614:

matrix at low concentrations (~0.2 weight %) cause significant improvements in the compressive and flexural mechanical properties of polymeric nanocomposites. Potentially, these nanocomposites may be used as a novel, mechanically strong, light weight composite as bone implants. The results suggest that mechanical reinforcement is dependent on the nanostructure morphology, defects, dispersion of nanomaterials in the polymer matrix, and the cross-linking density of the polymer. In general, two-dimensional nanostructures can reinforce the polymer better than one-dimensional nanostructures, and inorganic nanomaterials are better reinforcing agents than carbon based nanomaterials. In addition to mechanical properties, polymer nanocomposites based on carbon nanotubes or graphene have been used to enhance a wide range of properties, giving rise to functional materials for a wide range of high added value applications in fields such as energy conversion and storage, sensing and biomedical tissue engineering. For example, multi-walled carbon nanotubes based polymer nanocomposites have been used for the enhancement of the electrical conductivity.

567:, which is an emerging new material that is being developed to take advantage of the high tensile strength and electrical conductivity of carbon nanotube materials. Critical to the realization of CNT-MMC possessing optimal properties in these areas are the development of synthetic techniques that are (a) economically producible, (b) provide for a homogeneous dispersion of nanotubes in the metallic matrix, and (c) lead to strong interfacial adhesion between the metallic matrix and the carbon nanotubes. In addition to carbon nanotube metal matrix composites, boron nitride reinforced metal matrix composites and carbon nitride metal matrix composites are the new research areas on metal matrix nanocomposites.

654:

as a magnetic, electrical, or mechanical field. Specifically, magnetic nanocomposites are useful for use in these applications due to the nature of magnetic material's ability to respond both to electrical and magnetic stimuli. The penetration depth of a magnetic field is also high, leading to an increased area that the nanocomposite is affected by and therefore an increased response. In order to respond to a magnetic field, a matrix can be easily loaded with nanoparticles or nanorods The different morphologies for magnetic nanocomposite materials are vast, including matrix dispersed nanoparticles, core-shell nanoparticles, colloidal crystals, macroscale spheres, or Janus-type nanostructures.

571:

suggest that tungsten disulfide nanotubes reinforced PPF nanocomposites possess significantly higher mechanical properties and tungsten disulfide nanotubes are better reinforcing agents than carbon nanotubes. Increases in the mechanical properties can be attributed to a uniform dispersion of inorganic nanotubes in the polymer matrix (compared to carbon nanotubes that exist as micron sized aggregates) and increased crosslinking density of the polymer in the presence of tungsten disulfide nanotubes (increase in crosslinking density leads to an increase in the mechanical properties). These results suggest that inorganic

666:

great potential for improving the efficiency of power electronic devices by providing relatively high permeability and low losses. For example, As Iron oxide nano particles embedded in Ni matrix enables us to mitigate those losses at high frequency. The high resistive iron oxide nanoparticles helps to reduce the eddy current losses where as the Ni metal helps in attaining high permeability. DC magnetic properties such as

Saturation magnetization lies between each of its constituent parts indicating that the physical properties of the materials can be altered by creating these nanocomposites.

606:). This strategy is particularly effective in yielding high performance composites, when uniform dispersion of the filler is achieved and the properties of the nanoscale filler are substantially different or better than those of the matrix. The uniformity of the dispersion is in all nanocomposites is counteracted by thermodynamically driven phase separation. Clustering of nanoscale fillers produces aggregates that serve as structural defects and result in failure. Layer-by-layer (LbL) assembly when nanometer scale layers of

645:

range of natural and synthetic polymers are used to design polymeric nanocomposites for biomedical applications including starch, cellulose, alginate, chitosan, collagen, gelatin, and fibrin, poly(vinyl alcohol) (PVA), poly(ethylene glycol) (PEG), poly(caprolactone) (PCL), poly(lactic-co-glycolic acid) (PLGA), and poly(glycerol sebacate) (PGS). A range of nanoparticles including ceramic, polymeric, metal oxide and carbon-based nanomaterials are incorporated within polymeric network to obtain desired property combinations.

442:, especially for the most commonly used non-spherical, high aspect ratio fillers (e.g. nanometer-thin platelets, such as clays, or nanometer-diameter cylinders, such as carbon nanotubes). The orientation and arrangement of asymmetric nanoparticles, thermal property mismatch at the interface, interface density per unit volume of nanocomposite, and polydispersity of nanoparticles significantly affect the effective thermal conductivity of nanocomposites.

532:

397:. The reinforcing material can be made up of particles (e.g. minerals), sheets (e.g. exfoliated clay stacks) or fibres (e.g. carbon nanotubes or electrospun fibres). The area of the interface between the matrix and reinforcement phase(s) is typically an order of magnitude greater than for conventional composite materials. The matrix material properties are significantly affected in the vicinity of the reinforcement. Ajayan

687:

251:

701:

263:

332:, but is more usually taken to mean the solid combination of a bulk matrix and nano-dimensional phase(s) differing in properties due to dissimilarities in structure and chemistry. The mechanical, electrical, thermal, optical, electrochemical, catalytic properties of the nanocomposite will differ markedly from that of the component materials. Size limits for these effects have been proposed:

36:

466:

character. This is not an easily obeyed constraint because the preparation of the ceramic component generally requires high process temperatures. The safest measure thus is to carefully choose immiscible metal and ceramic phases. A good example of such a combination is represented by the ceramic-metal composite of

661:

Magnetic nanocomposites can also be utilized in the medical field, with magnetic nanorods embedded in a polymer matrix can aid in more precise drug delivery and release. Finally, magnetic nanocomposites can be used in high frequency/high-temperature applications. For example, multi-layer structures

653:

Nanocomposites that can respond to an external stimulus are of increased interest due to the fact that, because of the large amount of interaction between the phase interfaces, the stimulus response can have a larger effect on the composite as a whole. The external stimulus can take many forms, such

665:

In applications such as power micro-inductors where high magnetic permeability is desired at high operating frequencies. The traditional micro-fabricated magnetic core materials see both decrease in permeability and high losses at high operating frequency. In this case, magnetic nano composites have

401:

note that with polymer nanocomposites, properties related to local chemistry, degree of thermoset cure, polymer chain mobility, polymer chain conformation, degree of polymer chain ordering or crystallinity can all vary significantly and continuously from the interface with the reinforcement into the

644:

A range of polymeric nanocomposites are used for biomedical applications such as tissue engineering, drug delivery, cellular therapies. Due to unique interactions between polymer and nanoparticles, a range of property combinations can be engineered to mimic native tissue structure and properties. A

570:

A recent study, comparing the mechanical properties (Young's modulus, compressive yield strength, flexural modulus and flexural yield strength) of single- and multi-walled reinforced polymeric (polypropylene fumarate—PPF) nanocomposites to tungsten disulfide nanotubes reinforced PPF nanocomposites

624:

Nanoscale dispersion of filler or controlled nanostructures in the composite can introduce new physical properties and novel behaviors that are absent in the unfilled matrices. This effectively changes the nature of the original matrix (such composite materials can be better described by the term

465:

of the mixture should be considered in designing ceramic-metal nanocomposites and measures have to be taken to avoid a chemical reaction between both components. The last point mainly is of importance for the metallic component that may easily react with the ceramic and thereby lose its metallic

613:

Nanoparticles such as graphene, carbon nanotubes, molybdenum disulfide and tungsten disulfide are being used as reinforcing agents to fabricate mechanically strong biodegradable polymeric nanocomposites for bone tissue engineering applications. The addition of these nanoparticles in the polymer

657:

Magnetic nanocomposites can be utilized in a vast number of applications, including catalytic, medical, and technical. For example, palladium is a common transition metal used in catalysis reactions. Magnetic nanoparticle-supported palladium complexes can be used in catalysis to increase the

381:

mechanism. From the mid-1950s nanoscale organo-clays have been used to control flow of polymer solutions (e.g. as paint viscosifiers) or the constitution of gels (e.g. as a thickening substance in cosmetics, keeping the preparations in homogeneous form). By the 1970s

674:

In the recent years nanocomposites have been designed to withstand high temperatures by the addition of Carbon Dots (CDs) in the polymer matrix. Such nanocomposites can be utilized in environments wherein high temperature resistance is a prime criterion.

562:

Metal matrix nanocomposites can also be defined as reinforced metal matrix composites. This type of composites can be classified as continuous and non-continuous reinforced materials. One of the more important nanocomposites is

458:. Ideally both components are finely dispersed in each other in order to elicit particular optical, electrical and magnetic properties as well as tribological, corrosion-resistance and other protective properties.

405:

This large amount of reinforcement surface area means that a relatively small amount of nanoscale reinforcement can have an observable effect on the macroscale properties of the composite. For example, adding

496:

technique and is associated with high deposition rates up to some μm/s and the growth of nanoparticles in the gas phase. Nanocomposite layers in the ceramics range of composition were prepared from

1961:

Han, Kyu; Swaminathan, Madhavan; Pulugurtha, Raj; Sharma, Himani; Tummala, Rao; Yang, Songnan; Nair, Vijay (2016). "Magneto-Dielectric

Nanocomposite for Antenna Miniaturization and SAR Reduction".

600:

to a polymer matrix can enhance its performance, often dramatically, by simply capitalizing on the nature and properties of the nanoscale filler (these materials are better described by the term

1233:

Janeta, Mateusz; John, Łukasz; Ejfler, Jolanta; Szafert, Sławomir (2014-11-24). "High-Yield

Synthesis of Amido-Functionalized Polyoctahedral Oligomeric Silsesquioxanes by Using Acyl Chlorides".

578:

Another kind of nanocomposite is the energetic nanocomposite, generally as a hybrid sol–gel with a silica base, which, when combined with metal oxides and nano-scale aluminum powder, can form

1500:

Zeidi, Mahdi; Kim, Chun IL; Park, Chul B. (2021). "The role of interface on the toughening and failure mechanisms of thermoplastic nanocomposites reinforced with nanofibrillated rubbers".

450:

Ceramic matrix composites (CMCs) consist of ceramic fibers embedded in a ceramic matrix. The matrix and fibers can consist of any ceramic material, including carbon and carbon fibers. The

484:

that are solid layers of a few nm to some tens of μm thickness deposited upon an underlying substrate and that play an important role in the functionalization of technical surfaces.

2059:

Rimal, Vishal; Shishodia, Shubham; Srivastava, P.K. (2020). "Novel synthesis of high-thermal stability carbon dots and nanocomposites from oleic acid as an organic substrate".

610:

and a polymers are added one by one. LbL composites display performance parameters 10-1000 times better that the traditional nanocomposites made by extrusion or batch-mixing.

662:

can be fabricated for use in electronic applications. An electrodeposited Fe/Fe oxide multi-layered sample can be an example of this application of magnetic nanocomposites.

1926:

Markondeya Raj, P.; Sharma, Himani; Sitaraman, Srikrishna; Mishra, Dibyajat; Tummala, Rao (December 2017). "System

Scaling With Nanostructured Power and RF Components".

1551:

Gatti, Teresa; Vicentini, Nicola; Mba, Miriam; Menna, Enzo (2016-02-01). "Organic

Functionalized Carbon Nanostructures for Functional Polymer-Based Nanocomposites".

1402:

Lalwani, Gaurav; Henslee, Allan M.; Farshid, Behzad; Lin, Liangjun; Kasper, F. Kurtis; Yi-, Yi-Xian; Qin, Xian; Mikos, Antonios G.; Sitharaman, Balaji (2013).

72:

941:

F. E. Kruis, H. Fissan and A. Peled (1998). "Synthesis of nanoparticles in the gas phase for electronic, optical and magnetic applications – a review".

434:

and resistance to wear and damage. In general, the nano reinforcement is dispersed into the matrix during processing. The percentage by weight (called

369:

and bone. The use of nanoparticle-rich materials long predates the understanding of the physical and chemical nature of these materials. Jose-Yacaman

62:

564:

293:

847:

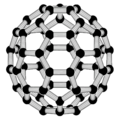

Functional

Polymer Composites with Nanoclays, Editors: Yuri Lvov, Baochun Guo, Rawil F Fakhrullin, Royal Society of Chemistry, Cambridge 2017,

67:

454:

occupying most of the volume is often from the group of oxides, such as nitrides, borides, silicides, whereas the second component is often a

1643:

883:

836:

1451:

Lalwani, Gaurav; Henslee, A. M.; Farshid, B; Parmar, P; Lin, L; Qin, Y. X.; Kasper, F. K.; Mikos, A. G.; Sitharaman, B (September 2013).

492:

technique turned out as a rather effective technique for the preparation of nanocomposite layers. The process operates as a vacuum-based

1813:

Behrens, Silke (2011). "Preparation of functional magnetic nanocomposites and hybrid materials: recent progress and future directions".

110:

621:, in which inorganic nanomaterials are grown within polymeric substrates using vapor-phase precursors that diffuse into the matrix.

618:

2004:

Smith, Connor S.; Savliwala, Shehaab; Mills, Sara C.; Andrew, Jennifer S.; Rinaldi, Carlos; Arnold, David P. (1 January 2020).

184:

2145:

903:

777:

Jose-Yacaman, M.; Rendon, L.; Arenas, J.; Serra Puche, M. C. (1996). "Maya Blue Paint: An

Ancient Nanostructured Material".

1704:

Carrow, James K.; Gaharwar, Akhilesh K. (November 2014). "Bioinspired

Polymeric Nanocomposites for Regenerative Medicine".

1326:

Rafiee, M.A.; et al. (December 3, 2009). "Enhanced

Mechanical Properties of Nanocomposites at Low Graphene Content".

204:

52:

144:

77:

1588:"Influence of Surface Modified MWCNTs on the Mechanical, Electrical and Thermal Properties of Polyimide Nanocomposites"

286:

1363:"Preparation and characterization of polyamide 6 nanocomposites using MWCNTs based on bimetallic Co-Mo/MgO catalyst"

159:

57:

237:

189:

2006:"Electro-infiltrated nickel/iron-oxide and permalloy/iron-oxide nanocomposites for integrated power inductors"

860:

313:(nm) or structures having nano-scale repeat distances between the different phases that make up the material.

1404:"Two-dimensional nanostructure-reinforced biodegradable polymeric nanocomposites for bone tissue engineering"

393:

due to the exceptionally high surface to volume ratio of the reinforcing phase and/or its exceptionally high

438:) of the nanoparticulates introduced can remain very low (on the order of 0.5% to 5%) due to the low filler

411:

179:

1733:"Developing hybrid carbon nanotube- and graphene-enhanced nanocomposite resins for the space launch system"

2140:

2005:

279:

1891:

Varga, L.K. (2007). "Soft magnetic nanocomposites for high-frequency and high-temperature applications".

309:

is a multiphase solid material where one of the phases has one, two or three dimensions of less than 100

968:

S. Zhang; D. Sun; Y. Fu; H. Du (2003). "Recent advances of superhard nanocomposite coatings: a review".

591:

489:

439:

431:

194:

2017:

1970:

1900:

1822:

1599:

1292:

915:

786:

493:

415:

232:

154:

115:

95:

477:, the mixtures of which were found immiscible over large areas in the Gibbs’ triangle of ' Cu-O-Ti.

199:

164:

105:

386:

composites were the topic of textbooks, although the term "nanocomposites" was not in common use.

2076:

2041:

1986:

1943:

1873:

1760:

1533:

1384:

810:

637:). Some examples of such new properties are fire resistance or flame retardancy, and accelerated

485:

390:

354:

134:

373:

investigated the origin of the depth of colour and the resistance to acids and bio-corrosion of

2119:

2033:

1838:

1795:

1752:

1686:

1639:

1568:

1525:

1517:

1482:

1433:

1343:

1308:

1258:

1250:

1126:

997:

Ternary Alloys. A Comprehensive

Compendium of Evaluated Constitutional Data and Phase Diagrams

879:

832:

802:

706:

267:

174:

2115:

927:

2111:

2068:

2025:

1978:

1935:

1908:

1865:

1830:

1787:

1744:

1713:

1676:

1668:

1615:

1607:

1560:

1509:

1472:

1464:

1453:"Tungsten disulfide nanotubes reinforced biodegradable polymers for bone tissue engineering"

1423:

1415:

1374:

1335:

1300:

1242:

1213:

1116:

1108:

1097:"Tungsten disulfide nanotubes reinforced biodegradable polymers for bone tissue engineering"

1057:

1026:

1012:"Nanocomposite layers of ceramic oxides and metals prepared by reactive gas-flow sputtering"

977:

950:

923:

794:

752:

714:

638:

607:

597:

407:

347:

906:(2013). "A molecular dynamics study of effective thermal conductivity in nanocomposites".

848:

43:

2021:

1974:

1904:

1826:

1603:

1296:

1176:

Energetic nanocomposites with sol-gel chemistry: synthesis, safety, and characterization

919:

790:

1681:

1656:

1620:

1587:

1477:

1452:

1428:

1403:

1121:

1096:

1092:

692:

255:

169:

1030:

981:

954:

531:

2134:

2080:

2045:

1764:

1537:

1202:"Environmental anomalies at the World Trade Center: evidence for energetic materials"

572:

462:

383:

213:

149:

100:

27:

1877:

1388:

1379:

1362:

814:

1990:

1947:

899:

686:

394:

378:

317:

250:

125:

1079:

1856:

Zhu, Yinghuai (2010). "Magnetic Nanocomposites: A New Perspective in Catalysis".

1791:

1468:

1112:

798:

358:

139:

2072:

2029:

1939:

1912:

1748:

1173:

1145:

1045:

1982:

1655:

Gaharwar, Akhilesh K.; Peppas, Nicholas A.; Khademhosseini, Ali (March 2014).

1611:

1218:

1201:

700:

682:

423:

310:

262:

2037:

1756:

1732:

1572:

1521:

1254:

1091:

Lalwani, G; Henslee, AM; Farshid, B; Parmar, P; Lin, L; Qin, YX; Kasper, FK;

575:, in general, may be better reinforcing agents compared to carbon nanotubes.

516:

481:

427:

374:

337:

329:

86:

2123:

1869:

1842:

1799:

1717:

1690:

1564:

1529:

1486:

1437:

1347:

1312:

1262:

1246:

1130:

1011:

806:

757:

740:

719:

512:

508:

227:

365:

Nanocomposites are found in nature, for example in the structure of the

1834:

1513:

1061:

451:

366:

321:

1672:

1419:

1339:

1304:

504:

474:

419:

1046:"Copper matrix nanocomposites based on carbon nanotubes or graphene"

35:

2099:

455:

1586:

Singh, BP; Singh, Deepankar; Mathur, R. B.; Dhami, T. L. (2008).

480:

The concept of ceramic-matrix nanocomposites was also applied to

497:

467:

1778:

Behrens, Silke; Appel, Ingo (2016). "Magnetic nanocomposites".

1283:

Manias, Evangelos (2007). "Nanocomposites: Stiffer by design".

1737:

The International Journal of Advanced Manufacturing Technology

526:

325:

1076:

Carbon nanotube reinforced metal matrix composites - A Review

389:

In mechanical terms, nanocomposites differ from conventional

1200:

Ryan, Kevin R.; Gourley, James R.; Jones, Steven E. (2008).

2100:"Nanocomposites: Structure, Phase Behavior, and Properties"

1278:

1276:

1274:

1272:

418:. Other kinds of nanoparticulates may result in enhanced

849:

https://pubs.rsc.org/en/content/ebook/978-1-78262-672-5

617:

An alternative route to synthesis of nanocomposites is

543:

343:<20 nm for making a hard magnetic material soft

2104:

Annual Review of Chemical and Biomolecular Engineering

1657:"Nanocomposite hydrogels for biomedical applications"

1078:, International Materials Reviews, vol. 55, (2010),

507:by the hollow cathode technique that showed a high

426:, heat resistance or mechanical properties such as

1638:" A. B. Morgan, C. A. Wilkie (eds.), Wiley, 2007;

829:Formation and Properties of Clay Polymer Complexes

316:In the broadest sense this definition can include

357:, mechanical strengthening or restricting matrix

995:G. Effenberg, F. Aldinger & P. Rogl (2001).

1080:http://web.eng.fiu.edu/agarwala/PDF/2010/12.pdf

874:P.M. Ajayan; L.S. Schadler; P.V. Braun (2003).

741:"What can be improved by nanometer composites?"

1963:IEEE Antennas and Wireless Propagation Letters

1148:Making nanostructured pyrotechnics in a Beaker

1361:Hassani, A. J.; et al. (March 1, 2014).

1010:M. Birkholz; U. Albers & T. Jung (2004).

658:efficiency of the palladium in the reaction.

287:

8:

765:Concise encyclopedia of composites materials

2010:Journal of Magnetism and Magnetic Materials

1893:Journal of Magnetism and Magnetic Materials

999:. Materials Science-International Services.

596:In the simplest case, appropriately adding

294:

280:

18:

1680:

1619:

1476:

1427:

1378:

1217:

1120:

1074:S. R. Bakshi, D. Lahiri, and A. Argawal,

756:

2116:10.1146/annurev-chembioeng-073009-100856

2098:Kumar, S. K.; Krishnamoorti, R. (2010).

928:10.1016/j.ijheatmasstransfer.2013.02.023

16:Solid material with nano-scale structure

731:

565:Carbon nanotube metal matrix composites

212:

123:

85:

42:

26:

1636:Flame Retardant Polymer Nanocomposites

1044:Janas, Dawid; Liszka, Barbara (2017).

1553:European Journal of Organic Chemistry

7:

1706:Macromolecular Chemistry and Physics

876:Nanocomposite science and technology

863:. Coventive Composites. 2020-09-09.

1095:; Sitharaman, B (September 2013).

861:"What are Polymer Nanocomposites?"

14:

745:J. Jpn. Soc. Powder Powder Metall

619:sequential infiltration synthesis

1780:Current Opinion in Biotechnology

1731:Thomas, Daniel J. (2020-09-01).

1661:Biotechnology and Bioengineering

699:

685:

530:

261:

249:

34:

1380:10.3144/expresspolymlett.2014.2

22:Part of a series of articles on

353:<100 nm for achieving

1:

1235:Chemistry: A European Journal

1031:10.1016/S0257-8972(03)00865-X

982:10.1016/S0257-8972(02)00903-9

955:10.1016/S0021-8502(97)10032-5

670:Heat resistant nanocomposites

603:nanofilled polymer composites

586:Polymer-matrix nanocomposites

446:Ceramic-matrix nanocomposites

1792:10.1016/j.copbio.2016.02.005

1469:10.1016/j.actbio.2013.05.018

1113:10.1016/j.actbio.2013.05.018

799:10.1126/science.273.5272.223

767:, Elsevier Science Ltd, 1994

523:Metal-matrix nanocomposites

377:paint, attributing it to a

2162:

2073:10.1007/s13204-019-01178-z

2030:10.1016/j.jmmm.2019.165718

1940:10.1109/JPROC.2017.2748520

1913:10.1016/j.jmmm.2007.03.180

1749:10.1007/s00170-020-06038-7

1592:Nanoscale Research Letters

908:Int. J. Heat Mass Transfer

589:

1983:10.1109/LAWP.2015.2430284

1612:10.1007/s11671-008-9179-4

1219:10.1007/s10669-008-9182-4

513:coefficients of friction

238:Nanocrystalline material

214:Nanostructured materials

1928:Proceedings of the IEEE

1367:Express Polymer Letters

649:Magnetic nanocomposites

517:resistance to corrosion

1870:10.1002/cctc.200900314

1718:10.1002/macp.201400427

1565:10.1002/ejoc.201501411

1247:10.1002/chem.201404153

1178:, LLNL UCRL-JC-146739"

831:", Elsevier, NY 1979;

628:genuine nanocomposites

2146:Solid-state chemistry

739:Kamigaito, O (1991).

592:Polymer nanocomposite

440:percolation threshold

424:dielectric properties

268:Technology portal

63:Mechanical properties

1206:The Environmentalist

758:10.2497/jjspm.38.315

416:thermal conductivity

402:bulk of the matrix.

233:Nanoporous materials

96:Buckminsterfullerene

2061:Applied Nanoscience

2022:2020JMMM..49365718S

1975:2016IAWPL..15...72H

1934:(12): 2330 - 2346.

1905:2007JMMM..316..442V

1827:2011Nanos...3..877B

1604:2008NRL.....3..444S

1508:(47): 20248–20280.

1297:2007NatMa...6....9M

1241:(48): 15966–15974.

1019:Surf. Coat. Technol

970:Surf. Coat. Technol

920:2013IJHMT..61..577T

791:1996Sci...273..223J

509:mechanical hardness

486:Gas flow sputtering

391:composite materials

346:<50 nm for

135:Carbon quantum dots

1835:10.1039/C0NR00634C

1514:10.1039/D1NR07363J

1457:Acta Biomaterialia

1101:Acta Biomaterialia

1062:10.1039/C7QM00316A

1050:Mater. Chem. Front

542:. You can help by

420:optical properties

355:superparamagnetism

336:<5 nm for

256:Science portal

68:Optical properties

1673:10.1002/bit.25160

1644:978-0-471-73426-0

1420:10.1021/bm301995s

1408:Biomacromolecules

1340:10.1021/nn9010472

1334:(12): 3884–3890.

885:978-3-527-30359-5

837:978-0-444-41706-0

707:Technology portal

560:

559:

304:

303:

116:Carbon allotropes

2153:

2127:

2085:

2084:

2056:

2050:

2049:

2001:

1995:

1994:

1958:

1952:

1951:

1923:

1917:

1916:

1888:

1882:

1881:

1853:

1847:

1846:

1810:

1804:

1803:

1775:

1769:

1768:

1743:(7): 2249–2255.

1728:

1722:

1721:

1701:

1695:

1694:

1684:

1652:

1646:

1632:

1626:

1625:

1623:

1583:

1577:

1576:

1559:(6): 1071–1090.

1548:

1542:

1541:

1497:

1491:

1490:

1480:

1463:(9): 8365–8373.

1448:

1442:

1441:

1431:

1399:

1393:

1392:

1382:

1358:

1352:

1351:

1323:

1317:

1316:

1305:10.1038/nmat1812

1285:Nature Materials

1280:

1267:

1266:

1230:

1224:

1223:

1221:

1197:

1191:

1190:

1188:

1187:

1182:

1169:

1163:

1162:

1160:

1159:

1154:

1141:

1135:

1134:

1124:

1088:

1082:

1072:

1066:

1065:

1041:

1035:

1034:

1025:(2–3): 279–285.

1016:

1007:

1001:

1000:

992:

986:

985:

976:(2–3): 113–119.

965:

959:

958:

949:(5–6): 511–535.

938:

932:

931:

896:

890:

889:

871:

865:

864:

857:

851:

845:

839:

825:

819:

818:

774:

768:

762:

760:

736:

715:Hybrid materials

709:

704:

703:

695:

690:

689:

639:biodegradability

608:nanoparticulates

598:nanoparticulates

555:

552:

534:

527:

408:carbon nanotubes

348:refractive index

296:

289:

282:

266:

265:

254:

253:

205:Titanium dioxide

44:Carbon nanotubes

38:

19:

2161:

2160:

2156:

2155:

2154:

2152:

2151:

2150:

2131:

2130:

2097:

2094:

2092:Further reading

2089:

2088:

2058:

2057:

2053:

2003:

2002:

1998:

1960:

1959:

1955:

1925:

1924:

1920:

1890:

1889:

1885:

1855:

1854:

1850:

1812:

1811:

1807:

1777:

1776:

1772:

1730:

1729:

1725:

1703:

1702:

1698:

1654:

1653:

1649:

1633:

1629:

1598:(11): 444–453.

1585:

1584:

1580:

1550:

1549:

1545:

1499:

1498:

1494:

1450:

1449:

1445:

1401:

1400:

1396:

1360:

1359:

1355:

1325:

1324:

1320:

1282:

1281:

1270:

1232:

1231:

1227:

1199:

1198:

1194:

1185:

1183:

1180:

1171:

1170:

1166:

1157:

1155:

1152:

1143:

1142:

1138:

1090:

1089:

1085:

1073:

1069:

1043:

1042:

1038:

1014:

1009:

1008:

1004:

994:

993:

989:

967:

966:

962:

940:

939:

935:

898:

897:

893:

886:

873:

872:

868:

859:

858:

854:

846:

842:

826:

822:

785:(5272): 223–5.

776:

775:

771:

738:

737:

733:

728:

705:

698:

691:

684:

681:

672:

651:

594:

588:

556:

550:

547:

540:needs expansion

525:

501:

471:

448:

300:

260:

248:

145:Aluminium oxide

17:

12:

11:

5:

2159:

2157:

2149:

2148:

2143:

2133:

2132:

2129:

2128:

2093:

2090:

2087:

2086:

2067:(2): 455–464.

2051:

1996:

1953:

1918:

1899:(2): 442–447.

1883:

1864:(4): 365–374.

1848:

1821:(3): 877–892.

1805:

1770:

1723:

1712:(3): 248–264.

1696:

1667:(3): 441–453.

1647:

1627:

1578:

1543:

1492:

1443:

1414:(3): 900–909.

1394:

1373:(3): 177–186.

1353:

1318:

1268:

1225:

1192:

1164:

1136:

1107:(9): 8365–73.

1083:

1067:

1036:

1002:

987:

960:

943:J. Aerosol Sci

933:

891:

884:

866:

852:

840:

827:B.K.G. Theng "

820:

769:

730:

729:

727:

724:

723:

722:

717:

711:

710:

696:

693:Science portal

680:

677:

671:

668:

650:

647:

590:Main article:

587:

584:

558:

557:

537:

535:

524:

521:

499:

490:hollow cathode

469:

447:

444:

363:

362:

351:

344:

341:

302:

301:

299:

298:

291:

284:

276:

273:

272:

271:

270:

258:

243:

242:

241:

240:

235:

230:

225:

217:

216:

210:

209:

208:

207:

202:

197:

192:

187:

182:

177:

172:

167:

162:

157:

152:

147:

142:

137:

129:

128:

121:

120:

119:

118:

113:

108:

103:

98:

90:

89:

83:

82:

81:

80:

75:

70:

65:

60:

55:

47:

46:

40:

39:

31:

30:

24:

23:

15:

13:

10:

9:

6:

4:

3:

2:

2158:

2147:

2144:

2142:

2141:Nanomaterials

2139:

2138:

2136:

2125:

2121:

2117:

2113:

2109:

2105:

2101:

2096:

2095:

2091:

2082:

2078:

2074:

2070:

2066:

2062:

2055:

2052:

2047:

2043:

2039:

2035:

2031:

2027:

2023:

2019:

2015:

2011:

2007:

2000:

1997:

1992:

1988:

1984:

1980:

1976:

1972:

1968:

1964:

1957:

1954:

1949:

1945:

1941:

1937:

1933:

1929:

1922:

1919:

1914:

1910:

1906:

1902:

1898:

1894:

1887:

1884:

1879:

1875:

1871:

1867:

1863:

1859:

1852:

1849:

1844:

1840:

1836:

1832:

1828:

1824:

1820:

1816:

1809:

1806:

1801:

1797:

1793:

1789:

1785:

1781:

1774:

1771:

1766:

1762:

1758:

1754:

1750:

1746:

1742:

1738:

1734:

1727:

1724:

1719:

1715:

1711:

1707:

1700:

1697:

1692:

1688:

1683:

1678:

1674:

1670:

1666:

1662:

1658:

1651:

1648:

1645:

1641:

1637:

1631:

1628:

1622:

1617:

1613:

1609:

1605:

1601:

1597:

1593:

1589:

1582:

1579:

1574:

1570:

1566:

1562:

1558:

1554:

1547:

1544:

1539:

1535:

1531:

1527:

1523:

1519:

1515:

1511:

1507:

1503:

1496:

1493:

1488:

1484:

1479:

1474:

1470:

1466:

1462:

1458:

1454:

1447:

1444:

1439:

1435:

1430:

1425:

1421:

1417:

1413:

1409:

1405:

1398:

1395:

1390:

1386:

1381:

1376:

1372:

1368:

1364:

1357:

1354:

1349:

1345:

1341:

1337:

1333:

1329:

1322:

1319:

1314:

1310:

1306:

1302:

1298:

1294:

1290:

1286:

1279:

1277:

1275:

1273:

1269:

1264:

1260:

1256:

1252:

1248:

1244:

1240:

1236:

1229:

1226:

1220:

1215:

1211:

1207:

1203:

1196:

1193:

1179:

1177:

1168:

1165:

1151:

1149:

1140:

1137:

1132:

1128:

1123:

1118:

1114:

1110:

1106:

1102:

1098:

1094:

1087:

1084:

1081:

1077:

1071:

1068:

1063:

1059:

1055:

1051:

1047:

1040:

1037:

1032:

1028:

1024:

1020:

1013:

1006:

1003:

998:

991:

988:

983:

979:

975:

971:

964:

961:

956:

952:

948:

944:

937:

934:

929:

925:

921:

917:

913:

909:

905:

901:

900:Tian, Zhiting

895:

892:

887:

881:

877:

870:

867:

862:

856:

853:

850:

844:

841:

838:

834:

830:

824:

821:

816:

812:

808:

804:

800:

796:

792:

788:

784:

780:

773:

770:

766:

763:in Kelly, A,

759:

754:

751:(3): 315–21.

750:

746:

742:

735:

732:

725:

721:

718:

716:

713:

712:

708:

702:

697:

694:

688:

683:

678:

676:

669:

667:

663:

659:

655:

648:

646:

642:

640:

636:

635:

630:

629:

622:

620:

615:

611:

609:

605:

604:

599:

593:

585:

583:

581:

580:superthermite

576:

574:

573:nanomaterials

568:

566:

554:

551:November 2008

545:

541:

538:This section

536:

533:

529:

528:

522:

520:

518:

514:

510:

506:

502:

495:

491:

487:

483:

478:

476:

472:

464:

463:phase diagram

459:

457:

453:

445:

443:

441:

437:

436:mass fraction

433:

429:

425:

421:

417:

413:

410:improves the

409:

403:

400:

396:

392:

387:

385:

380:

376:

372:

368:

367:abalone shell

360:

356:

352:

349:

345:

342:

339:

335:

334:

333:

331:

327:

323:

319:

314:

312:

308:

307:Nanocomposite

297:

292:

290:

285:

283:

278:

277:

275:

274:

269:

264:

259:

257:

252:

247:

246:

245:

244:

239:

236:

234:

231:

229:

226:

224:

223:Nanocomposite

221:

220:

219:

218:

215:

211:

206:

203:

201:

198:

196:

193:

191:

188:

186:

185:Iron–platinum

183:

181:

178:

176:

173:

171:

168:

166:

163:

161:

158:

156:

153:

151:

148:

146:

143:

141:

138:

136:

133:

132:

131:

130:

127:

126:nanoparticles

122:

117:

114:

112:

111:Health impact

109:

107:

104:

102:

101:C70 fullerene

99:

97:

94:

93:

92:

91:

88:

84:

79:

76:

74:

71:

69:

66:

64:

61:

59:

56:

54:

51:

50:

49:

48:

45:

41:

37:

33:

32:

29:

28:Nanomaterials

25:

21:

20:

2107:

2103:

2064:

2060:

2054:

2013:

2009:

1999:

1966:

1962:

1956:

1931:

1927:

1921:

1896:

1892:

1886:

1861:

1857:

1851:

1818:

1814:

1808:

1783:

1779:

1773:

1740:

1736:

1726:

1709:

1705:

1699:

1664:

1660:

1650:

1635:

1630:

1595:

1591:

1581:

1556:

1552:

1546:

1505:

1501:

1495:

1460:

1456:

1446:

1411:

1407:

1397:

1370:

1366:

1356:

1331:

1327:

1321:

1288:

1284:

1238:

1234:

1228:

1209:

1205:

1195:

1184:. Retrieved

1175:

1167:

1156:. Retrieved

1147:

1139:

1104:

1100:

1086:

1075:

1070:

1053:

1049:

1039:

1022:

1018:

1005:

996:

990:

973:

969:

963:

946:

942:

936:

911:

907:

894:

875:

869:

855:

843:

828:

823:

782:

778:

772:

764:

748:

744:

734:

673:

664:

660:

656:

652:

643:

633:

632:

627:

626:

623:

616:

612:

602:

601:

595:

579:

577:

569:

561:

548:

544:adding to it

539:

479:

460:

449:

435:

404:

398:

395:aspect ratio

388:

379:nanoparticle

370:

364:

318:porous media

315:

306:

305:

222:

160:Cobalt oxide

140:Quantum dots

73:Applications

1858:ChemCatChem

1291:(1): 9–11.

914:: 577–582.

902:; Hu, Han;

582:materials.

515:and a high

461:The binary

359:dislocation

2135:Categories

2016:: 165718.

1186:2008-09-28

1172:Gash, AE.

1158:2008-09-28

1144:Gash, AE.

726:References

494:deposition

482:thin films

412:electrical

330:copolymers

311:nanometers

180:Iron oxide

87:Fullerenes

2110:: 37–58.

2081:203986488

2046:202137993

2038:0304-8853

1969:: 72–75.

1815:Nanoscale

1786:: 89–96.

1765:225292702

1757:1433-3015

1573:1099-0690

1538:244288401

1522:2040-3372

1502:Nanoscale

1255:1521-3765

1212:: 56–63.

1093:Mikos, AG

1056:: 22–35.

904:Sun, Ying

878:. Wiley.

428:stiffness

375:Maya blue

338:catalytic

150:Cellulose

106:Chemistry

58:Chemistry

53:Synthesis

2124:22432572

1878:96894484

1843:21165500

1800:26938504

1691:24264728

1530:34851346

1487:23727293

1438:23405887

1389:97169049

1348:19957928

1328:ACS Nano

1313:17199118

1263:25302846

1131:23727293

815:34424830

720:Aquamelt

679:See also

511:, small

432:strength

382:polymer/

361:movement

340:activity

322:colloids

228:Nanofoam

195:Platinum

78:Timeline

2018:Bibcode

1991:1335792

1971:Bibcode

1948:6587533

1901:Bibcode

1823:Bibcode

1682:3924876

1621:3244951

1600:Bibcode

1478:3732565

1429:3601907

1293:Bibcode

1122:3732565

916:Bibcode

807:8662502

787:Bibcode

779:Science

634:hybrids

488:by the

452:ceramic

350:changes

155:Ceramic

2122:

2079:

2044:

2036:

1989:

1946:

1876:

1841:

1798:

1763:

1755:

1689:

1679:

1642:

1618:

1571:

1536:

1528:

1520:

1485:

1475:

1436:

1426:

1387:

1346:

1311:

1261:

1253:

1129:

1119:

882:

835:

813:

805:

399:et al.

371:et al.

200:Silver

165:Copper

124:Other

2077:S2CID

2042:S2CID

1987:S2CID

1944:S2CID

1874:S2CID

1761:S2CID

1534:S2CID

1385:S2CID

1181:(PDF)

1153:(PDF)

1015:(PDF)

811:S2CID

456:metal

190:Lipid

2120:PMID

2034:ISSN

1839:PMID

1796:PMID

1753:ISSN

1687:PMID

1640:ISBN

1569:ISSN

1557:2016

1526:PMID

1518:ISSN

1483:PMID

1434:PMID

1344:PMID

1309:PMID

1259:PMID

1251:ISSN

1127:PMID

880:ISBN

833:ISBN

803:PMID

503:and

473:and

414:and

384:clay

328:and

326:gels

175:Iron

170:Gold

2112:doi

2069:doi

2026:doi

2014:493

1979:doi

1936:doi

1932:105

1909:doi

1897:316

1866:doi

1831:doi

1788:doi

1745:doi

1741:110

1714:doi

1710:216

1677:PMC

1669:doi

1665:111

1616:PMC

1608:doi

1561:doi

1510:doi

1473:PMC

1465:doi

1424:PMC

1416:doi

1375:doi

1336:doi

1301:doi

1243:doi

1214:doi

1117:PMC

1109:doi

1058:doi

1027:doi

1023:179

978:doi

974:167

951:doi

924:doi

795:doi

783:273

753:doi

631:or

546:.

498:TiO

468:TiO

2137::

2118:.

2106:.

2102:.

2075:.

2065:10

2063:.

2040:.

2032:.

2024:.

2012:.

2008:.

1985:.

1977:.

1967:15

1965:.

1942:.

1930:.

1907:.

1895:.

1872:.

1860:.

1837:.

1829:.

1817:.

1794:.

1784:39

1782:.

1759:.

1751:.

1739:.

1735:.

1708:.

1685:.

1675:.

1663:.

1659:.

1614:.

1606:.

1594:.

1590:.

1567:.

1555:.

1532:.

1524:.

1516:.

1506:13

1504:.

1481:.

1471:.

1459:.

1455:.

1432:.

1422:.

1412:14

1410:.

1406:.

1383:.

1369:.

1365:.

1342:.

1330:.

1307:.

1299:.

1287:.

1271:^

1257:.

1249:.

1239:20

1237:.

1210:29

1208:.

1204:.

1125:.

1115:.

1103:.

1099:.

1052:.

1048:.

1021:.

1017:.

972:.

947:29

945:.

922:.

912:61

910:.

809:.

801:.

793:.

781:.

749:38

747:.

743:.

641:.

519:.

505:Cu

475:Cu

430:,

422:,

324:,

320:,

2126:.

2114::

2108:1

2083:.

2071::

2048:.

2028::

2020::

1993:.

1981::

1973::

1950:.

1938::

1915:.

1911::

1903::

1880:.

1868::

1862:2

1845:.

1833::

1825::

1819:3

1802:.

1790::

1767:.

1747::

1720:.

1716::

1693:.

1671::

1634:"

1624:.

1610::

1602::

1596:3

1575:.

1563::

1540:.

1512::

1489:.

1467::

1461:9

1440:.

1418::

1391:.

1377::

1371:8

1350:.

1338::

1332:3

1315:.

1303::

1295::

1289:6

1265:.

1245::

1222:.

1216::

1189:.

1174:"

1161:.

1150:"

1146:"

1133:.

1111::

1105:9

1064:.

1060::

1054:2

1033:.

1029::

984:.

980::

957:.

953::

930:.

926::

918::

888:.

817:.

797::

789::

761:.

755::

553:)

549:(

500:2

470:2

295:e

288:t

281:v

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.