25:

1428:

184:

352:), then the lever amplifies the input force. If the distance from the fulcrum to the input force is less than from the fulcrum to the output force, then the lever reduces the input force. To Archimedes, who recognized the profound implications and practicalities of the law of the lever, has been attributed the famous claim, "Give me a place to stand and with a lever I will move the whole world."

180:

gearset). In such a gearset, gears having smaller radii and less inherent mechanical advantage are used. In order to make use of non-collapsed mechanical advantage, it is necessary to use a 'true length' rotary lever. See, also, the incorporation of mechanical advantage into the design of certain types of electric motors; one design is an 'outrunner'.

128:

1682:

1673:

is an assembly of a rope and pulleys that is used to lift loads. A number of pulleys are assembled together to form the blocks, one that is fixed and one that moves with the load. The rope is threaded through the pulleys to provide mechanical advantage that amplifies that force applied to the rope.

1436:

Consider the 18-speed bicycle with 7 in (radius) cranks and 26 in (diameter) wheels. If the sprockets at the crank and at the rear drive wheel are the same size, then the ratio of the output force on the tire to the input force on the pedal can be calculated from the law of the lever to be

1418:

Chains and belts dissipate power through friction, stretch and wear, which means the power output is actually less than the power input, which means the mechanical advantage of the real system will be less than that calculated for an ideal mechanism. A chain or belt drive can lose as much as 5% of

1677:

In order to determine the mechanical advantage of a block and tackle system consider the simple case of a gun tackle, which has a single mounted, or fixed, pulley and a single movable pulley. The rope is threaded around the fixed block and falls down to the moving block where it is threaded around

179:

In modern times, this kind of rotary leverage is widely used; see a (rotary) 2nd-class lever; see gears, pulleys or friction drive, used in a mechanical power transmission scheme. It is common for mechanical advantage to be manipulated in a 'collapsed' form, via the use of more than one gear (a

610:

Gear teeth are designed so that the number of teeth on a gear is proportional to the radius of its pitch circle, and so that the pitch circles of meshing gears roll on each other without slipping. The speed ratio for a pair of meshing gears can be computed from ratio of the radii of the pitch

1431:

Mechanical advantage in different gears of a bicycle. Typical forces applied to the bicycle pedal and to the ground are shown, as are corresponding distances moved by the pedal and rotated by the wheel. Note that even in low gear the MA of a bicycle is less than

2489:, is the mechanical advantage of a device with the assumption that its components do not flex, there is no friction, and there is no wear. It is calculated using the physical dimensions of the device and defines the maximum performance the device can achieve.

2725:

2468:

of force out. In an actual system, the force out would be less than 600 pounds due to friction in the pulleys. The second ratio also yields a MA of 6 in the ideal case but a smaller value in the practical scenario; it does not properly account for

194:

into and out of the lever is the same, so must come out the same when calculations are being done. Power is the product of force and velocity, so forces applied to points farther from the pivot must be less than when applied to points closer in.

1656:

The ratio of the force driving the bicycle to the force on the pedal, which is the total mechanical advantage of the bicycle, is the product of the speed ratio (or teeth ratio of output sprocket/input sprocket) and the crank-wheel lever ratio.

1516:

Now, assume that the front sprockets have a choice of 28 and 52 teeth, and that the rear sprockets have a choice of 16 and 32 teeth. Using different combinations, we can compute the following speed ratios between the front and rear sprockets

1198:

828:

579:

2363:

2262:

2384:

Mechanical advantage that is computed using the assumption that no power is lost through deflection, friction and wear of a machine is the maximum performance that can be achieved. For this reason, it is often called the

176:. Where a lever rotates continuously, it functions as a rotary 2nd-class lever. The motion of the lever's end-point describes a fixed orbit, where mechanical energy can be exchanged. (see a hand-crank as an example.)

1413:

1323:

949:

1511:

619:

2566:

2030:

2807:

2632:

1660:

Notice that in every case the force on the pedals is greater than the force driving the bicycle forward (in the illustration above, the corresponding backward-directed reaction force on the ground is indicated).

323:

2730:

The speed ratio of a machine can be calculated from its physical dimensions. The assumption of constant power thus allows use of the speed ratio to determine the maximum value for the mechanical advantage.

2872:

2743:(AMA) is the mechanical advantage determined by physical measurement of the input and output forces. Actual mechanical advantage takes into account energy loss due to deflection, friction, and wear.

2492:

The assumptions of an ideal machine are equivalent to the requirement that the machine does not store or dissipate energy; the power into the machine thus equals the power out. Therefore, the power

1069:

701:

489:

1864:

172:

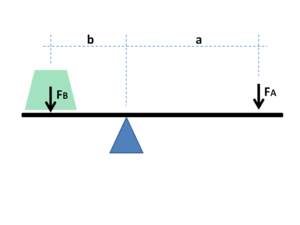

attached to or positioned on or across a fixed point. The lever operates by applying forces at different distances from the fulcrum, or pivot. The location of the fulcrum determines a lever's

104:. An ideal mechanism transmits power without adding to or subtracting from it. This means the ideal machine does not include a power source, is frictionless, and is constructed from

2168:

1923:

991:

Mechanisms consisting of two sprockets connected by a chain, or two pulleys connected by a belt are designed to provide a specific mechanical advantage in power transmission systems.

2643:

373:

The requirement for power input to an ideal mechanism to equal power output provides a simple way to compute mechanical advantage from the input-output speed ratio of the system.

108:

that do not deflect or wear. The performance of a real system relative to this ideal is expressed in terms of efficiency factors that take into account departures from the ideal.

1758:

1105:

735:

1685:

The mechanical advantage of a block and tackle equals the number of sections of rope that support the moving block; shown here it is 2, 3, 4, 5, and 6, respectively.

1928:

The negative sign shows that the velocity of the load is opposite to the velocity of the applied force, which means as we pull down on the rope the load moves up.

2077:

For an ideal block and tackle system there is no friction in the pulleys and no deflection or wear in the rope, which means the power input by the applied force

500:

258:

92:

or machine system. The device trades off input forces against movement to obtain a desired amplification in the output force. The model for this is the

2277:

2179:

983:(Force multiplier). In this case, because the output gear must have more teeth than the input gear, the speed reducer will amplify the input torque.

1334:

1244:

870:

1443:

1221:

drive, the number of teeth on the sprocket can be used. For friction belt drives the pitch radius of the input and output pulleys must be used.

2502:

1951:

3058:

2752:

2577:

2389:(IMA). In operation, deflection, friction and wear will reduce the mechanical advantage. The amount of this reduction from the ideal to the

3101:

3080:

3012:

2982:

46:

584:

This shows that for an ideal mechanism the input-output speed ratio equals the mechanical advantage of the system. This applies to all

3147:

68:

2825:

2571:

The ideal mechanical advantage is the ratio of the force out of the machine (load) to the force into the machine (effort), or

1004:

636:

424:

2637:

Applying the constant power relationship yields a formula for this ideal mechanical advantage in terms of the speed ratio:

1798:

2939:

2496:

is constant through the machine and force times velocity into the machine equals the force times velocity out—that is,

1419:

the power through the system in friction heat, deformation and wear, in which case the efficiency of the drive is 95%.

2898:

190:

As the lever pivots on the fulcrum, points farther from this pivot move faster than points closer to the pivot. The

39:

33:

153:

149:

2720:{\displaystyle {\mathit {IMA}}={\frac {F_{\text{out}}}{F_{\text{in}}}}={\frac {v_{\text{in}}}{v_{\text{out}}}}.}

50:

2933:

1767:

is the constant length of rope that passes over the pulleys and does not change as the block and tackle moves.

2109:

1875:

2473:

losses such as rope stretch. Subtracting those losses from the IMA or using the first ratio yields the AMA.

2173:

The ratio of the output force to the input force is the mechanical advantage of an ideal gun tackle system,

979:

If the output gear of a gear train rotates more slowly than the input gear, then the gear train is called a

101:

2746:

The AMA of a machine is calculated as the ratio of the measured force output to the measured force input,

2815:

The ratio of the experimentally determined mechanical advantage to the ideal mechanical advantage is the

2945:

2816:

1224:

The mechanical advantage of a pair of a chain drive or toothed belt drive with an input sprocket with

593:

972:

the input torque. And, if the output gear has fewer teeth than the input gear, then the gear train

2998:

2883:

3122:

3142:

1718:

1193:{\displaystyle {\frac {\omega _{A}}{\omega _{B}}}={\frac {r_{B}}{r_{A}}}={\frac {N_{B}}{N_{A}}}.}

823:{\displaystyle {\frac {\omega _{A}}{\omega _{B}}}={\frac {r_{B}}{r_{A}}}={\frac {N_{B}}{N_{A}}}.}

157:

137:

1427:

3097:

3076:

3018:

3008:

2978:

2913:

585:

89:

3002:

2408:

load, the operator of an ideal system would be required to pull the rope six feet and exert

2401:

1670:

355:

The use of velocity in the static analysis of a lever is an application of the principle of

183:

143:

1701:

be the distance from the axle of the fixed block to the axle of the moving block, which is

2928:

630:

of the point of contact on the pitch circles is the same on both gears, and is given by

252:

so the ratio of the output force to the input force, or mechanical advantage, is given by

191:

574:{\displaystyle {\mathit {MA}}={\frac {T_{B}}{T_{A}}}={\frac {\omega _{A}}{\omega _{B}}}.}

2267:

This analysis generalizes to an ideal block and tackle with a moving block supported by

3117:

2893:

2888:

3136:

2923:

2411:

998:

of the chain or belt is the same when in contact with the two sprockets or pulleys:

3042:

2918:

1218:

356:

105:

1693:

be the distance from the axle of the fixed block to the end of the rope, which is

850:

The mechanical advantage of a pair of meshing gears for which the input gear has

3091:

3070:

2358:{\displaystyle {\mathit {MA}}={\frac {F_{B}}{F_{A}}}={\frac {V_{A}}{V_{B}}}=n.\!}

2257:{\displaystyle {\mathit {MA}}={\frac {F_{B}}{F_{A}}}={\frac {V_{A}}{V_{B}}}=2.\!}

100:

Machine components designed to manage forces and movement in this way are called

2908:

368:

3007:. Harvard University Press (reprinted by Dover Publications 1988). p. 94.

3127:

2903:

618:

612:

605:

333:

1408:{\displaystyle {\mathit {MA}}={\frac {T_{B}}{T_{A}}}={\frac {r_{B}}{r_{A}}}.}

1318:{\displaystyle {\mathit {MA}}={\frac {T_{B}}{T_{A}}}={\frac {N_{B}}{N_{A}}}.}

944:{\displaystyle {\mathit {MA}}={\frac {r_{B}}{r_{A}}}={\frac {N_{B}}{N_{A}}}.}

1945:

be positive upwards, so this relationship can be written as the speed ratio

156:

to the section by replacing the section with a link and a summary or by

1506:{\displaystyle {\mathit {MA}}={\frac {F_{B}}{F_{A}}}={\frac {7}{13}}=0.54.}

3022:

2561:{\displaystyle P=F_{\text{in}}v_{\text{in}}=F_{\text{out}}v_{\text{out}}.}

169:

2025:{\displaystyle {\frac {V_{A}}{V_{B}}}={\frac {\dot {S}}{-{\dot {R}}}}=2,}

2802:{\displaystyle {\mathit {AMA}}={\frac {F_{\text{out}}}{F_{\text{in}}}},}

2627:{\displaystyle {\mathit {IMA}}={\frac {F_{\text{out}}}{F_{\text{in}}}}.}

2470:

318:{\displaystyle {\mathit {MA}}={\frac {F_{b}}{F_{a}}}={\frac {a}{b}}.}

2035:

where 2 is the number of rope sections supporting the moving block.

383:

applied to the drive pulley which rotates at an angular velocity of

336:

formulated using geometric reasoning. It shows that if the distance

1681:

2950:

2368:

This shows that the force exerted by an ideal block and tackle is

1680:

1426:

617:

589:

182:

173:

117:

95:

85:

2812:

where the input and output forces are determined experimentally.

2376:

is the number of sections of rope that support the moving block.

1678:

the pulley and brought back up to be knotted to the fixed block.

611:

circles and the ratio of the number of teeth on each gear, its

1328:

The mechanical advantage for friction belt drives is given by

121:

18:

2867:{\displaystyle \eta ={\frac {\mathit {AMA}}{\mathit {IMA}}}.}

3048:

p 129-130, 12th century AD, translation by

Francis R. Walton

2855:

2852:

2849:

2844:

2841:

2838:

2764:

2761:

2758:

2655:

2652:

2649:

2589:

2586:

2583:

2286:

2283:

2188:

2185:

1452:

1449:

1343:

1340:

1253:

1250:

879:

876:

509:

506:

340:

from the fulcrum to where the input force is applied (point

267:

264:

16:

Measure of the force amplification achieved by using a tool

348:

from fulcrum to where the output force is applied (point

2973:

Uicker, John J.; Pennock, G. R.; Shigley, J. E. (2011).

1792:

are related by the constant length of the rope, that is

1217:

is the number of teeth on the output sprocket. For a

1089:

meshes with this chain or belt along the pitch radius

1064:{\displaystyle v=r_{A}\omega _{A}=r_{B}\omega _{B},\!}

696:{\displaystyle v=r_{A}\omega _{A}=r_{B}\omega _{B},\!}

484:{\displaystyle P=T_{A}\omega _{A}=T_{B}\omega _{B},\!}

236:

is the output, the ratio of the velocities of points

3096:(Revised 1994 ed.), Courier Dover Publications,

2828:

2755:

2646:

2580:

2505:

2397:, a quantity which is determined by experimentation.

2280:

2182:

2112:

1954:

1878:

1801:

1721:

1446:

1337:

1247:

1108:

1078:

meshes with the chain or belt along the pitch radius

1007:

873:

738:

639:

503:

427:

261:

3072:

How to Dunk a

Doughnut: The Science of Everyday Life

2420:

of force to lift the load one foot. Both the ratios

1859:{\displaystyle {\dot {L}}=2{\dot {R}}+{\dot {S}}=0,}

2866:

2801:

2719:

2626:

2560:

2357:

2256:

2162:

2024:

1917:

1858:

1752:

1505:

1407:

1317:

1192:

1063:

943:

822:

695:

573:

483:

317:

2354:

2253:

2159:

1749:

1210:is the number of teeth on the input sprocket and

1060:

692:

480:

3090:United States Bureau of Naval Personnel (1971),

2448:show that the IMA is six. For the first ratio,

404:Because the power flow is constant, the torque

376:The power input to a gear train with a torque

840:is the number of teeth on the input gear and

622:Two meshing gears transmit rotational motion.

418:of the output gear must satisfy the relation

8:

2090:must equal the power out acting on the load

168:The lever is a movable bar that pivots on a

847:is the number of teeth on the output gear.

3123:Nice demonstration of mechanical advantage

2060:on the moving block. Like the velocities

2848:

2837:

2835:

2827:

2788:

2778:

2772:

2757:

2756:

2754:

2706:

2696:

2690:

2679:

2669:

2663:

2648:

2647:

2645:

2613:

2603:

2597:

2582:

2581:

2579:

2549:

2539:

2526:

2516:

2504:

2337:

2327:

2321:

2310:

2300:

2294:

2282:

2281:

2279:

2239:

2229:

2223:

2212:

2202:

2196:

2184:

2183:

2181:

2150:

2140:

2127:

2117:

2111:

1999:

1998:

1984:

1982:

1971:

1961:

1955:

1953:

1901:

1900:

1880:

1879:

1877:

1836:

1835:

1821:

1820:

1803:

1802:

1800:

1720:

1487:

1476:

1466:

1460:

1448:

1447:

1445:

1394:

1384:

1378:

1367:

1357:

1351:

1339:

1338:

1336:

1304:

1294:

1288:

1277:

1267:

1261:

1249:

1248:

1246:

1179:

1169:

1163:

1152:

1142:

1136:

1125:

1115:

1109:

1107:

1051:

1041:

1028:

1018:

1006:

930:

920:

914:

903:

893:

887:

875:

874:

872:

809:

799:

793:

782:

772:

766:

755:

745:

739:

737:

683:

673:

660:

650:

638:

560:

550:

544:

533:

523:

517:

505:

504:

502:

471:

461:

448:

438:

426:

302:

291:

281:

275:

263:

262:

260:

206:are distances from the fulcrum to points

69:Learn how and when to remove this message

2968:

2966:

2163:{\displaystyle F_{A}V_{A}=F_{B}V_{B}.\!}

1918:{\displaystyle {\dot {S}}=-2{\dot {R}}.}

1519:

88:amplification achieved by using a tool,

32:This article includes a list of general

2962:

1697:where the input force is applied. Let

2977:. New York: Oxford University Press.

7:

2393:(AMA) is defined by a factor called

2461:

2451:

2412:

1074:where the input sprocket or pulley

961:has more teeth than the input gear

954:This shows that if the output gear

3128:Mechanical advantage — video

3004:A History of Mechanical Inventions

1231:teeth and the output sprocket has

1085:and the output sprocket or pulley

38:it lacks sufficient corresponding

14:

2975:Theory of machines and mechanisms

3093:Basic machines and how they work

2487:theoretical mechanical advantage

126:

23:

3046:Book of Histories (Chiliades) 2

857:teeth and the output gear has

344:) is greater than the distance

2045:be the input force applied at

1:

2404:with six rope sections and a

2372:times the input force, where

2049:the end of the rope, and let

1708:The total length of the rope

2940:On the Equilibrium of Planes

1423:Example: bicycle chain drive

717:and meshes with output gear

2899:Mechanical advantage device

2741:actual mechanical advantage

2735:Actual mechanical advantage

2391:actual mechanical advantage

1753:{\displaystyle L=2R+S+K,\!}

1705:where the load is applied.

140:the scope of other articles

3164:

3059:ConstructionKnowledge.net

2483:ideal mechanical advantage

2477:Ideal mechanical advantage

2458:of force input results in

2387:ideal mechanical advantage

2067:is directed downwards and

1938:be positive downwards and

1521:Speed ratios and total MA

603:

366:

115:

1628:

1602:

1576:

1550:

1545:

1542:

1539:

1536:

1533:

1530:

1527:

1525:

3148:Mechanisms (engineering)

2934:Transmission (mechanics)

2400:As an example, using a

225:is the input force and

53:more precise citations.

2868:

2803:

2721:

2628:

2562:

2359:

2258:

2164:

2026:

1919:

1860:

1754:

1686:

1507:

1433:

1409:

1319:

1194:

1065:

968:, then the gear train

945:

824:

697:

623:

575:

485:

319:

187:

3075:, Arcade Publishing,

2946:Mechanical efficiency

2869:

2817:mechanical efficiency

2804:

2722:

2629:

2563:

2360:

2259:

2165:

2074:is directed upwards.

2027:

1920:

1861:

1755:

1684:

1508:

1430:

1410:

1320:

1195:

1066:

987:Chain and belt drives

946:

825:

698:

621:

576:

486:

411:and angular velocity

320:

186:

158:splitting the content

152:and help introduce a

3069:Fisher, Len (2003),

2826:

2753:

2644:

2578:

2503:

2278:

2180:

2110:

1952:

1876:

1799:

1719:

1444:

1335:

1245:

1106:

1005:

871:

736:

637:

501:

425:

259:

84:is a measure of the

82:Mechanical advantage

2884:Outline of machines

1522:

160:into a new article.

2864:

2819:η of the machine,

2799:

2717:

2624:

2558:

2355:

2254:

2160:

2022:

1915:

1856:

1750:

1712:can be written as

1687:

1543:crank-wheel ratio

1520:

1503:

1434:

1405:

1315:

1238:teeth is given by

1190:

1061:

976:the input torque.

941:

864:teeth is given by

820:

693:

624:

586:mechanical systems

571:

481:

315:

188:

150:discuss this issue

3118:Gears and pulleys

3103:978-0-486-21709-3

3082:978-1-55970-680-3

3014:978-0-486-14359-0

2984:978-0-19-537123-9

2914:Belt (mechanical)

2859:

2794:

2791:

2781:

2712:

2709:

2699:

2685:

2682:

2672:

2619:

2616:

2606:

2552:

2542:

2529:

2519:

2343:

2316:

2245:

2218:

2011:

2007:

1992:

1977:

1909:

1888:

1844:

1829:

1811:

1654:

1653:

1495:

1482:

1400:

1373:

1310:

1283:

1185:

1158:

1131:

936:

909:

815:

788:

761:

706:where input gear

566:

539:

310:

297:

166:

165:

90:mechanical device

79:

78:

71:

3155:

3106:

3085:

3061:

3055:

3049:

3040:

3034:

3033:

3031:

3029:

2995:

2989:

2988:

2970:

2873:

2871:

2870:

2865:

2860:

2858:

2847:

2836:

2808:

2806:

2805:

2800:

2795:

2793:

2792:

2789:

2783:

2782:

2779:

2773:

2768:

2767:

2726:

2724:

2723:

2718:

2713:

2711:

2710:

2707:

2701:

2700:

2697:

2691:

2686:

2684:

2683:

2680:

2674:

2673:

2670:

2664:

2659:

2658:

2633:

2631:

2630:

2625:

2620:

2618:

2617:

2614:

2608:

2607:

2604:

2598:

2593:

2592:

2567:

2565:

2564:

2559:

2554:

2553:

2550:

2544:

2543:

2540:

2531:

2530:

2527:

2521:

2520:

2517:

2467:

2466:

2457:

2456:

2419:

2417:

2407:

2402:block and tackle

2364:

2362:

2361:

2356:

2344:

2342:

2341:

2332:

2331:

2322:

2317:

2315:

2314:

2305:

2304:

2295:

2290:

2289:

2263:

2261:

2260:

2255:

2246:

2244:

2243:

2234:

2233:

2224:

2219:

2217:

2216:

2207:

2206:

2197:

2192:

2191:

2169:

2167:

2166:

2161:

2155:

2154:

2145:

2144:

2132:

2131:

2122:

2121:

2056:be the force at

2031:

2029:

2028:

2023:

2012:

2010:

2009:

2008:

2000:

1993:

1985:

1983:

1978:

1976:

1975:

1966:

1965:

1956:

1924:

1922:

1921:

1916:

1911:

1910:

1902:

1890:

1889:

1881:

1865:

1863:

1862:

1857:

1846:

1845:

1837:

1831:

1830:

1822:

1813:

1812:

1804:

1759:

1757:

1756:

1751:

1671:block and tackle

1665:Block and tackle

1523:

1512:

1510:

1509:

1504:

1496:

1488:

1483:

1481:

1480:

1471:

1470:

1461:

1456:

1455:

1414:

1412:

1411:

1406:

1401:

1399:

1398:

1389:

1388:

1379:

1374:

1372:

1371:

1362:

1361:

1352:

1347:

1346:

1324:

1322:

1321:

1316:

1311:

1309:

1308:

1299:

1298:

1289:

1284:

1282:

1281:

1272:

1271:

1262:

1257:

1256:

1199:

1197:

1196:

1191:

1186:

1184:

1183:

1174:

1173:

1164:

1159:

1157:

1156:

1147:

1146:

1137:

1132:

1130:

1129:

1120:

1119:

1110:

1070:

1068:

1067:

1062:

1056:

1055:

1046:

1045:

1033:

1032:

1023:

1022:

950:

948:

947:

942:

937:

935:

934:

925:

924:

915:

910:

908:

907:

898:

897:

888:

883:

882:

829:

827:

826:

821:

816:

814:

813:

804:

803:

794:

789:

787:

786:

777:

776:

767:

762:

760:

759:

750:

749:

740:

702:

700:

699:

694:

688:

687:

678:

677:

665:

664:

655:

654:

580:

578:

577:

572:

567:

565:

564:

555:

554:

545:

540:

538:

537:

528:

527:

518:

513:

512:

490:

488:

487:

482:

476:

475:

466:

465:

453:

452:

443:

442:

330:law of the lever

324:

322:

321:

316:

311:

303:

298:

296:

295:

286:

285:

276:

271:

270:

161:

144:Law of the lever

130:

129:

122:

74:

67:

63:

60:

54:

49:this article by

40:inline citations

27:

26:

19:

3163:

3162:

3158:

3157:

3156:

3154:

3153:

3152:

3133:

3132:

3114:

3104:

3089:

3083:

3068:

3065:

3064:

3056:

3052:

3041:

3037:

3027:

3025:

3015:

2997:

2996:

2992:

2985:

2972:

2971:

2964:

2959:

2929:Bicycle gearing

2880:

2824:

2823:

2784:

2774:

2751:

2750:

2737:

2702:

2692:

2675:

2665:

2642:

2641:

2609:

2599:

2576:

2575:

2545:

2535:

2522:

2512:

2501:

2500:

2479:

2465:

2459:

2455:

2449:

2447:

2440:

2433:

2426:

2416:

2409:

2405:

2382:

2333:

2323:

2306:

2296:

2276:

2275:

2271:rope sections,

2235:

2225:

2208:

2198:

2178:

2177:

2146:

2136:

2123:

2113:

2108:

2107:

2102:

2096:

2089:

2083:

2073:

2066:

2055:

2044:

1994:

1967:

1957:

1950:

1949:

1944:

1937:

1874:

1873:

1797:

1796:

1783:

1776:

1770:The velocities

1717:

1716:

1667:

1537:output (large)

1534:output (small)

1472:

1462:

1442:

1441:

1425:

1390:

1380:

1363:

1353:

1333:

1332:

1300:

1290:

1273:

1263:

1243:

1242:

1236:

1229:

1215:

1208:

1175:

1165:

1148:

1138:

1121:

1111:

1104:

1103:

1094:

1083:

1047:

1037:

1024:

1014:

1003:

1002:

989:

967:

960:

926:

916:

899:

889:

869:

868:

862:

855:

845:

838:

805:

795:

778:

768:

751:

741:

734:

733:

726:

715:

679:

669:

656:

646:

635:

634:

608:

602:

556:

546:

529:

519:

499:

498:

467:

457:

444:

434:

423:

422:

416:

409:

399:

395:

388:

381:

371:

365:

287:

277:

257:

256:

230:

219:

162:

147:

142:, specifically

131:

127:

120:

114:

75:

64:

58:

55:

45:Please help to

44:

28:

24:

17:

12:

11:

5:

3161:

3159:

3151:

3150:

3145:

3135:

3134:

3131:

3130:

3125:

3120:

3113:

3112:External links

3110:

3109:

3108:

3102:

3087:

3081:

3063:

3062:

3050:

3035:

3013:

2990:

2983:

2961:

2960:

2958:

2955:

2954:

2953:

2948:

2943:

2936:

2931:

2926:

2921:

2916:

2911:

2906:

2901:

2896:

2894:Simple machine

2891:

2889:Compound lever

2886:

2879:

2876:

2875:

2874:

2863:

2857:

2854:

2851:

2846:

2843:

2840:

2834:

2831:

2810:

2809:

2798:

2787:

2777:

2771:

2766:

2763:

2760:

2736:

2733:

2728:

2727:

2716:

2705:

2695:

2689:

2678:

2668:

2662:

2657:

2654:

2651:

2635:

2634:

2623:

2612:

2602:

2596:

2591:

2588:

2585:

2569:

2568:

2557:

2548:

2538:

2534:

2525:

2515:

2511:

2508:

2478:

2475:

2463:

2453:

2445:

2438:

2431:

2424:

2414:

2381:

2378:

2366:

2365:

2353:

2350:

2347:

2340:

2336:

2330:

2326:

2320:

2313:

2309:

2303:

2299:

2293:

2288:

2285:

2265:

2264:

2252:

2249:

2242:

2238:

2232:

2228:

2222:

2215:

2211:

2205:

2201:

2195:

2190:

2187:

2171:

2170:

2158:

2153:

2149:

2143:

2139:

2135:

2130:

2126:

2120:

2116:

2100:

2094:

2087:

2081:

2071:

2064:

2053:

2042:

2033:

2032:

2021:

2018:

2015:

2006:

2003:

1997:

1991:

1988:

1981:

1974:

1970:

1964:

1960:

1942:

1935:

1926:

1925:

1914:

1908:

1905:

1899:

1896:

1893:

1887:

1884:

1867:

1866:

1855:

1852:

1849:

1843:

1840:

1834:

1828:

1825:

1819:

1816:

1810:

1807:

1784:of the points

1781:

1774:

1761:

1760:

1748:

1745:

1742:

1739:

1736:

1733:

1730:

1727:

1724:

1666:

1663:

1652:

1651:

1648:

1645:

1642:

1639:

1636:

1633:

1630:

1626:

1625:

1622:

1619:

1616:

1613:

1610:

1607:

1604:

1600:

1599:

1596:

1593:

1590:

1587:

1584:

1581:

1578:

1574:

1573:

1570:

1567:

1564:

1561:

1558:

1555:

1552:

1548:

1547:

1544:

1541:

1538:

1535:

1532:

1531:input (large)

1529:

1528:input (small)

1526:

1514:

1513:

1502:

1499:

1494:

1491:

1486:

1479:

1475:

1469:

1465:

1459:

1454:

1451:

1424:

1421:

1416:

1415:

1404:

1397:

1393:

1387:

1383:

1377:

1370:

1366:

1360:

1356:

1350:

1345:

1342:

1326:

1325:

1314:

1307:

1303:

1297:

1293:

1287:

1280:

1276:

1270:

1266:

1260:

1255:

1252:

1234:

1227:

1213:

1206:

1201:

1200:

1189:

1182:

1178:

1172:

1168:

1162:

1155:

1151:

1145:

1141:

1135:

1128:

1124:

1118:

1114:

1092:

1081:

1072:

1071:

1059:

1054:

1050:

1044:

1040:

1036:

1031:

1027:

1021:

1017:

1013:

1010:

988:

985:

965:

958:

952:

951:

940:

933:

929:

923:

919:

913:

906:

902:

896:

892:

886:

881:

878:

860:

853:

843:

836:

831:

830:

819:

812:

808:

802:

798:

792:

785:

781:

775:

771:

765:

758:

754:

748:

744:

724:

713:

704:

703:

691:

686:

682:

676:

672:

668:

663:

659:

653:

649:

645:

642:

604:Main article:

601:

598:

582:

581:

570:

563:

559:

553:

549:

543:

536:

532:

526:

522:

516:

511:

508:

492:

491:

479:

474:

470:

464:

460:

456:

451:

447:

441:

437:

433:

430:

414:

407:

397:

393:

386:

379:

367:Main article:

364:

361:

326:

325:

314:

309:

306:

301:

294:

290:

284:

280:

274:

269:

266:

228:

217:

164:

163:

134:

132:

125:

116:Main article:

113:

110:

77:

76:

31:

29:

22:

15:

13:

10:

9:

6:

4:

3:

2:

3160:

3149:

3146:

3144:

3141:

3140:

3138:

3129:

3126:

3124:

3121:

3119:

3116:

3115:

3111:

3105:

3099:

3095:

3094:

3088:

3084:

3078:

3074:

3073:

3067:

3066:

3060:

3054:

3051:

3047:

3044:

3039:

3036:

3024:

3020:

3016:

3010:

3006:

3005:

3000:

2994:

2991:

2986:

2980:

2976:

2969:

2967:

2963:

2956:

2952:

2949:

2947:

2944:

2942:

2941:

2937:

2935:

2932:

2930:

2927:

2925:

2924:Bicycle chain

2922:

2920:

2917:

2915:

2912:

2910:

2907:

2905:

2902:

2900:

2897:

2895:

2892:

2890:

2887:

2885:

2882:

2881:

2877:

2861:

2832:

2829:

2822:

2821:

2820:

2818:

2813:

2796:

2785:

2775:

2769:

2749:

2748:

2747:

2744:

2742:

2734:

2732:

2714:

2703:

2693:

2687:

2676:

2666:

2660:

2640:

2639:

2638:

2621:

2610:

2600:

2594:

2574:

2573:

2572:

2555:

2546:

2536:

2532:

2523:

2513:

2509:

2506:

2499:

2498:

2497:

2495:

2490:

2488:

2484:

2476:

2474:

2472:

2444:

2437:

2430:

2423:

2418:

2403:

2398:

2396:

2392:

2388:

2379:

2377:

2375:

2371:

2351:

2348:

2345:

2338:

2334:

2328:

2324:

2318:

2311:

2307:

2301:

2297:

2291:

2274:

2273:

2272:

2270:

2250:

2247:

2240:

2236:

2230:

2226:

2220:

2213:

2209:

2203:

2199:

2193:

2176:

2175:

2174:

2156:

2151:

2147:

2141:

2137:

2133:

2128:

2124:

2118:

2114:

2106:

2105:

2104:

2099:

2093:

2086:

2080:

2075:

2070:

2063:

2059:

2052:

2048:

2041:

2036:

2019:

2016:

2013:

2004:

2001:

1995:

1989:

1986:

1979:

1972:

1968:

1962:

1958:

1948:

1947:

1946:

1941:

1934:

1929:

1912:

1906:

1903:

1897:

1894:

1891:

1885:

1882:

1872:

1871:

1870:

1853:

1850:

1847:

1841:

1838:

1832:

1826:

1823:

1817:

1814:

1808:

1805:

1795:

1794:

1793:

1791:

1787:

1780:

1773:

1768:

1766:

1746:

1743:

1740:

1737:

1734:

1731:

1728:

1725:

1722:

1715:

1714:

1713:

1711:

1706:

1704:

1700:

1696:

1692:

1683:

1679:

1675:

1672:

1664:

1662:

1658:

1649:

1646:

1643:

1640:

1637:

1634:

1631:

1627:

1623:

1620:

1617:

1614:

1611:

1608:

1605:

1601:

1597:

1594:

1591:

1588:

1585:

1582:

1579:

1575:

1571:

1568:

1565:

1562:

1559:

1556:

1553:

1549:

1524:

1518:

1500:

1497:

1492:

1489:

1484:

1477:

1473:

1467:

1463:

1457:

1440:

1439:

1438:

1429:

1422:

1420:

1402:

1395:

1391:

1385:

1381:

1375:

1368:

1364:

1358:

1354:

1348:

1331:

1330:

1329:

1312:

1305:

1301:

1295:

1291:

1285:

1278:

1274:

1268:

1264:

1258:

1241:

1240:

1239:

1237:

1230:

1222:

1220:

1216:

1209:

1187:

1180:

1176:

1170:

1166:

1160:

1153:

1149:

1143:

1139:

1133:

1126:

1122:

1116:

1112:

1102:

1101:

1100:

1097:

1095:

1088:

1084:

1077:

1057:

1052:

1048:

1042:

1038:

1034:

1029:

1025:

1019:

1015:

1011:

1008:

1001:

1000:

999:

997:

994:The velocity

992:

986:

984:

982:

981:speed reducer

977:

975:

971:

964:

957:

938:

931:

927:

921:

917:

911:

904:

900:

894:

890:

884:

867:

866:

865:

863:

856:

848:

846:

839:

817:

810:

806:

800:

796:

790:

783:

779:

773:

769:

763:

756:

752:

746:

742:

732:

731:

730:

728:

720:

716:

709:

689:

684:

680:

674:

670:

666:

661:

657:

651:

647:

643:

640:

633:

632:

631:

629:

626:The velocity

620:

616:

614:

607:

599:

597:

595:

591:

588:ranging from

587:

568:

561:

557:

551:

547:

541:

534:

530:

524:

520:

514:

497:

496:

495:

494:which yields

477:

472:

468:

462:

458:

454:

449:

445:

439:

435:

431:

428:

421:

420:

419:

417:

410:

402:

400:

389:

382:

374:

370:

362:

360:

358:

353:

351:

347:

343:

339:

335:

331:

312:

307:

304:

299:

292:

288:

282:

278:

272:

255:

254:

253:

251:

247:

243:

239:

235:

231:

224:

220:

214:and if force

213:

209:

205:

201:

196:

193:

185:

181:

177:

175:

171:

159:

155:

154:summary style

151:

145:

141:

139:

135:This section

133:

124:

123:

119:

111:

109:

107:

103:

99:

97:

91:

87:

83:

73:

70:

62:

52:

48:

42:

41:

35:

30:

21:

20:

3092:

3071:

3057:Ned Pelger,

3053:

3045:

3043:John Tzetzes

3038:

3026:. Retrieved

3003:

2999:Usher, A. P.

2993:

2974:

2938:

2919:Roller chain

2814:

2811:

2745:

2740:

2738:

2729:

2636:

2570:

2493:

2491:

2486:

2482:

2480:

2442:

2435:

2428:

2421:

2399:

2394:

2390:

2386:

2383:

2373:

2369:

2367:

2268:

2266:

2172:

2097:

2091:

2084:

2078:

2076:

2068:

2061:

2057:

2050:

2046:

2039:

2037:

2034:

1939:

1932:

1930:

1927:

1868:

1789:

1785:

1778:

1771:

1769:

1764:

1762:

1709:

1707:

1702:

1698:

1694:

1690:

1688:

1676:

1668:

1659:

1655:

1540:speed ratio

1515:

1435:

1417:

1327:

1232:

1225:

1223:

1219:toothed belt

1211:

1204:

1202:

1098:

1090:

1086:

1079:

1075:

1073:

995:

993:

990:

980:

978:

973:

969:

962:

955:

953:

858:

851:

849:

841:

834:

832:

722:

718:

711:

707:

705:

627:

625:

609:

583:

493:

412:

405:

403:

391:

384:

377:

375:

372:

357:virtual work

354:

349:

345:

341:

337:

329:

328:This is the

327:

249:

245:

244:is given by

241:

237:

233:

226:

222:

215:

211:

207:

203:

199:

197:

189:

178:

167:

136:

106:rigid bodies

93:

81:

80:

65:

56:

37:

2909:Chain drive

2406:600 lb

1629:high speed

729:therefore,

710:has radius

600:Gear trains

369:Speed ratio

363:Speed ratio

232:exerted at

221:applied to

94:law of the

51:introducing

3137:Categories

2957:References

2904:Gear ratio

2485:(IMA), or

2395:efficiency

2380:Efficiency

2103:, that is

1551:low speed

1099:therefore

721:of radius

613:gear ratio

606:Gear train

334:Archimedes

138:duplicates

102:mechanisms

59:April 2017

34:references

3143:Mechanics

2830:η

2460:600

2450:100

2410:100

2005:˙

1996:−

1990:˙

1907:˙

1895:−

1886:˙

1842:˙

1827:˙

1809:˙

1546:total MA

1123:ω

1113:ω

1049:ω

1026:ω

970:amplifies

753:ω

743:ω

681:ω

658:ω

558:ω

548:ω

469:ω

446:ω

3001:(1929).

2878:See also

594:linkages

332:, which

3028:7 April

974:reduces

170:fulcrum

148:Please

47:improve

3100:

3079:

3023:514178

3021:

3011:

2981:

2471:energy

1763:where

1603:mid 2

1577:mid 1

1203:where

833:where

590:robots

112:Levers

36:, but

2951:Wedge

1650:0.16

1624:0.31

1598:0.33

1572:0.62

1501:0.54.

192:power

174:class

118:Lever

96:lever

86:force

3098:ISBN

3077:ISBN

3030:2013

3019:OCLC

3009:ISBN

2979:ISBN

2739:The

2481:The

2434:and

2038:Let

1931:Let

1788:and

1777:and

1689:Let

1647:0.54

1644:0.30

1621:0.54

1618:0.57

1595:0.54

1592:0.62

1569:0.54

1566:1.14

240:and

210:and

202:and

2780:out

2708:out

2671:out

2605:out

2551:out

2541:out

2446:out

2425:out

1869:or

592:to

392:P=T

390:is

198:If

3139::

3017:.

2965:^

2790:in

2698:in

2681:in

2615:in

2528:in

2518:in

2462:lb

2452:lb

2441:/

2439:in

2432:in

2427:/

2413:lb

2251:2.

1669:A

1638:16

1635:52

1612:16

1606:28

1589:32

1583:52

1563:32

1554:28

1493:13

1432:1.

1096:,

615:.

596:.

401:.

359:.

3107:.

3086:.

3032:.

2987:.

2862:.

2856:A

2853:M

2850:I

2845:A

2842:M

2839:A

2833:=

2797:,

2786:F

2776:F

2770:=

2765:A

2762:M

2759:A

2715:.

2704:v

2694:v

2688:=

2677:F

2667:F

2661:=

2656:A

2653:M

2650:I

2622:.

2611:F

2601:F

2595:=

2590:A

2587:M

2584:I

2556:.

2547:v

2537:F

2533:=

2524:v

2514:F

2510:=

2507:P

2494:P

2464:F

2454:F

2443:V

2436:V

2429:F

2422:F

2415:F

2374:n

2370:n

2352:.

2349:n

2346:=

2339:B

2335:V

2329:A

2325:V

2319:=

2312:A

2308:F

2302:B

2298:F

2292:=

2287:A

2284:M

2269:n

2248:=

2241:B

2237:V

2231:A

2227:V

2221:=

2214:A

2210:F

2204:B

2200:F

2194:=

2189:A

2186:M

2157:.

2152:B

2148:V

2142:B

2138:F

2134:=

2129:A

2125:V

2119:A

2115:F

2101:B

2098:V

2095:B

2092:F

2088:A

2085:V

2082:A

2079:F

2072:B

2069:F

2065:A

2062:F

2058:B

2054:B

2051:F

2047:A

2043:A

2040:F

2020:,

2017:2

2014:=

2002:R

1987:S

1980:=

1973:B

1969:V

1963:A

1959:V

1943:B

1940:V

1936:A

1933:V

1913:.

1904:R

1898:2

1892:=

1883:S

1854:,

1851:0

1848:=

1839:S

1833:+

1824:R

1818:2

1815:=

1806:L

1790:B

1786:A

1782:B

1779:V

1775:A

1772:V

1765:K

1747:,

1744:K

1741:+

1738:S

1735:+

1732:R

1729:2

1726:=

1723:L

1710:L

1703:B

1699:R

1695:A

1691:S

1641:-

1632:-

1615:-

1609:-

1586:-

1580:-

1560:-

1557:-

1498:=

1490:7

1485:=

1478:A

1474:F

1468:B

1464:F

1458:=

1453:A

1450:M

1403:.

1396:A

1392:r

1386:B

1382:r

1376:=

1369:A

1365:T

1359:B

1355:T

1349:=

1344:A

1341:M

1313:.

1306:A

1302:N

1296:B

1292:N

1286:=

1279:A

1275:T

1269:B

1265:T

1259:=

1254:A

1251:M

1235:B

1233:N

1228:A

1226:N

1214:B

1212:N

1207:A

1205:N

1188:.

1181:A

1177:N

1171:B

1167:N

1161:=

1154:A

1150:r

1144:B

1140:r

1134:=

1127:B

1117:A

1093:B

1091:r

1087:B

1082:A

1080:r

1076:A

1058:,

1053:B

1043:B

1039:r

1035:=

1030:A

1020:A

1016:r

1012:=

1009:v

996:v

966:A

963:G

959:B

956:G

939:.

932:A

928:N

922:B

918:N

912:=

905:A

901:r

895:B

891:r

885:=

880:A

877:M

861:B

859:N

854:A

852:N

844:B

842:N

837:A

835:N

818:.

811:A

807:N

801:B

797:N

791:=

784:A

780:r

774:B

770:r

764:=

757:B

747:A

727:,

725:B

723:r

719:B

714:A

712:r

708:A

690:,

685:B

675:B

671:r

667:=

662:A

652:A

648:r

644:=

641:v

628:v

569:.

562:B

552:A

542:=

535:A

531:T

525:B

521:T

515:=

510:A

507:M

478:,

473:B

463:B

459:T

455:=

450:A

440:A

436:T

432:=

429:P

415:B

413:ω

408:B

406:T

398:A

396:ω

394:A

387:A

385:ω

380:A

378:T

350:B

346:b

342:A

338:a

313:.

308:b

305:a

300:=

293:a

289:F

283:b

279:F

273:=

268:A

265:M

250:b

248:/

246:a

242:B

238:A

234:B

229:B

227:F

223:A

218:A

216:F

212:B

208:A

204:b

200:a

146:.

98:.

72:)

66:(

61:)

57:(

43:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.