1206:), the grain size of the samples was observed to double from 10 to 20 nm after 24 hours of exposure to ambient temperatures. Although materials with higher melting points are more stable at room temperatures, consolidating nanocrystalline feedstock into a macroscopic component often requires exposing the material to elevated temperatures for extended periods of time, which will result in coarsening of the nanocrystalline microstructure. Thus, thermally

361:

373:

33:

686:, as grain boundaries are extremely effective at blocking the motion of dislocations. Yielding occurs when the stress due to dislocation pileup at a grain boundary becomes sufficient to activate slip of dislocations in the adjacent grain. This critical stress increases as the grain size decreases, and these physics are empirically captured by the Hall-Petch relationship,

146:

864:

Hall-Petch regime, any further decrease in the grain size weakens the material because an increase in grain boundary area results in increased grain boundary sliding. Chandross & Argibay modeled grain boundary sliding as viscous flow and related the yield strength of the material in this regime to material properties as

567:

amorphous grain boundary phase. For example, the elastic modulus has been shown to decrease by 30% for nanocrystalline metals and more than 50% for nanocrystalline ionic materials. This is because the amorphous grain boundary regions are less dense than the crystalline grains, and thus have a larger volume per atom,

1219:

While the mechanical behavior of ceramics is often dominated by flaws, i.e. porosity, instead of grain size, grain-size strengthening is also observed in high-density ceramic specimens. Additionally, nanocrystalline ceramics have been shown to sinter more rapidly than bulk ceramics, leading to higher

566:

Nanocrystalline materials show exceptional mechanical properties relative to their coarse-grained varieties. Because the volume fraction of grain boundaries in nanocrystalline materials can be as large as 30%, the mechanical properties of nanocrystalline materials are significantly influenced by this

1270:

While the synthesis of nanocrystalline feedstocks in the form of foils, powders, and wires is relatively straightforward, the tendency of nanocrystalline feedstocks to coarsen upon extended exposure to elevated temperatures means that low-temperature and rapid densification techniques are necessary

863:

As the grain size continues to decrease, a critical grain size is reached at which intergranular deformation, i.e. grain boundary sliding, becomes more energetically favorable than intragranular dislocation motion. Below this critical grain size, often referred to as the “reverse” or “inverse”

1261:

and linearly with the grain boundary diffusivity, refining the grain size from 10 μm to 10 nm can increase the diffusional creep rate by approximately 11 orders of magnitude. This superplasticity could prove invaluable for the processing of ceramic components, as the material may be

1210:

are of considerable engineering interest. Experiments have shown that traditional microstructural stabilization techniques such as grain boundary pinning via solute segregation or increasing solute concentrations have proven successful in some alloy systems, such as Pd-Zr and Ni-W.

972:

1170: is the grain boundary thickness and typically on the order of 1 nm. The maximum strength of a metal is given by the intersection of this line with the Hall-Petch relationship, which typically occurs around a grain size of

1610:

Wollmershauser, James; Feigelson, Boris; Gorzkowski, Edward; Ellis, Chase; Gosami, Ramasis; Qadri, Syed; Tischler, Joseph; Kub, Fritz; Everett, Richard (May 2014). "An extended hardness limit in bulk nanoceramics".

1193:

Due to the large amount of interfacial energy associated with a large volume fraction of grain boundaries, nanocrystalline metals are thermally unstable. In nanocrystalline samples of low-melting point metals (i.e.

1220:

densities and improved mechanical properties, although extended exposure to the high pressures and elevated temperatures required to sinter the part to full density can result in coarsening of the nanostructure.

668:

1390:

Jiang, Jie; Zhu, Liping; Wu, Yazhen; Zeng, Yujia; He, Haiping; Lin, Junming; Ye, Zhizhen (February 2012). "Effects of phosphorus doping in ZnO nanocrystals by metal organic chemical vapor deposition".

757:

856:

is the average grain size. Additionally, because nanocrystalline grains are too small to contain a significant number of dislocations, nanocrystalline metals undergo negligible amounts of

1417:

Giallonardo, J.D.; Erb, U.; Aust, K.T.; Palumbo, G. (21 December 2011). "The influence of grain size and texture on the Young's modulus of nanocrystalline nickel and nickel–iron alloys".

1148:

870:

1538:

Cordero, Zachary; Knight, Braden; Schuh, Christopher (November 2016). "Six decades of the Hall–Petch effect – a survey of grain-size strengthening studies on pure metals".

1034:

814:

787:

487:

Solid-state processes do not involve melting or evaporating the material and are typically done at relatively low temperatures. Examples of solid state processes include

614:

463:, or more sophisticated methods such as the Warren-Averbach method or computer modeling of the diffraction pattern. The crystallite size can be measured directly using

1168:

585:

1259:

1207:

1088:

1061:

1188:

995:

854:

834:

182:

172:

50:

455:. In materials with very small grain sizes, the diffraction peaks will be broadened. This broadening can be related to a crystallite size using the

403:

1223:

The large volume fraction of grain boundaries associated with nanocrystalline materials causes interesting behavior in ceramic systems, such as

177:

1231:, analogous to the grain boundary sliding deformation mechanism in nanocrystalline metals. Because the diffusional creep rate scales as

1638:

Cha, Seung; Hong, Soon; Kim, Byung (June 2003). "Spark plasma sintering behavior of nanocrystalline WC–10Co cemented carbide powders".

97:

220:

69:

1583:

Detor, Andrew; Schuh, Christopher (November 2007). "Microstructural evolution during the heat treatment of nanocrystalline alloys".

1276:

1227:

in otherwise brittle ceramics. The large volume fraction of grain boundaries allows for a significant diffusional flow of atoms via

116:

619:

464:

76:

294:

1317:

54:

1307:

314:

162:

83:

692:

683:

254:

187:

1271:

to consolidate these feedstocks into bulk components. A variety of techniques show potential in this respect, such as

836:

is a material-specific constant that describes the magnitude of the metal's response to grain size strengthening, and

396:

65:

492:

444:

and conventional coarse-grained materials. Definitions vary, but nanocrystalline material is commonly defined as a

43:

1341:"Low temperature synthesis and characterization of single phase multi-component fluorite oxide nanoparticle sols"

516:

448:(grain) size below 100 nm. Grain sizes from 100 to 500 nm are typically considered "ultrafine" grains.

269:

167:

299:

1093:

1262:

converted back into a conventional, coarse-grained material via additional thermal treatment after forming.

289:

967:{\displaystyle \tau ={\bigg (}L{\frac {\rho _{L}}{M}}{\bigg )}{\bigg (}1-{\frac {T}{T_{m}}}{\bigg )}f_{g},}

816: is a material-specific constant that accounts for the effects of all other strengthening mechanisms,

1709:

1272:

512:

475:

Nanocrystalline materials can be prepared in several ways. Methods are typically categorized based on the

389:

304:

90:

1279:, although the synthesis of bulk nanocrystalline components on a commercial scale remains untenable.

342:

264:

225:

205:

511:. This often produces an amorphous metal, which can be transformed into an nanocrystalline metal by

1714:

488:

309:

274:

215:

1565:

1434:

1004:

998:

792:

765:

460:

244:

590:

674:, a nanocrystalline material will have a lower elastic modulus than its bulk crystalline form.

1704:

1478:

1362:

1313:

456:

452:

377:

284:

1153:

570:

1678:

1647:

1620:

1592:

1555:

1547:

1518:

1468:

1426:

1399:

1370:

1352:

1234:

857:

671:

531:

441:

1066:

1039:

1224:

476:

425:

153:

1309:

Amorphous and nanocrystalline materials : preparation, properties, and applications

1375:

1340:

1173:

980:

860:, and nanocrystalline materials can thus be assumed to behave with perfect plasticity.

839:

819:

670:, will be smaller in the grain boundary regions than in the bulk grains. Thus, via the

555:

504:

365:

279:

1651:

616:, is the same within the grain boundaries as in the bulk grains, the elastic modulus,

1698:

1683:

1666:

1569:

1523:

1506:

1438:

551:

508:

332:

323:

259:

210:

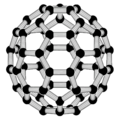

137:

1473:

1456:

1339:

Anandkumar, Mariappan; Bhattacharya, Saswata; Deshpande, Atul Suresh (2019-08-23).

1288:

1090:

is the volume fraction of material in the grains vs the grain boundaries, given by

479:

the material transitions through before forming the nanocrystalline final product.

360:

235:

1624:

1551:

1430:

1403:

1665:

Ward, Austin; French, Matthew; Leonard, Donovan; Cordero, Zachary (April 2018).

1293:

1228:

445:

429:

249:

32:

17:

372:

1366:

527:

437:

433:

196:

1482:

1596:

1560:

1195:

337:

1357:

547:

145:

682:

The exceptional yield strength of nanocrystalline metals is due to

1667:"Grain growth during ultrasonic welding of nanocrystalline alloys"

535:

1203:

1199:

26:

663:{\displaystyle E\propto \partial ^{2}U/\partial \Omega ^{2}}

1237:

1176:

1156:

1096:

1069:

1042:

1007:

983:

873:

842:

822:

795:

768:

695:

622:

593:

573:

451:

The grain size of a NC sample can be estimated using

1455:Chandross, Michael; Argibay, Nicolas (March 2020).

530:of nanocrystalline materials can be produced using

491:using a high-energy ball mill and certain types of

57:. Unsourced material may be challenged and removed.

1253:

1182:

1162:

1142:

1082:

1055:

1028:

989:

966:

848:

828:

808:

781:

752:{\displaystyle \sigma _{y}=\sigma _{0}+Kd^{-1/2},}

751:

662:

608:

579:

946:

916:

909:

882:

503:Nanocrystalline metals can be produced by rapid

554:, can be made into nanocrystalline foils using

1036:is the atomic volume in the amorphous phase,

397:

8:

1334:

1332:

1450:

1448:

1671:Journal of Materials Processing Technology

404:

390:

128:

1682:

1559:

1522:

1500:

1498:

1496:

1494:

1492:

1472:

1374:

1356:

1242:

1236:

1175:

1155:

1134:

1122:

1101:

1095:

1074:

1068:

1047:

1041:

1018:

1012:

1006:

982:

955:

945:

944:

936:

927:

915:

914:

908:

907:

896:

890:

881:

880:

872:

841:

821:

800:

794:

773:

767:

736:

729:

713:

700:

694:

654:

642:

633:

621:

592:

572:

117:Learn how and when to remove this message

507:from the liquid using a process such as

1328:

1143:{\displaystyle f_{g}=(1-\delta /d)^{3}}

436:. These materials fill the gap between

322:

233:

195:

152:

136:

587:. Assuming the interatomic potential,

1306:A. Inoue; K. Hashimoto, eds. (2001).

1190:= 10 nm for BCC and FCC metals.

7:

1640:Materials Science and Engineering: A

55:adding citations to reliable sources

651:

647:

630:

600:

574:

459:(applicable up to ~50 nm), a

25:

1277:ultrasonic additive manufacturing

1684:10.1016/j.jmatprotec.2017.11.049

1063:is the melting temperature, and

465:transmission electron microscopy

371:

359:

144:

31:

1540:International Materials Reviews

132:Part of a series of articles on

42:needs additional citations for

1474:10.1103/PhysRevLett.124.125501

1131:

1110:

603:

597:

1:

1652:10.1016/S0921-5093(02)00605-6

1625:10.1016/j.actamat.2014.01.030

1585:Journal of Materials Research

1552:10.1080/09506608.2016.1191808

1511:Progress in Materials Science

1457:"Ultimate strength of metals"

1208:stable nanocrystalline alloys

1524:10.1016/0079-6425(89)90001-7

1431:10.1080/14786435.2011.615350

1404:10.1016/j.matlet.2011.10.072

684:grain boundary strengthening

1507:"Nanocrystalline materials"

1029:{\displaystyle \rho _{L}/M}

809:{\displaystyle \sigma _{0}}

782:{\displaystyle \sigma _{y}}

517:crystallization temperature

1731:

609:{\displaystyle U(\Omega )}

546:Some metals, particularly

493:severe plastic deformation

66:"Nanocrystalline material"

1505:Gleiter, Herbert (1989).

1215:Nanocrystalline ceramics

348:Nanocrystalline material

324:Nanostructured materials

1461:Physical Review Letters

1163:{\displaystyle \delta }

580:{\displaystyle \Omega }

1419:Philosophical Magazine

1273:spark plasma sintering

1255:

1254:{\displaystyle d^{-3}}

1184:

1164:

1144:

1084:

1057:

1030:

991:

968:

850:

830:

810:

783:

753:

678:Nanocrystalline metals

664:

610:

581:

523:Vapor-phase processing

483:Solid-state processing

440:materials without any

1597:10.1557/JMR.2007.0403

1467:(12): 125501–125505.

1256:

1185:

1165:

1145:

1085:

1083:{\displaystyle f_{g}}

1058:

1056:{\displaystyle T_{m}}

1031:

992:

969:

851:

831:

811:

789:is the yield stress,

784:

754:

665:

611:

582:

562:Mechanical properties

378:Technology portal

173:Mechanical properties

1312:. Berlin: Springer.

1235:

1174:

1154:

1094:

1067:

1040:

1005:

981:

871:

840:

820:

793:

766:

693:

620:

591:

571:

461:Williamson-Hall plot

343:Nanoporous materials

206:Buckminsterfullerene

51:improve this article

1351:(46): 26825–26830.

542:Solution processing

489:mechanical alloying

432:size of only a few

245:Carbon quantum dots

1358:10.1039/C9RA04636D

1251:

1180:

1160:

1140:

1080:

1053:

1026:

999:enthalpy of fusion

987:

964:

846:

826:

806:

779:

749:

660:

606:

577:

534:processes such as

366:Science portal

178:Optical properties

1591:(11): 3233–3248.

1425:(36): 4594–4605.

1392:Materials Letters

1183:{\displaystyle d}

990:{\displaystyle L}

942:

905:

849:{\displaystyle d}

829:{\displaystyle K}

556:electrodeposition

499:Liquid processing

457:Scherrer equation

453:x-ray diffraction

414:

413:

226:Carbon allotropes

127:

126:

119:

101:

16:(Redirected from

1722:

1689:

1688:

1686:

1662:

1656:

1655:

1635:

1629:

1628:

1607:

1601:

1600:

1580:

1574:

1573:

1563:

1535:

1529:

1528:

1526:

1502:

1487:

1486:

1476:

1452:

1443:

1442:

1414:

1408:

1407:

1387:

1381:

1380:

1378:

1360:

1336:

1323:

1260:

1258:

1257:

1252:

1250:

1249:

1189:

1187:

1186:

1181:

1169:

1167:

1166:

1161:

1149:

1147:

1146:

1141:

1139:

1138:

1126:

1106:

1105:

1089:

1087:

1086:

1081:

1079:

1078:

1062:

1060:

1059:

1054:

1052:

1051:

1035:

1033:

1032:

1027:

1022:

1017:

1016:

996:

994:

993:

988:

973:

971:

970:

965:

960:

959:

950:

949:

943:

941:

940:

928:

920:

919:

913:

912:

906:

901:

900:

891:

886:

885:

858:strain-hardening

855:

853:

852:

847:

835:

833:

832:

827:

815:

813:

812:

807:

805:

804:

788:

786:

785:

780:

778:

777:

758:

756:

755:

750:

745:

744:

740:

718:

717:

705:

704:

672:rule of mixtures

669:

667:

666:

661:

659:

658:

646:

638:

637:

615:

613:

612:

607:

586:

584:

583:

578:

532:vapor deposition

442:long range order

428:material with a

424:) material is a

406:

399:

392:

376:

375:

364:

363:

315:Titanium dioxide

154:Carbon nanotubes

148:

129:

122:

115:

111:

108:

102:

100:

59:

35:

27:

21:

1730:

1729:

1725:

1724:

1723:

1721:

1720:

1719:

1695:

1694:

1693:

1692:

1664:

1663:

1659:

1637:

1636:

1632:

1613:Acta Materialia

1609:

1608:

1604:

1582:

1581:

1577:

1537:

1536:

1532:

1504:

1503:

1490:

1454:

1453:

1446:

1416:

1415:

1411:

1389:

1388:

1384:

1338:

1337:

1330:

1320:

1305:

1302:

1285:

1268:

1238:

1233:

1232:

1225:superplasticity

1217:

1172:

1171:

1152:

1151:

1130:

1097:

1092:

1091:

1070:

1065:

1064:

1043:

1038:

1037:

1008:

1003:

1002:

979:

978:

951:

932:

892:

869:

868:

838:

837:

818:

817:

796:

791:

790:

769:

764:

763:

725:

709:

696:

691:

690:

680:

650:

629:

618:

617:

589:

588:

569:

568:

564:

544:

525:

501:

485:

477:phase of matter

473:

426:polycrystalline

418:nanocrystalline

410:

370:

358:

255:Aluminium oxide

123:

112:

106:

103:

60:

58:

48:

36:

23:

22:

18:Nanocrystalline

15:

12:

11:

5:

1728:

1726:

1718:

1717:

1712:

1707:

1697:

1696:

1691:

1690:

1657:

1646:(1–2): 31–38.

1630:

1602:

1575:

1546:(8): 495–512.

1530:

1517:(4): 223–315.

1488:

1444:

1409:

1382:

1327:

1326:

1325:

1324:

1318:

1301:

1298:

1297:

1296:

1291:

1284:

1281:

1267:

1264:

1248:

1245:

1241:

1216:

1213:

1179:

1159:

1137:

1133:

1129:

1125:

1121:

1118:

1115:

1112:

1109:

1104:

1100:

1077:

1073:

1050:

1046:

1025:

1021:

1015:

1011:

986:

975:

974:

963:

958:

954:

948:

939:

935:

931:

926:

923:

918:

911:

904:

899:

895:

889:

884:

879:

876:

845:

825:

803:

799:

776:

772:

760:

759:

748:

743:

739:

735:

732:

728:

724:

721:

716:

712:

708:

703:

699:

679:

676:

657:

653:

649:

645:

641:

636:

632:

628:

625:

605:

602:

599:

596:

576:

563:

560:

543:

540:

524:

521:

505:solidification

500:

497:

484:

481:

472:

469:

412:

411:

409:

408:

401:

394:

386:

383:

382:

381:

380:

368:

353:

352:

351:

350:

345:

340:

335:

327:

326:

320:

319:

318:

317:

312:

307:

302:

297:

292:

287:

282:

277:

272:

267:

262:

257:

252:

247:

239:

238:

231:

230:

229:

228:

223:

218:

213:

208:

200:

199:

193:

192:

191:

190:

185:

180:

175:

170:

165:

157:

156:

150:

149:

141:

140:

134:

133:

125:

124:

39:

37:

30:

24:

14:

13:

10:

9:

6:

4:

3:

2:

1727:

1716:

1713:

1711:

1710:Nanomaterials

1708:

1706:

1703:

1702:

1700:

1685:

1680:

1676:

1672:

1668:

1661:

1658:

1653:

1649:

1645:

1641:

1634:

1631:

1626:

1622:

1618:

1614:

1606:

1603:

1598:

1594:

1590:

1586:

1579:

1576:

1571:

1567:

1562:

1561:1721.1/112642

1557:

1553:

1549:

1545:

1541:

1534:

1531:

1525:

1520:

1516:

1512:

1508:

1501:

1499:

1497:

1495:

1493:

1489:

1484:

1480:

1475:

1470:

1466:

1462:

1458:

1451:

1449:

1445:

1440:

1436:

1432:

1428:

1424:

1420:

1413:

1410:

1405:

1401:

1397:

1393:

1386:

1383:

1377:

1372:

1368:

1364:

1359:

1354:

1350:

1346:

1342:

1335:

1333:

1329:

1321:

1315:

1311:

1310:

1304:

1303:

1299:

1295:

1292:

1290:

1287:

1286:

1282:

1280:

1278:

1274:

1265:

1263:

1246:

1243:

1239:

1230:

1226:

1221:

1214:

1212:

1209:

1205:

1201:

1197:

1191:

1177:

1157:

1135:

1127:

1123:

1119:

1116:

1113:

1107:

1102:

1098:

1075:

1071:

1048:

1044:

1023:

1019:

1013:

1009:

1000:

984:

961:

956:

952:

937:

933:

929:

924:

921:

902:

897:

893:

887:

877:

874:

867:

866:

865:

861:

859:

843:

823:

801:

797:

774:

770:

746:

741:

737:

733:

730:

726:

722:

719:

714:

710:

706:

701:

697:

689:

688:

687:

685:

677:

675:

673:

655:

643:

639:

634:

626:

623:

594:

561:

559:

557:

553:

552:nickel alloys

549:

541:

539:

537:

533:

529:

522:

520:

518:

514:

510:

509:melt spinning

506:

498:

496:

494:

490:

482:

480:

478:

470:

468:

466:

462:

458:

454:

449:

447:

443:

439:

435:

431:

427:

423:

419:

407:

402:

400:

395:

393:

388:

387:

385:

384:

379:

374:

369:

367:

362:

357:

356:

355:

354:

349:

346:

344:

341:

339:

336:

334:

333:Nanocomposite

331:

330:

329:

328:

325:

321:

316:

313:

311:

308:

306:

303:

301:

298:

296:

295:Iron–platinum

293:

291:

288:

286:

283:

281:

278:

276:

273:

271:

268:

266:

263:

261:

258:

256:

253:

251:

248:

246:

243:

242:

241:

240:

237:

236:nanoparticles

232:

227:

224:

222:

221:Health impact

219:

217:

214:

212:

211:C70 fullerene

209:

207:

204:

203:

202:

201:

198:

194:

189:

186:

184:

181:

179:

176:

174:

171:

169:

166:

164:

161:

160:

159:

158:

155:

151:

147:

143:

142:

139:

138:Nanomaterials

135:

131:

130:

121:

118:

110:

107:December 2013

99:

96:

92:

89:

85:

82:

78:

75:

71:

68: –

67:

63:

62:Find sources:

56:

52:

46:

45:

40:This article

38:

34:

29:

28:

19:

1674:

1670:

1660:

1643:

1639:

1633:

1616:

1612:

1605:

1588:

1584:

1578:

1543:

1539:

1533:

1514:

1510:

1464:

1460:

1422:

1418:

1412:

1395:

1391:

1385:

1348:

1345:RSC Advances

1344:

1308:

1289:Nanoparticle

1269:

1222:

1218:

1192:

976:

862:

761:

681:

565:

545:

526:

502:

486:

474:

450:

421:

417:

415:

347:

270:Cobalt oxide

250:Quantum dots

183:Applications

113:

104:

94:

87:

80:

73:

61:

49:Please help

44:verification

41:

1677:: 373–382.

1398:: 258–260.

1294:Quantum dot

1229:Coble creep

495:processes.

446:crystallite

430:crystallite

1715:Metallurgy

1699:Categories

1319:3540672710

1300:References

1266:Processing

528:Thin films

515:above the

434:nanometers

290:Iron oxide

197:Fullerenes

77:newspapers

1570:138754677

1439:136571167

1367:2046-2069

1244:−

1158:δ

1120:δ

1117:−

1010:ρ

925:−

894:ρ

875:τ

798:σ

771:σ

731:−

711:σ

698:σ

652:Ω

648:∂

631:∂

627:∝

601:Ω

575:Ω

513:annealing

471:Synthesis

438:amorphous

260:Cellulose

216:Chemistry

168:Chemistry

163:Synthesis

1705:Crystals

1619:: 9–16.

1483:32281861

1283:See also

1196:aluminum

1150:, where

338:Nanofoam

305:Platinum

188:Timeline

1376:9070433

997:is the

265:Ceramic

91:scholar

1568:

1481:

1437:

1373:

1365:

1316:

1202:, and

977:where

762:where

548:nickel

310:Silver

275:Copper

234:Other

93:

86:

79:

72:

64:

1566:S2CID

1435:S2CID

536:MOCVD

300:Lipid

98:JSTOR

84:books

1479:PMID

1363:ISSN

1314:ISBN

1204:lead

550:and

285:Iron

280:Gold

70:news

1679:doi

1675:254

1648:doi

1644:351

1621:doi

1593:doi

1556:hdl

1548:doi

1519:doi

1469:doi

1465:124

1427:doi

1400:doi

1371:PMC

1353:doi

1275:or

1200:tin

53:by

1701::

1673:.

1669:.

1642:.

1617:69

1615:.

1589:22

1587:.

1564:.

1554:.

1544:61

1542:.

1515:33

1513:.

1509:.

1491:^

1477:.

1463:.

1459:.

1447:^

1433:.

1423:91

1421:.

1396:68

1394:.

1369:.

1361:.

1347:.

1343:.

1331:^

1198:,

1001:,

558:.

538:.

519:.

467:.

422:NC

416:A

1687:.

1681::

1654:.

1650::

1627:.

1623::

1599:.

1595::

1572:.

1558::

1550::

1527:.

1521::

1485:.

1471::

1441:.

1429::

1406:.

1402::

1379:.

1355::

1349:9

1322:.

1247:3

1240:d

1178:d

1136:3

1132:)

1128:d

1124:/

1114:1

1111:(

1108:=

1103:g

1099:f

1076:g

1072:f

1049:m

1045:T

1024:M

1020:/

1014:L

985:L

962:,

957:g

953:f

947:)

938:m

934:T

930:T

922:1

917:(

910:)

903:M

898:L

888:L

883:(

878:=

844:d

824:K

802:0

775:y

747:,

742:2

738:/

734:1

727:d

723:K

720:+

715:0

707:=

702:y

656:2

644:/

640:U

635:2

624:E

604:)

598:(

595:U

420:(

405:e

398:t

391:v

120:)

114:(

109:)

105:(

95:·

88:·

81:·

74:·

47:.

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.