2178:. Under the same condition in a torque converter, the returning fluid will be redirected by the stator so that it aids the rotation of the impeller, instead of impeding it. The result is that much of the energy in the returning fluid is recovered and added to the energy being applied to the impeller by the prime mover. This action causes a substantial increase in the mass of fluid being directed to the turbine, producing an increase in output torque. Since the returning fluid is initially traveling in a direction opposite to impeller rotation, the stator will likewise attempt to counter-rotate as it forces the fluid to change direction, an effect that is prevented by the

2211:

power-absorbing turbulence. Most of the loss, however, is caused by the curved and angled turbine blades, which do not absorb kinetic energy from the fluid mass as well as radially straight blades. Since the turbine blade geometry is a crucial factor in the converter's ability to multiply torque, trade-offs between torque multiplication and coupling efficiency are inevitable. In automotive applications, where steady improvements in fuel economy have been mandated by market forces and government edict, the nearly universal use of a lock-up clutch has helped to eliminate the converter from the efficiency equation during cruising operation.

1787:

2476:: A very abrupt application of power, as in putting the transmission in neutral and increasing engine RPMs before engaging a gear (commonly called a "neutral start"), can cause shock loading of the stator clutch, resulting in breakage. If this occurs, the stator will freely counter-rotate in the direction opposite to that of the pump and almost no power transmission will take place. In an automobile, the effect is similar to a severe case of transmission slippage and the vehicle is all but incapable of moving under its own power.

2429:). In practice, the maximum torque capacity is limited by the mechanical characteristics of the materials used in the converter's components, as well as the ability of the converter to dissipate heat (often through water cooling). As an aid to strength, reliability and economy of production, most automotive converter housings are of welded construction. Industrial units are usually assembled with bolted housings, a design feature that eases the process of inspection and repair, but adds to the cost of producing the converter.

1130:

133:

147:

2482:: If subjected to abrupt loading or excessive heating of the converter, pump and/or turbine blades may be deformed, separated from their hubs and/or annular rings, or may break up into fragments. At the least, such a failure will result in a significant loss of efficiency, producing symptoms similar (although less pronounced) to those accompanying stator clutch failure. In extreme cases, catastrophic destruction of the converter will occur.

1782:{\displaystyle \rho (S_{p}{\dot {w_{p}}}+S_{t}{\dot {w_{t}}}+S_{s}{\dot {w_{s}}})+\rho {\frac {L_{f}}{A}}{\dot {Q}}=\rho (R_{p}^{2}w_{p}^{2}+R_{t}^{2}w_{t}^{2}+R_{s}^{2}w_{s}^{2}-R_{s}^{2}w_{p}w_{s}-R_{p}^{2}w_{t}w_{p}-R_{t}^{2}w_{s}w_{t})+w_{p}{\frac {Q}{A}}\rho (R_{p}\tan {a_{p}}-R_{s}\tan {a_{s}})+w_{t}{\frac {Q}{A}}\rho (R_{t}\tan {a_{t}}-R_{p}\tan {a_{p}})+w_{s}{\frac {Q}{A}}\rho (R_{s}\tan {a_{s}}-R_{t}\tan {a_{t}})-P_{L}}

3304:

3294:

36:

2151:. The load is accelerating but there still is a relatively large difference between impeller and turbine speed. Under this condition, the converter will produce torque multiplication that is less than what could be achieved under stall conditions. The amount of multiplication will depend upon the actual difference between pump and turbine speed, as well as various other design factors.

2190:

decrease, causing pressure on the stator to likewise decrease. Once in the coupling phase, the returning fluid will reverse direction and now rotate in the direction of the impeller and turbine, an effect which will attempt to forward-rotate the stator. At this point, the stator clutch will release and the impeller, turbine and stator will all (more or less) turn as a unit.

198:. This is a feature beyond what a simple fluid coupling provides, which can match rotational speed but does not multiply torque. Fluid-coupling–based torque converters also typically include a lock-up function to rigidly couple input and output and avoid the efficiency losses associated with transmitting torque by fluid flow when operating conditions permit.

2436:, in which molten brass is drawn into seams and joints to produce a stronger bond between the blades, hubs and annular ring(s). Because the furnace brazing process creates a small radius at the point where a blade meets with a hub or annular ring, a theoretical decrease in turbulence will occur, resulting in a corresponding increase in efficiency.

1124:

883:

642:

2233:

could produce more). Specialized converters designed for industrial, rail, or heavy marine power transmission systems are capable of as much as 5.0:1 multiplication. Generally speaking, there is a trade-off between maximum torque multiplication and efficiency—high stall ratio converters tend

2101:

Modifications to the basic three element design have been periodically incorporated, especially in applications where higher than normal torque multiplication is required. Most commonly, these have taken the form of multiple turbines and stators, each set being designed to produce differing amounts

193:

when the output rotational speed is low. In the fluid coupling embodiment, it uses a fluid, driven by the vanes of an input impeller, and directed through the vanes of a fixed stator, to drive an output turbine in such a manner that torque on the output is increased when the output shaft is rotating

2279:

also existed. The Buick

Dynaflow utilized the torque-multiplying characteristics of its planetary gear set in conjunction with the torque converter for low gear and bypassed the first turbine, using only the second turbine as vehicle speed increased. The unavoidable trade-off with this arrangement

2246:

automatic transmissions often use converters modified to produce high stall speeds to improve off-the-line torque, and to get into the power band of the engine more quickly. Highway vehicles generally use lower stall torque converters to limit heat production, and provide a more firm feeling to the

2185:

Unlike the radially straight blades used in a plain fluid coupling, a torque converter's turbine and stator use angled and curved blades. The blade shape of the stator is what alters the path of the fluid, forcing it to coincide with the impeller rotation. The matching curve of the turbine blades

2469:

of the mating parts occurs, which triggers seizure. A converter with a seized stator clutch will exhibit very poor efficiency during the coupling phase, and in a motor vehicle, fuel consumption will drastically increase. Converter overheating under such conditions will usually occur if continued

2453:

that retain fluid inside the converter. A prime example in passenger cars would be getting stuck in snow or mud and having to rock the vehicle forward and backward to gain momentum by going back and forth from drive to reverse using significant power. The transmission fluid will quickly overheat,

2492:

may cause the shape of the converter's housing to be physically distorted due to internal pressure and/or the stress imposed by inertia. Under extreme conditions, ballooning will cause the converter housing to rupture, resulting in the violent dispersal of hot oil and metal fragments over a wide

2258:

could be varied in response to changes in engine speed and load. The effect of this was to vary the amount of torque multiplication produced by the converter. At the normal angle of attack, the stator caused the converter to produce a moderate amount of multiplication but with a higher level of

2206:

A torque converter cannot achieve 100 percent coupling efficiency. The classic three element torque converter has an efficiency curve that resembles ∩: zero efficiency at stall, generally increasing efficiency during the acceleration phase and low efficiency in the coupling phase. The loss of

2197:

will be lost due to friction and turbulence, causing the converter to generate waste heat (dissipated in many applications by water cooling). This effect, often referred to as pumping loss, will be most pronounced at or near stall conditions. In modern designs, the blade geometry minimizes oil

2210:

Even with the benefit of the one-way stator clutch, a converter cannot achieve the same level of efficiency in the coupling phase as an equivalently sized fluid coupling. Some loss is due to the presence of the stator (even though rotating as part of the assembly), as it always generates some

2189:

During the stall and acceleration phases, in which torque multiplication occurs, the stator remains stationary due to the action of its one-way clutch. However, as the torque converter approaches the coupling phase, the energy and volume of the fluid returning from the turbine will gradually

2454:

not to mention the repeated impacts on the stator clutch (next topic). Also, overheating transmission fluid causes it to lose viscosity and damage the transmission. Such abuse can in rare cases cause the torque converter to leak and eventually stop functioning due to lack of fluid.

2311:

transmissions produced during the 1950s. It fell out of favor in subsequent years due to its extra complexity and cost. In the late 1970s lock-up clutches started to reappear in response to demands for improved fuel economy, and are now nearly universal in automotive applications.

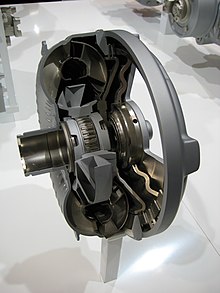

2090:; and the stator, which is interposed between the impeller and turbine so that it can alter oil flow returning from the turbine to the impeller. The classic torque converter design dictates that the stator be prevented from rotating under any condition, hence the term

889:

648:

407:

2262:

Some torque converters use multiple stators and/or multiple turbines to provide a wider range of torque multiplication. Such multiple-element converters are more common in industrial environments than in automotive transmissions, but automotive applications such as

2109:

automatic transmission was a non-shifting design and, under normal conditions, relied solely upon the converter to multiply torque. The

Dynaflow used a five-element converter to produce the wide range of torque multiplication needed to propel a heavy vehicle.

2280:

was low efficiency and eventually these transmissions were discontinued in favor of the more efficient three speed units with a conventional three element torque converter. It is also found that efficiency of torque converter is maximum at very low speeds.

2078:

is a two-element drive that is incapable of multiplying torque, while a torque converter has at least one extra element—the stator—which alters the drive's characteristics during periods of high slippage, producing an increase in output torque.

2198:

velocity at low impeller speeds, which allows the turbine to be stalled for long periods with little danger of overheating (as when a vehicle with an automatic transmission is stopped at a traffic signal or in traffic congestion while still in gear).

2214:

The maximum amount of torque multiplication produced by a converter is highly dependent on the size and geometry of the turbine and stator blades, and is generated only when the converter is at or near the stall phase of operation. Typical

2117:

to improve cruising power transmission efficiency and reduce heat. The application of the clutch locks the turbine to the impeller, causing all power transmission to be mechanical, thus eliminating losses associated with fluid drive.

2207:

efficiency as the converter enters the coupling phase is a result of the turbulence and fluid flow interference generated by the stator, and as previously mentioned, is commonly overcome by mounting the stator on a one-way clutch.

2464:

become permanently locked together, thus preventing the stator from rotating during the coupling phase. Most often, seizure is precipitated by severe loading and subsequent distortion of the clutch components. Eventually,

2157:. The turbine has reached approximately 90 percent of the speed of the impeller. Torque multiplication has essentially ceased and the torque converter is behaving in a manner similar to a simple fluid coupling. In modern

2173:

design, periods of high slippage cause the fluid flow returning from the turbine to the impeller to oppose the direction of impeller rotation, leading to a significant loss of efficiency and the generation of considerable

2809:

2241:

of the power source and the intended application. Changing the blade geometry of the stator and/or turbine will change the torque-stall characteristics, as well as the overall efficiency of the unit. For example,

2186:

helps to correctly direct the returning fluid to the stator so the latter can do its job. The shape of the blades is important as minor variations can result in significant changes to the converter's performance.

2855:

1119:{\displaystyle I_{s}{\dot {\omega _{s}}}+\rho S_{s}{\dot {Q}}=-\rho (\omega _{s}R_{s}^{2}+R_{s}{\frac {Q}{A}}\tan {\alpha _{s}}-\omega _{t}R_{t}^{2}-R_{t}{\frac {Q}{A}}\tan {\alpha _{t}})Q+\tau _{s}}

878:{\displaystyle I_{t}{\dot {\omega _{t}}}+\rho S_{t}{\dot {Q}}=-\rho (\omega _{t}R_{t}^{2}+R_{t}{\frac {Q}{A}}\tan {\alpha _{t}}-\omega _{i}R_{i}^{2}-R_{i}{\frac {Q}{A}}\tan {\alpha _{i}})Q+\tau _{t}}

637:{\displaystyle I_{i}{\dot {\omega _{i}}}+\rho S_{i}{\dot {Q}}=-\rho (\omega _{i}R_{i}^{2}+R_{i}{\frac {Q}{A}}\tan {\alpha _{i}}-\omega _{s}R_{s}^{2}-R_{s}{\frac {Q}{A}}\tan {\alpha _{s}})Q+\tau _{i}}

2259:

efficiency. If the driver abruptly opened the throttle, a valve would switch the stator pitch to a different angle of attack, increasing torque multiplication at the expense of efficiency.

2288:

As described above, impelling losses within the torque converter reduce efficiency and generate waste heat. In modern automotive applications, this problem is commonly avoided by use of a

2145:). The stall phase actually lasts for a brief period when the load (e.g., vehicle) initially starts to move, as there will be a very large difference between pump and turbine speed.

2133:. The prime mover is applying power to the impeller but the turbine cannot rotate. For example, in an automobile, this stage of operation would occur when the driver has placed the

402:

Hrovat derived the equations of the pump, turbine, stator, and conservation of energy. Four first-order differential equations can define the performance of the torque converter.

2292:

that physically links the impeller and turbine, effectively changing the converter into a purely mechanical coupling. The result is no slippage, and virtually no power loss.

391:

2359:

2059:

2008:

1979:

1950:

1921:

1892:

1863:

1812:

3348:

2423:

2399:

2379:

2030:

1834:

3343:

2859:

2141:. At stall, the torque converter can produce maximum torque multiplication if sufficient input power is applied (the resulting multiplication is called the

178:, the torque converter connects the prime mover to the automatic gear train, which then drives the load. It is thus usually located between the engine's

396:

The equation expands to include the fifth power of radius; as a result, torque converter properties are very dependent on the size of the device.

2234:

to be relatively inefficient around the coupling speed, whereas low stall ratio converters tend to provide less possible torque multiplication.

3338:

2830:

2907:

311:

2432:

In high performance, racing and heavy duty commercial converters, the pump and turbine may be further strengthened by a process called

3023:

227:

3333:

2793:

119:

53:

3033:

2219:

multiplication ratios range from 1.8:1 to 2.5:1 for most automotive applications (although multi-element designs as used in the

231:

100:

2161:

applications, it is usually at this stage of operation where the lock-up clutch is applied, a procedure that tends to improve

2980:

2627:

2488:: Prolonged operation under excessive loading, very abrupt application of load, or operating a torque converter at very high

72:

57:

3058:

2446:: Continuous high levels of slippage may overwhelm the converter's ability to dissipate heat, resulting in damage to the

79:

3133:

2082:

In a torque converter there are at least three rotating elements: the impeller, which is mechanically driven by the

3358:

2970:

2631:

171:

86:

46:

3269:

3158:

3098:

3063:

2584:

3048:

2900:

2698:

2134:

2098:, which prevents the stator from counter-rotating with respect to the prime mover but allows forward rotation.

195:

167:

68:

3018:

2990:

2661:

2439:

Overloading a converter can result in several failure modes, some of them potentially dangerous in nature:

3008:

2998:

2489:

2402:

282:

247:

211:

207:

175:

2638:

2303:

transmission, introduced in 1949, which locked up the converter at cruising speeds, unlocking when the

2113:

Although not strictly a part of classic torque converter design, many automotive converters include a

320:

3103:

3038:

2592:

2557:

2514:

151:

140:

2834:

3128:

3108:

2893:

2323:

2307:

was floored for quick acceleration or as the vehicle slowed. This feature was also present in some

132:

3293:

3328:

3274:

3179:

2597:

2588:

2461:

2320:

As with a basic fluid coupling the theoretical torque capacity of a converter is proportional to

2179:

2169:

The key to the torque converter's ability to multiply torque lies in the stator. In the classic

2095:

289:

226:

There are also mechanical designs for torque converters, many of which are similar to mechanical

215:

136:

146:

3068:

2955:

2937:

2789:

2450:

93:

2950:

2763:

2736:

2693:

2553:

2517:, used in bus, refuse, fire, construction, distribution, military and specialty applications

286:

2037:

1986:

1957:

1928:

1899:

1870:

1841:

1797:

3353:

3163:

3093:

2657:

2433:

2255:

2162:

2087:

27:

Fluid coupling that transfers rotating power from a prime mover to a rotating driven load

2083:

3264:

3078:

3073:

2964:

2960:

2688:

2683:

2623:

2408:

2384:

2364:

2289:

2251:

2194:

2170:

2075:

2015:

1819:

399:

Mathematical formulations for the torque converter are available from several authors.

307:

263:

182:

and the transmission. The equivalent device in a manual transmission is the mechanical

163:

3322:

3307:

3246:

3231:

3211:

3138:

2975:

2945:

2875:

2740:

3216:

3153:

3123:

3118:

2785:

2238:

2216:

278:

3297:

3221:

3194:

3189:

3053:

3043:

3003:

2703:

2619:

2308:

2243:

35:

2724:

194:

more slowly than the input shaft, thus providing the equivalent of an adaptive

3279:

3241:

3083:

2916:

2880:

2651:

2601:

2567:

2548:

2539:

2530:

2524:

2520:

2300:

2276:

2230:

2175:

2158:

251:

235:

2725:"Bond Graph Modeling and Computer Simulation of Automotive Torque Converters"

2237:

The characteristics of the torque converter must be carefully matched to the

2137:

in gear but is preventing the vehicle from moving by continuing to apply the

3236:

3226:

3148:

3113:

2572:

2447:

2272:

2254:

automatic transmissions was the variable-pitch stator, in which the blades'

2227:

257:

179:

3028:

2508:

2304:

2268:

2223:

2106:

270:

2647:

2466:

2296:

274:

17:

230:

or capable of acting as such as well. They include the pendulum-based

3199:

3013:

2678:

2563:

2114:

190:

183:

2767:

3184:

3088:

2578:

2544:

2535:

2426:

2264:

2220:

2138:

2103:

145:

131:

2755:

3206:

234:, the Lambert friction gearing disk drive transmission and the

2889:

2927:

2605:

2295:

The first automotive application of the lock-up principle was

29:

2885:

210:

is the hydrodynamic device described above. There are also

2856:"The Sydney Morning Herald - Google News Archive Search"

214:

systems which are widely used in small machines such as

2756:"Dynamic Models for Torque Converter Equipped Vehicles"

2581:, produces Torque converter for Ford, GM, Mazda, Subaru

2411:

2387:

2367:

2326:

2094:. In practice, however, the stator is mounted on an

2040:

2018:

1989:

1960:

1931:

1902:

1873:

1844:

1822:

1800:

1133:

892:

651:

410:

323:

306:

Torque converter equations of motion are governed by

3257:

3172:

2989:

2936:

2575:, used in vehicle, marine and oilfield applications

206:By far the most common form of torque converter in

174:, to a rotating driven load. In a vehicle with an

60:. Unsourced material may be challenged and removed.

2626:and used in buses from 1933 to 1939 and also some

2417:

2393:

2373:

2353:

2126:A torque converter has three stages of operation:

2053:

2024:

2002:

1973:

1944:

1915:

1886:

1857:

1828:

1806:

1781:

1118:

877:

636:

385:

189:A torque converter serves to increase transmitted

254:, such as cars, buses, and on/off highway trucks.

2831:"Mekydro Transmission | InterTrains.co.uk"

2066:A simpler correlation is provided by Kotwicki.

162:is a device, usually implemented as a type of

2901:

8:

2102:of torque multiplication. For example, the

2556:, produces Torque Converters for Ford, GM,

2908:

2894:

2886:

2876:HowStuffWorks article on torque converters

2618:Lysholm-Smith, named after its inventor,

2410:

2386:

2381:is the mass density of the fluid (kg/m),

2366:

2345:

2335:

2330:

2325:

2045:

2039:

2017:

1994:

1988:

1965:

1959:

1936:

1930:

1907:

1901:

1878:

1872:

1849:

1843:

1821:

1799:

1773:

1756:

1751:

1739:

1725:

1720:

1708:

1688:

1682:

1665:

1660:

1648:

1634:

1629:

1617:

1597:

1591:

1574:

1569:

1557:

1543:

1538:

1526:

1506:

1500:

1484:

1474:

1464:

1459:

1446:

1436:

1426:

1421:

1408:

1398:

1388:

1383:

1370:

1365:

1355:

1350:

1337:

1332:

1322:

1317:

1304:

1299:

1289:

1284:

1260:

1259:

1248:

1242:

1221:

1215:

1214:

1208:

1189:

1183:

1182:

1176:

1157:

1151:

1150:

1144:

1132:

1110:

1090:

1085:

1069:

1063:

1050:

1045:

1035:

1021:

1016:

1000:

994:

981:

976:

966:

939:

938:

932:

910:

904:

903:

897:

891:

869:

849:

844:

828:

822:

809:

804:

794:

780:

775:

759:

753:

740:

735:

725:

698:

697:

691:

669:

663:

662:

656:

650:

628:

608:

603:

587:

581:

568:

563:

553:

539:

534:

518:

512:

499:

494:

484:

457:

456:

450:

428:

422:

421:

415:

409:

344:

322:

238:with expanding pulleys and a belt drive.

120:Learn how and when to remove this message

2715:

166:, that transfers rotating power from a

2784:. Automotive Handbook (3rd ed.).

2604:, forestry machines, popular in city

2460:: The inner and outer elements of the

269:Industrial power transmission such as

2881:YouTube video about torque converters

2812:. Worldwide.espacenet.com. 1933-03-07

2782:Hydrodynamic couplings and converters

273:drives, almost all modern forklifts,

7:

3349:Automotive transmission technologies

2250:A design feature once found in some

2202:Efficiency and torque multiplication

58:adding citations to reliable sources

3344:Continuously variable transmissions

2480:Blade deformation and fragmentation

228:continuously variable transmissions

3024:Continuously variable transmission

25:

2729:Journal of the Franklin Institute

2193:Unavoidably, some of the fluid's

3303:

3302:

3292:

2086:; the turbine, which drives the

386:{\displaystyle \tau =\sum \left}

34:

2810:"Espacenet - Original document"

232:Constantinesco torque converter

45:needs additional citations for

2654:automobile transmission system

2628:British Rail Derby Lightweight

1763:

1701:

1672:

1610:

1581:

1519:

1490:

1277:

1233:

1137:

1097:

959:

856:

718:

615:

477:

260:and other heavy duty vehicles.

1:

3339:Mechanical power transmission

3059:Automated manual transmission

2723:Hrovat, D; Tobler, W (1985).

2354:{\displaystyle r\,N^{2}D^{5}}

2741:10.1016/0016-0032(85)90067-5

3134:Semi-automatic transmission

2247:vehicle's characteristics.

154:model of a torque converter

3375:

2971:Internal combustion engine

2760:SAE Technical Paper Series

2632:Ulster Transport Authority

2316:Capacity and failure modes

172:internal combustion engine

3288:

3270:Hybrid vehicle drivetrain

3159:Transmission control unit

3099:Limited-slip differential

3064:Electrorheological clutch

2923:

2585:Voith turbo transmissions

2284:Lock-up torque converters

2070:Torque converter elements

3334:Mechanical power control

3049:Dual-clutch transmission

2754:Kotwicki, A. J. (1982).

2699:Transmission (mechanics)

2401:is the impeller speed (

208:automobile transmissions

3019:Constant-velocity joint

2662:British United Traction

2658:Rolls-Royce (Twin Disc)

2470:operation is attempted.

2269:Triple Turbine Dynaflow

2061:is fluid inertia length

248:Automatic transmissions

2999:Automatic transmission

2474:Stator clutch breakage

2419:

2395:

2375:

2355:

2055:

2026:

2004:

1975:

1946:

1917:

1888:

1859:

1830:

1808:

1783:

1120:

879:

638:

387:

310:'s eighteenth century

283:construction equipment

176:automatic transmission

155:

143:

2788:. 1993. p. 539.

2664:diesel multiple units

2639:British Rail Class 35

2634:diesel multiple units

2593:diesel multiple units

2511:, used in automobiles

2462:one-way stator clutch

2458:Stator clutch seizure

2420:

2396:

2376:

2356:

2180:one-way stator clutch

2056:

2054:{\displaystyle L_{f}}

2027:

2005:

2003:{\displaystyle a_{s}}

1981:is turbine exit angle

1976:

1974:{\displaystyle a_{t}}

1947:

1945:{\displaystyle a_{p}}

1918:

1916:{\displaystyle R_{s}}

1889:

1887:{\displaystyle R_{t}}

1860:

1858:{\displaystyle R_{p}}

1831:

1809:

1807:{\displaystyle \rho }

1784:

1121:

880:

639:

388:

312:turbomachine equation

149:

135:

3104:Locking differential

3039:Direct-shift gearbox

2558:Allison Transmission

2515:Allison Transmission

2409:

2385:

2365:

2324:

2038:

2016:

2010:is stator exit angle

1987:

1958:

1929:

1900:

1871:

1842:

1820:

1798:

1131:

890:

649:

408:

321:

54:improve this article

3129:Preselector gearbox

3109:Manual transmission

1469:

1431:

1393:

1375:

1360:

1342:

1327:

1309:

1294:

1055:

986:

814:

745:

573:

504:

302:Theory of operation

290:railway locomotives

266:propulsion systems.

3275:Electric generator

3180:Wheel hub assembly

2598:ZF Friedrichshafen

2589:diesel locomotives

2415:

2391:

2371:

2351:

2122:Operational phases

2096:overrunning clutch

2051:

2022:

2000:

1971:

1952:is pump exit angle

1942:

1913:

1884:

1855:

1826:

1804:

1779:

1455:

1417:

1379:

1361:

1346:

1328:

1313:

1295:

1280:

1116:

1041:

972:

875:

800:

731:

634:

559:

490:

383:

222:Mechanical systems

216:compact excavators

156:

144:

69:"Torque converter"

3359:Torque converters

3316:

3315:

3069:Epicyclic gearing

2938:Automotive engine

2637:Mekydro, used in

2425:is the diameter (

2418:{\displaystyle D}

2394:{\displaystyle N}

2374:{\displaystyle r}

2025:{\displaystyle I}

1894:is turbine radius

1829:{\displaystyle A}

1696:

1605:

1514:

1268:

1257:

1230:

1198:

1166:

1077:

1008:

947:

919:

836:

767:

706:

678:

595:

526:

465:

437:

357:

202:Hydraulic systems

139:torque converter

130:

129:

122:

104:

16:(Redirected from

3366:

3306:

3305:

3296:

3173:Wheels and tires

3144:Torque converter

2910:

2903:

2896:

2887:

2864:

2863:

2858:. Archived from

2852:

2846:

2845:

2843:

2842:

2833:. Archived from

2827:

2821:

2820:

2818:

2817:

2806:

2800:

2799:

2778:

2772:

2771:

2751:

2745:

2744:

2720:

2694:Torque amplifier

2424:

2422:

2421:

2416:

2400:

2398:

2397:

2392:

2380:

2378:

2377:

2372:

2360:

2358:

2357:

2352:

2350:

2349:

2340:

2339:

2060:

2058:

2057:

2052:

2050:

2049:

2031:

2029:

2028:

2023:

2009:

2007:

2006:

2001:

1999:

1998:

1980:

1978:

1977:

1972:

1970:

1969:

1951:

1949:

1948:

1943:

1941:

1940:

1923:is stator radius

1922:

1920:

1919:

1914:

1912:

1911:

1893:

1891:

1890:

1885:

1883:

1882:

1864:

1862:

1861:

1856:

1854:

1853:

1835:

1833:

1832:

1827:

1813:

1811:

1810:

1805:

1788:

1786:

1785:

1780:

1778:

1777:

1762:

1761:

1760:

1744:

1743:

1731:

1730:

1729:

1713:

1712:

1697:

1689:

1687:

1686:

1671:

1670:

1669:

1653:

1652:

1640:

1639:

1638:

1622:

1621:

1606:

1598:

1596:

1595:

1580:

1579:

1578:

1562:

1561:

1549:

1548:

1547:

1531:

1530:

1515:

1507:

1505:

1504:

1489:

1488:

1479:

1478:

1468:

1463:

1451:

1450:

1441:

1440:

1430:

1425:

1413:

1412:

1403:

1402:

1392:

1387:

1374:

1369:

1359:

1354:

1341:

1336:

1326:

1321:

1308:

1303:

1293:

1288:

1270:

1269:

1261:

1258:

1253:

1252:

1243:

1232:

1231:

1226:

1225:

1216:

1213:

1212:

1200:

1199:

1194:

1193:

1184:

1181:

1180:

1168:

1167:

1162:

1161:

1152:

1149:

1148:

1125:

1123:

1122:

1117:

1115:

1114:

1096:

1095:

1094:

1078:

1070:

1068:

1067:

1054:

1049:

1040:

1039:

1027:

1026:

1025:

1009:

1001:

999:

998:

985:

980:

971:

970:

949:

948:

940:

937:

936:

921:

920:

915:

914:

905:

902:

901:

884:

882:

881:

876:

874:

873:

855:

854:

853:

837:

829:

827:

826:

813:

808:

799:

798:

786:

785:

784:

768:

760:

758:

757:

744:

739:

730:

729:

708:

707:

699:

696:

695:

680:

679:

674:

673:

664:

661:

660:

643:

641:

640:

635:

633:

632:

614:

613:

612:

596:

588:

586:

585:

572:

567:

558:

557:

545:

544:

543:

527:

519:

517:

516:

503:

498:

489:

488:

467:

466:

458:

455:

454:

439:

438:

433:

432:

423:

420:

419:

392:

390:

389:

384:

382:

378:

377:

373:

358:

356:

345:

287:diesel-hydraulic

160:torque converter

125:

118:

114:

111:

105:

103:

62:

38:

30:

21:

3374:

3373:

3369:

3368:

3367:

3365:

3364:

3363:

3319:

3318:

3317:

3312:

3284:

3253:

3168:

3164:Universal joint

3094:Hotchkiss drive

2985:

2932:

2919:

2914:

2872:

2867:

2854:

2853:

2849:

2840:

2838:

2829:

2828:

2824:

2815:

2813:

2808:

2807:

2803:

2796:

2780:

2779:

2775:

2753:

2752:

2748:

2722:

2721:

2717:

2713:

2708:

2674:

2660:, used in some

2615:

2587:, used in many

2529:Exedy, used in

2505:

2500:

2434:furnace brazing

2407:

2406:

2383:

2382:

2363:

2362:

2341:

2331:

2322:

2321:

2318:

2286:

2256:angle of attack

2204:

2163:fuel efficiency

2124:

2072:

2065:

2041:

2036:

2035:

2014:

2013:

1990:

1985:

1984:

1961:

1956:

1955:

1932:

1927:

1926:

1903:

1898:

1897:

1874:

1869:

1868:

1845:

1840:

1839:

1818:

1817:

1796:

1795:

1769:

1752:

1735:

1721:

1704:

1678:

1661:

1644:

1630:

1613:

1587:

1570:

1553:

1539:

1522:

1496:

1480:

1470:

1442:

1432:

1404:

1394:

1244:

1217:

1204:

1185:

1172:

1153:

1140:

1129:

1128:

1106:

1086:

1059:

1031:

1017:

990:

962:

928:

906:

893:

888:

887:

865:

845:

818:

790:

776:

749:

721:

687:

665:

652:

647:

646:

624:

604:

577:

549:

535:

508:

480:

446:

424:

411:

406:

405:

363:

359:

349:

337:

333:

319:

318:

304:

299:

244:

224:

204:

126:

115:

109:

106:

63:

61:

51:

39:

28:

23:

22:

15:

12:

11:

5:

3372:

3370:

3362:

3361:

3356:

3351:

3346:

3341:

3336:

3331:

3321:

3320:

3314:

3313:

3311:

3310:

3300:

3289:

3286:

3285:

3283:

3282:

3277:

3272:

3267:

3265:Electric motor

3261:

3259:

3255:

3254:

3252:

3251:

3250:

3249:

3244:

3239:

3234:

3229:

3224:

3219:

3214:

3204:

3203:

3202:

3197:

3192:

3182:

3176:

3174:

3170:

3169:

3167:

3166:

3161:

3156:

3151:

3146:

3141:

3136:

3131:

3126:

3121:

3116:

3111:

3106:

3101:

3096:

3091:

3086:

3081:

3079:Friction drive

3076:

3074:Fluid coupling

3071:

3066:

3061:

3056:

3051:

3046:

3041:

3036:

3031:

3026:

3021:

3016:

3011:

3006:

3001:

2995:

2993:

2987:

2986:

2984:

2983:

2978:

2973:

2968:

2965:Plug-in hybrid

2958:

2953:

2948:

2942:

2940:

2934:

2933:

2924:

2921:

2920:

2915:

2913:

2912:

2905:

2898:

2890:

2884:

2883:

2878:

2871:

2870:External links

2868:

2866:

2865:

2862:on 2016-05-12.

2847:

2822:

2801:

2794:

2773:

2768:10.4271/820393

2746:

2714:

2712:

2709:

2707:

2706:

2701:

2696:

2691:

2689:Servomechanism

2686:

2684:Fluid coupling

2681:

2675:

2673:

2670:

2669:

2668:

2667:Vickers-Coates

2665:

2655:

2650:, used in the

2645:

2635:

2624:Leyland Motors

2622:, produced by

2614:

2611:

2610:

2609:

2595:

2582:

2576:

2570:

2561:

2551:

2542:

2533:

2527:

2518:

2512:

2504:

2501:

2499:

2496:

2495:

2494:

2483:

2477:

2471:

2455:

2414:

2390:

2370:

2348:

2344:

2338:

2334:

2329:

2317:

2314:

2290:lock-up clutch

2285:

2282:

2252:General Motors

2203:

2200:

2195:kinetic energy

2171:fluid coupling

2167:

2166:

2152:

2146:

2123:

2120:

2115:lock-up clutch

2076:fluid coupling

2071:

2068:

2063:

2062:

2048:

2044:

2033:

2021:

2011:

1997:

1993:

1982:

1968:

1964:

1953:

1939:

1935:

1924:

1910:

1906:

1895:

1881:

1877:

1866:

1865:is pump radius

1852:

1848:

1837:

1825:

1815:

1803:

1776:

1772:

1768:

1765:

1759:

1755:

1750:

1747:

1742:

1738:

1734:

1728:

1724:

1719:

1716:

1711:

1707:

1703:

1700:

1695:

1692:

1685:

1681:

1677:

1674:

1668:

1664:

1659:

1656:

1651:

1647:

1643:

1637:

1633:

1628:

1625:

1620:

1616:

1612:

1609:

1604:

1601:

1594:

1590:

1586:

1583:

1577:

1573:

1568:

1565:

1560:

1556:

1552:

1546:

1542:

1537:

1534:

1529:

1525:

1521:

1518:

1513:

1510:

1503:

1499:

1495:

1492:

1487:

1483:

1477:

1473:

1467:

1462:

1458:

1454:

1449:

1445:

1439:

1435:

1429:

1424:

1420:

1416:

1411:

1407:

1401:

1397:

1391:

1386:

1382:

1378:

1373:

1368:

1364:

1358:

1353:

1349:

1345:

1340:

1335:

1331:

1325:

1320:

1316:

1312:

1307:

1302:

1298:

1292:

1287:

1283:

1279:

1276:

1273:

1267:

1264:

1256:

1251:

1247:

1241:

1238:

1235:

1229:

1224:

1220:

1211:

1207:

1203:

1197:

1192:

1188:

1179:

1175:

1171:

1165:

1160:

1156:

1147:

1143:

1139:

1136:

1113:

1109:

1105:

1102:

1099:

1093:

1089:

1084:

1081:

1076:

1073:

1066:

1062:

1058:

1053:

1048:

1044:

1038:

1034:

1030:

1024:

1020:

1015:

1012:

1007:

1004:

997:

993:

989:

984:

979:

975:

969:

965:

961:

958:

955:

952:

946:

943:

935:

931:

927:

924:

918:

913:

909:

900:

896:

872:

868:

864:

861:

858:

852:

848:

843:

840:

835:

832:

825:

821:

817:

812:

807:

803:

797:

793:

789:

783:

779:

774:

771:

766:

763:

756:

752:

748:

743:

738:

734:

728:

724:

720:

717:

714:

711:

705:

702:

694:

690:

686:

683:

677:

672:

668:

659:

655:

631:

627:

623:

620:

617:

611:

607:

602:

599:

594:

591:

584:

580:

576:

571:

566:

562:

556:

552:

548:

542:

538:

533:

530:

525:

522:

515:

511:

507:

502:

497:

493:

487:

483:

479:

476:

473:

470:

464:

461:

453:

449:

445:

442:

436:

431:

427:

418:

414:

394:

393:

381:

376:

372:

369:

366:

362:

355:

352:

348:

343:

340:

336:

332:

329:

326:

308:Leonhard Euler

303:

300:

298:

295:

294:

293:

267:

261:

255:

243:

240:

223:

220:

203:

200:

196:reduction gear

164:fluid coupling

128:

127:

42:

40:

33:

26:

24:

14:

13:

10:

9:

6:

4:

3:

2:

3371:

3360:

3357:

3355:

3352:

3350:

3347:

3345:

3342:

3340:

3337:

3335:

3332:

3330:

3327:

3326:

3324:

3309:

3301:

3299:

3295:

3291:

3290:

3287:

3281:

3278:

3276:

3273:

3271:

3268:

3266:

3263:

3262:

3260:

3256:

3248:

3245:

3243:

3240:

3238:

3235:

3233:

3230:

3228:

3225:

3223:

3220:

3218:

3215:

3213:

3210:

3209:

3208:

3205:

3201:

3198:

3196:

3193:

3191:

3188:

3187:

3186:

3183:

3181:

3178:

3177:

3175:

3171:

3165:

3162:

3160:

3157:

3155:

3152:

3150:

3147:

3145:

3142:

3140:

3139:Shift-by-wire

3137:

3135:

3132:

3130:

3127:

3125:

3122:

3120:

3117:

3115:

3112:

3110:

3107:

3105:

3102:

3100:

3097:

3095:

3092:

3090:

3087:

3085:

3082:

3080:

3077:

3075:

3072:

3070:

3067:

3065:

3062:

3060:

3057:

3055:

3052:

3050:

3047:

3045:

3042:

3040:

3037:

3035:

3032:

3030:

3027:

3025:

3022:

3020:

3017:

3015:

3012:

3010:

3007:

3005:

3002:

3000:

2997:

2996:

2994:

2992:

2988:

2982:

2979:

2977:

2976:Petrol engine

2974:

2972:

2969:

2966:

2962:

2959:

2957:

2954:

2952:

2949:

2947:

2946:Diesel engine

2944:

2943:

2941:

2939:

2935:

2931:

2929:

2922:

2918:

2911:

2906:

2904:

2899:

2897:

2892:

2891:

2888:

2882:

2879:

2877:

2874:

2873:

2869:

2861:

2857:

2851:

2848:

2837:on 2010-03-02

2836:

2832:

2826:

2823:

2811:

2805:

2802:

2797:

2795:0-8376-0330-7

2791:

2787:

2783:

2777:

2774:

2769:

2765:

2761:

2757:

2750:

2747:

2742:

2738:

2734:

2730:

2726:

2719:

2716:

2710:

2705:

2702:

2700:

2697:

2695:

2692:

2690:

2687:

2685:

2682:

2680:

2677:

2676:

2671:

2666:

2663:

2659:

2656:

2653:

2649:

2646:

2643:

2640:

2636:

2633:

2629:

2625:

2621:

2617:

2616:

2612:

2607:

2603:

2599:

2596:

2594:

2590:

2586:

2583:

2580:

2577:

2574:

2571:

2569:

2565:

2562:

2560:, and Hyundai

2559:

2555:

2552:

2550:

2546:

2543:

2541:

2537:

2534:

2532:

2528:

2526:

2522:

2519:

2516:

2513:

2510:

2507:

2506:

2502:

2498:Manufacturers

2497:

2491:

2487:

2484:

2481:

2478:

2475:

2472:

2468:

2463:

2459:

2456:

2452:

2449:

2445:

2442:

2441:

2440:

2437:

2435:

2430:

2428:

2412:

2404:

2388:

2368:

2346:

2342:

2336:

2332:

2327:

2315:

2313:

2310:

2306:

2302:

2298:

2293:

2291:

2283:

2281:

2278:

2274:

2270:

2266:

2260:

2257:

2253:

2248:

2245:

2240:

2235:

2232:

2229:

2225:

2222:

2218:

2212:

2208:

2201:

2199:

2196:

2191:

2187:

2183:

2181:

2177:

2172:

2164:

2160:

2156:

2153:

2150:

2147:

2144:

2140:

2136:

2132:

2129:

2128:

2127:

2121:

2119:

2116:

2111:

2108:

2105:

2099:

2097:

2093:

2089:

2085:

2080:

2077:

2069:

2067:

2046:

2042:

2034:

2019:

2012:

1995:

1991:

1983:

1966:

1962:

1954:

1937:

1933:

1925:

1908:

1904:

1896:

1879:

1875:

1867:

1850:

1846:

1838:

1823:

1816:

1801:

1794:

1793:

1792:

1789:

1774:

1770:

1766:

1757:

1753:

1748:

1745:

1740:

1736:

1732:

1726:

1722:

1717:

1714:

1709:

1705:

1698:

1693:

1690:

1683:

1679:

1675:

1666:

1662:

1657:

1654:

1649:

1645:

1641:

1635:

1631:

1626:

1623:

1618:

1614:

1607:

1602:

1599:

1592:

1588:

1584:

1575:

1571:

1566:

1563:

1558:

1554:

1550:

1544:

1540:

1535:

1532:

1527:

1523:

1516:

1511:

1508:

1501:

1497:

1493:

1485:

1481:

1475:

1471:

1465:

1460:

1456:

1452:

1447:

1443:

1437:

1433:

1427:

1422:

1418:

1414:

1409:

1405:

1399:

1395:

1389:

1384:

1380:

1376:

1371:

1366:

1362:

1356:

1351:

1347:

1343:

1338:

1333:

1329:

1323:

1318:

1314:

1310:

1305:

1300:

1296:

1290:

1285:

1281:

1274:

1271:

1265:

1262:

1254:

1249:

1245:

1239:

1236:

1227:

1222:

1218:

1209:

1205:

1201:

1195:

1190:

1186:

1177:

1173:

1169:

1163:

1158:

1154:

1145:

1141:

1134:

1126:

1111:

1107:

1103:

1100:

1091:

1087:

1082:

1079:

1074:

1071:

1064:

1060:

1056:

1051:

1046:

1042:

1036:

1032:

1028:

1022:

1018:

1013:

1010:

1005:

1002:

995:

991:

987:

982:

977:

973:

967:

963:

956:

953:

950:

944:

941:

933:

929:

925:

922:

916:

911:

907:

898:

894:

885:

870:

866:

862:

859:

850:

846:

841:

838:

833:

830:

823:

819:

815:

810:

805:

801:

795:

791:

787:

781:

777:

772:

769:

764:

761:

754:

750:

746:

741:

736:

732:

726:

722:

715:

712:

709:

703:

700:

692:

688:

684:

681:

675:

670:

666:

657:

653:

644:

629:

625:

621:

618:

609:

605:

600:

597:

592:

589:

582:

578:

574:

569:

564:

560:

554:

550:

546:

540:

536:

531:

528:

523:

520:

513:

509:

505:

500:

495:

491:

485:

481:

474:

471:

468:

462:

459:

451:

447:

443:

440:

434:

429:

425:

416:

412:

403:

400:

397:

379:

374:

370:

367:

364:

360:

353:

350:

346:

341:

338:

334:

330:

327:

324:

317:

316:

315:

313:

309:

301:

296:

291:

288:

284:

280:

279:drilling rigs

276:

272:

268:

265:

262:

259:

256:

253:

249:

246:

245:

241:

239:

237:

233:

229:

221:

219:

217:

213:

209:

201:

199:

197:

192:

187:

185:

181:

177:

173:

169:

165:

161:

153:

148:

142:

138:

134:

124:

121:

113:

102:

99:

95:

92:

88:

85:

81:

78:

74:

71: –

70:

66:

65:Find sources:

59:

55:

49:

48:

43:This article

41:

37:

32:

31:

19:

3217:Racing slick

3154:Transfer box

3143:

3124:Park-by-wire

3119:Parking pawl

3034:Differential

3009:Direct-drive

2991:Transmission

2981:Steam engine

2926:Part of the

2925:

2860:the original

2850:

2839:. Retrieved

2835:the original

2825:

2814:. Retrieved

2804:

2786:Robert Bosch

2781:

2776:

2759:

2749:

2732:

2728:

2718:

2644:locomotives.

2641:

2608:applications

2485:

2479:

2473:

2457:

2443:

2438:

2431:

2319:

2294:

2287:

2261:

2249:

2239:torque curve

2236:

2217:stall torque

2213:

2209:

2205:

2192:

2188:

2184:

2168:

2154:

2149:Acceleration

2148:

2142:

2135:transmission

2130:

2125:

2112:

2100:

2091:

2081:

2073:

2064:

1836:is flow area

1790:

1127:

886:

645:

404:

401:

398:

395:

305:

225:

205:

188:

159:

157:

116:

107:

97:

90:

83:

76:

64:

52:Please help

47:verification

44:

3195:Alloy wheel

3054:Drive wheel

3044:Drive shaft

3004:Chain drive

2704:Water brake

2620:Alf Lysholm

2602:automobiles

2568:automobiles

2554:LuK USA LLC

2549:automobiles

2540:automobiles

2531:automobiles

2525:automobiles

2444:Overheating

2309:Borg-Warner

2244:drag racing

2143:stall ratio

2084:prime mover

252:automobiles

212:hydrostatic

168:prime mover

3323:Categories

3280:Alternator

2928:Automobile

2917:Powertrain

2841:2009-10-31

2816:2014-07-21

2735:: 93–114.

2711:References

2652:Ultramatic

2566:, used in

2547:, used in

2538:, used in

2523:, used in

2521:BorgWarner

2486:Ballooning

2301:Ultramatic

2277:Turboglide

2231:Turboglide

2176:waste heat

2159:automotive

2032:is inertia

1814:is density

258:Forwarders

236:Variomatic

170:, like an

80:newspapers

3329:Variators

3149:Transaxle

3114:Manumatic

3084:Gearshift

2956:Fuel cell

2573:Twin Disc

2448:elastomer

2273:Chevrolet

2228:Chevrolet

1802:ρ

1767:−

1749:

1733:−

1718:

1699:ρ

1658:

1642:−

1627:

1608:ρ

1567:

1551:−

1536:

1517:ρ

1453:−

1415:−

1377:−

1275:ρ

1266:˙

1240:ρ

1228:˙

1196:˙

1164:˙

1135:ρ

1108:τ

1088:α

1083:

1057:−

1033:ω

1029:−

1019:α

1014:

964:ω

957:ρ

954:−

945:˙

926:ρ

917:˙

908:ω

867:τ

847:α

842:

816:−

792:ω

788:−

778:α

773:

723:ω

716:ρ

713:−

704:˙

685:ρ

676:˙

667:ω

626:τ

606:α

601:

575:−

551:ω

547:−

537:α

532:

482:ω

475:ρ

472:−

463:˙

444:ρ

435:˙

426:ω

368:⋅

342:×

331:∑

325:τ

180:flexplate

110:July 2017

3308:Category

3247:Tubeless

3232:Run-flat

3212:Off-road

3029:Coupling

2951:Electric

2672:See also

2509:Aisin AW

2361:, where

2305:throttle

2224:Dynaflow

2155:Coupling

2107:Dynaflow

297:Function

271:conveyor

152:cut-away

141:cut-away

2648:Packard

2503:Current

2467:galling

2405:), and

2297:Packard

275:winches

94:scholar

18:Mekydro

3354:Torque

3298:Portal

3258:Hybrid

3222:Radial

3200:Hubcap

3014:Clutch

2961:Hybrid

2930:series

2792:

2679:Clutch

2564:Subaru

2139:brakes

2092:stator

1791:where

285:, and

264:Marine

191:torque

184:clutch

96:

89:

82:

75:

67:

3242:Spare

3185:Wheel

3089:Giubo

2642:Hymek

2579:Valeo

2545:Jatco

2536:Isuzu

2493:area.

2451:seals

2265:Buick

2221:Buick

2131:Stall

2104:Buick

242:Usage

101:JSTOR

87:books

3237:Snow

3227:Rain

3207:Tire

2790:ISBN

2630:and

2613:Past

2591:and

2271:and

2226:and

2088:load

73:news

3190:Rim

2764:doi

2737:doi

2733:319

2606:bus

2490:RPM

2403:rpm

2299:'s

2275:'s

2267:'s

1746:tan

1715:tan

1655:tan

1624:tan

1564:tan

1533:tan

1080:tan

1011:tan

839:tan

770:tan

598:tan

529:tan

250:on

56:by

3325::

2762:.

2758:.

2731:.

2727:.

2600:,

2182:.

2074:A

314::

281:,

277:,

218:.

186:.

158:A

150:A

137:ZF

2967:)

2963:(

2909:e

2902:t

2895:v

2844:.

2819:.

2798:.

2770:.

2766::

2743:.

2739::

2427:m

2413:D

2389:N

2369:r

2347:5

2343:D

2337:2

2333:N

2328:r

2165:.

2047:f

2043:L

2020:I

1996:s

1992:a

1967:t

1963:a

1938:p

1934:a

1909:s

1905:R

1880:t

1876:R

1851:p

1847:R

1824:A

1775:L

1771:P

1764:)

1758:t

1754:a

1741:t

1737:R

1727:s

1723:a

1710:s

1706:R

1702:(

1694:A

1691:Q

1684:s

1680:w

1676:+

1673:)

1667:p

1663:a

1650:p

1646:R

1636:t

1632:a

1619:t

1615:R

1611:(

1603:A

1600:Q

1593:t

1589:w

1585:+

1582:)

1576:s

1572:a

1559:s

1555:R

1545:p

1541:a

1528:p

1524:R

1520:(

1512:A

1509:Q

1502:p

1498:w

1494:+

1491:)

1486:t

1482:w

1476:s

1472:w

1466:2

1461:t

1457:R

1448:p

1444:w

1438:t

1434:w

1428:2

1423:p

1419:R

1410:s

1406:w

1400:p

1396:w

1390:2

1385:s

1381:R

1372:2

1367:s

1363:w

1357:2

1352:s

1348:R

1344:+

1339:2

1334:t

1330:w

1324:2

1319:t

1315:R

1311:+

1306:2

1301:p

1297:w

1291:2

1286:p

1282:R

1278:(

1272:=

1263:Q

1255:A

1250:f

1246:L

1237:+

1234:)

1223:s

1219:w

1210:s

1206:S

1202:+

1191:t

1187:w

1178:t

1174:S

1170:+

1159:p

1155:w

1146:p

1142:S

1138:(

1112:s

1104:+

1101:Q

1098:)

1092:t

1075:A

1072:Q

1065:t

1061:R

1052:2

1047:t

1043:R

1037:t

1023:s

1006:A

1003:Q

996:s

992:R

988:+

983:2

978:s

974:R

968:s

960:(

951:=

942:Q

934:s

930:S

923:+

912:s

899:s

895:I

871:t

863:+

860:Q

857:)

851:i

834:A

831:Q

824:i

820:R

811:2

806:i

802:R

796:i

782:t

765:A

762:Q

755:t

751:R

747:+

742:2

737:t

733:R

727:t

719:(

710:=

701:Q

693:t

689:S

682:+

671:t

658:t

654:I

630:i

622:+

619:Q

616:)

610:s

593:A

590:Q

583:s

579:R

570:2

565:s

561:R

555:s

541:i

524:A

521:Q

514:i

510:R

506:+

501:2

496:i

492:R

486:i

478:(

469:=

460:Q

452:i

448:S

441:+

430:i

417:i

413:I

380:]

375:)

371:v

365:m

361:(

354:t

351:d

347:d

339:r

335:[

328:=

292:.

123:)

117:(

112:)

108:(

98:·

91:·

84:·

77:·

50:.

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.