167:

an electrostatically actuated device, similar to

Espinosa’s original design, was developed in Silicon-On-Insulator technology by the Michler’s group. These devices have the advantage of a higher aspect ratio and therefore a higher sensitivity in the sensing structures. Some other researchers have developed other devices following the models outlines by Espinosa, Saif and Haque; for example Victor Bright at University of Colorado – Boulder. The technology has reached a level of maturity such that standard devices are now offered by the Center for Integrated Nanotechnologies (CINT) at Sandia National Labs to researchers interested in mechanical testing of nanoscale samples.

151:

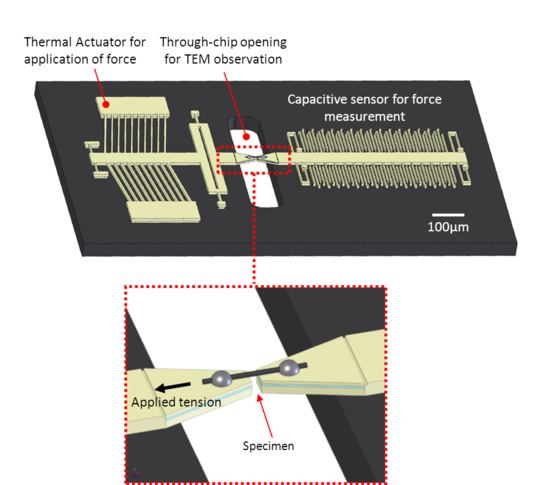

University. They designed and developed a true MEM system that incorporated capacitive sensing for electronic measurement of load and thermal actuation for specimen straining in one single chip. The system could be operated inside a transmission electron microscope. The MEMS based platform was applied to the study of poly-Silicon samples, multi-walled CNTs and more recently metallic and semiconducting nanowires. In particular, the theoretical strength of carbon nanotubes was experimentally measured for the first time using this device.

114:(AFM) to perform a three-point bending test, SEM and TEM to perform bending resonance tests and nanoindenters to perform compression tests. In recent years, it has been found that results are not completely unambiguous. This was exemplified by the fact that different researchers obtained different values of the same property for the same material. This spurred the development of MEMS with the capability of carrying out tensile tests on individual nanoscale elements.

188:

biological systems finds application in disease diagnosis and treatment, and in the engineering of new materials. The size scales in biological testing are in the micron range, with structures that are typically very compliant. This requires the development of devices with high displacement capabilities and very high force resolution. Recent examples are the tensile characterization of collagen fibrils and DNA bundles.

155:

175:

Several nanomechanical characterization methods have yielded many results for properties of matter at the nanoscale. What has been found consistently is that mechanical properties of materials change as a function of size. In metals, elastic modulus, yield strength and fracture strength all increase,

166:

Following these pioneering works, other research groups have followed on developing their own MEMS for mechanical testing. Important examples include the deBoer group at Sandia

National Labs who specializes in the testing of polysilicon samples. At the Ecole Polythecnique Federale de Lausanne (EPFL),

105:

Typical macroscale mechanical characterization is mostly performed under uniaxial tensile conditions. Despite the existence of other methods of mechanical characterization such as three-point bending, hardness testing, etc., uniaxial tensile testing allows for the measurement of the most fundamental

150:

SEM and TEM were demonstrated for thin films by his group including a stage for simultaneous electrical and mechanical testing, although this set-up used external actuation and sensing. A major breakthrough in MEMS-electronic integration was made by

Horacio D. Espinosa and his group at Northwestern

187:

On the other hand, given that MEMS has demonstrated to be a feasible technology for characterizing mechanical properties at the nanoscale, application of the technology to other types of problems has been sought. In particular, biological systems spur an interest because understanding mechanics in

179:

The discovery that mechanical properties are intrinsically size-dependent has spurred theoretical and experimental interest in the size-dependence of other material properties, such as thermal and electrical; and also coupled effects like electromechanical or thermomechanical behavior. Particular

109:

At the nanoscale, owing to the reduced size of the specimen and the forces and displacements to be measured, uniaxial testing or any mechanical testing for that matter, are challenging. As a result, most tests are carried in configurations other than uniaxial-tensile, using available nanoscale

106:

mechanical measurement of the specimen, namely its stress-strain curve. From this curve, important properties like the Young’s modulus, Yield strength, Fracture

Strength can be computed. Other properties such as toughness and ductility can be computed as well.

766:

Bernal, R.A., R. Agrawal, B. Peng, K.A. Bertness, N.A. Sanford, A.V. Davydov, and H.D. Espinosa (2010). "Effect of Growth

Orientation and Diameter on the Elasticity of GaN Nanowires. A Combined in Situ TEM and Atomistic Modeling Investigation".

134:, which were fabricated by standard machining techniques. However, important contributions and insights were provided into specimen gripping mechanisms and the mechanics of materials at the micron scale. Likewise, Horacio D. Espinosa at

659:

Peng, B., M. Locascio, P. Zapol, S. Li, S.L. Mielke, G.C. Schatz, and H.D. Espinosa (2008). "Measurements of near-ultimate strength for multiwalled carbon nanotubes and irradiation-induced crosslinking improvements".

96:

mechanical testing coupled with other type of measurements, such as electrical or thermal, and to extend the range of samples tested to the biological domain, testing specimens such as cells and collagen fibrils.

138:

developed a membrane deflection experiment, which was employed at the MEMS level as well as in thin film specimens. The latest revealed the first experimental evidence of size scale plasticity in thin metallic

863:

Zhang, Dongfeng; Breguet, Jean-Marc; Clavel, Reymond; Philippe, Laetitia; Utke, Ivo; Michler, Johann (2009). "In situ tensile testing of individual Co nanowires inside a scanning electron microscope".

1150:

Yamahata, C., D. Collard, B. Legrand, T. Takekawa, M. Kumemura, G. Hashiguchi, and H. Fujita (2008). "Silicon

Nanotweezers With Subnanometer Resolution for the Micromanipulation of Biomolecules".

85:

can be used to further characterize the sample, providing a complete picture of the evolution of the specimen as it is loaded and fails. Owing to the development of mature MEMS

180:

interest has been focused on characterizing electromechanical properties such as piezoresistivity and piezoelectricity. Most of the current focus in the developing of MEMS for

914:

Brown, J.J., A.I. Baca, K.A. Bertness, D.A. Dikin, R.S. Ruoff, and V.M. Bright (2011). "Tensile measurement of single crystal gallium nitride nanowires on MEMS test stages".

130:

conducted pioneering work in the testing of microscale specimen of polycrystalline silicon. Some of the initial developments consisted mostly of miniaturized versions of

1185:

1136:

1065:

1002:

941:

810:

752:

695:

642:

423:

374:

318:

54:. They distinguish themselves from other methods of nanomechanical testing because the sensing and actuation mechanisms are embedded and/or co-fabricated in the

709:

Agrawal, R., B. Peng, E.E. Gdoutos, and H.D. Espinosa (2008). "Elasticity size effects in ZnO nanowires – A combined

Experimental-Computational approach".

388:

Espinosa, H.D., B.C. Prorok, and B. Peng (2004). "Plasticity size effects in free-standing submicron polycrystalline FCC films subjected to pure tension".

143:

films. Later, size effect studies were performed on single crystal pillars using nanoindentation of microfabricated samples by means of focused ion beam.

283:

Espinosa, H.D., B.C. Prorok, and M. Fischer (2003). "A methodology for determining mechanical properties of freestanding thin films and MEMS materials".

605:

Peng, B., Y.G. Sun, Y. Zhu, H.-H. Wang, and H.D. Espinosa (2008). "Nanoscale testing of One-dimensional nanostructures". In F. Yang; C.J.M. Li (eds.).

122:

The interest in nanomechanical testing was initially spurred by a need to characterize the materials that were used in the fabrication of MEMS.

505:

Han, J.H. & M.T.A. Saif (2006). "In situ microtensile stage for electromechanical characterization of nanoscale freestanding films".

146:

Later on, Taher Saif at

University of Illinois- Urbana Champaign can be credited on developing microfabricated stages. Several results

967:

Haque, M.A., H.D. Espinosa, and H.J. Lee (2010). "MEMS for In Situ

Testing – Handling, Actuation, Loading, Displacement Measurement".

626:

74:

27:

70:

176:

while in semiconducting brittle materials, either increments or reductions are observed depending on the material.

333:

131:

334:"An Experimental/Computational approach to identify Moduli and Residual Stress in MEMS Radio-Frequency Switches"

127:

221:

Agrawal, R. & Espinosa, H.D. (2009). "Multiscale

Experiments: State of the Art and Remaining Challenges".

65:, i.e., testing while observing the evolution of the sample in high magnification instruments such as optical

1204:

135:

111:

1179:

1130:

1059:

996:

935:

804:

746:

689:

470:

Haque, M.A. & M.T.A. Saif (2002). "In-situ tensile testing of nano-scale specimens in SEM and TEM".

417:

368:

312:

89:

technologies, the use of these microsystems for research purposes has been increasing in recent years.

1092:

872:

776:

718:

556:

514:

397:

292:

31:

61:

This level of integration and miniaturization allows carrying out the mechanical characterization

1167:

984:

896:

845:

636:

487:

356:

238:

545:"An electromechanical material testing system for in situ electron microscopy and applications"

1118:

1047:

888:

792:

734:

677:

622:

584:

123:

35:

1159:

1108:

1100:

1037:

1029:

976:

923:

880:

837:

784:

726:

669:

614:

606:

574:

564:

522:

479:

450:

405:

348:

300:

265:

230:

86:

39:

77:(TEM) and X-ray setups. Furthermore, analytical capabilities of these instruments such as

1018:"Nano measurements with micro-devices: mechanical properties of hydrated collagen fibrils"

884:

1096:

876:

841:

780:

722:

560:

518:

401:

296:

154:

1113:

1080:

1042:

1017:

579:

544:

304:

1198:

849:

607:

491:

455:

438:

197:

1171:

988:

900:

360:

242:

1079:

Shen, Z.L., Kahn, H., Ballarini, R., Eppell, S.J.; Kahn; Ballarini; Eppell (2011).

78:

618:

954:

82:

55:

549:

Proceedings of the National Academy of Sciences of the United States of America

409:

1163:

1104:

927:

269:

66:

569:

51:

43:

1122:

1051:

1033:

892:

796:

738:

681:

673:

588:

47:

980:

256:

Sharpe, W.N. (2008). "A review of tension test methods for thin films".

184:

testing lies in this area with examples from Haque, Espinosa and Zhang.

58:, providing—in the majority of cases—greater sensitivity and precision.

483:

352:

788:

730:

526:

234:

153:

332:

Espinosa, H.D., Y. Zhu, M. Fischer, and J. Hutchinson (2003).

30:(MEMS) used to measure the mechanical properties (such as the

16:

MEMS that measure mechanical properties of nanoscale objects

1016:

Eppell, S.J., Smith, B.N., Kahn, H., Ballarini, R. (2006).

609:

Micro and Nano Mechanical Testing of Materials and Devices

1081:"Viscoelastic Properties of Isolated Collagen Fibrils"

92:Most of the current developments aim to implement

223:Journal of Engineering Materials and Technology

830:Journal of Micromechanics and Microengineering

390:Journal of the Mechanics and Physics of Solids

285:Journal of the Mechanics and Physics of Solids

824:Siddharth, S.H. (2009). "Demonstration of an

8:

1184:: CS1 maint: multiple names: authors list (

1135:: CS1 maint: multiple names: authors list (

1064:: CS1 maint: multiple names: authors list (

1001:: CS1 maint: multiple names: authors list (

940:: CS1 maint: multiple names: authors list (

809:: CS1 maint: multiple names: authors list (

751:: CS1 maint: multiple names: authors list (

694:: CS1 maint: multiple names: authors list (

641:: CS1 maint: multiple names: authors list (

422:: CS1 maint: multiple names: authors list (

373:: CS1 maint: multiple names: authors list (

317:: CS1 maint: multiple names: authors list (

101:Mechanical characterization at the nanoscale

437:Saif, M.T.A. & MacDonald, N.C. (1996).

1152:Journal of Microelectromechanical Systems

1112:

1041:

578:

568:

454:

208:

118:Historical context and state of the art

1177:

1128:

1057:

1022:Journal of the Royal Society Interface

994:

933:

802:

744:

687:

634:

415:

366:

310:

654:

652:

600:

598:

543:Zhu, Y. & Espinosa, H.D. (2005).

7:

538:

536:

216:

214:

212:

439:"A millinewton microloading device"

14:

162:tensile testing of nanostructures

75:transmission electron microscopes

507:Review of Scientific Instruments

885:10.1088/0957-4484/20/36/365706

613:. Springer. pp. 280–304.

28:microelectromechanical systems

1:

842:10.1088/0960-1317/19/8/082001

305:10.1016/S0022-5096(02)00062-5

71:scanning electron microscopes

619:10.1007/978-0-387-78701-5_11

456:10.1016/0924-4247(96)80127-0

24:mechanical characterization

1221:

410:10.1016/j.jmps.2003.07.001

158:Schematic of the MEMS for

132:universal testing machines

50:, whiskers, nanotubes and

1164:10.1109/JMEMS.2008.922080

1105:10.1016/j.bpj.2011.04.052

928:10.1016/j.sna.2010.04.002

828:on-chip tensile tester".

270:10.1557/PROC-1052-DD01-01

128:Johns Hopkins University

916:Sensors and Actuators A

570:10.1073/pnas.0506544102

443:Sensors and Actuators A

229:(4): 0412081–04120815.

136:Northwestern University

112:atomic force microscope

110:science tools like the

1034:10.1098/rsif.2005.0100

957:. cint.lanl.gov (2009)

674:10.1038/nnano.2008.211

472:Experimental Mechanics

341:Experimental Mechanics

163:

662:Nature Nanotechnology

157:

1097:2011BpJ...100.3008S

1085:Biophysical Journal

981:10.1557/mrs2010.570

955:Discovery Platforms

877:2009Nanot..20J5706Z

781:2011NanoL..11..548B

723:2008NanoL...8.3668A

561:2005PNAS..10214503Z

555:(41): 14503–14508.

519:2006RScI...77d5102H

402:2004JMPSo..52..667E

297:2003JMPSo..51...47E

484:10.1007/BF02411059

353:10.1007/BF02410529

164:

42:specimens such as

1091:(12): 3008–3015.

789:10.1021/nl103450e

731:10.1021/nl801724b

717:(11): 3668–3674.

527:10.1063/1.2188368

235:10.1115/1.3183782

171:Future directions

124:William N. Sharpe

36:fracture strength

1212:

1190:

1189:

1183:

1175:

1147:

1141:

1140:

1134:

1126:

1116:

1076:

1070:

1069:

1063:

1055:

1045:

1013:

1007:

1006:

1000:

992:

964:

958:

952:

946:

945:

939:

931:

911:

905:

904:

860:

854:

853:

821:

815:

814:

808:

800:

763:

757:

756:

750:

742:

706:

700:

699:

693:

685:

656:

647:

646:

640:

632:

612:

602:

593:

592:

582:

572:

540:

531:

530:

502:

496:

495:

467:

461:

460:

458:

434:

428:

427:

421:

413:

385:

379:

378:

372:

364:

338:

329:

323:

322:

316:

308:

280:

274:

273:

253:

247:

246:

218:

87:microfabrication

1220:

1219:

1215:

1214:

1213:

1211:

1210:

1209:

1195:

1194:

1193:

1176:

1149:

1148:

1144:

1127:

1078:

1077:

1073:

1056:

1015:

1014:

1010:

993:

966:

965:

961:

953:

949:

932:

913:

912:

908:

862:

861:

857:

823:

822:

818:

801:

765:

764:

760:

743:

708:

707:

703:

686:

668:(10): 626–631.

658:

657:

650:

633:

629:

604:

603:

596:

542:

541:

534:

513:(4): 045102–8.

504:

503:

499:

469:

468:

464:

436:

435:

431:

414:

387:

386:

382:

365:

336:

331:

330:

326:

309:

282:

281:

277:

258:MRS Proceedings

255:

254:

250:

220:

219:

210:

206:

194:

173:

120:

103:

32:Young’s modulus

17:

12:

11:

5:

1218:

1216:

1208:

1207:

1205:Nanotechnology

1197:

1196:

1192:

1191:

1158:(3): 623–631.

1142:

1071:

1028:(6): 117–121.

1008:

959:

947:

922:(2): 177–186.

906:

871:(36): 365706.

865:Nanotechnology

855:

816:

758:

701:

648:

628:978-0387787008

627:

594:

532:

497:

478:(1): 123–128.

462:

449:(1–3): 65–75.

429:

396:(3): 667–689.

380:

347:(3): 309–316.

324:

275:

248:

207:

205:

202:

201:

200:

193:

190:

172:

169:

119:

116:

102:

99:

15:

13:

10:

9:

6:

4:

3:

2:

1217:

1206:

1203:

1202:

1200:

1187:

1181:

1173:

1169:

1165:

1161:

1157:

1153:

1146:

1143:

1138:

1132:

1124:

1120:

1115:

1110:

1106:

1102:

1098:

1094:

1090:

1086:

1082:

1075:

1072:

1067:

1061:

1053:

1049:

1044:

1039:

1035:

1031:

1027:

1023:

1019:

1012:

1009:

1004:

998:

990:

986:

982:

978:

974:

970:

963:

960:

956:

951:

948:

943:

937:

929:

925:

921:

917:

910:

907:

902:

898:

894:

890:

886:

882:

878:

874:

870:

866:

859:

856:

851:

847:

843:

839:

836:(8): 082001.

835:

831:

827:

820:

817:

812:

806:

798:

794:

790:

786:

782:

778:

775:(2): 548–55.

774:

770:

762:

759:

754:

748:

740:

736:

732:

728:

724:

720:

716:

712:

705:

702:

697:

691:

683:

679:

675:

671:

667:

663:

655:

653:

649:

644:

638:

630:

624:

620:

616:

611:

610:

601:

599:

595:

590:

586:

581:

576:

571:

566:

562:

558:

554:

550:

546:

539:

537:

533:

528:

524:

520:

516:

512:

508:

501:

498:

493:

489:

485:

481:

477:

473:

466:

463:

457:

452:

448:

444:

440:

433:

430:

425:

419:

411:

407:

403:

399:

395:

391:

384:

381:

376:

370:

362:

358:

354:

350:

346:

342:

335:

328:

325:

320:

314:

306:

302:

298:

294:

290:

286:

279:

276:

271:

267:

263:

259:

252:

249:

244:

240:

236:

232:

228:

224:

217:

215:

213:

209:

203:

199:

198:Lab-on-a-chip

196:

195:

191:

189:

185:

183:

177:

170:

168:

161:

156:

152:

149:

144:

142:

137:

133:

129:

125:

117:

115:

113:

107:

100:

98:

95:

90:

88:

84:

80:

76:

72:

68:

64:

59:

57:

53:

49:

45:

41:

37:

33:

29:

25:

23:

1180:cite journal

1155:

1151:

1145:

1131:cite journal

1088:

1084:

1074:

1060:cite journal

1025:

1021:

1011:

997:cite journal

972:

969:MRS Bulletin

968:

962:

950:

936:cite journal

919:

915:

909:

868:

864:

858:

833:

829:

825:

819:

805:cite journal

772:

769:Nano Letters

768:

761:

747:cite journal

714:

711:Nano Letters

710:

704:

690:cite journal

665:

661:

608:

552:

548:

510:

506:

500:

475:

471:

465:

446:

442:

432:

418:cite journal

393:

389:

383:

369:cite journal

344:

340:

327:

313:cite journal

291:(1): 47–67.

288:

284:

278:

261:

257:

251:

226:

222:

186:

181:

178:

174:

165:

159:

147:

145:

141:freestanding

140:

121:

108:

104:

93:

91:

79:spectroscopy

62:

60:

21:

19:

18:

83:diffraction

67:microscopes

56:microsystem

204:References

52:thin films

26:refers to

850:107353691

637:cite book

492:136678366

44:nanowires

40:nanoscale

20:MEMS for

1199:Category

1172:44220818

1123:21689535

1052:16849223

989:12455370

901:12696787

893:19687546

797:21171602

739:18839998

682:18839003

589:16195381

361:15913817

264:: 3–14.

243:16778097

192:See also

48:nanorods

1114:3123930

1093:Bibcode

1043:1618494

975:: 375.

873:Bibcode

826:in situ

777:Bibcode

719:Bibcode

580:1253576

557:Bibcode

515:Bibcode

398:Bibcode

293:Bibcode

182:in situ

160:in situ

148:in situ

94:in situ

73:(SEM),

63:in situ

22:in situ

1170:

1121:

1111:

1050:

1040:

987:

899:

891:

848:

795:

737:

680:

625:

587:

577:

490:

359:

241:

1168:S2CID

985:S2CID

897:S2CID

846:S2CID

488:S2CID

357:S2CID

337:(PDF)

239:S2CID

38:) of

1186:link

1137:link

1119:PMID

1066:link

1048:PMID

1003:link

942:link

889:PMID

811:link

793:PMID

753:link

735:PMID

696:link

678:PMID

643:link

623:ISBN

585:PMID

424:link

375:link

319:link

262:1052

81:and

34:and

1160:doi

1109:PMC

1101:doi

1089:100

1038:PMC

1030:doi

977:doi

924:doi

920:166

881:doi

838:doi

785:doi

727:doi

670:doi

615:doi

575:PMC

565:doi

553:102

523:doi

480:doi

451:doi

406:doi

349:doi

301:doi

266:doi

231:doi

227:131

126:at

1201::

1182:}}

1178:{{

1166:.

1156:17

1154:.

1133:}}

1129:{{

1117:.

1107:.

1099:.

1087:.

1083:.

1062:}}

1058:{{

1046:.

1036:.

1024:.

1020:.

999:}}

995:{{

983:.

973:35

971:.

938:}}

934:{{

918:.

895:.

887:.

879:.

869:20

867:.

844:.

834:19

832:.

807:}}

803:{{

791:.

783:.

773:11

771:.

749:}}

745:{{

733:.

725:.

713:.

692:}}

688:{{

676:.

664:.

651:^

639:}}

635:{{

621:.

597:^

583:.

573:.

563:.

551:.

547:.

535:^

521:.

511:77

509:.

486:.

476:42

474:.

447:52

445:.

441:.

420:}}

416:{{

404:.

394:52

392:.

371:}}

367:{{

355:.

345:43

343:.

339:.

315:}}

311:{{

299:.

289:51

287:.

260:.

237:.

225:.

211:^

69:,

46:,

1188:)

1174:.

1162::

1139:)

1125:.

1103::

1095::

1068:)

1054:.

1032::

1026:3

1005:)

991:.

979::

944:)

930:.

926::

903:.

883::

875::

852:.

840::

813:)

799:.

787::

779::

755:)

741:.

729::

721::

715:8

698:)

684:.

672::

666:3

645:)

631:.

617::

591:.

567::

559::

529:.

525::

517::

494:.

482::

459:.

453::

426:)

412:.

408::

400::

377:)

363:.

351::

321:)

307:.

303::

295::

272:.

268::

245:.

233::

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.