

242:

240:

236:

235:metal forming

233:, as well as

232:

226:

224:

220:

216:

212:

208:

204:

199:

194:

192:

188:

184:

179:

177:

173:

169:

165:

161:

157:

153:

149:

145:

141:

137:

133:

125:

117:

109:

101:

91:

88:

80:

70:

66:

60:

59:

53:

48:

39:

38:

33:

19:

18:Welding torch

2890:Router table

2855:Power trowel

2800:Hammer drill

2774:

2765:Concrete saw

2760:Circular saw

2566:Power supply

2556:Filler metal

2519:

2510:Laser-hybrid

2437:Plasma (PAW)

2353:Metalworking

2273:

2257:

2233:

2203:

2192:

2183:Bibliography

2160:

2153:

2144:

2135:

2124:. Retrieved

2117:the original

2104:

2091:

2082:

2076:

2064:

2057:

2052:

2039:

2028:. Retrieved

2024:

2015:

2004:. Retrieved

2000:

1991:

1979:

1960:

1954:

1943:. Retrieved

1939:

1913:. Retrieved

1909:the original

1895:

1884:. Retrieved

1871:

1865:. p. 5.

1850:

1842:the original

1783:

1777:

1766:. Retrieved

1762:

1753:

1733:

1726:

1710:

1705:

1623:

1622:

1574:

1546:

1521:

1517:

1505:

1495:(3,000

1490:

1477:

1469:

1446:

1417:wrought iron

1410:

1399:

1395:shipbuilding

1391:

1376:

1355:

1347:

1319:

1312:

1308:

1289:lead burning

1282:

1278:

1274:

1270:

1266:

1257:

1253:

1245:

1241:

1233:

1229:

1191:

1178:distillation

1175:

1164:

969:

954:

945:

938:Please help

934:

923:

900:

897:

889:

879:

866:

857:

853:

847:

843:

839:

838:

802:electrolysis

799:

788:

773:

764:

760:

756:

741:

732:

717:by removing

713:Please help

705:

674:

659:

623:

573:

560:

548:

539:

535:

532:

523:

506:

497:

484:

481:

477:

466:

446:

442:

430:

426:

417:

409:

402:

387:

376:

353:

344:

286:

269:

252:

250:

245:

243:

227:

195:

180:

147:

143:

139:

135:

131:

130:

83:

74:

55:

3019:Woodworking

2945:Wood shaper

2940:Wood router

2780:Die grinder

2750:Belt sander

2706:Power tools

2629:Fabrication

2607:Weldability

2399:Arc welding

2097:MythBusters

2069:Miller 1916

2043:davco.biz,

1984:Jeffus 1997

1499:; 210

1298:MIG welding

942:if you can.

815:electronics

785:Oxyhydrogen

643:kilopascals

588:natural gas

494:Check valve

487:shock waves

379:oxyhydrogen

215:arc welding

198:arc welding

187:oxyhydrogen

158:, etc) and

144:gas welding

140:oxy welding

69:introducing

3035:Categories

2905:Scroll saw

2885:Rotary saw

2835:Multi-tool

2820:Jackhammer

2735:Air hammer

2649:Metallurgy

2530:Ultrasonic

2525:Spot (RSW)

2480:Exothermic

2126:2015-10-03

2030:2021-05-12

2006:2021-05-12

1945:2024-05-20

1915:2012-01-07

1886:2016-02-02

1768:2015-07-02

1692:References

1605:zinc oxide

1601:Galvanized

1351:iron oxide

1248:hardfacing

1171:combustion

783:See also:

735:March 2022

715:improve it

618:See also:

449:hose clips

299:hardfacing

52:references

3061:Acetylene

2930:Table saw

2925:Steam box

2900:Screw gun

2875:Rivet gun

2755:Blowtorch

2722:Workbench

2644:Machining

2639:Jewellery

2551:Electrode

2544:Equipment

1624:Flashback

1619:Flashback

1613:influenza

1597:oxidizing

1585:fluorides

1566:manganese

1553:beryllium

1535:→ 2CO + H

1421:cast iron

997:Acetylene

791:aluminium

620:Acetylene

602:Acetylene

580:propylene

576:acetylene

469:explosive

423:Gas hoses

393:Regulator

364:soldering

356:cylinders

350:Apparatus

330:limelight

326:quicklime

273:soldering

211:magnesium

207:aluminium

203:cast iron

191:acetylene

181:A common

168:acetylene

2974:Forestry

2964:Cleaning

2840:Nail gun

2805:Heat gun

2795:Glue gun

2717:Sawhorse

2654:Smithing

2490:Friction

1635:See also

1480:Didymium

1293:flashing

1283:Welding

1198:nitrogen

1154:$ 55.89

1151:$ 131.30

1098:$ 27.52

1095:$ 45.252

1084:$ 19.67

1070:$ 7.852

1067:$ 35.079

1000:Propane

994:Gasoline

924:require